Patents

Literature

56results about How to "Dry evenly and thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

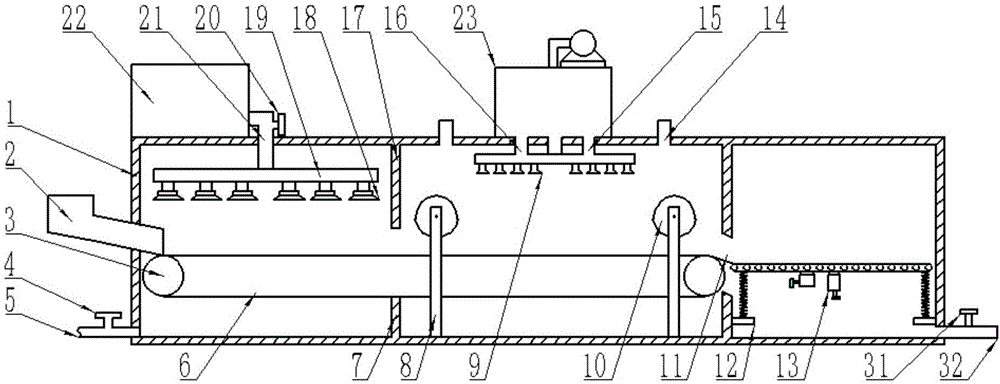

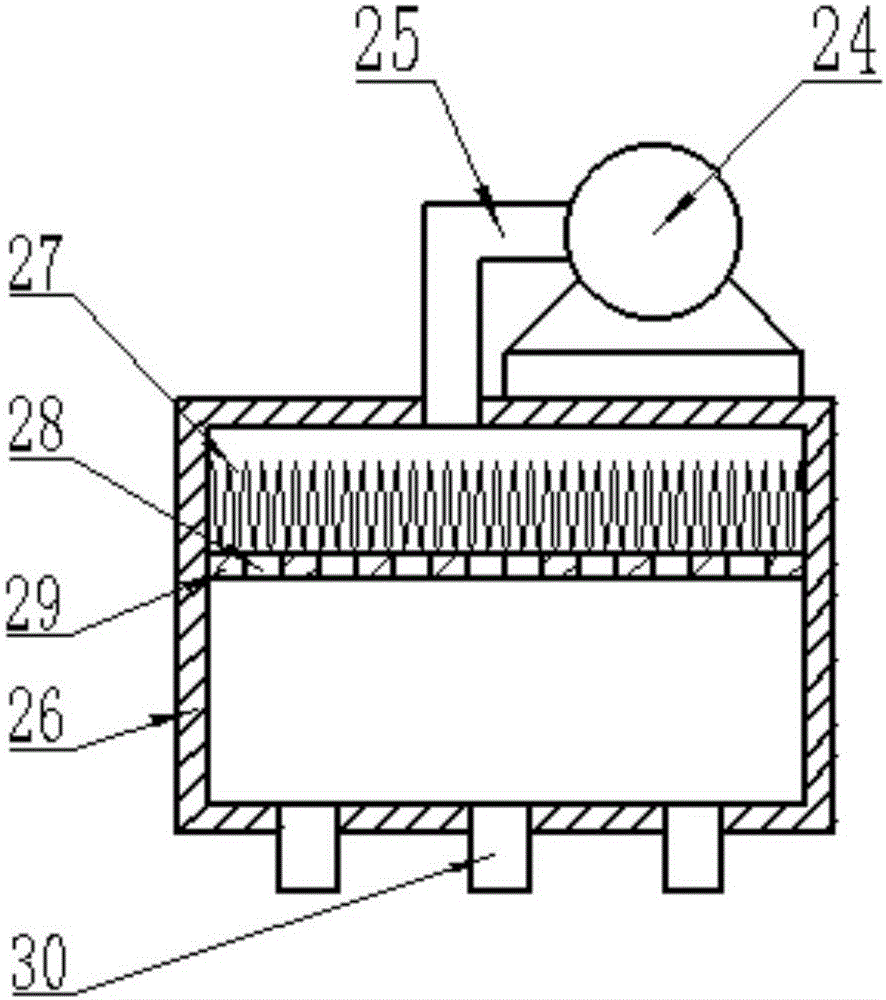

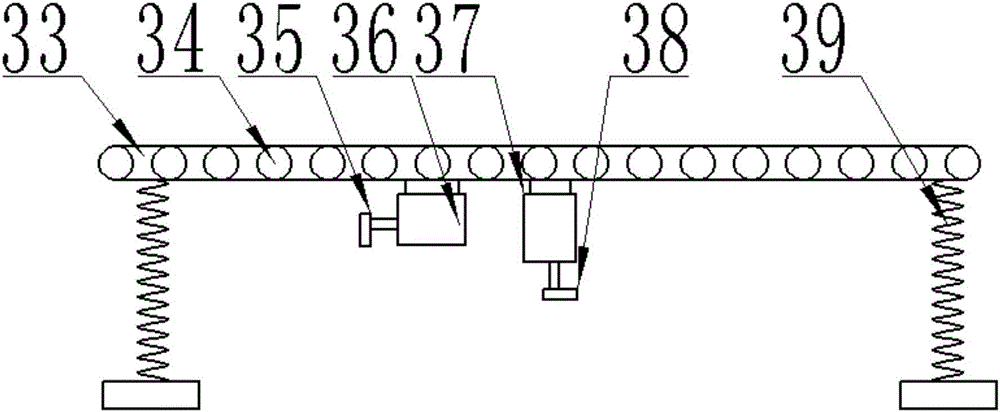

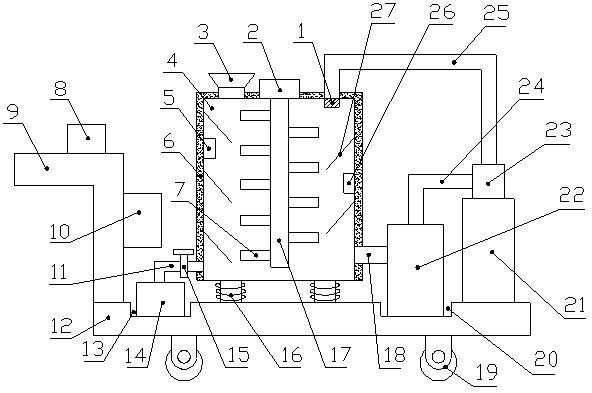

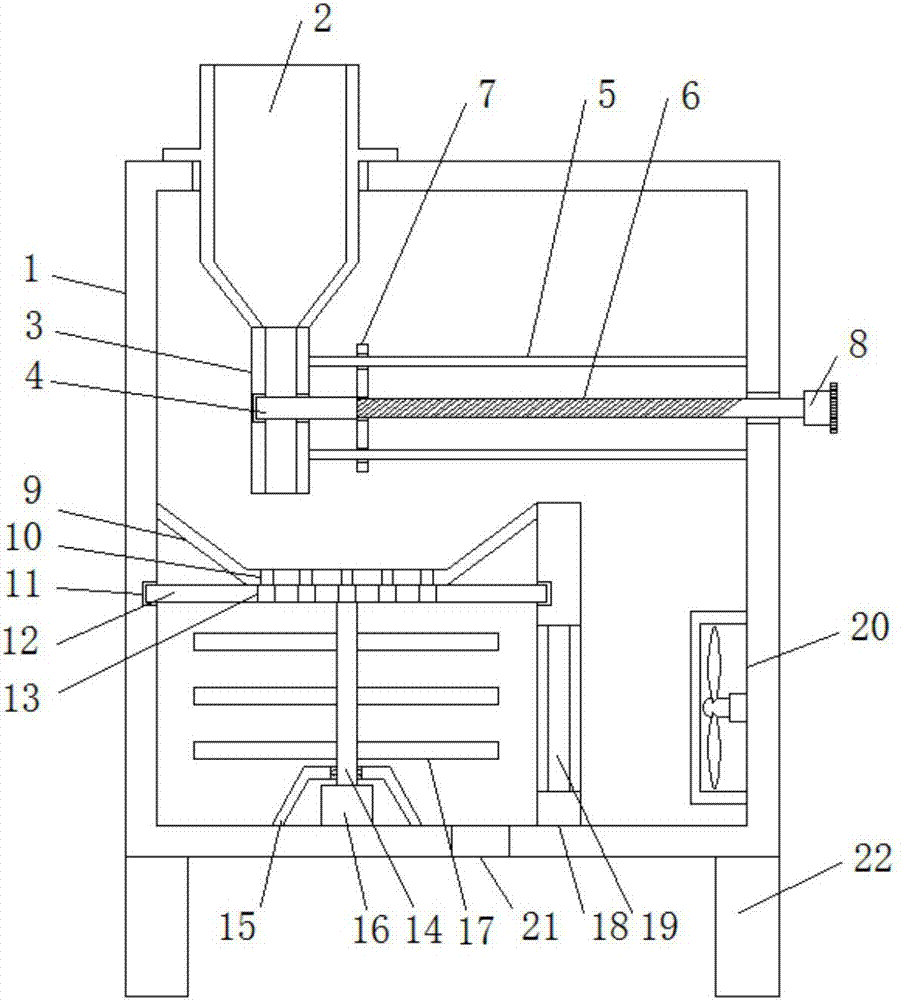

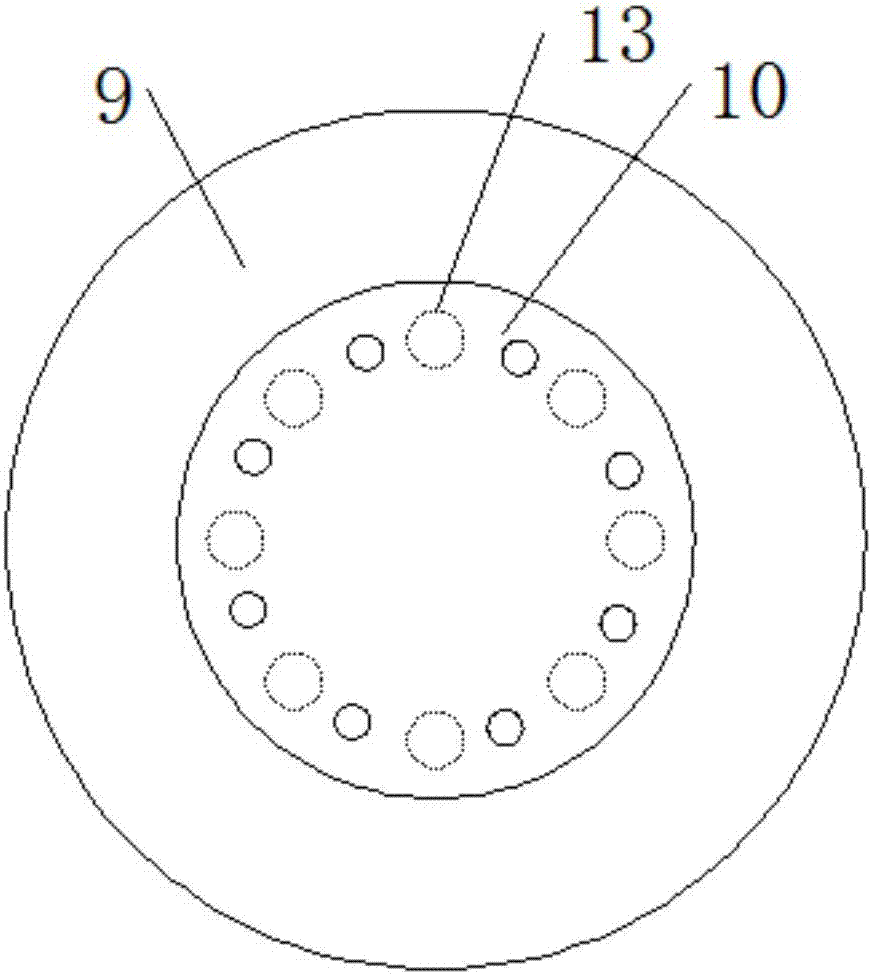

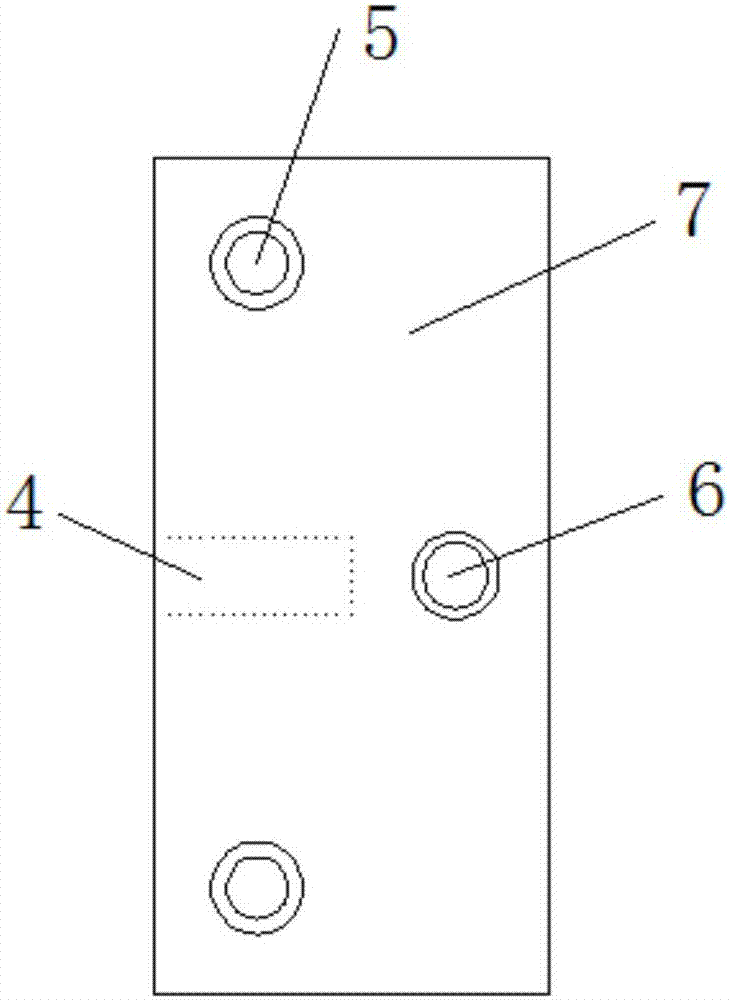

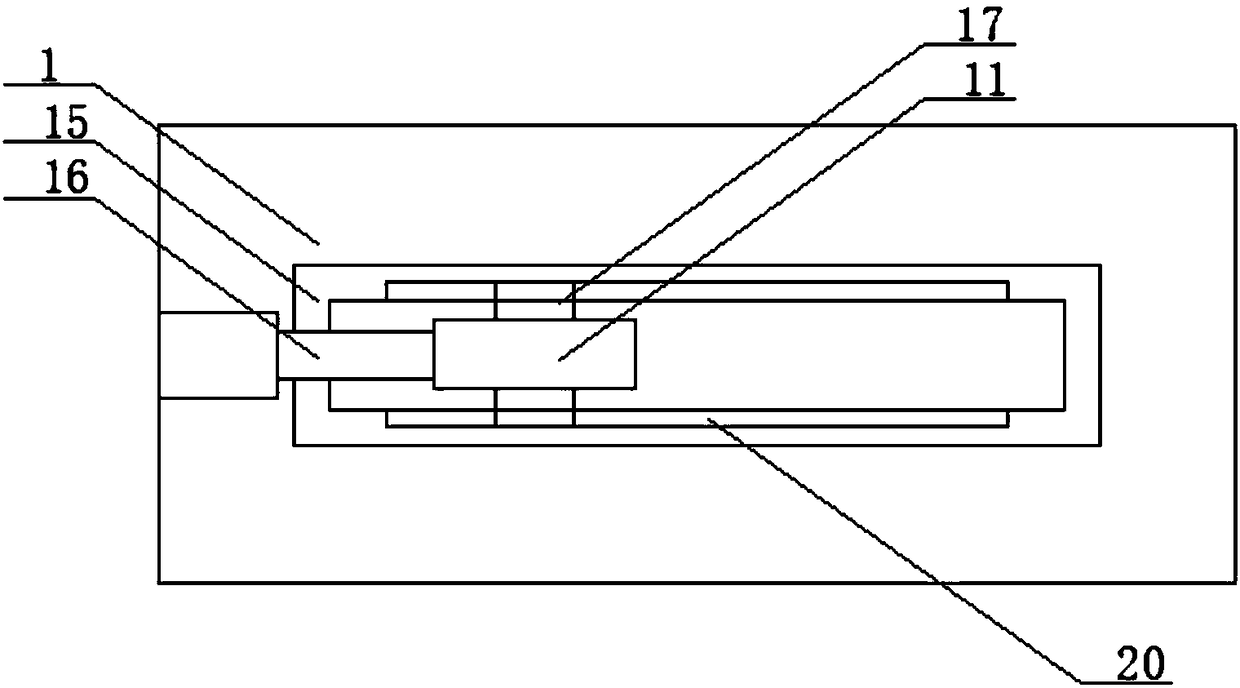

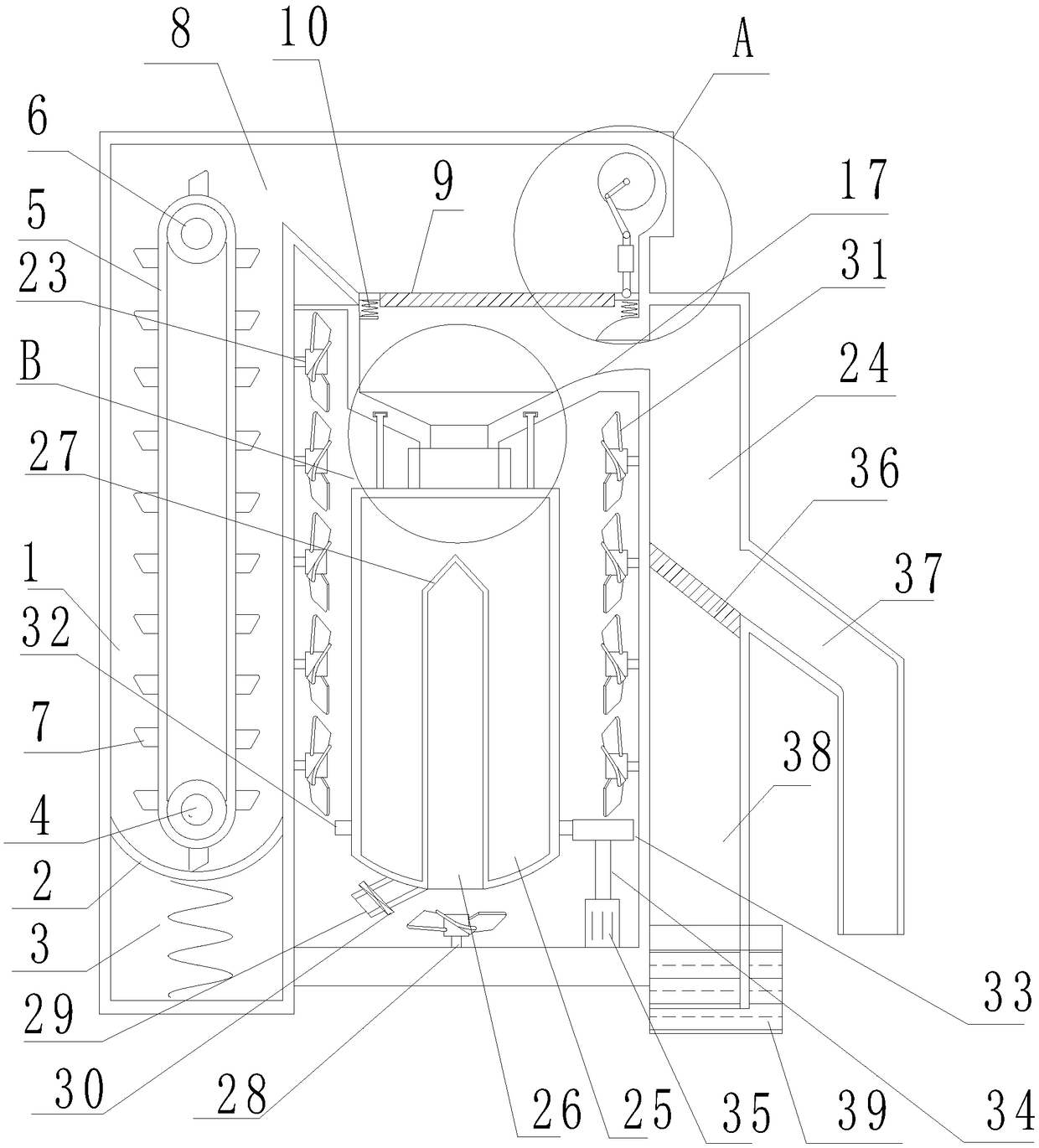

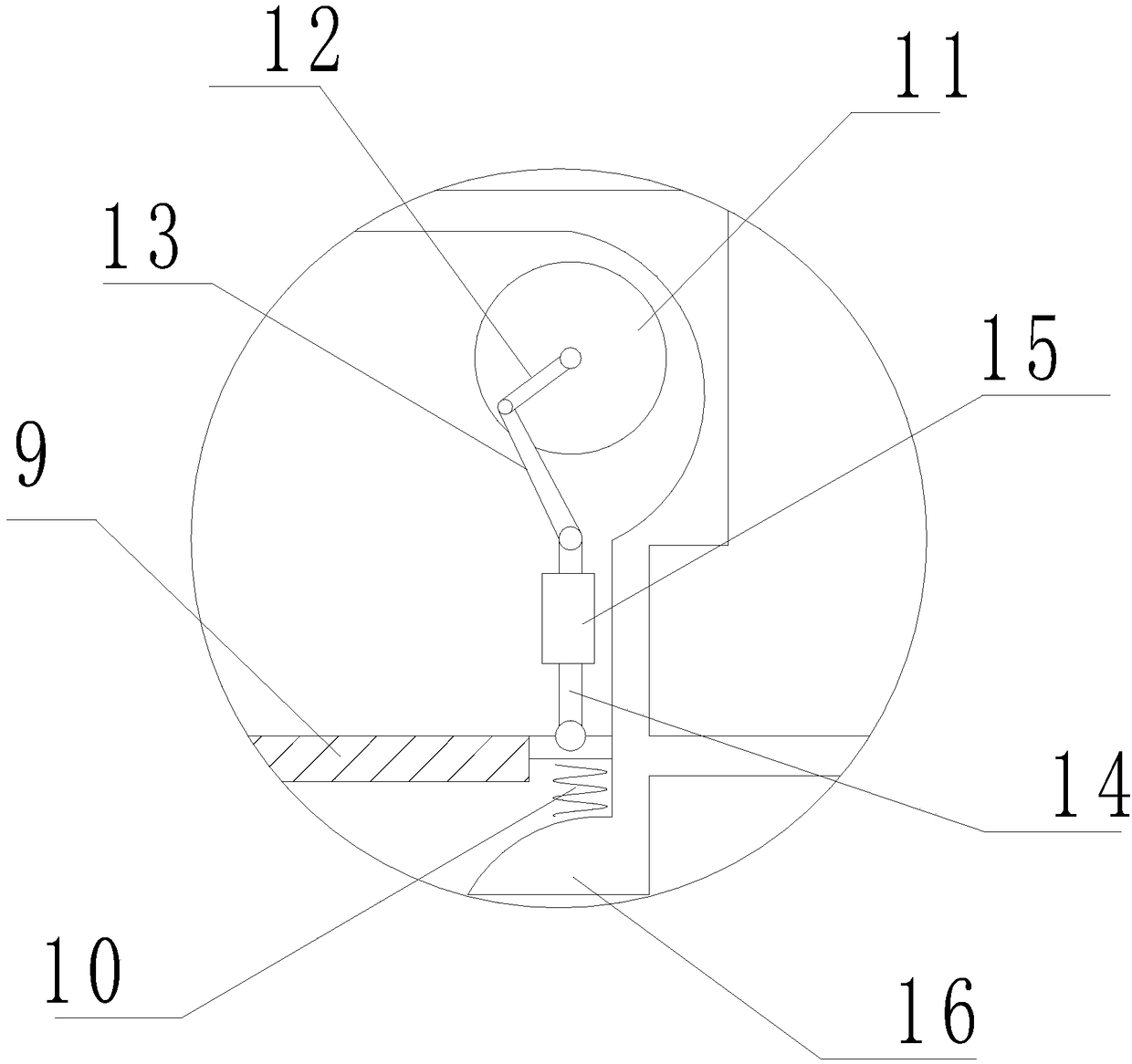

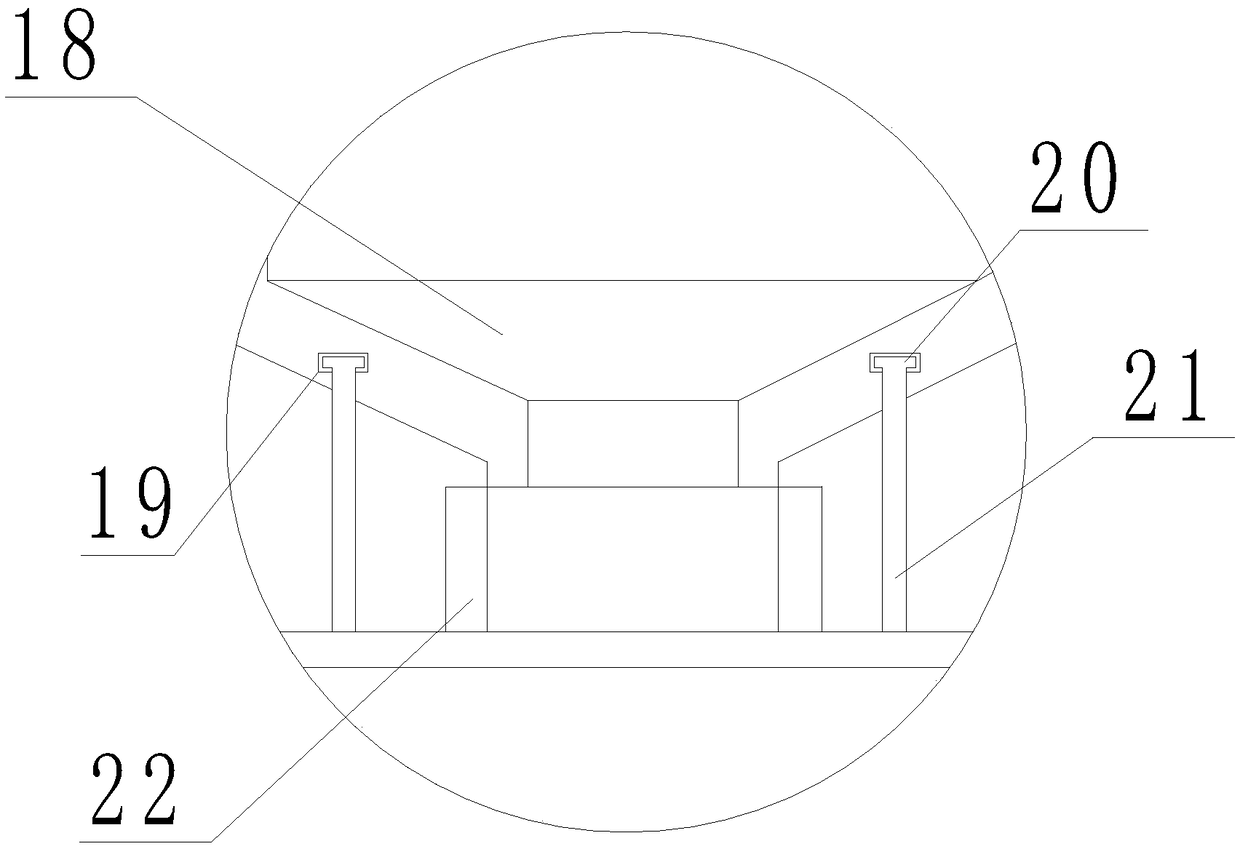

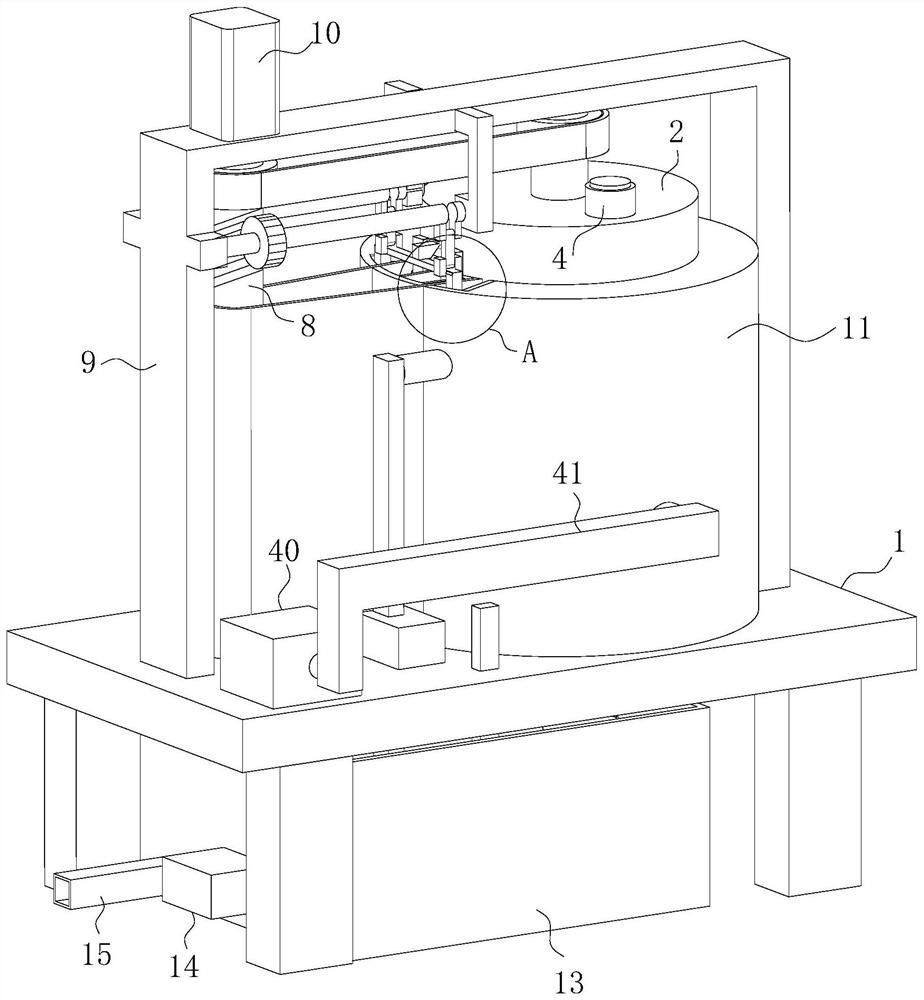

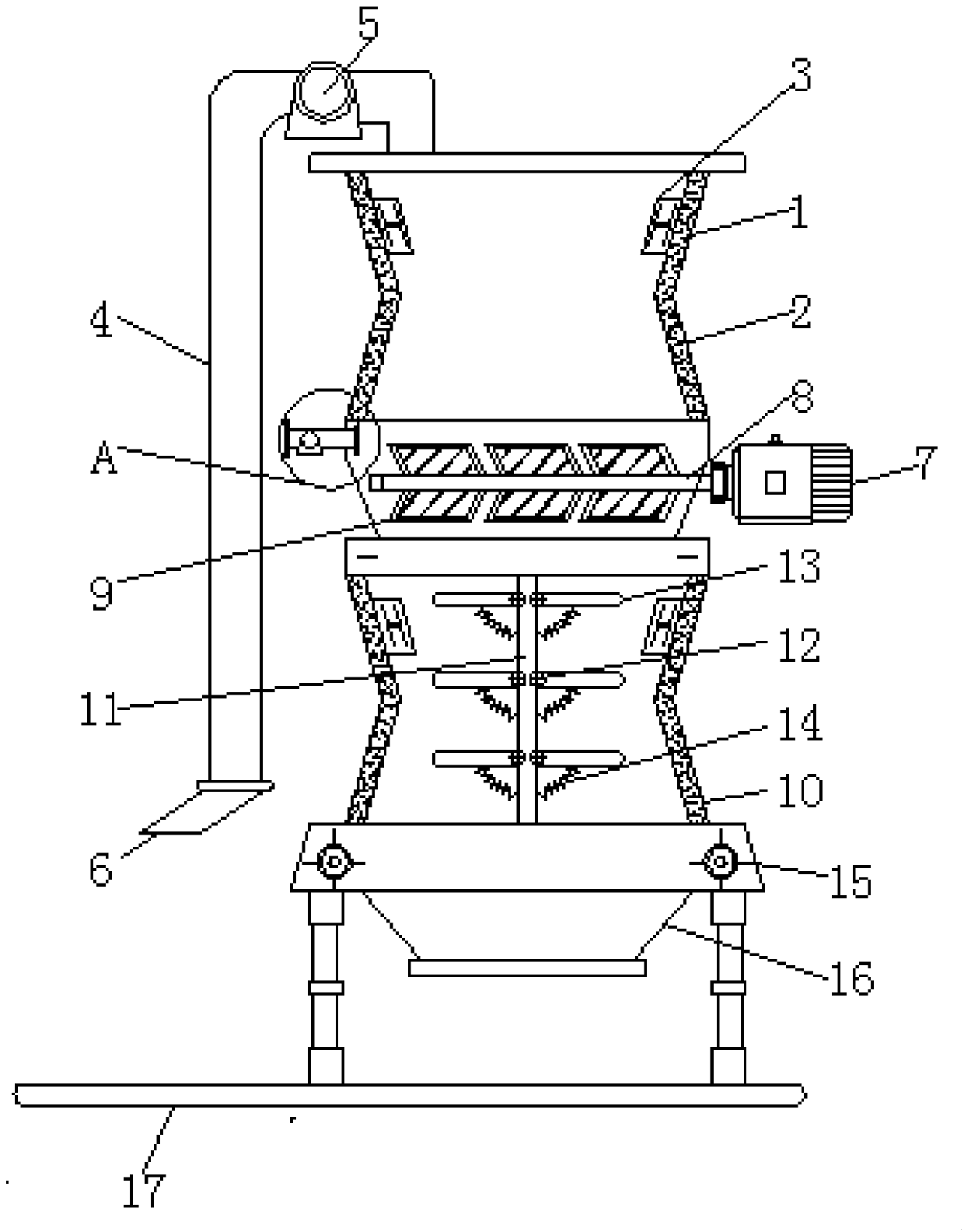

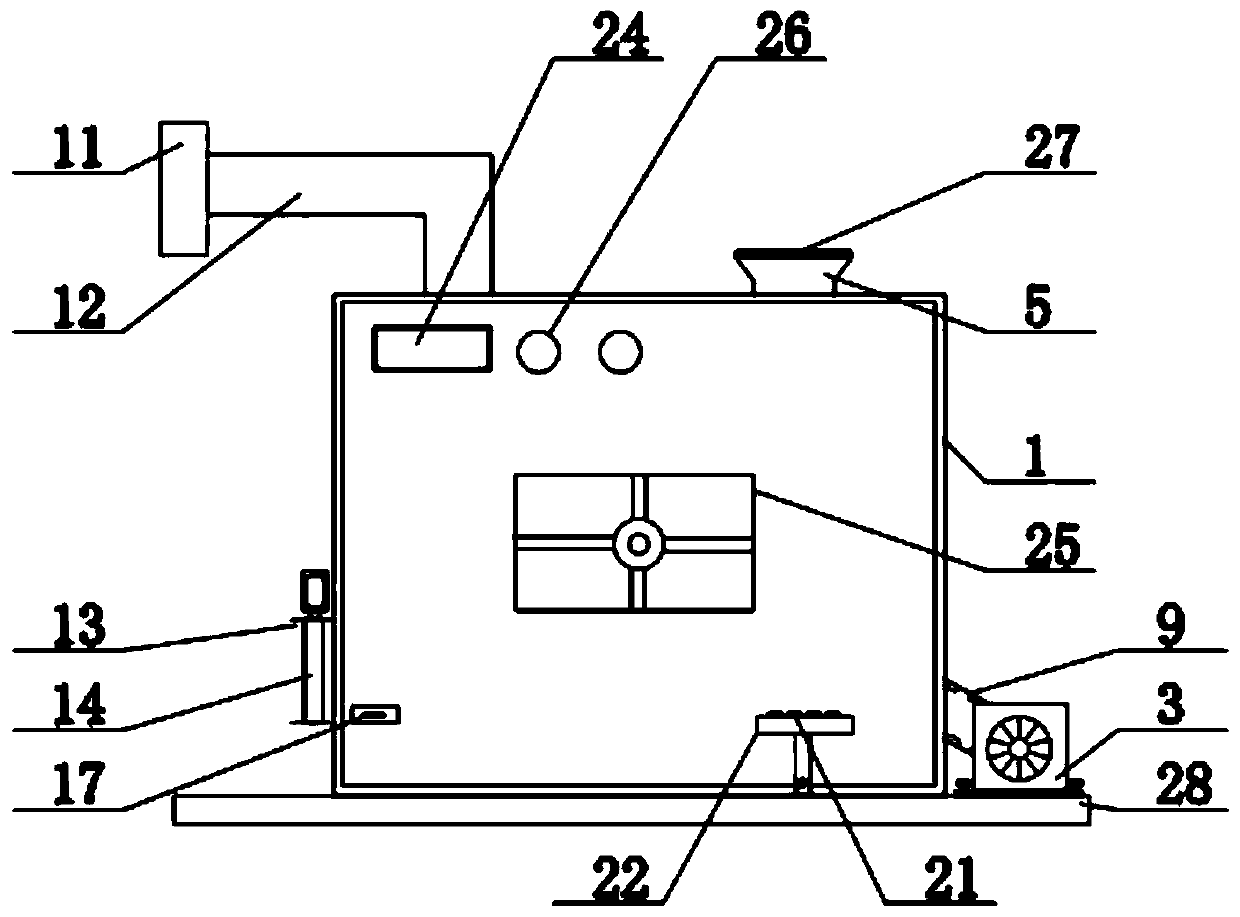

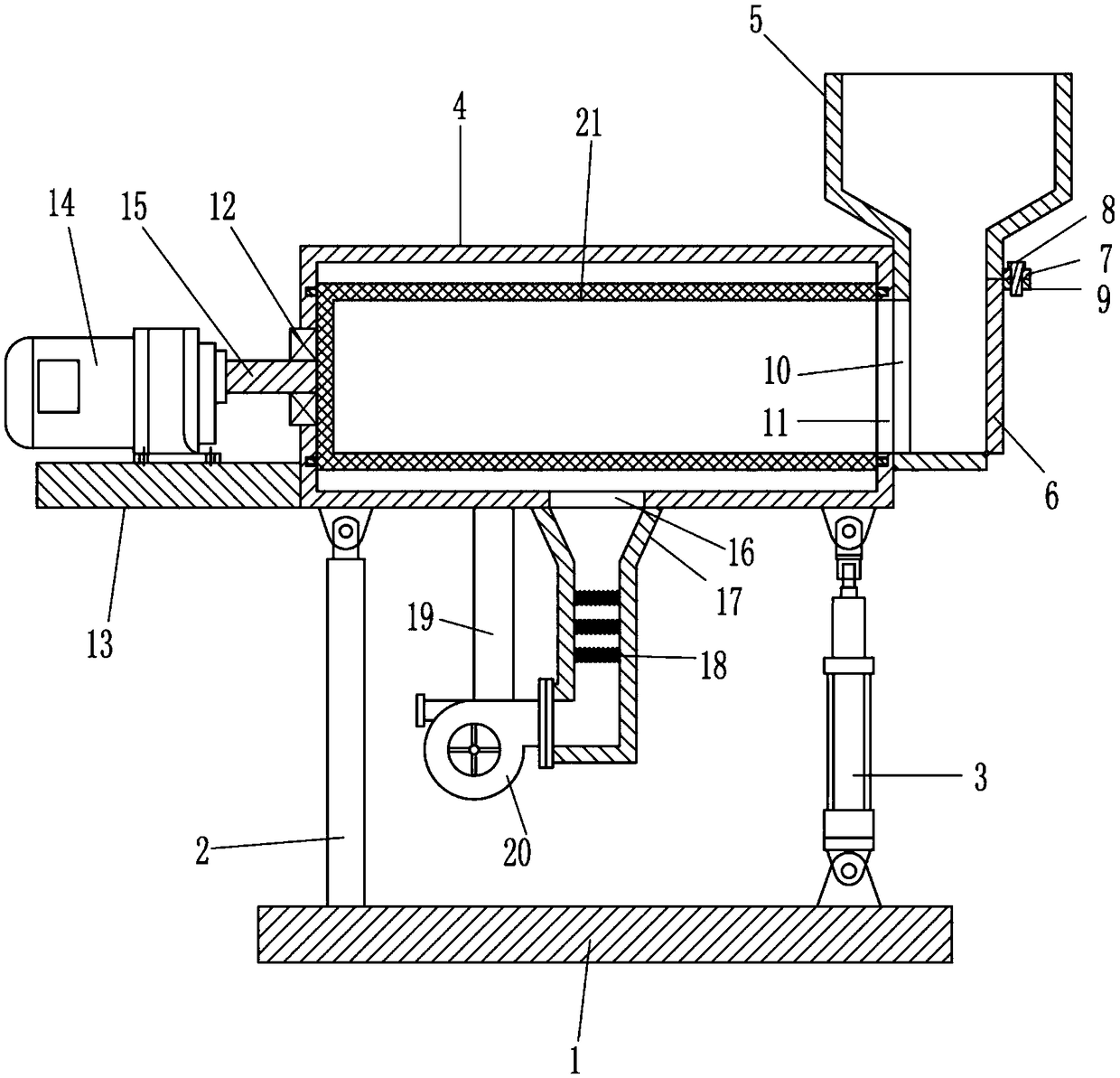

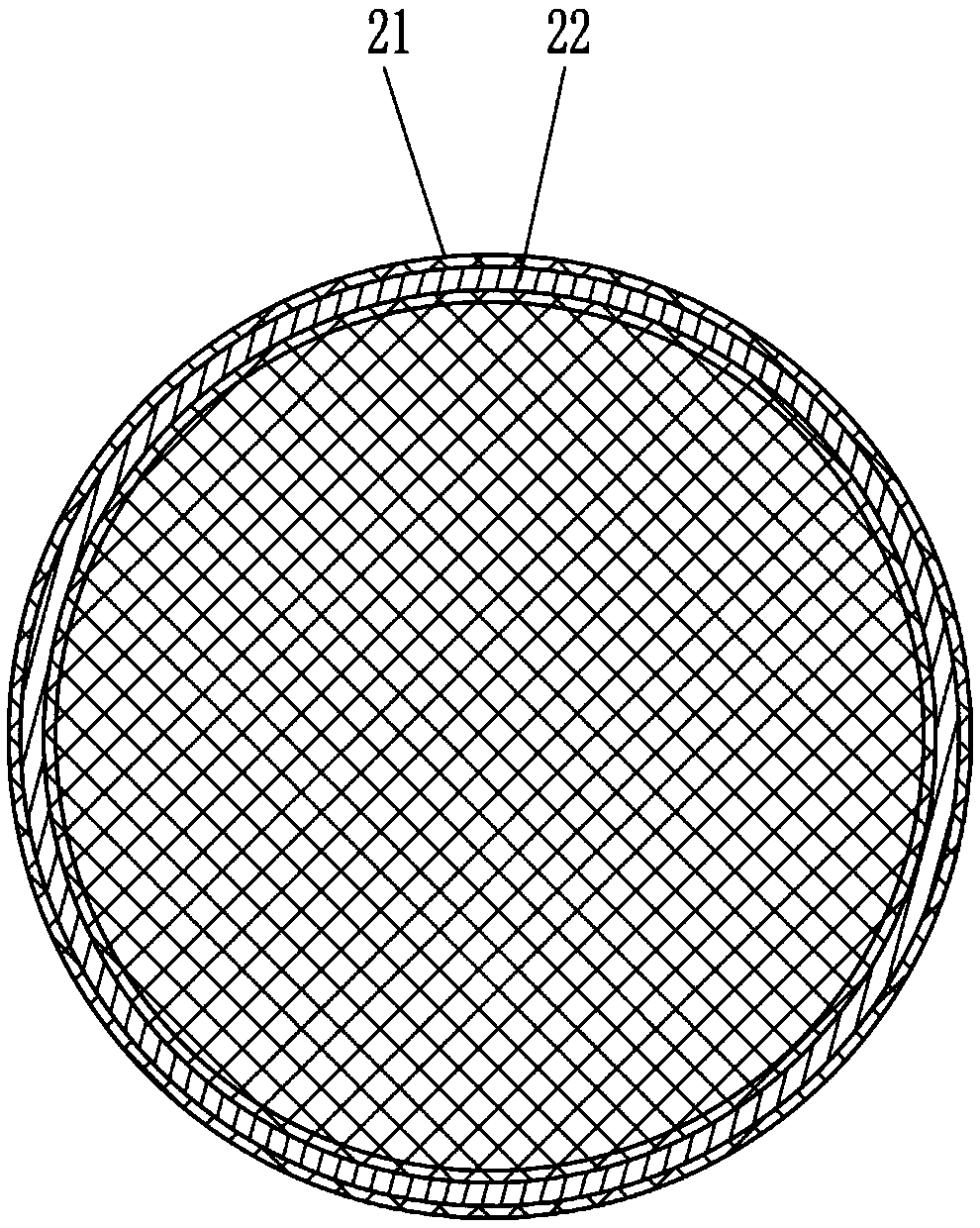

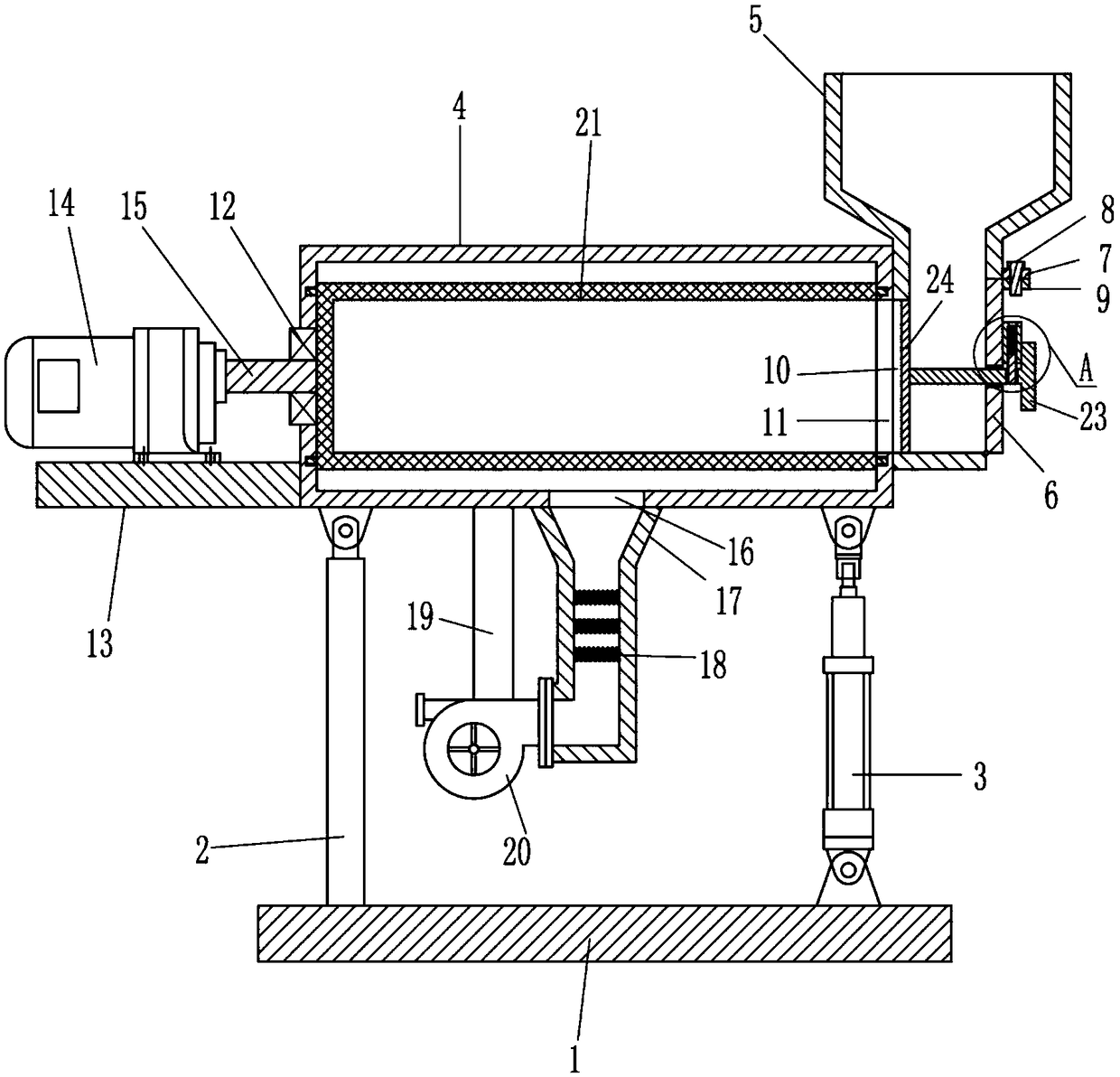

A traditional Chinese medicinal material cleaning, drying and screening device

The invention provides a traditional Chinese medicinal material cleaning, drying and screening device comprising a tank body, a cleaning device, a conveying device, a drying device and a vibration screening device. The tank body is provided with a feeding hopper, a water discharge pipe, lower separation plates, upper separation plates and a residue outlet pipe. The cleaning device comprises a water tank which is placed on the leftmost side of the upper end of the tank body, and a water inlet pipe is arranged on the water tank. The conveying device comprises conveying rollers and a conveying belt. The drying device comprises leveling rollers, vent pipes, an air blower, a blowing channel and an electric heating case, wherein the electric heating case is provided with an electric heating wire bearing plate and a middle air inlet pipe. The vibration screening device comprises fixing plates, a vibration screen, a first motor, a second motor and springs, wherein the vibration screen is fixed by the springs and is provided with a rubber sheet; the first motor is provided with a first eccentric hammer and the second motor is provided with a second eccentric hammer. The traditional Chinese medicinal material cleaning, drying and screening device integrates cleaning, drying and screening, has the advantages of high efficiency, uniform drying and high screening speed and causes no damage to medicinal materials.

Owner:郑州吉音动漫科技有限公司

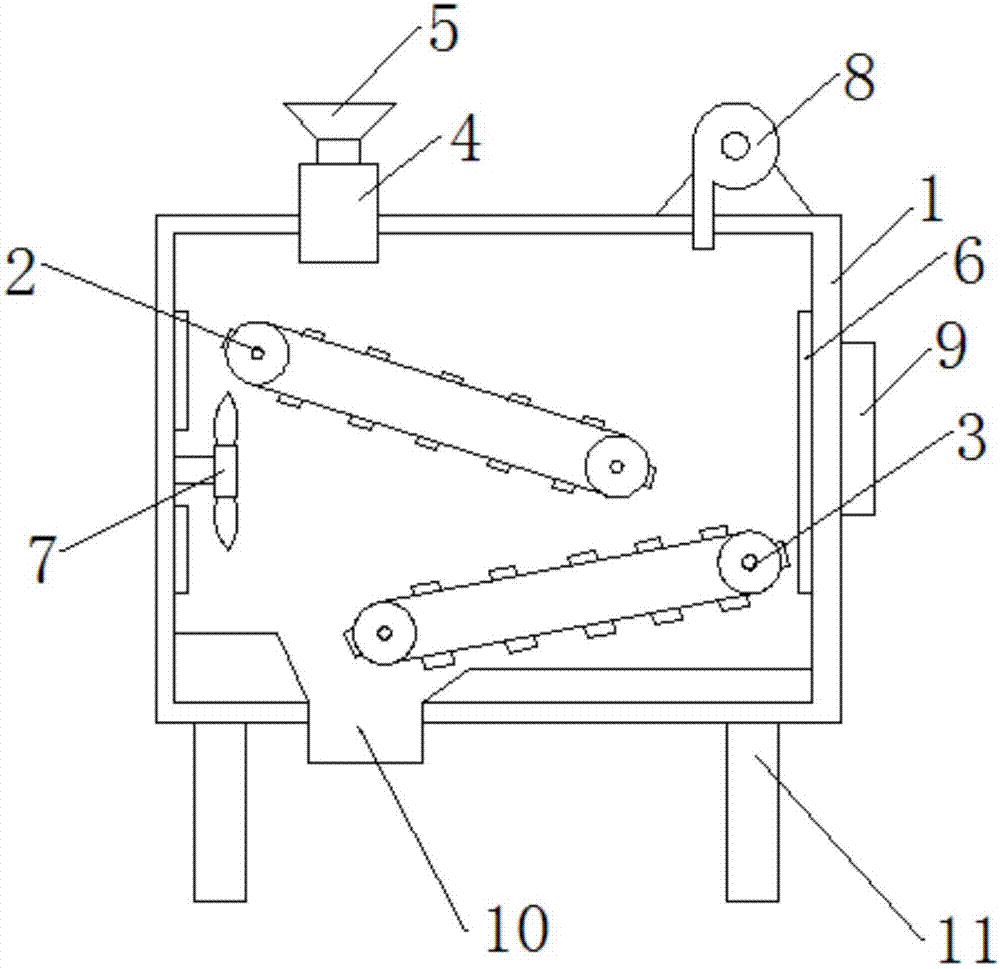

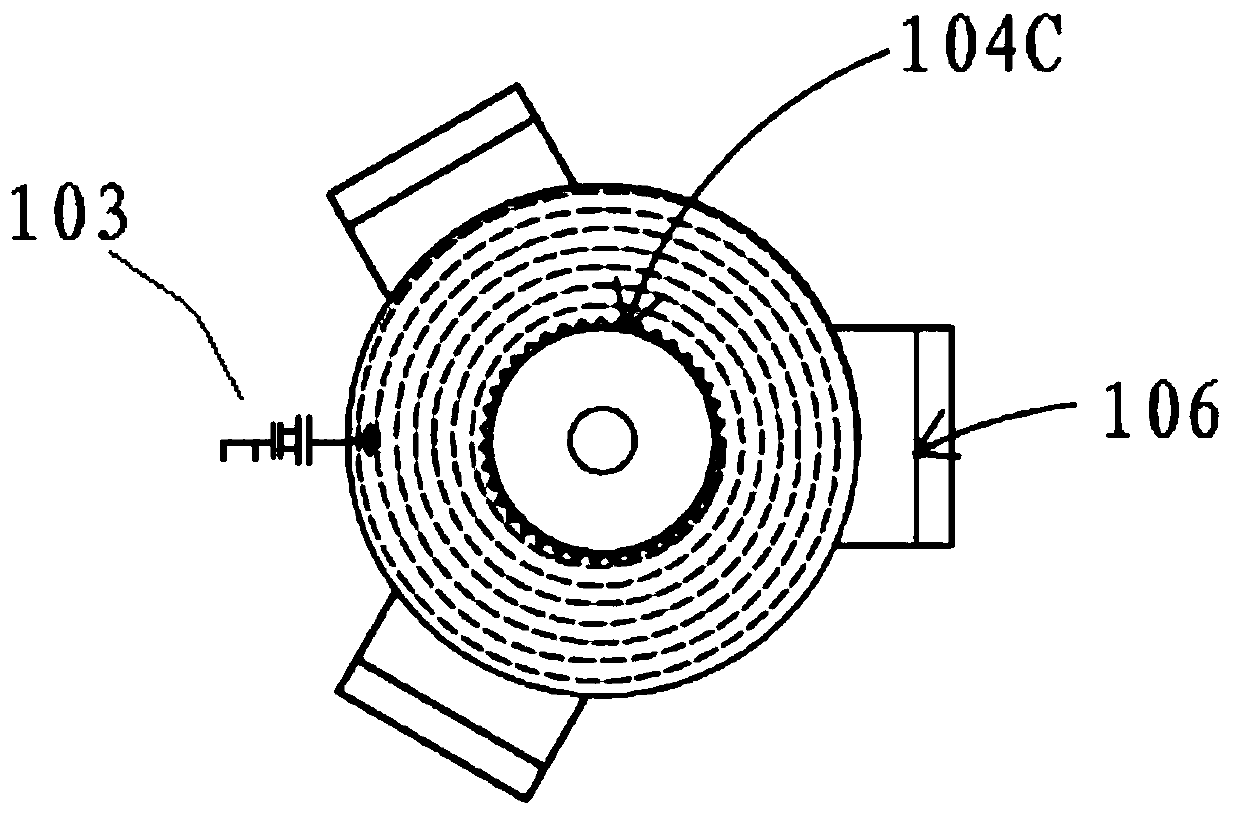

Multifunctional fertilizer pelletizer

InactiveCN109499475AAvoid stickingAvoid affecting the granulation effectGranulation in rotating drumsGrain treatmentsDrive shaftAgricultural engineering

The invention belongs to the technical field of fertilizer pelletizing equipment and in particular discloses a multifunctional fertilizer pelletizer which comprises a frame and a controller, wherein atransmission shaft is fixedly connected with the rotating shaft of a motor; a crushing unit is arranged below a feeding hole; a pelletizing unit is formed below the crushing unit; the pelletizing unit comprises a pelletizing bucket, a conveying plate and a conveying tube; the pelletizing bucket is of elliptical design; a first discharge hole, a second discharge hole and a third discharge hole areformed in the lower surface of the pelletizing bucket; a drying unit is arranged below the pelletizing unit; the drying unit comprises a rotating disc, a fixing ring and a discharge ring; grooves areformed in both sides of the first discharge hole, the second discharge hole and the third discharge hole of the pelletizing bucket; the grooves are all fixedly connected with cylinders; the cylindersare communicated with a fifth cavity; extrusion blocks are fixedly connected with extension ends of the cylinders. The multifunctional fertilizer pelletizer is simple in structure and high in pelletizing efficiency, and a chemical fertilizer can be classified according to granule sizes after being pelletized and is applicable to different application purposes, thus being wide in application range.

Owner:汪通鲜

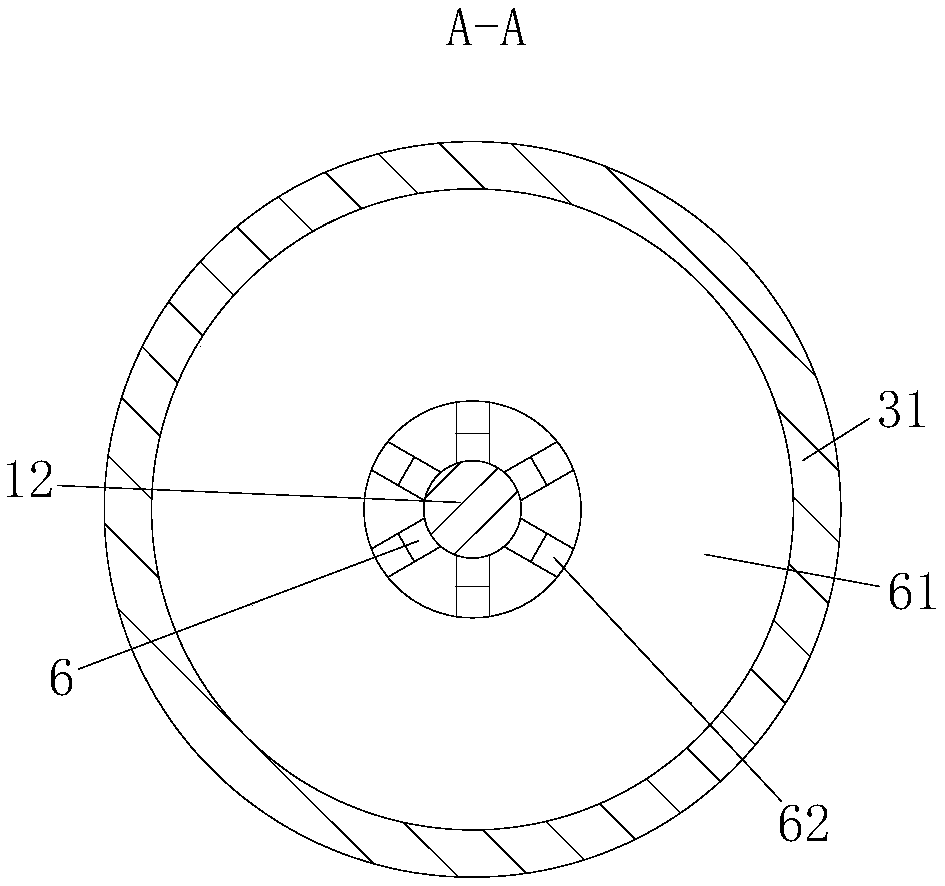

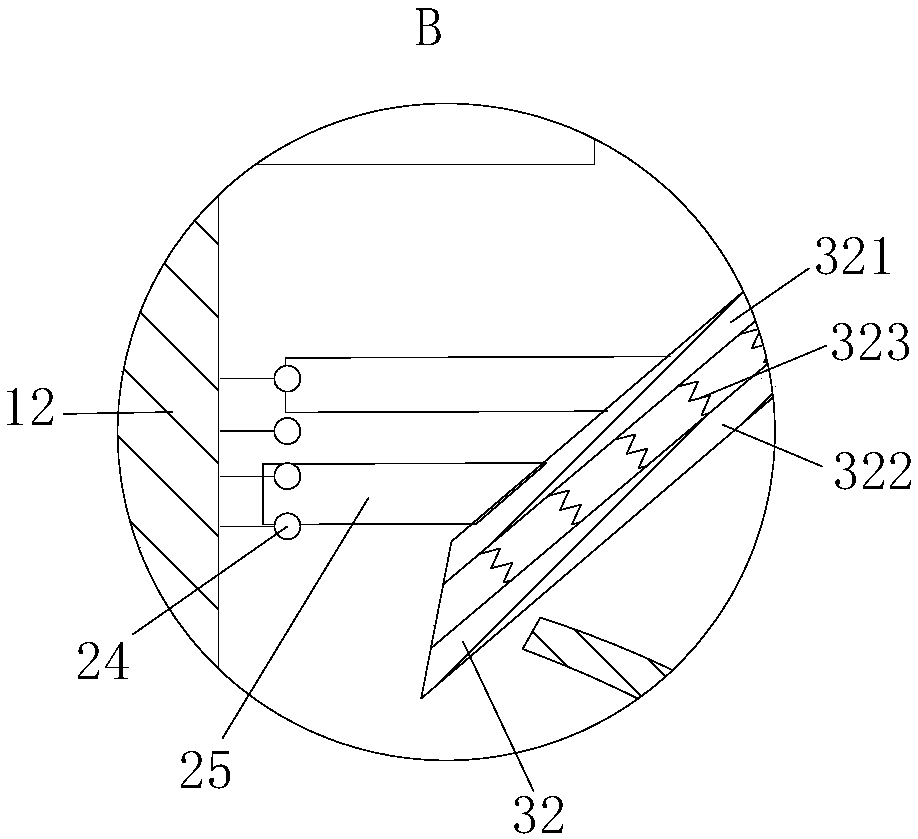

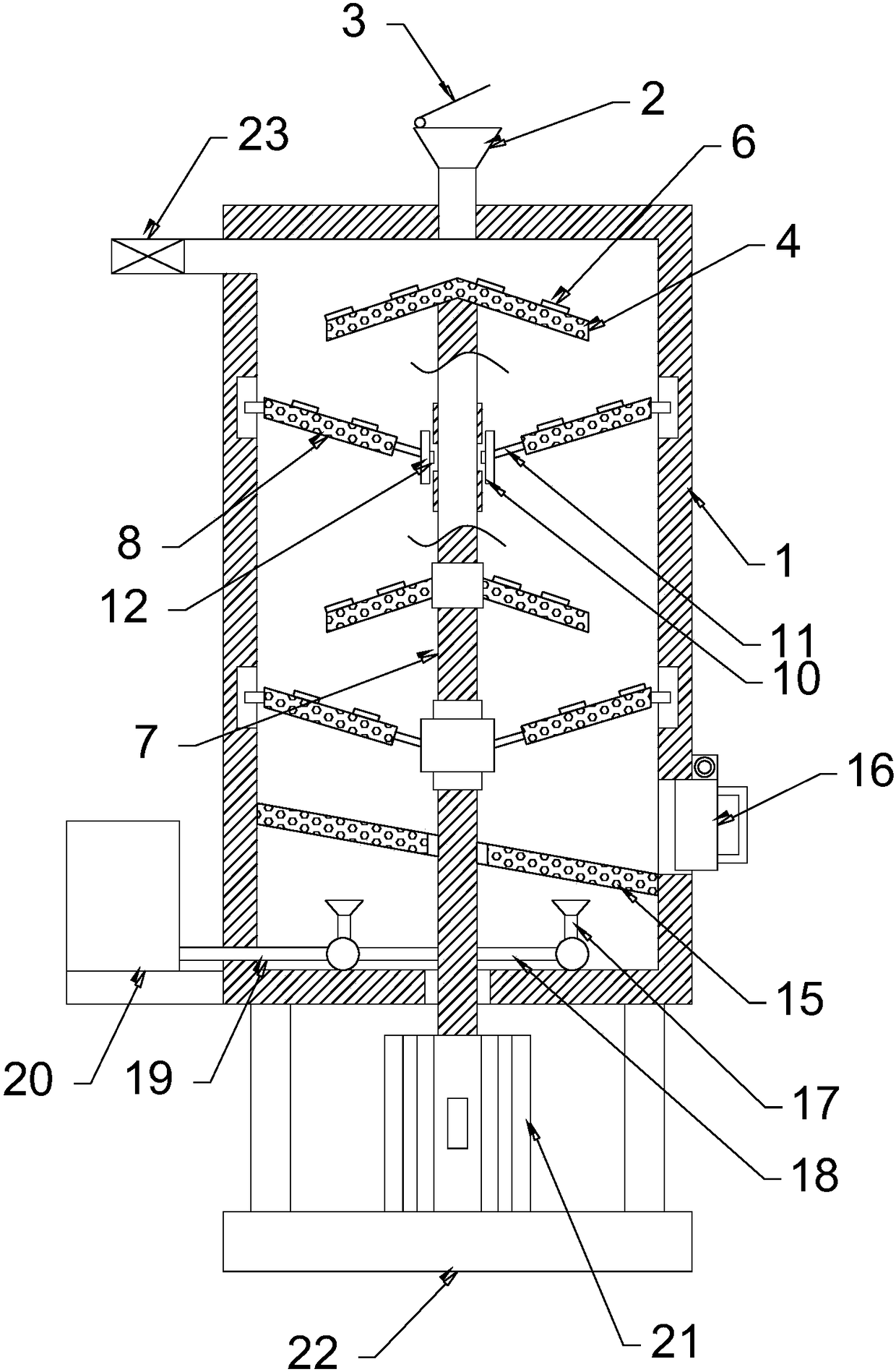

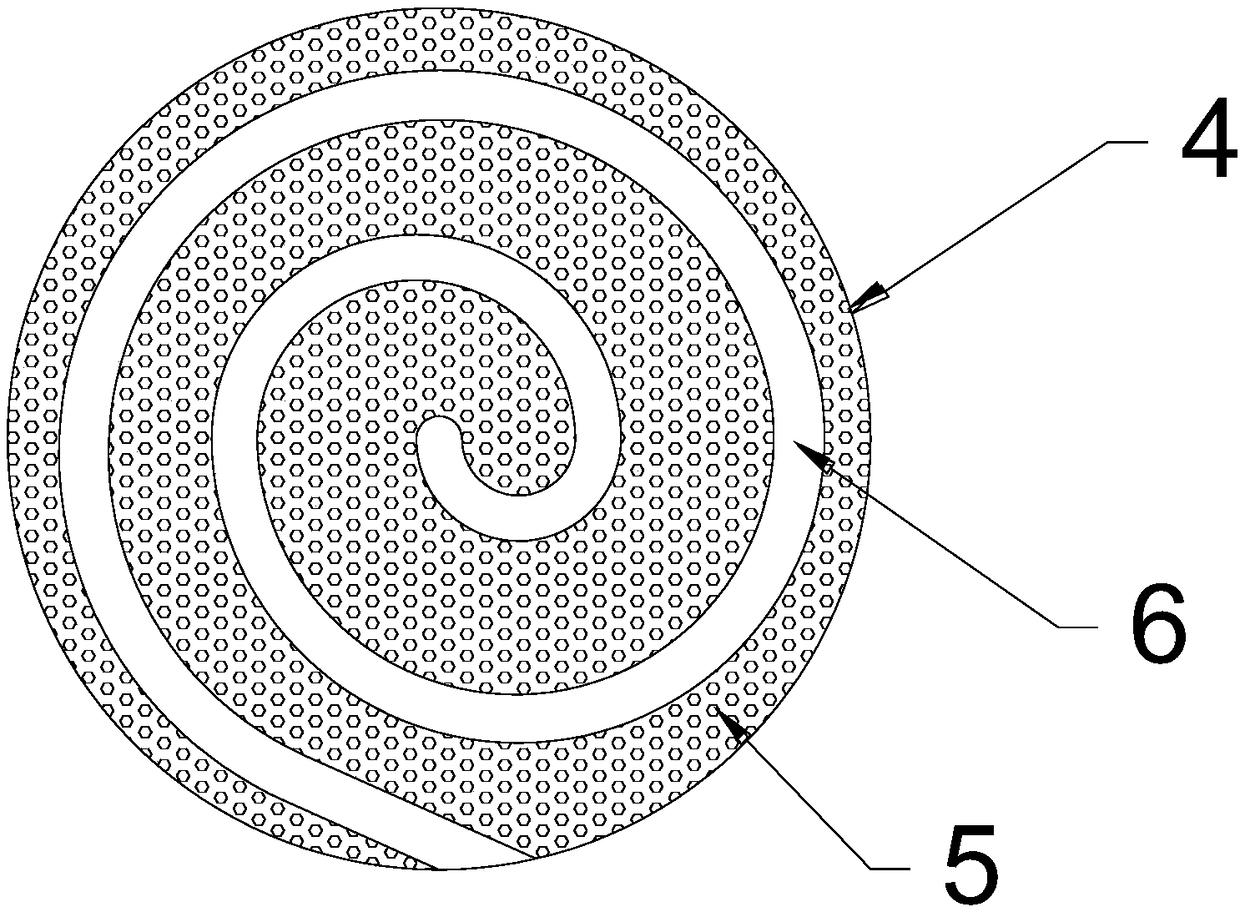

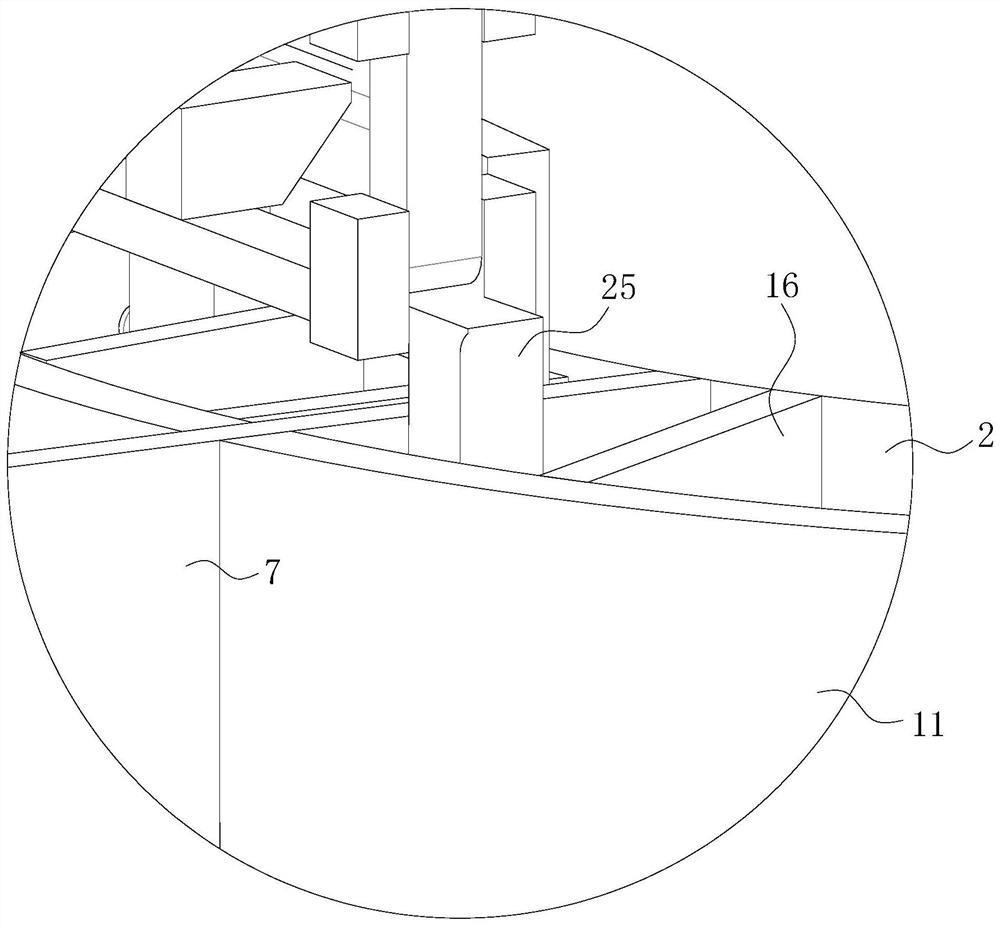

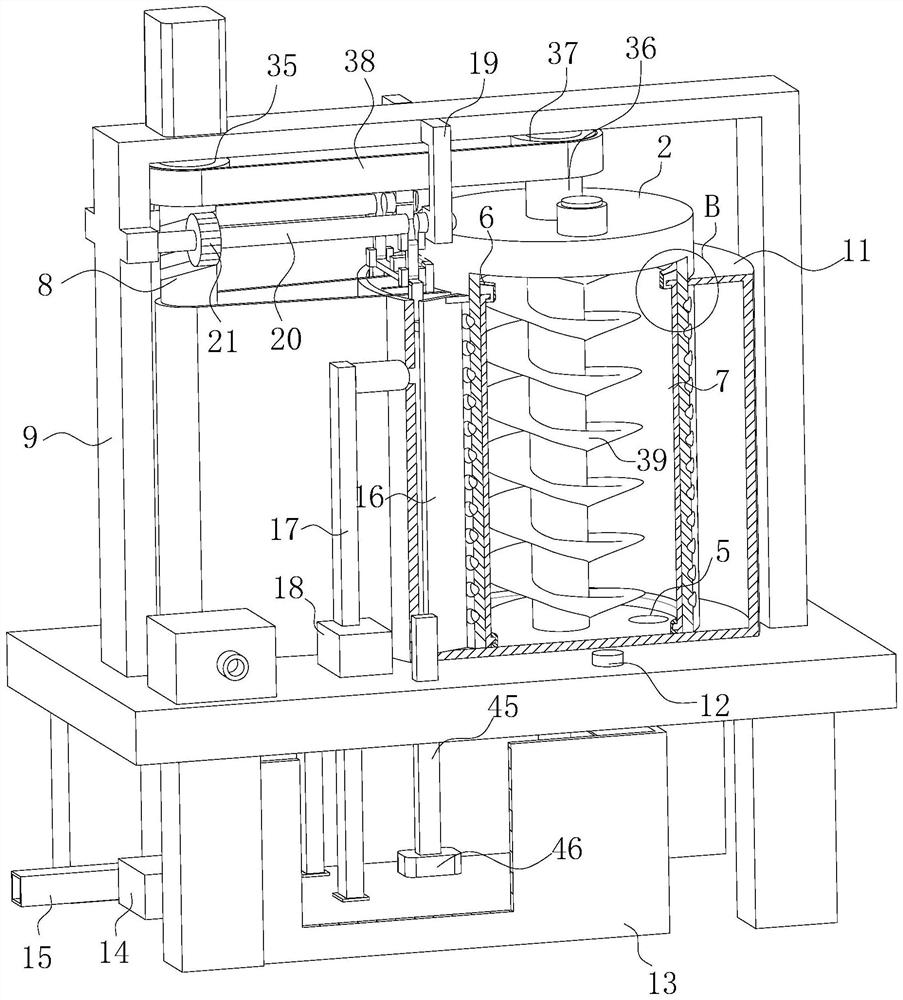

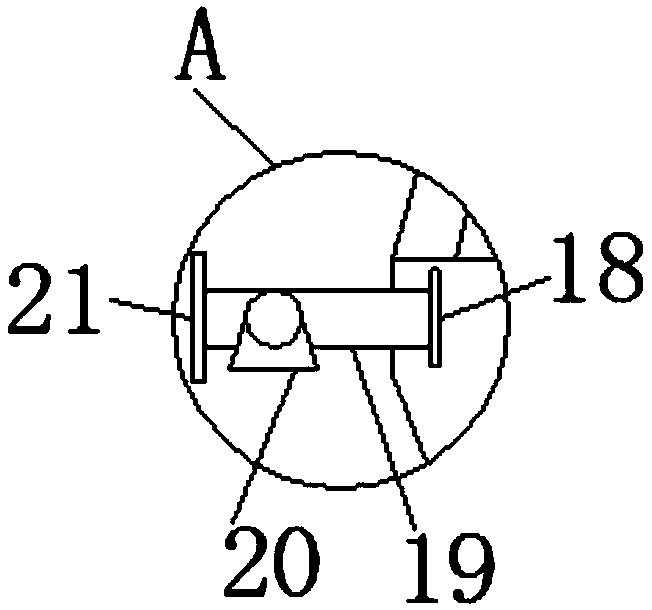

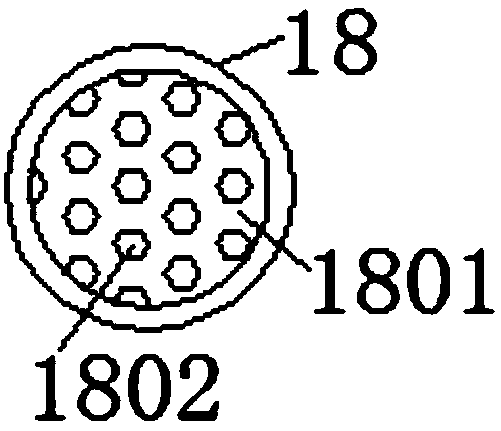

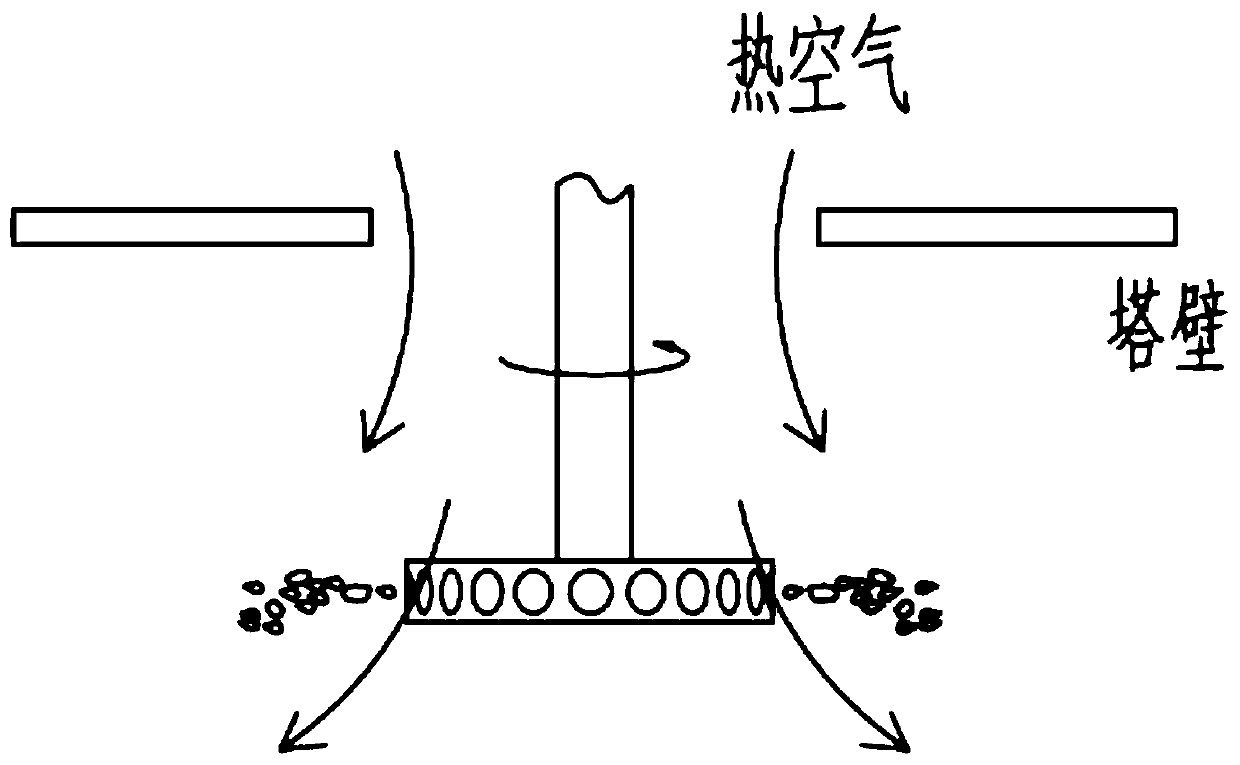

Puer tea drying device

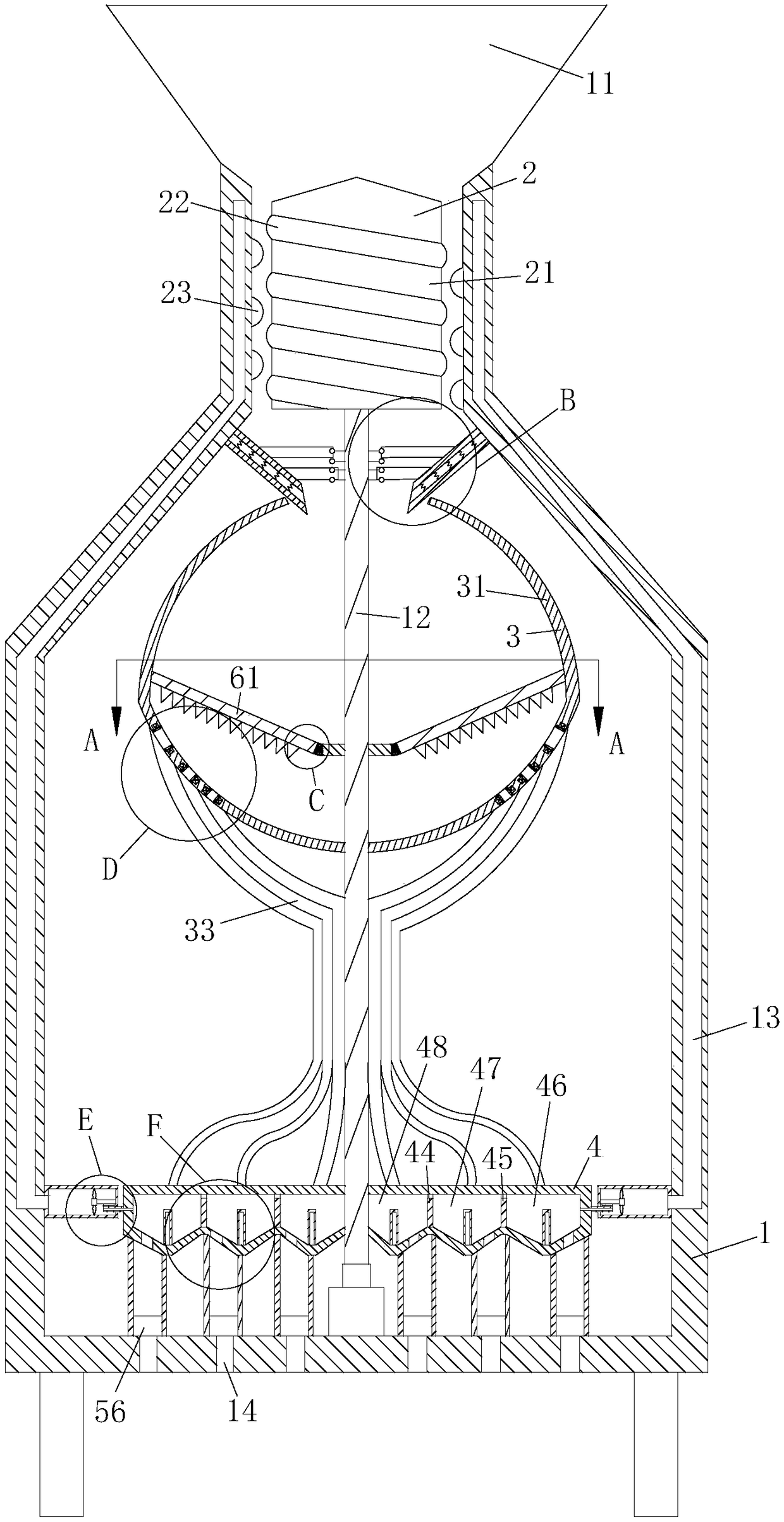

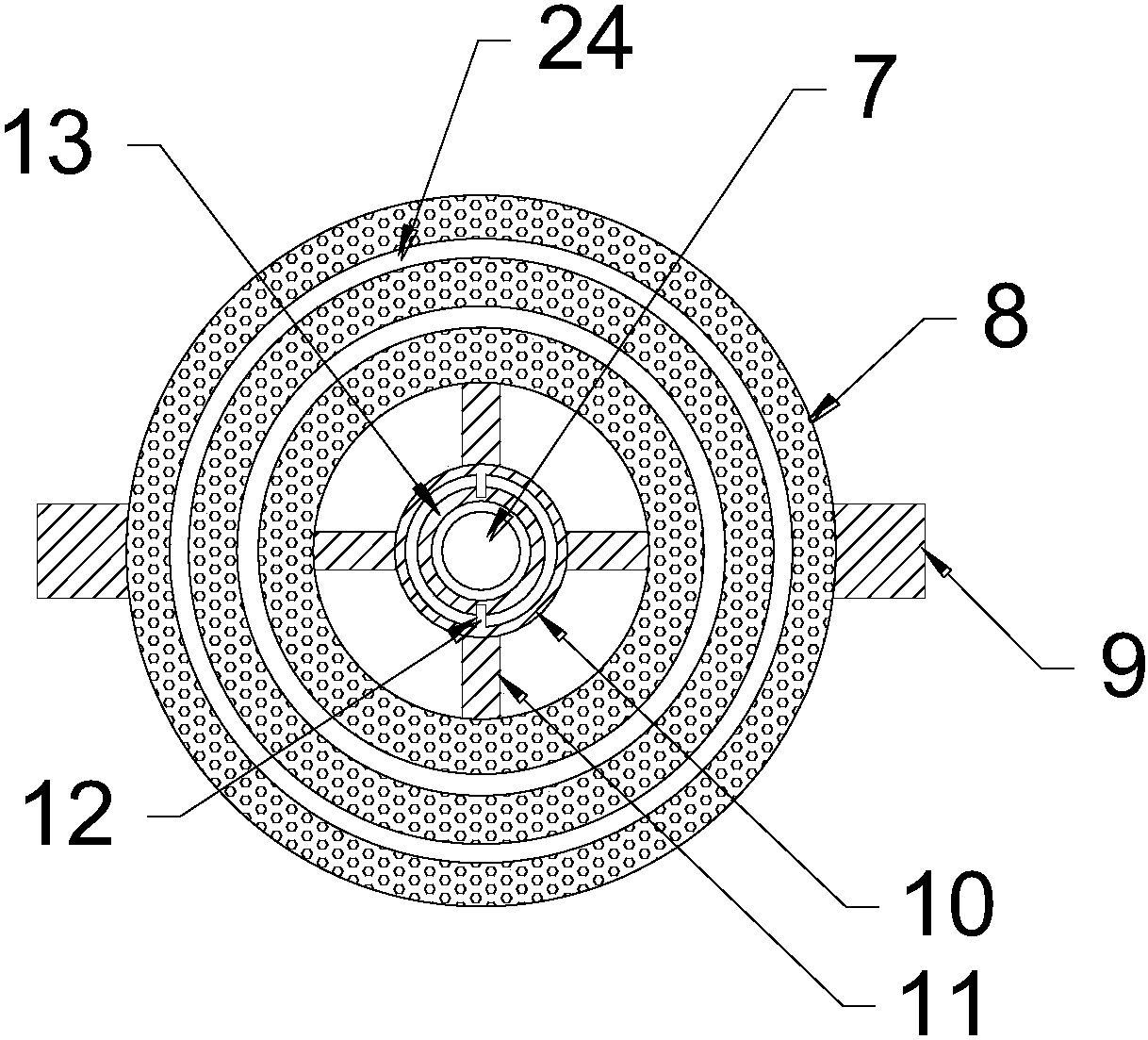

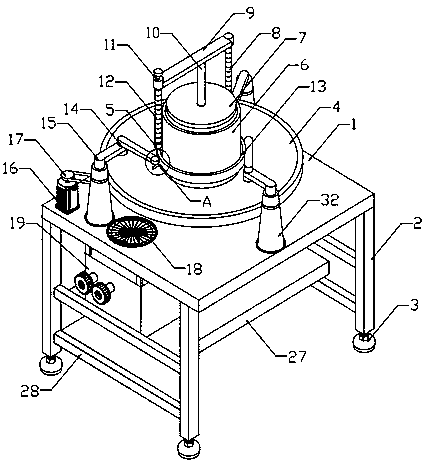

InactiveCN108332544ADry evenly and thoroughlyAvoid accumulationPre-extraction tea treatmentTea dryingDrive shaftEngineering

The invention discloses a puer tea drying device. The puer tea drying device comprises a box. The part, located below a feeding hopper, of the box is internally provided with scattering drying discs,and meshes are evenly distributed in the scattering drying discs. The surfaces of the scattering drying discs are fixedly connected with spiral-shaped spiral protruding strips. The scattering drying discs are fixedly connected with a drive shaft, and the drive shaft extends to the position below the box and is connected with a drive motor. Through the arrangement of multiple sets of rotating scattering drying discs and vibration gathering drying discs, puer tea is constantly overturned, puer tea stacking is avoided, the overturned puer tea is dried through hot air, and drying is more uniform and thorough; meanwhile, the scattering drying discs are provided with the spiral protruding strips, the gathering drying discs are provided with annular protruding strips, the slipping speed of the puer tea is delayed, and the drying time is prolonged; and the prepared puer tea appearance and inner quality are superior to the appearance and the inner quality of puer tea prepared through an ordinary oven, and the drying effect is improved.

Owner:苏州高新区鼎正精密机电有限公司

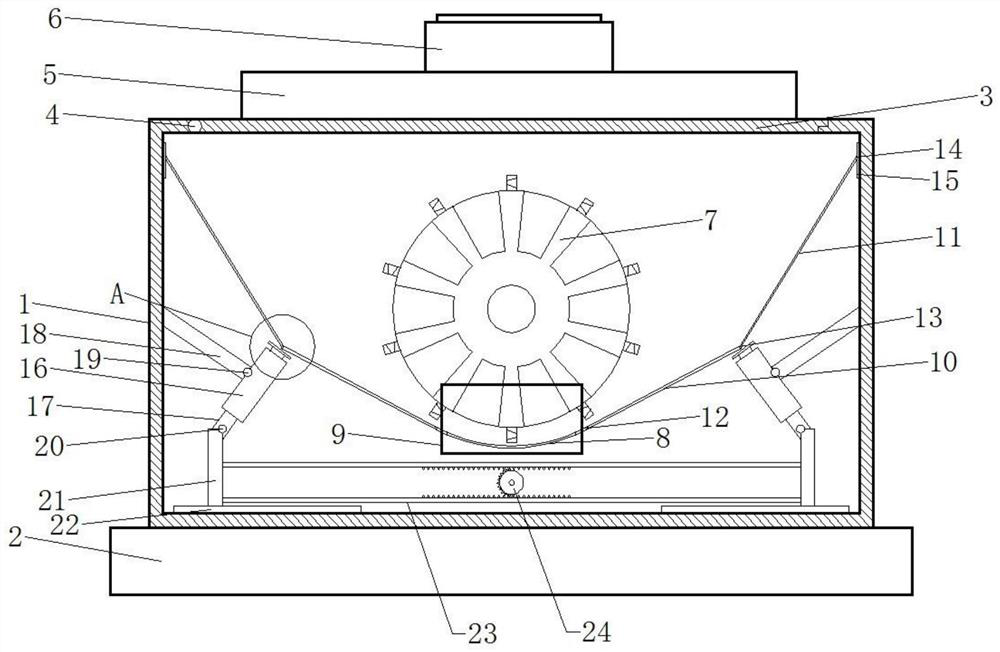

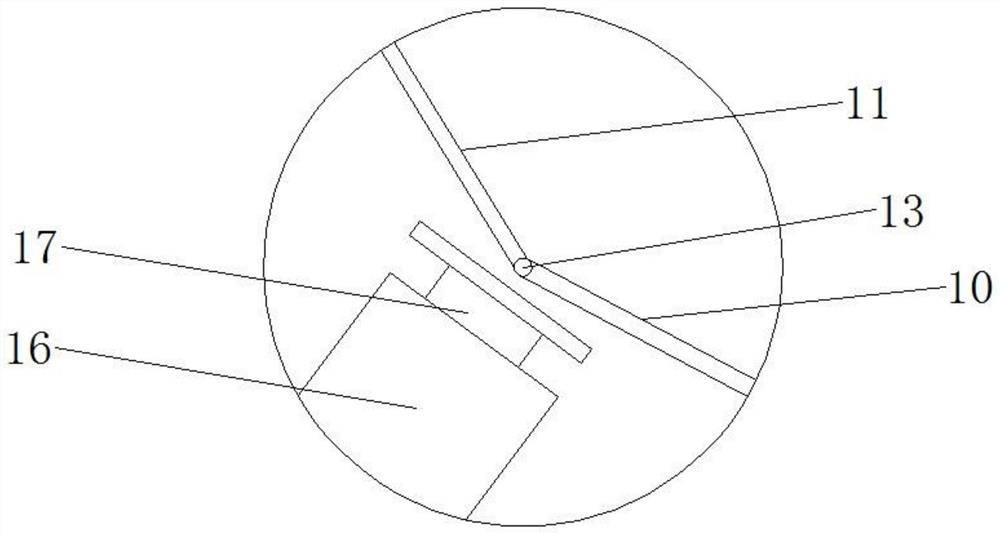

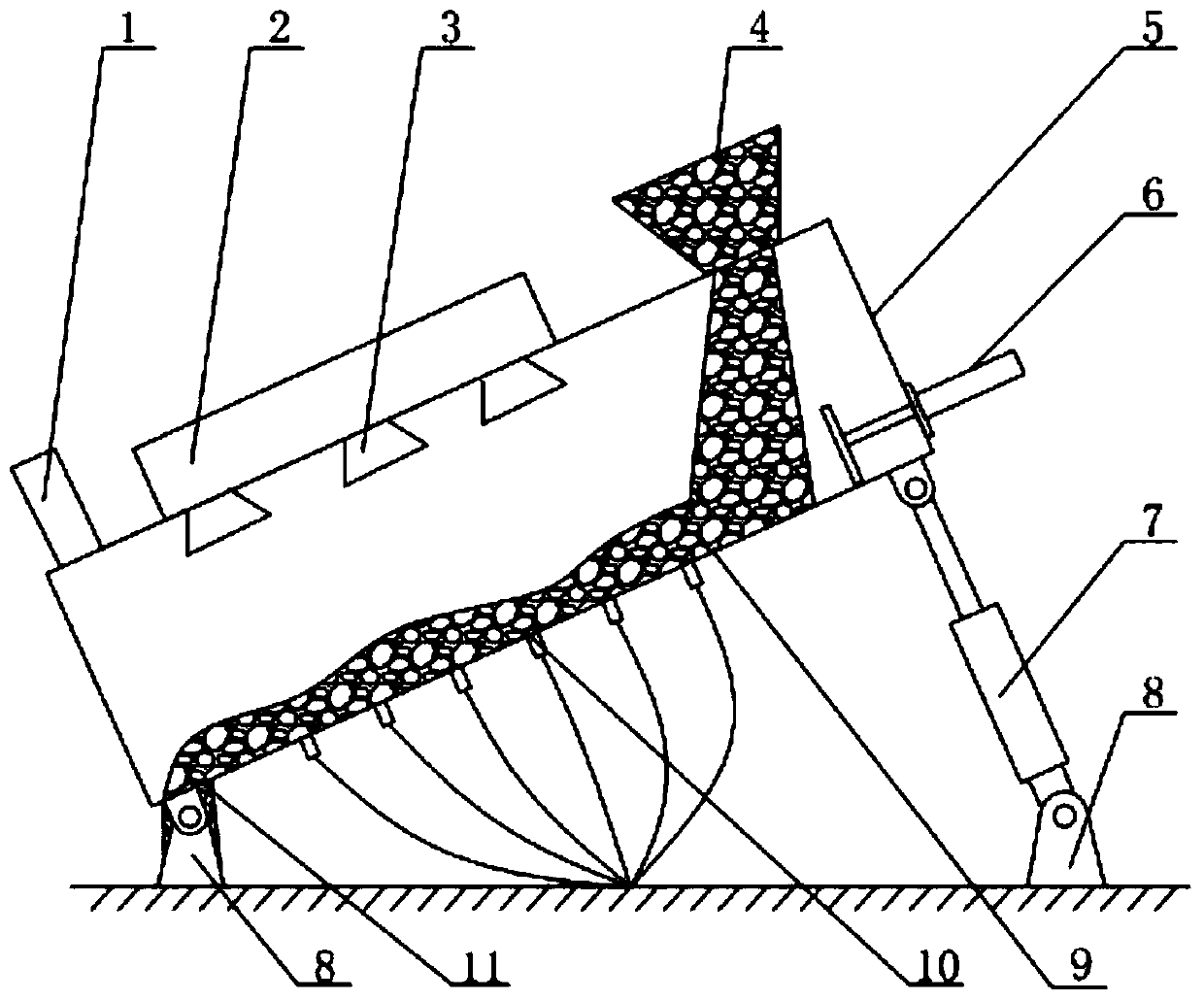

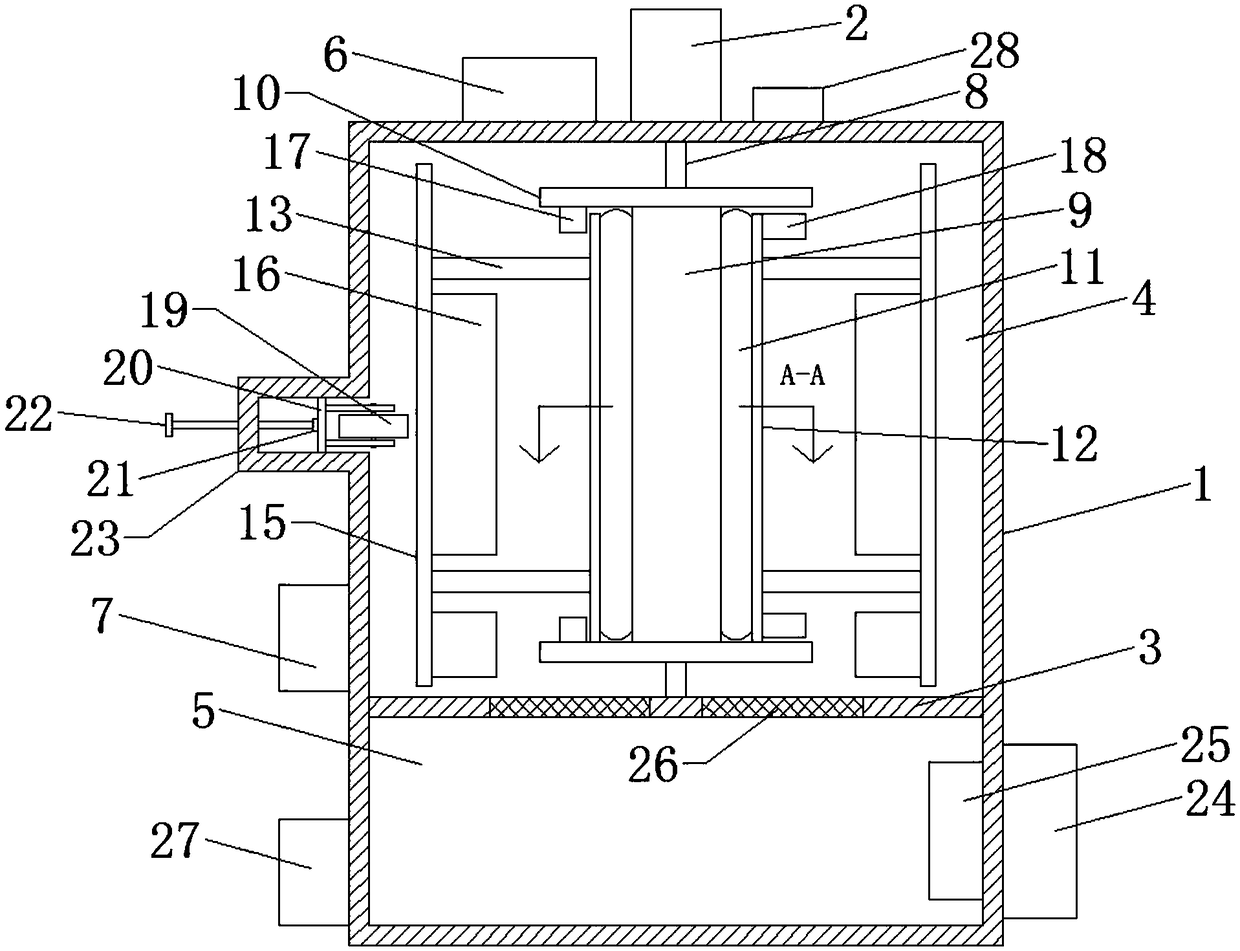

Drying and twisting device for tea leaf production

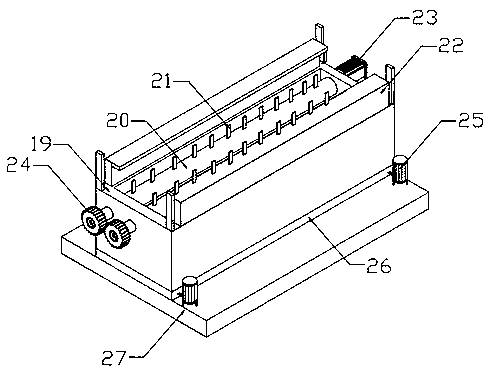

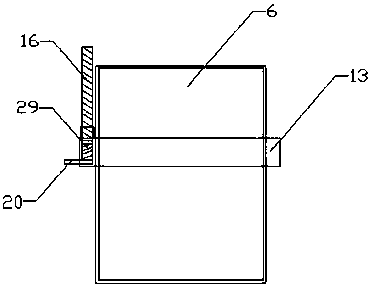

PendingCN110720523ADry evenly and thoroughlyIncrease the degree of flippingPre-extraction tea treatmentAgricultural engineeringStructural engineering

The invention discloses a drying and twisting device for tea leaf production. The drying and twisting device comprises a processing platform, wherein a twisting disk is fixedly arranged at the top ofthe processing platform; a rotating and twisting mechanism is fixedly arranged on one side of the twisting disk; a pressurizing and twisting mechanism is fixedly arranged at the top of the twisting disk; a vibrating mechanism is fixedly arranged at the bottom of the drying tank; and an air heater is fixedly mounted in a ventilating opening. According to the drying and twisting device for tea leafproduction disclosed by the invention, a tea leaf overturning mechanism is arranged, and two overturning rollers and a plurality of overturning blades are arranged, so that tea leaves in the drying tank can be continuously overturned, the heating angle of the tea leaves is continuously adjusted, and the situation that every position of the tea leaves is dried is guaranteed; and besides, through two gears which are in meshing connection, the two overturning rollers and the overturning blades can be driven to rotate in a forward and reverse manner, so that the overturning degree of the tea leaves is further increased, the drying of the tea leaves is more uniform and thorough, the drying efficiency is high, and the shaping effect of the tea leaves is improved.

Owner:HUNAN GUDONGCHUN TEA IND

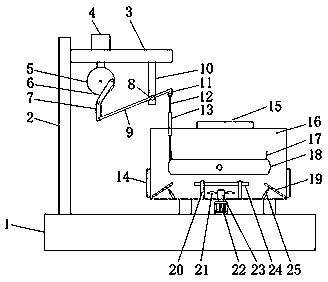

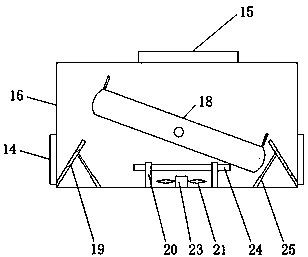

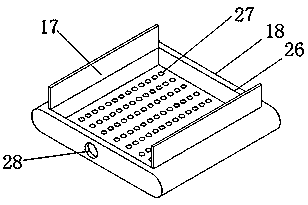

Traditional Chinese medicine drying device

InactiveCN109654841ADry evenly and thoroughlyPrevent taking awaySolar heating energySolar heat storageFiberDrive motor

The invention discloses a traditional Chinese medicine drying device comprising a base and a drying box. A stand column is connected with the right side of the upper end of the base. The upper end ofthe stand column is provided with a dehumidifier. A damping spring is connected with the middle of the upper end of the base. The upper end of the damping spring is connected with the lower end of thedrying box. The upper end of the drying box is sequentially connected with a feeding hopper, a drive motor and an air outlet pipe from left to right. The other end of the air outlet pipe is connectedwith the dehumidifier. An output shaft of the drive motor is connected with a stirring shaft. The upper portion of the left inner wall and the middle portion of the right inner wall of the drying boxare connected with a temperature sensor and a humidity sensor correspondingly. The lower portion of the left side of the drying box is connected with a discharging pipe. The lower portion of the right side of the drying box is connected with an air inlet pipe. The other end of the air inlet pipe is connected with a hot air blower. The dehumidifier is connected with the hot air blower through an air conveying pipe. The outer portions of the upper side wall, the left and right side walls and the front and back side walls of the drying box are all intertwined with heat storage and insulation fiber. The traditional Chinese medicine drying device has the advantages of being good in drying effect, low in energy consumption and high in cyclic utilization degree, reducing production cost, monitoring the temperature and humidity in real time and having high drying efficiency.

Owner:YUZHOU HETONGTAI PHARMA CO LTD

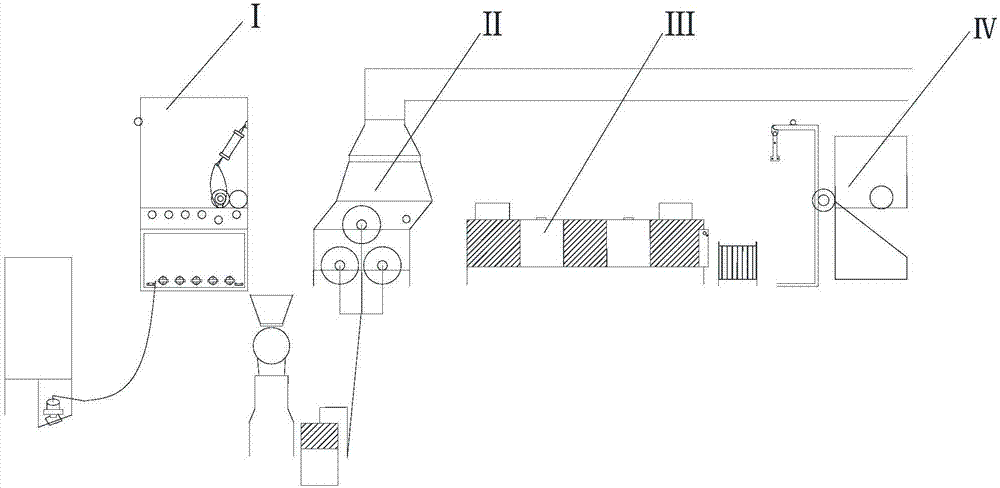

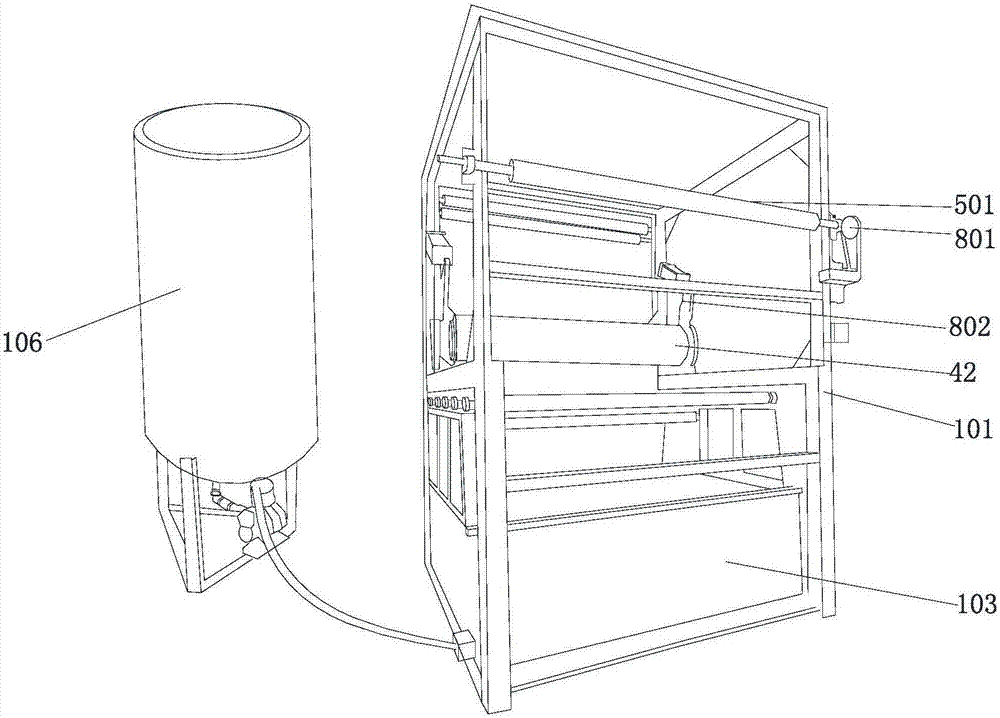

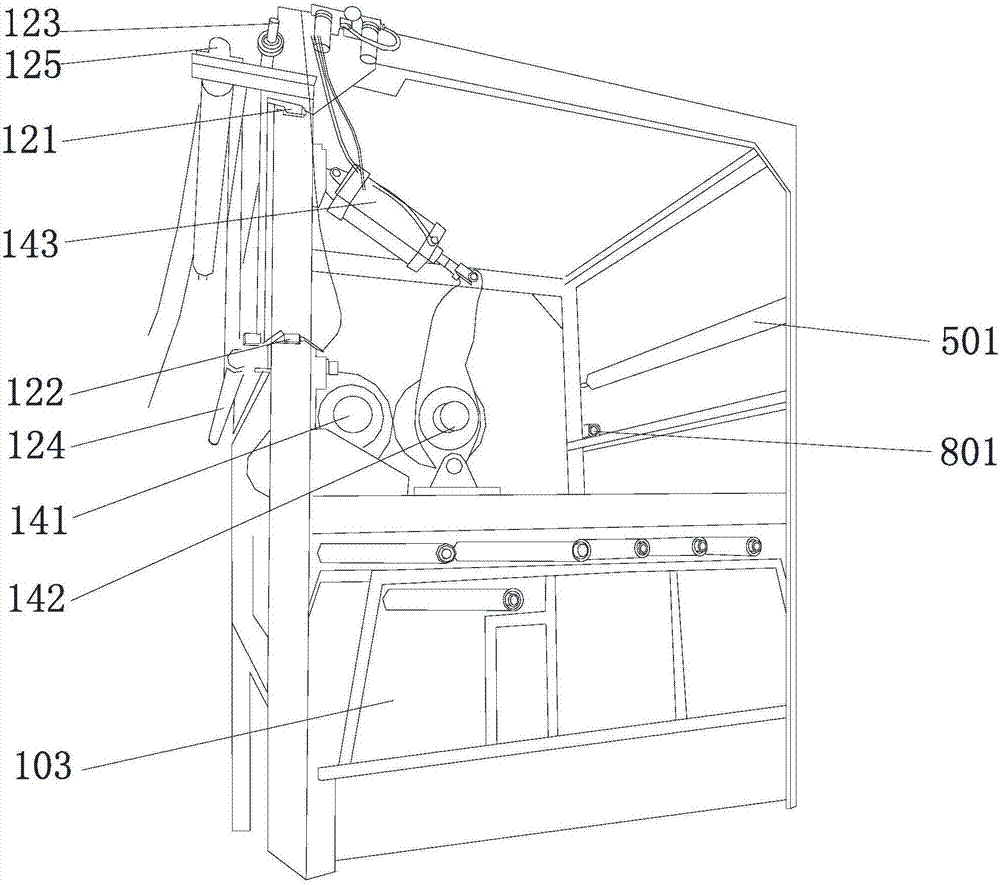

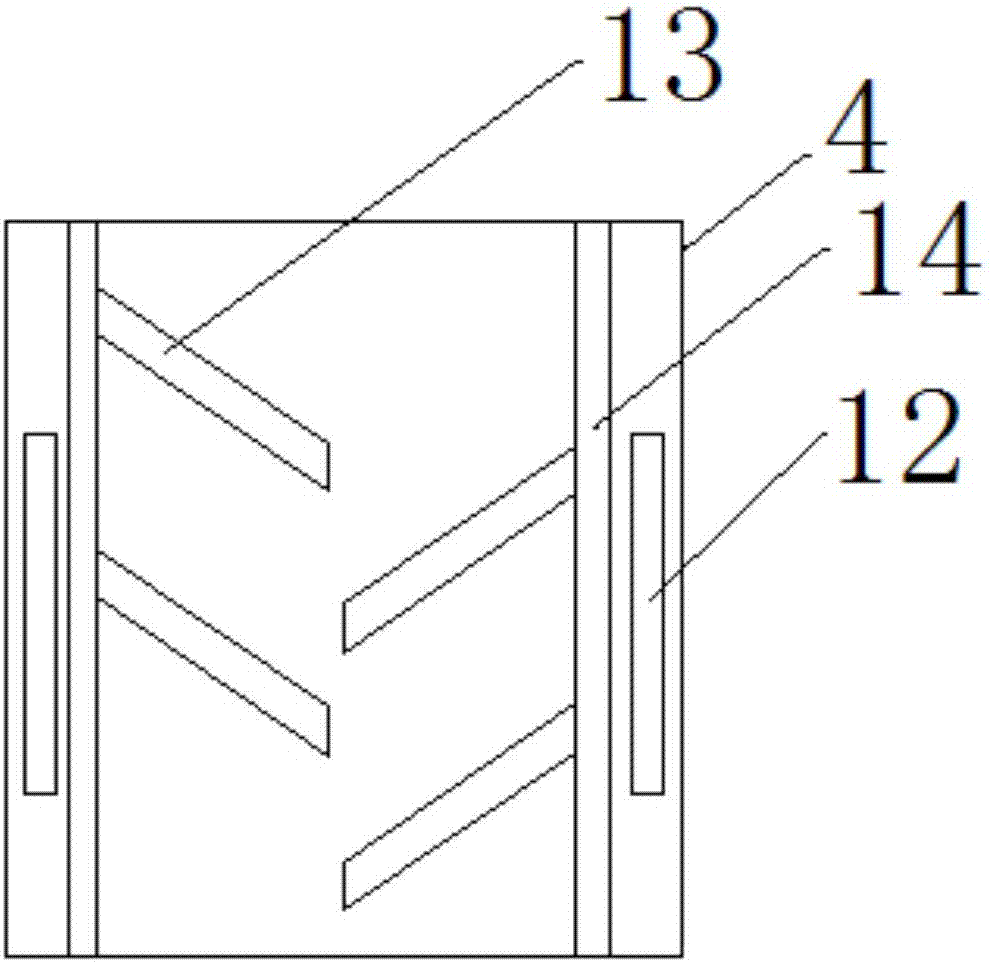

Padding and drying and stock coiling all-in-one machine for piece goods

ActiveCN106868756ADry evenly and thoroughlyDip evenlySucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersProcess engineeringMechanical engineering

The invention discloses a padding and drying and stock coiling all-in-one machine for piece goods. The machine comprises a cloth padding device, a thermal drying cylinder dryer, an oven and an automatic cloth rolling machine, the back side of the cloth padding device is connected with the front side of the thermal drying cylinder dryer, the back side of the thermal drying cylinder dryer is connected with the left side of the oven, and the right side of the oven is connected with the back side of the automatic clothing rolling machine. The padding and drying and stock coiling all-in-one machine for the piece goods has the following advantages that the padding, drying and rolling of the piece goods are integrated, the automatication level is high, it is can be ensured that the piece goods dipping is even and the drying is even and thorough, and the stock coiling is flat and the edge is neat.

Owner:江西正博实业有限公司

Feeding accurate-control device for producing and processing health-care tea

InactiveCN107242316AIt is convenient to control whether to feedEasy to control feed volumePre-extraction tea treatmentTea dryingEngineeringScrew thread

The invention discloses a device for precise control of feeding in the production and processing of health-care tea. In the main body, a vertically arranged feeding pipe is provided in the feeding hopper, and the feeding pipe is connected with the feeding hopper, and a horizontally arranged baffle is arranged in the feeding pipe, and one side of the feeding pipe is respectively connected with Horizontally arranged guide rods and screw rods, wherein the guide rods are located above and below the screw rods, and a movable plate perpendicular to the guide rods is slidably connected between the two guide rods, and the movable plate is threadedly connected with the screw rod, and the movable plate is also connected to the baffle One end is fixedly connected, a handle is installed at one end of the screw rod, and a fixed plate and a rotating plate are respectively provided under the baffle plate, wherein the fixed plate is slidably installed on the top of the rotating plate. The invention has a reasonable design, conveniently controls whether the tea leaves are fed and the amount of feed, and the drying is uniform and thorough, thereby improving the quality of the tea leaves.

Owner:浙江正汇生物科技有限公司

Drying device for underwear production and processing

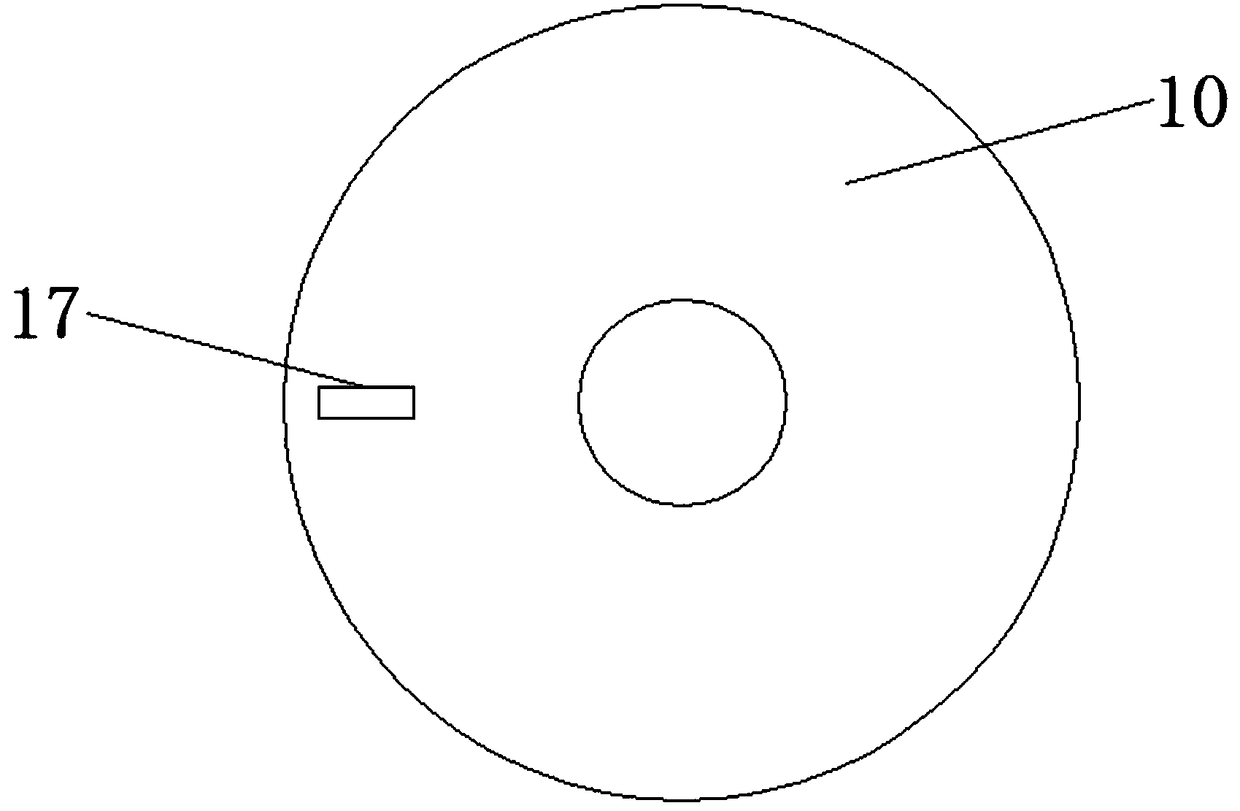

InactiveCN112284097ADry evenly and thoroughlyImprove drying efficiencyDrying gas arrangementsDrying chambers/containersCircular discTransmission belt

The invention discloses a drying device for underwear production and processing. The drying device comprises a bottom plate, a transmission assembly and a turnover assembly. Supporting plates are symmetrically arranged on the two sides of the surface of the bottom plate separately, and frame plates are fixedly connected with the top ends of the supporting plates on the two sides; a disc is fixedlyconnected with the opposite ends of the frame plates on the two sides, and a rotating assembly is arranged on the surface of the bottom plate; and a drying assembly is arranged on the rotating assembly. The transmission assembly comprises a rotating shaft, an auxiliary belt wheel, a bracket, a mounting shaft, a first motor, a main belt wheel and a transmission belt, and the rotating shaft is rotatably connected with the middle of the disc; the auxiliary belt wheel is fixedly sleeved with the top of the rotating shaft, and the bracket is fixedly connected with one side of the surface of the disc; and the top of the mounting shaft is rotatably connected with the surface of the bracket, and the first motor is fixedly connected with the surface of the bracket. According to the drying device for underwear production and processing, clothes can be dried more evenly and thoroughly, the drying efficiency is effectively improved, the clothes are fixed more firmly and are not prone to falling off, and the practicability is higher.

Owner:温州盛阳服装有限公司

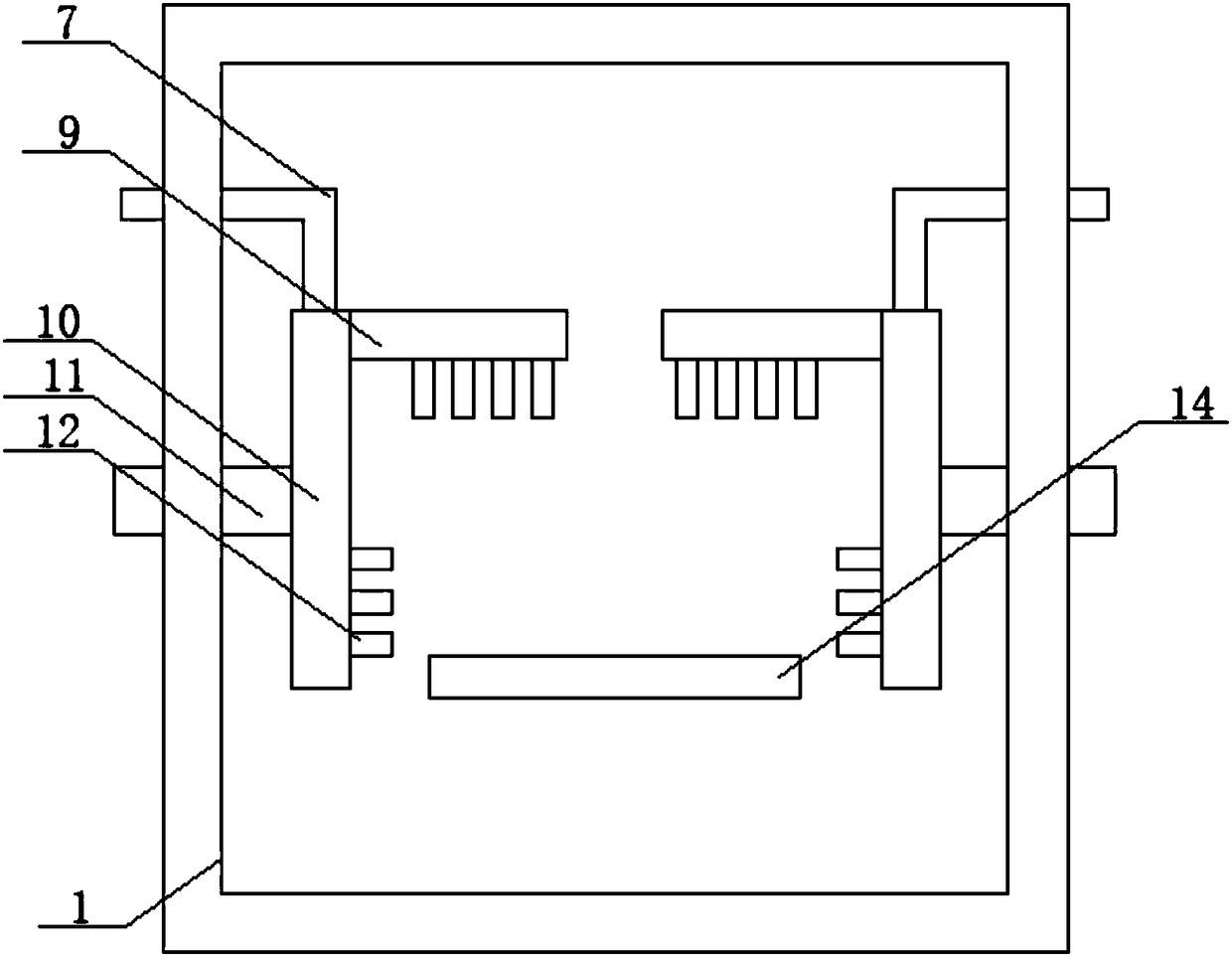

Instrument cleaning device for department of respiration

InactiveCN108435661AWash evenlyShorten the timeDrying gas arrangementsCleaning using liquidsEngineeringMedical instruments

The invention discloses an instrument cleaning device for the department of respiration. The instrument cleaning device comprises a bearing plate, wherein a damping device is arranged at the lower endof the bearing plate; the upper end of the bearing plate is fixedly equipped with a cleaning box, a drying box and a sterilizing box from left to right in sequence; a sterilizing device is arranged in the sterilizing box; two first placing plates are arranged in the cleaning box; first openings are formed in side walls of the two ends of the cleaning box; first slide slots are formed in oppositeside walls of the first openings; first slide blocks are mounted in the first slide slots; ends of the two first slide blocks are fixedly equipped with mounting rods; and the side walls of the two ends of the cleaning box are fixedly equipped with first electric telescopic poles. The instrument cleaning device can be used for cleaning medical instruments more uniformly, so that medical instrumentcleaning time is shortened, and drying of medical instruments is more uniform and complete, and therefore, the problem that drying of medical instruments is uneven and incomplete is solved, and use isconvenient.

Owner:吕彬

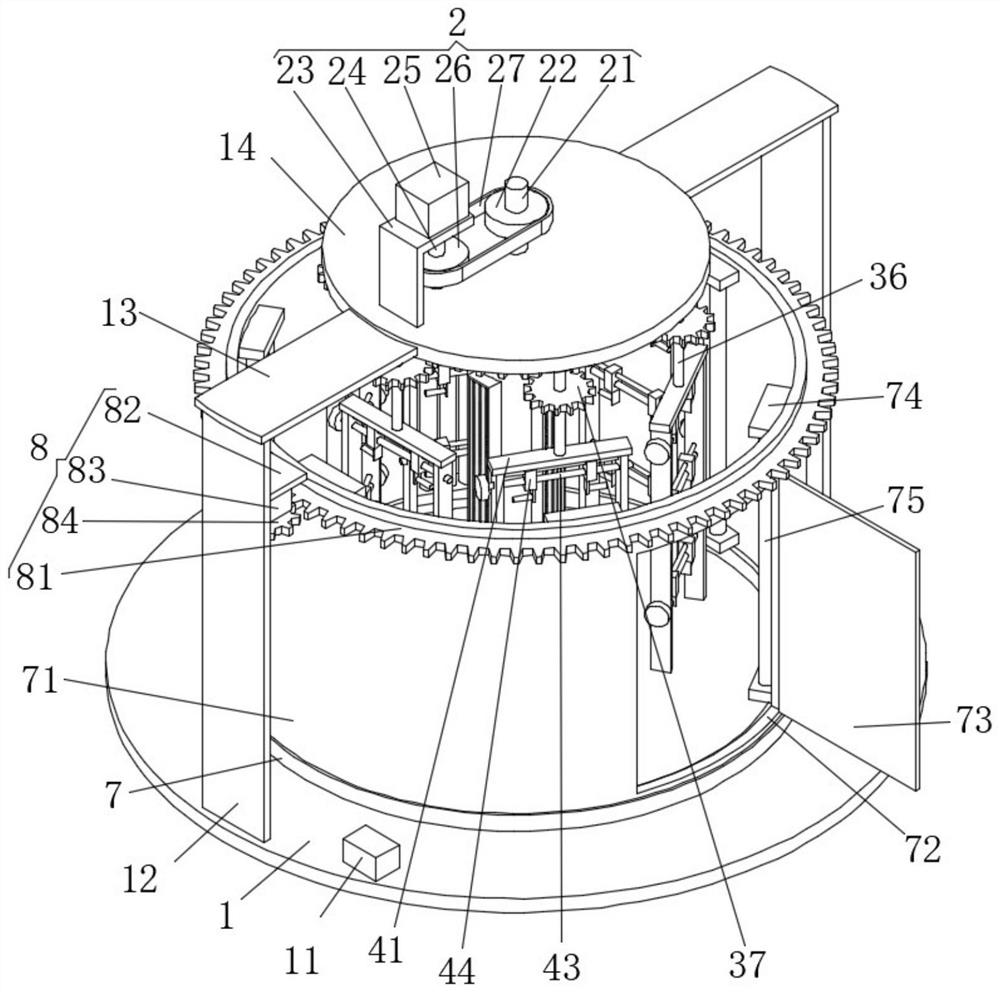

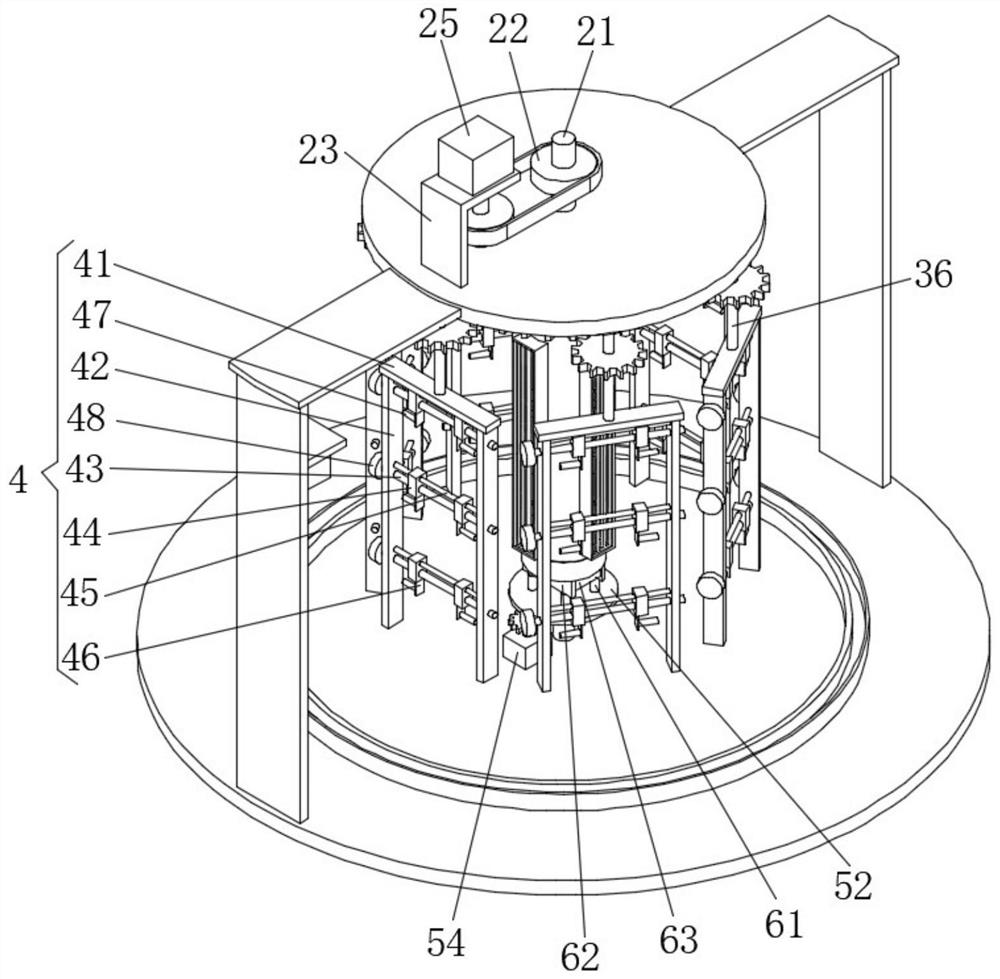

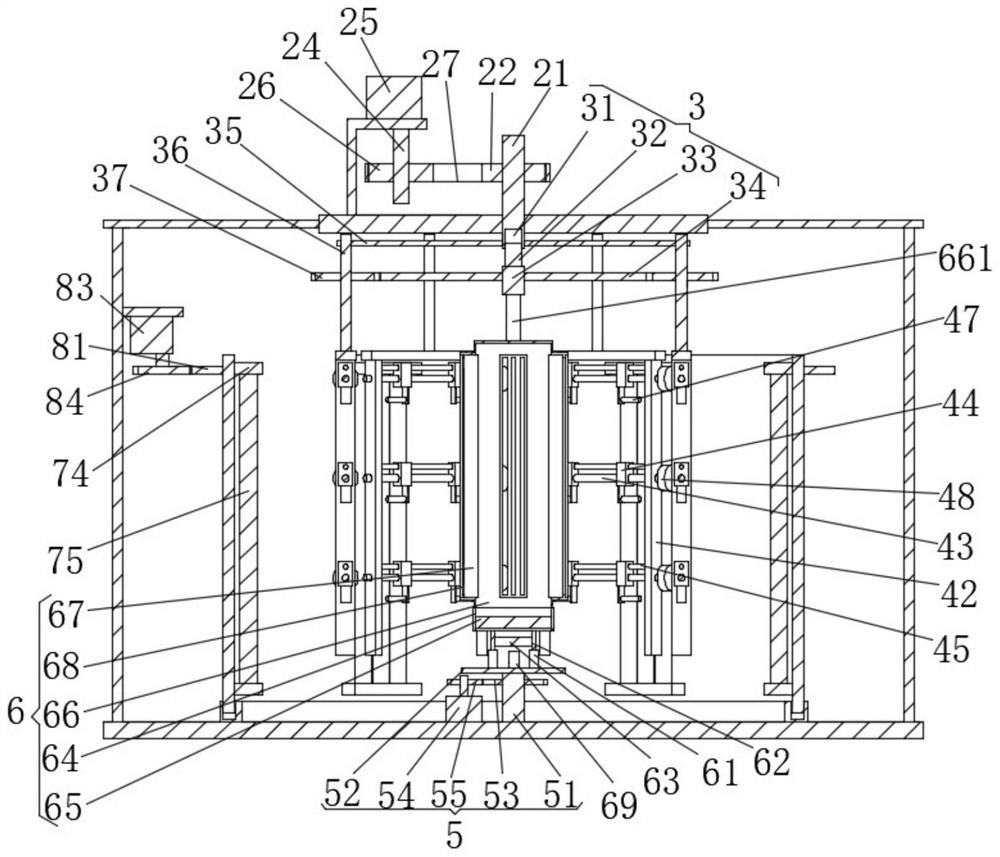

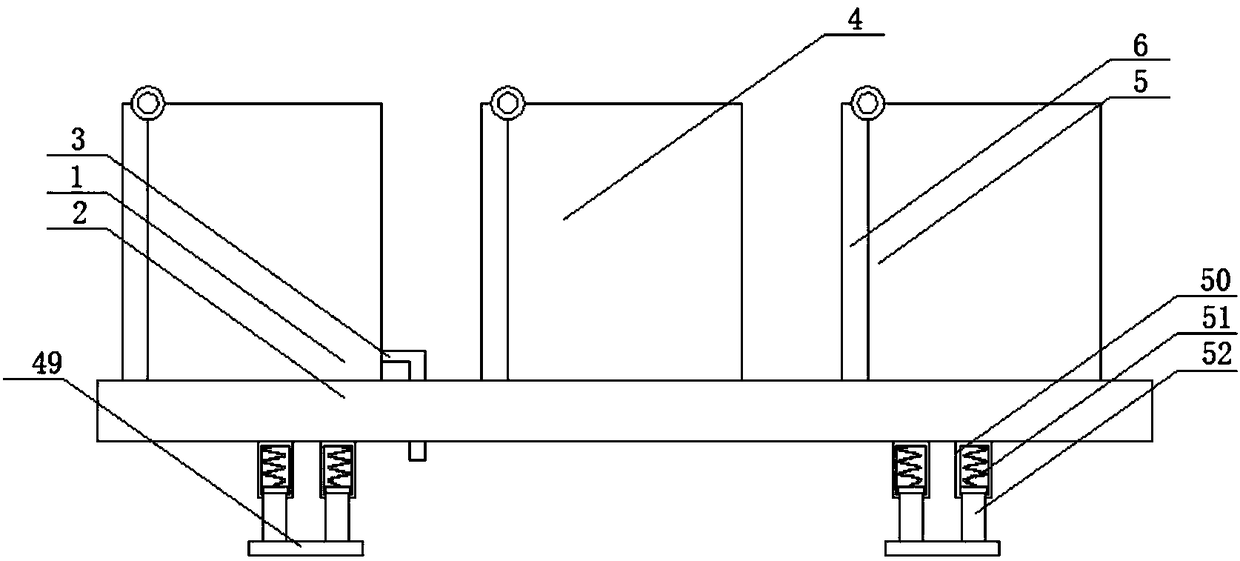

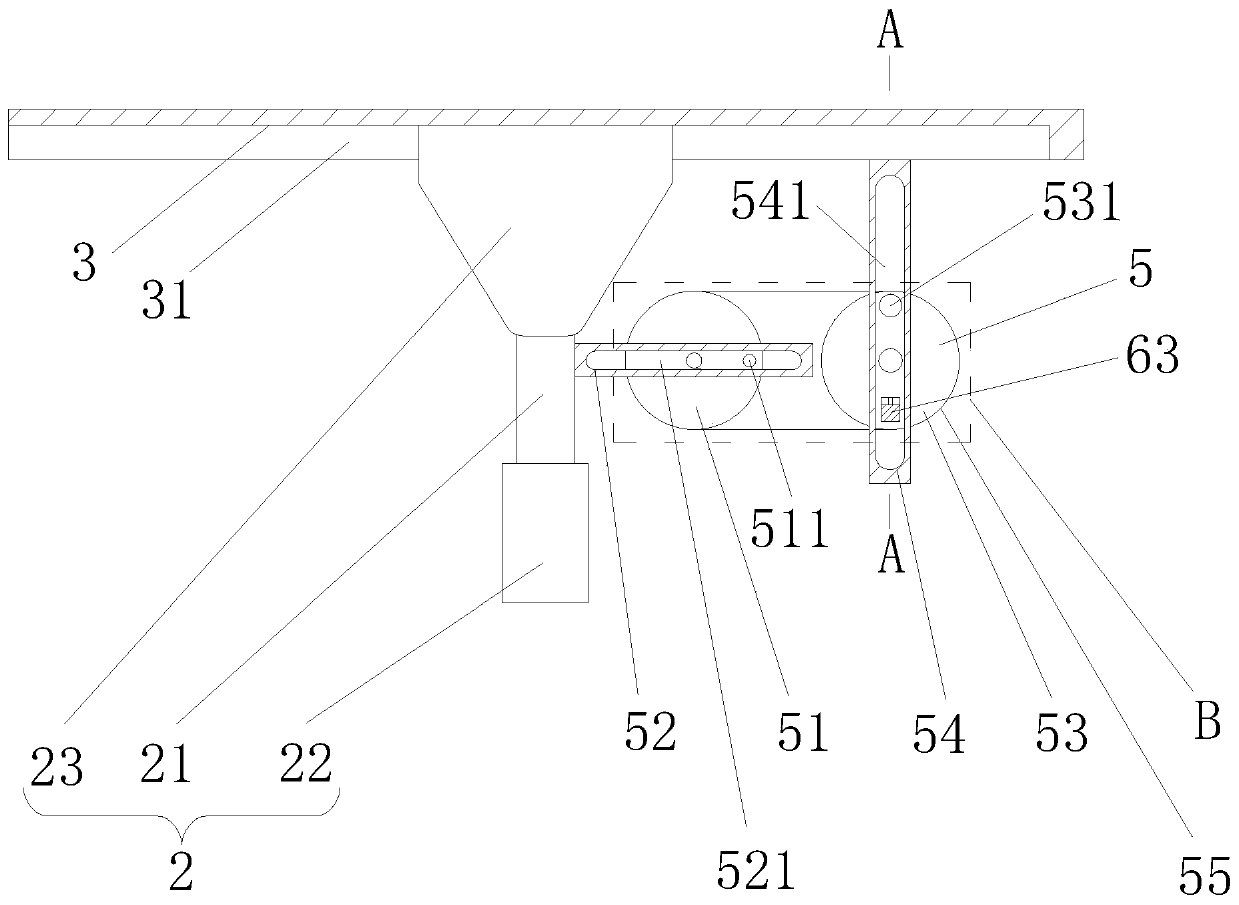

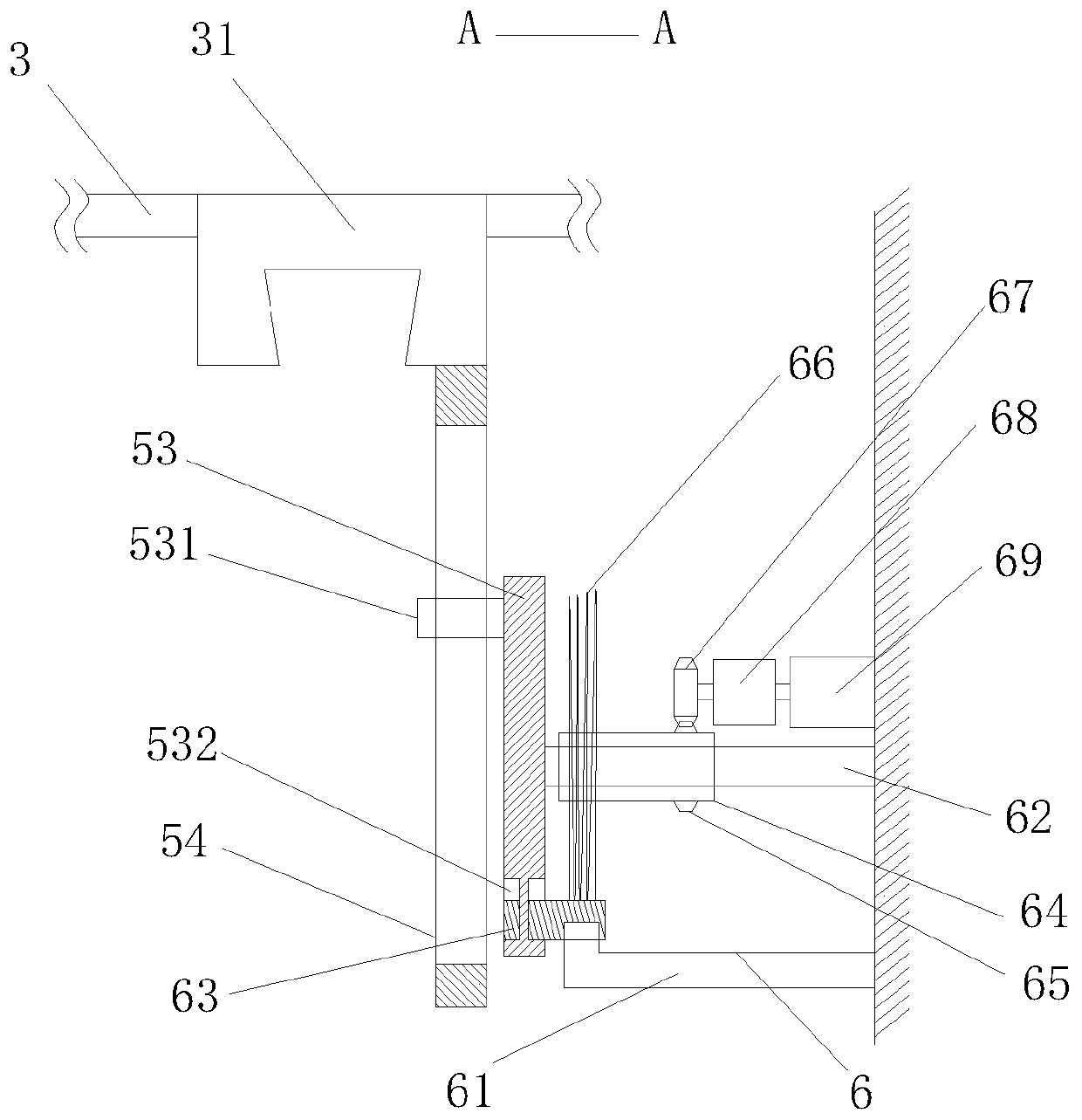

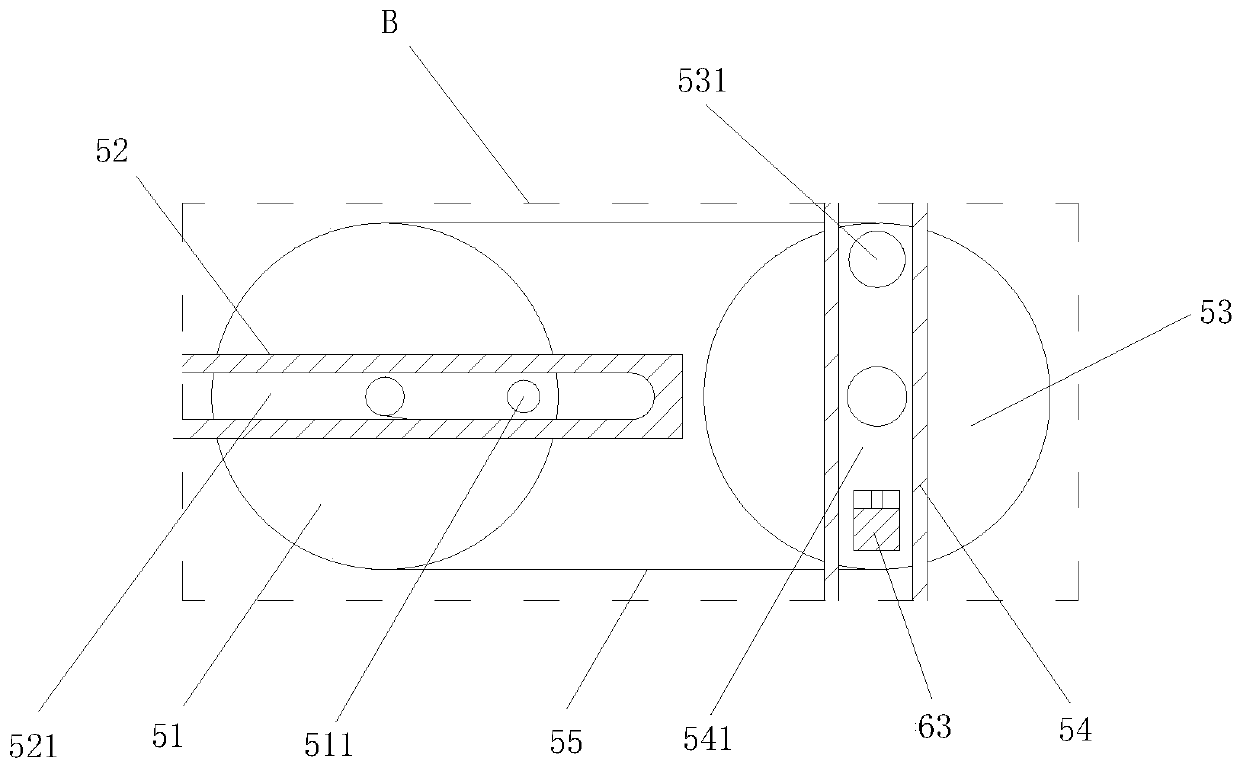

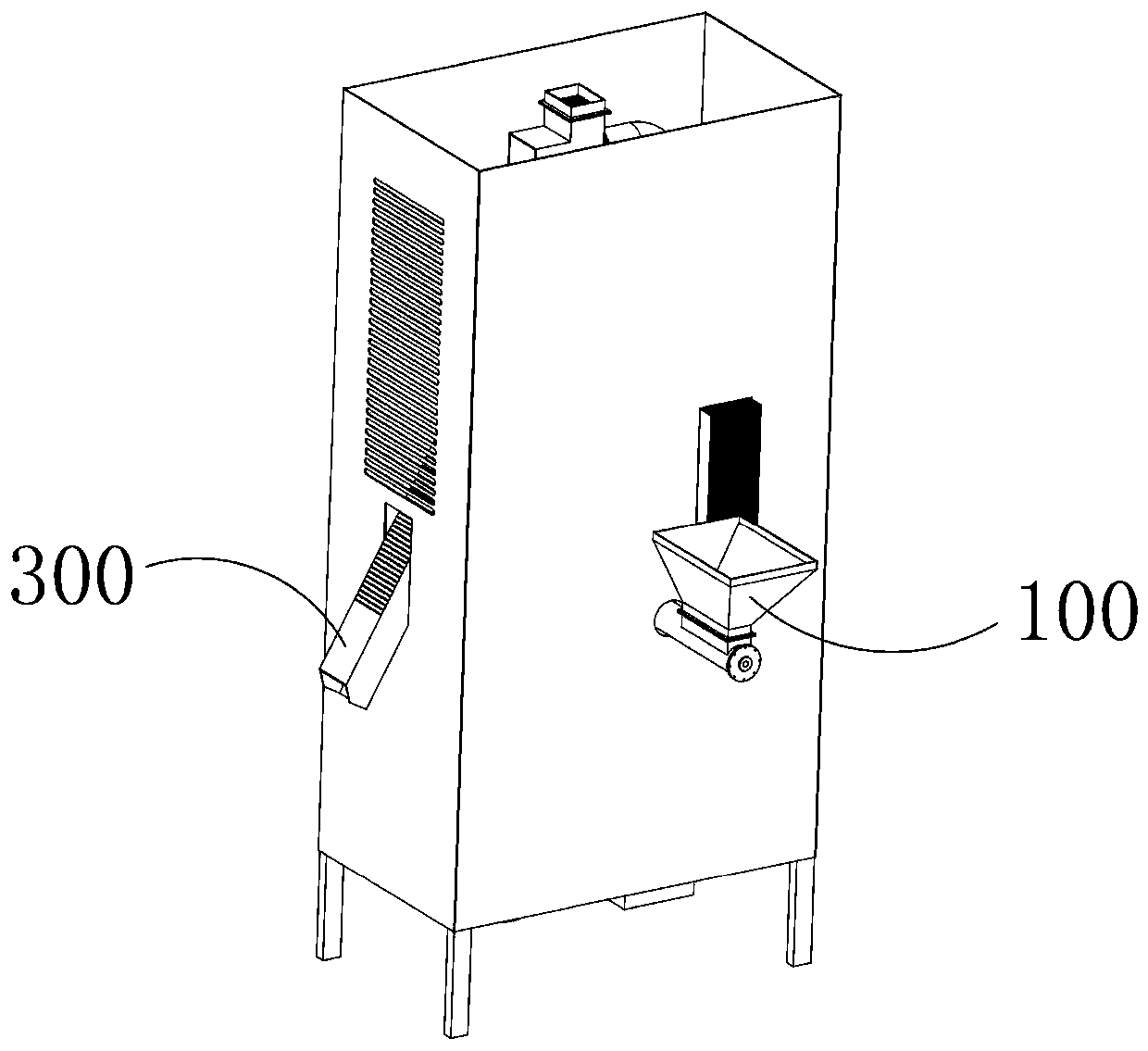

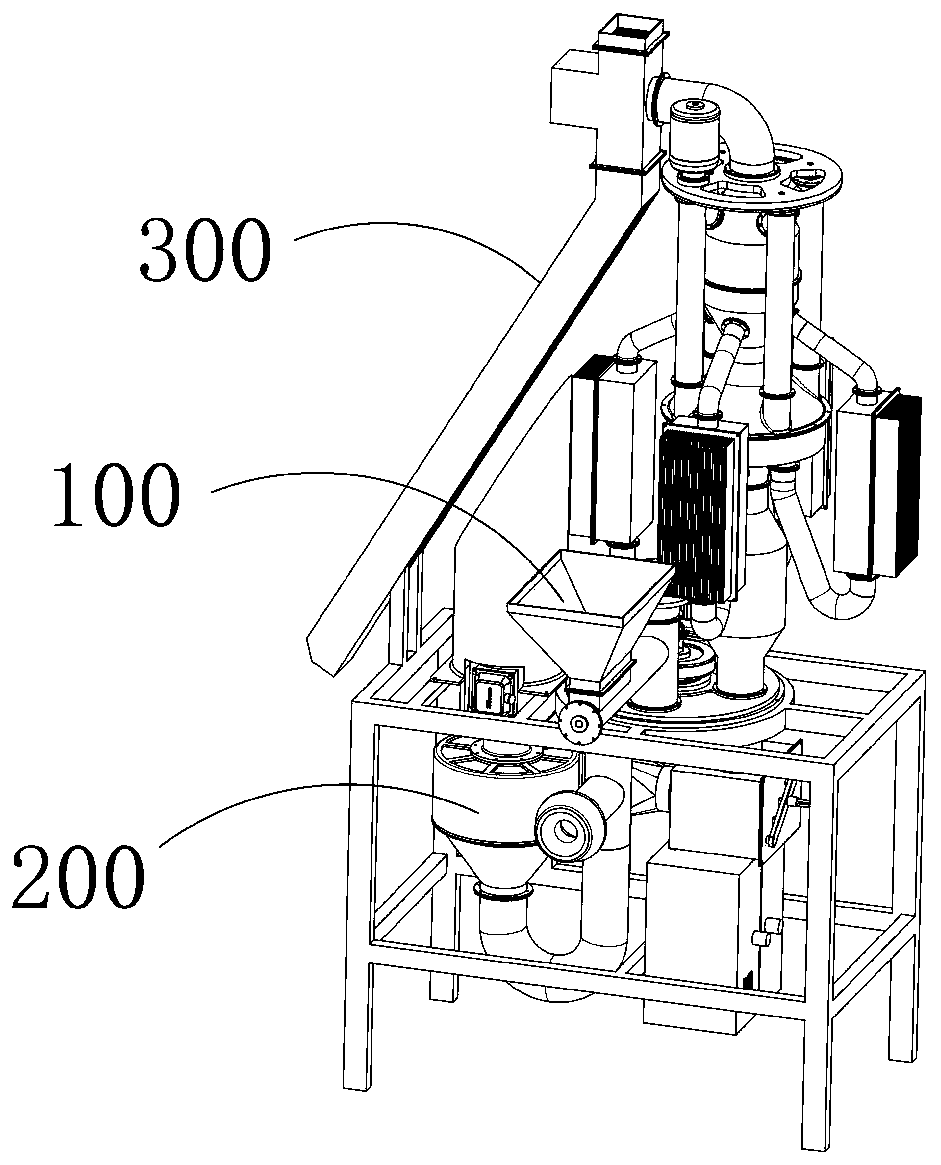

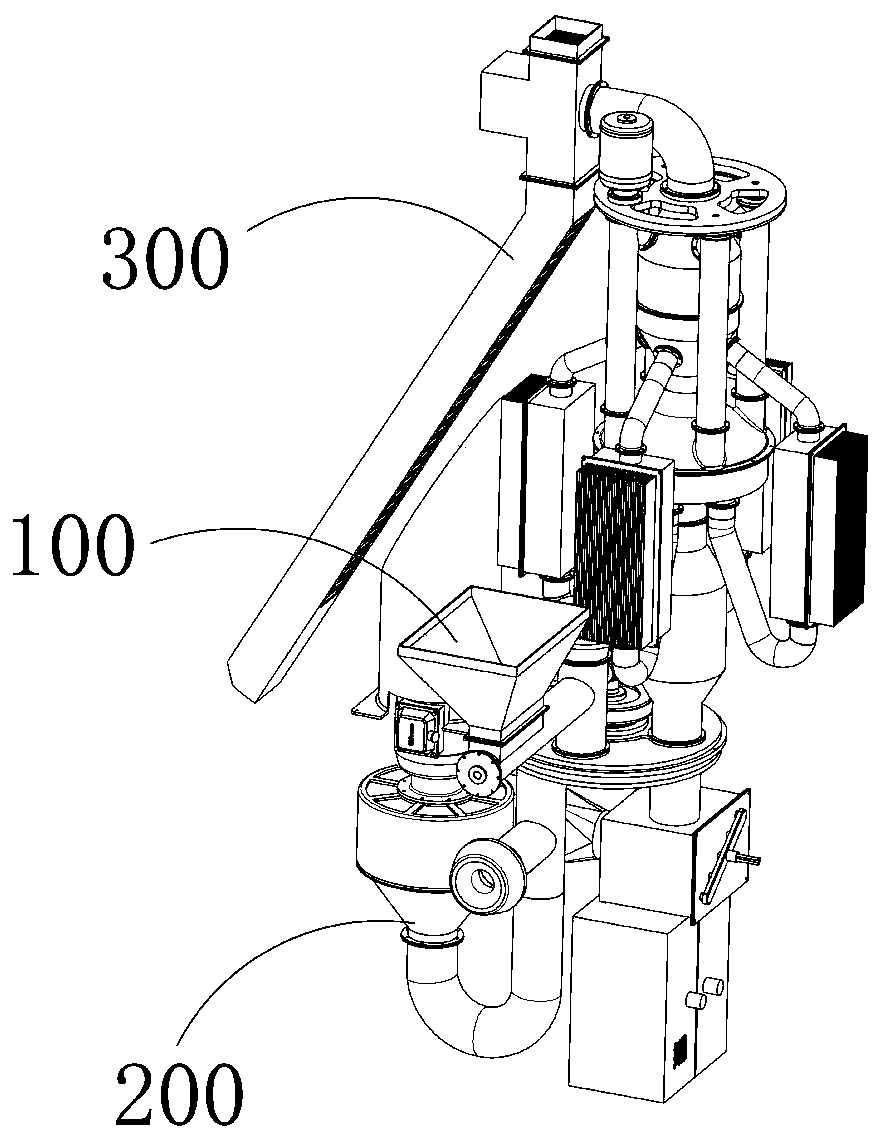

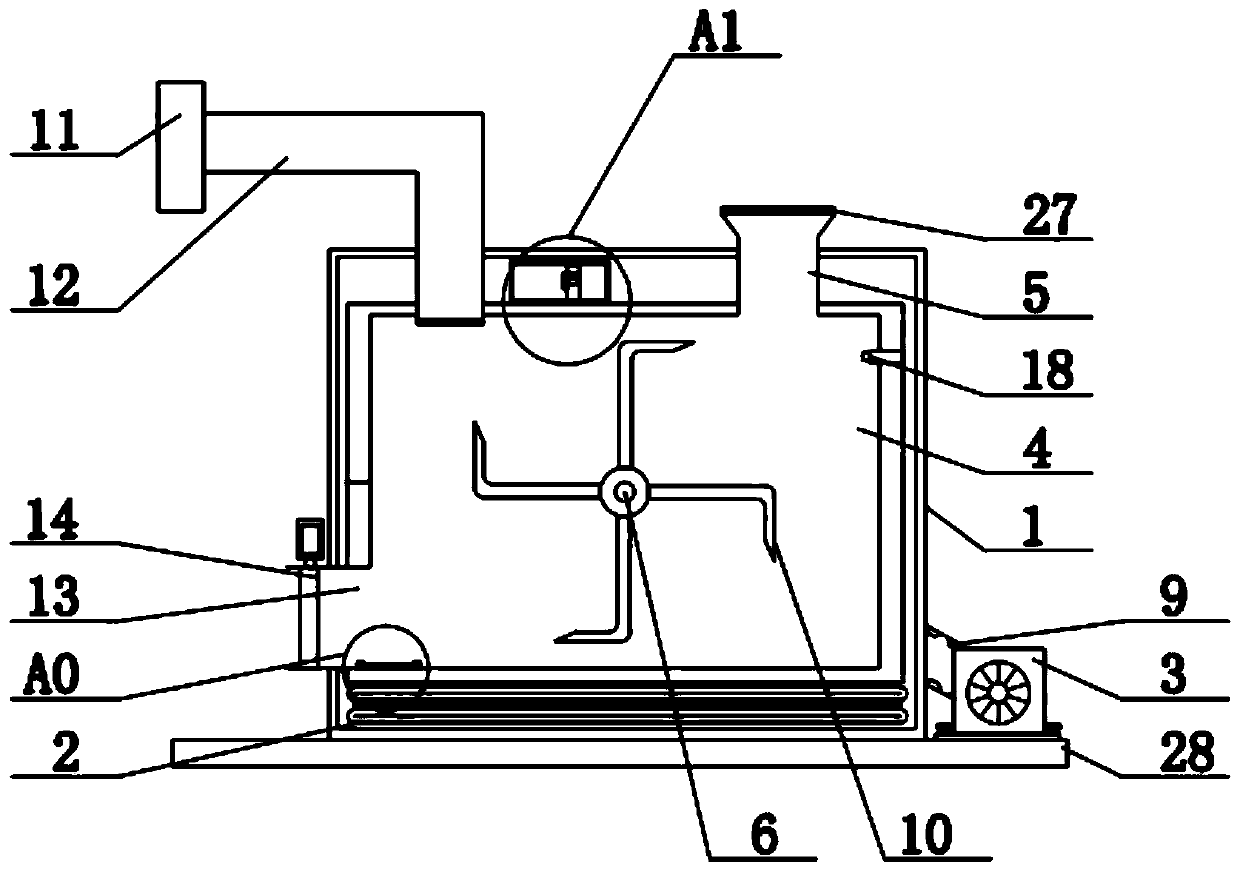

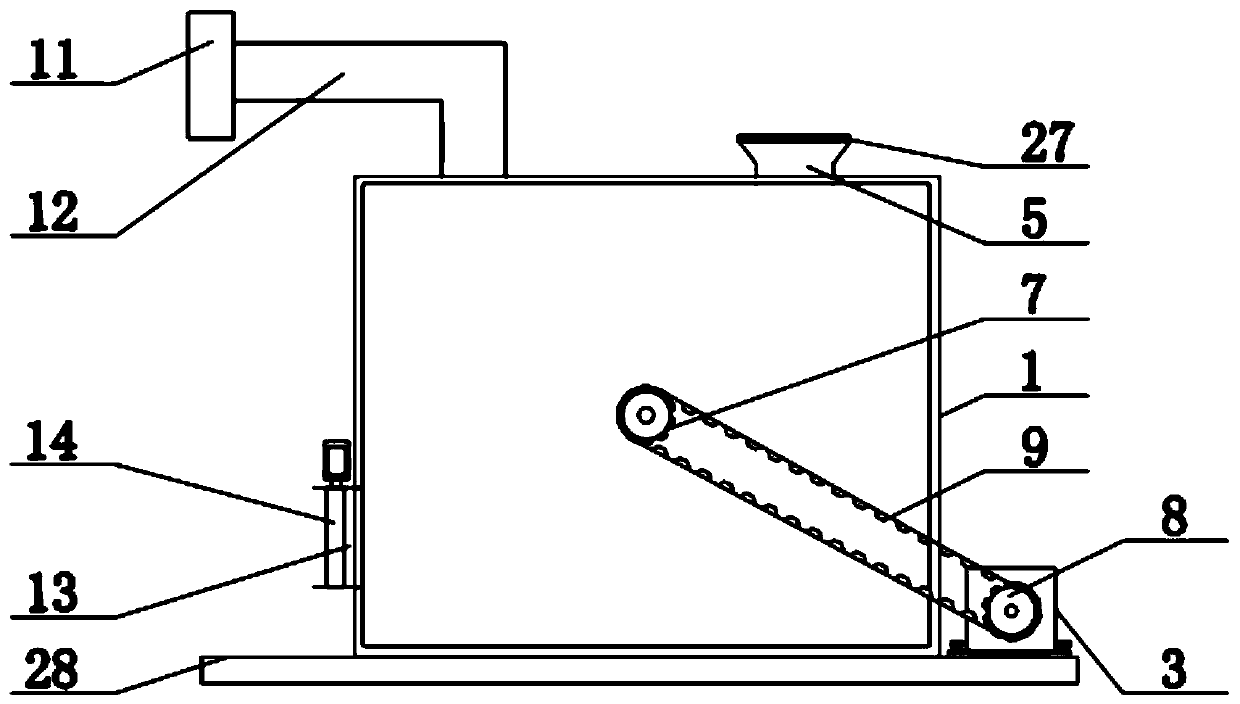

Rotary type rice drying and screening device

InactiveCN109261520ADry and screen evenly and thoroughlyImprove filtration efficiencySievingGas current separationEngineeringContamination

The invention provides a rotary type rice drying and screening device. The rotary type rice drying and screening device comprises a lifting bin, a movable bottom plate is arranged on the bottom of thelifting bin, a lifting mechanism is arranged in the lifting bin, a lifting bin outlet is formed in the top of the lifting bin, a first filter screen is arranged under the lifting bin outlet, and a screening blower and a sorting slope are arranged below the first filter screen. A drying bin is arranged below the filter screen, a drying cavity is formed in the drying bin, an annular gear is installed on the drying bin, and the annular gear is matched with a rotary gear. A bottom drying blower is arranged on the bottom of the drying cavity, a plurality of peripheral drying blowers are uniformlyarranged around the drying bin, the sorting slope is connected with a screening pipeline, the tail end of the screening pipeline is communicated with a division pipeline and a dust collection pipeline, a second filter screen is arranged at the communication position of the dust collection pipeline and the screening pipeline, and a dirt collection pond is arranged at the tail end of the dust collection pipeline, so that impurities in rice are filtered in the drying process of the rice, dust in the rice is precipitated, and contaminations are effectively reduced; due to rotation of the drying bin, drying is more uniform; due to the drying cavity, the heating area of the rice is increased, the drying efficiency is improved, and the drying quality is improved.

Owner:JIXI YUANDAO AGRI IND TECH

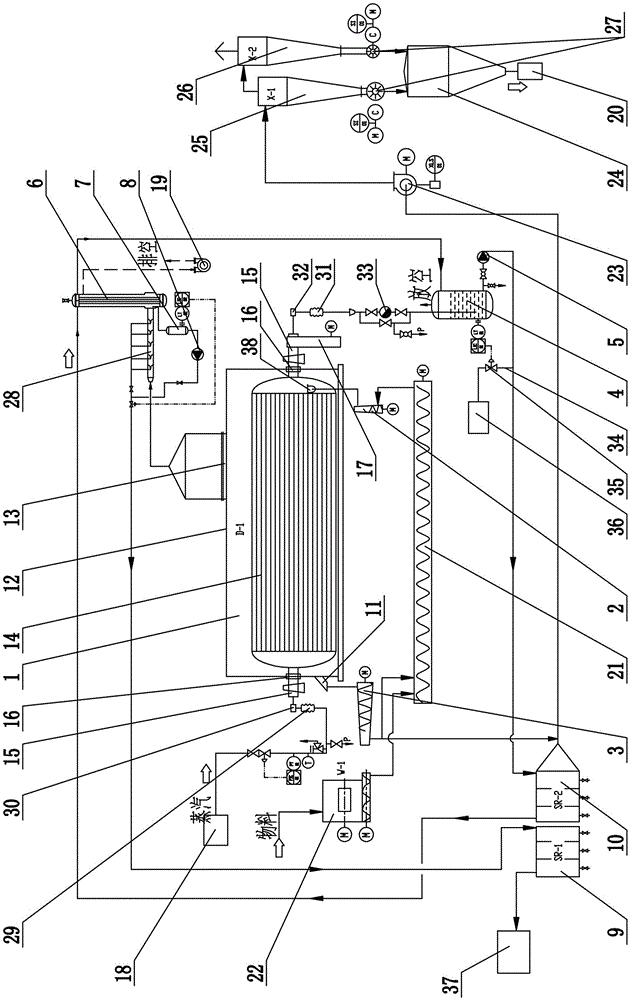

Vacuum tube bundle drying system with waste heat for pneumatic drying

ActiveCN105466171ADry evenly and thoroughlyReduce the temperatureDrying machines with non-progressive movementsDrying solid materialsSteam condensationDust control

The invention relates to a vacuum tube bundle drying system with waste heat for and pneumatic drying; the internal of a shell of a tube bundle drying machine is modified to a closed subatmospheric vacuum sealing space; a powder material is primarily dried under vacuum condition; the needed drying temperature is effectively lowered; meanwhile, after secondary steam generated in drying of the powder material is washed to remove dust, the secondary steam is cooled and condensed to form secondary condensed water; the secondary condensed water, circular cooling water for condensing of the secondary steam and primary condensed water generated in steam condensation are all conveyed to an air heat exchanger; the air heat exchanger absorbs afterheat in the primary condensed water and the secondary condensed water; the afterheat is used for secondarily drying the powder material dried by the tube bundle drying machine; the secondary drying enables the material drying to become more thorough and uniform; the afterheat is recycled; the energy is recycled; the energy is saved; and the emission is reduced.

Owner:郑州博大浓缩干燥设备有限公司

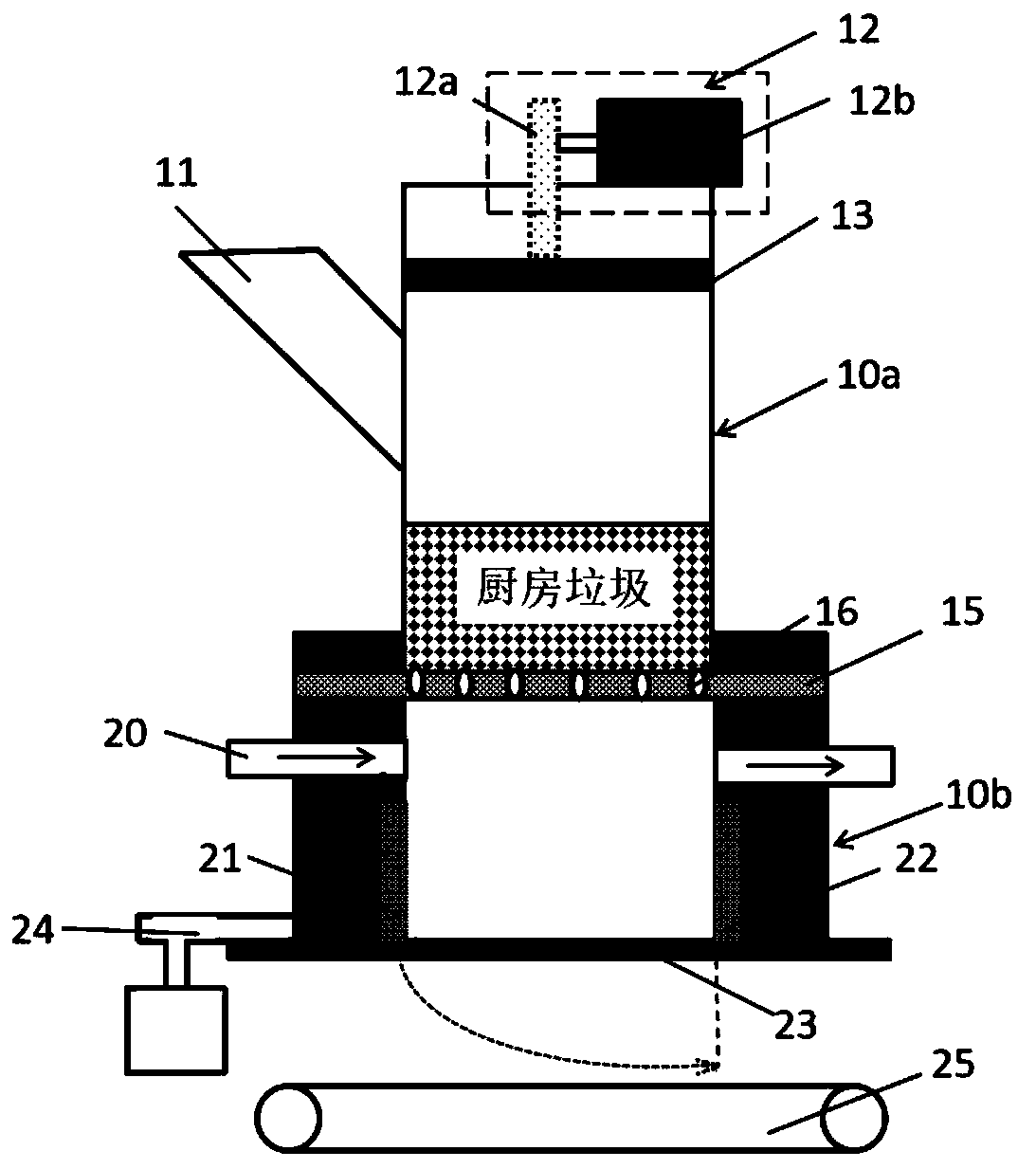

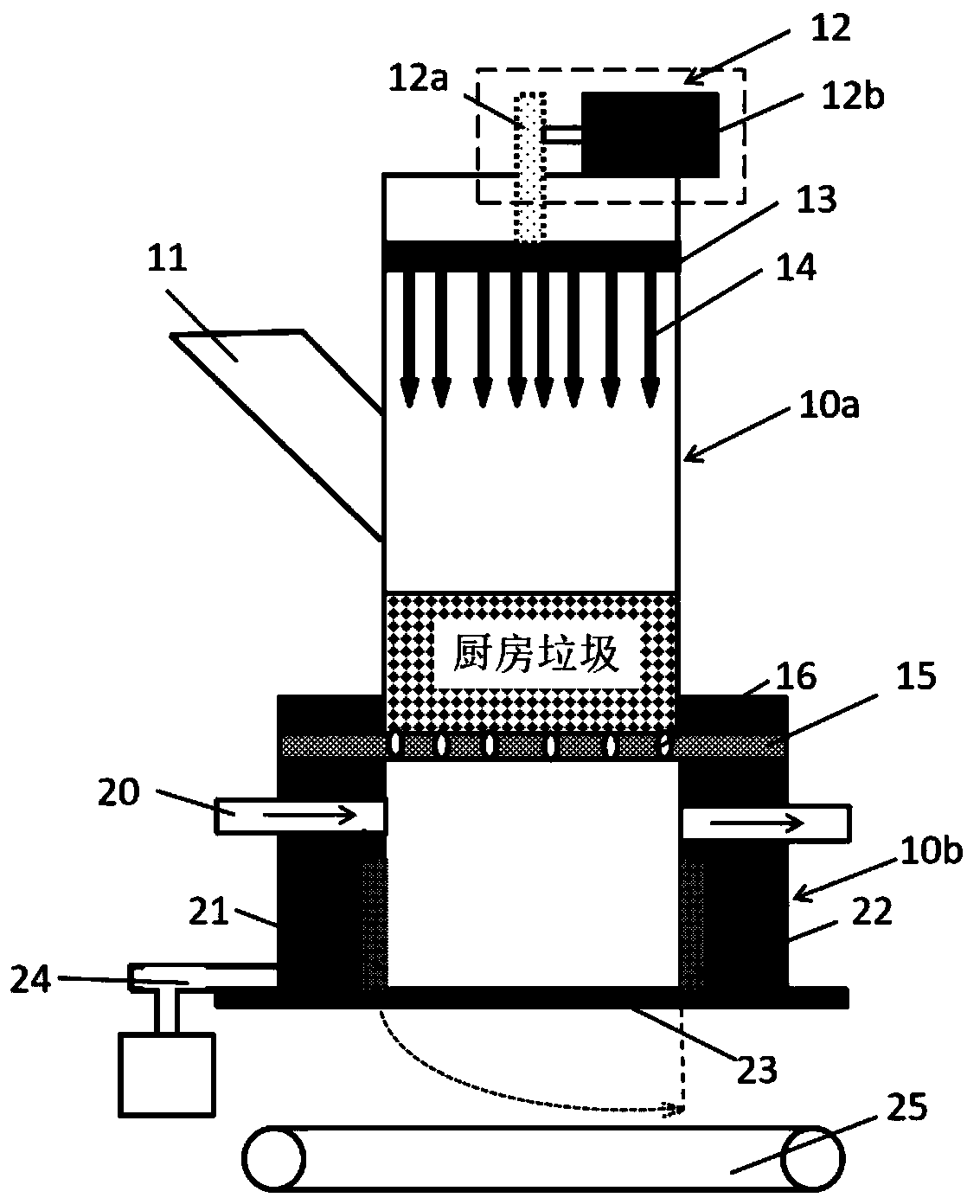

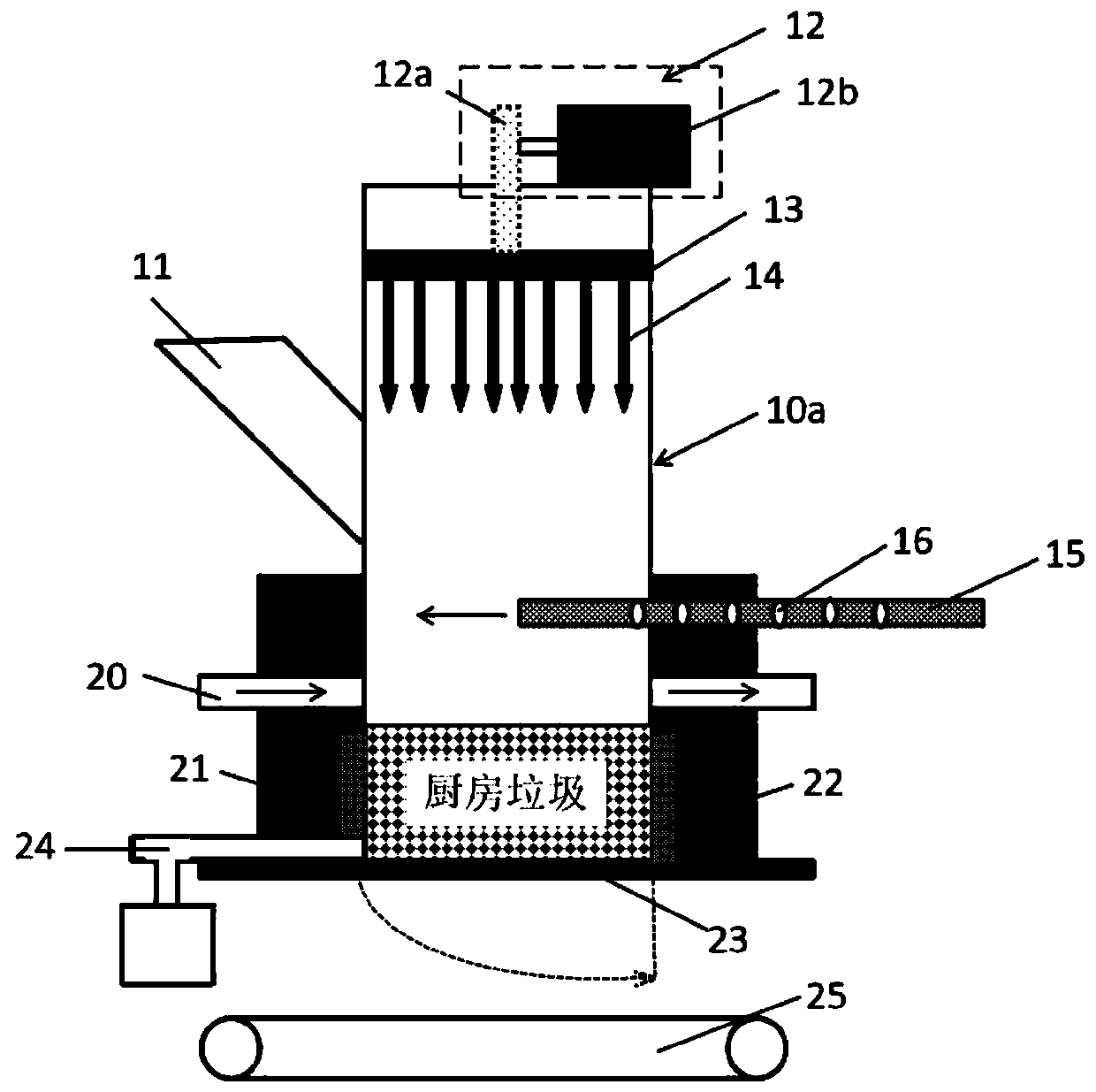

Treatment and reusing device for kitchen waste

InactiveCN110624931AReduce volumeSimple structureSolid waste disposalTransportation and packagingLitterEngineering

The invention relates to the field of waste treatment equipment, in particular to a treatment and reusing device for kitchen waste. The device comprises a compression crushing part and a drying sterilization part, wherein a puncture rod is arranged on a compression cover plate of the compression crushing part, solid waste can be crushed while solid-liquid separation of waste can be achieved, the interior of the waste can be dredged so as to facilitate full-drying, blockage of a through hole in a compressed bottom plate can also be cleared when necessary, the solid waste can be dried and sterilized after being compressed, the storage life of the waste can be prolonged, and transportation is convenient, the solid waste can be taken as a feed for animals. According to the device, once the device is popularized, the utilization efficiency of the kitchen waste is greatly improved, and the pollution to the environment and the waste of resources are reduced.

Owner:宁波沙泰智能科技有限公司

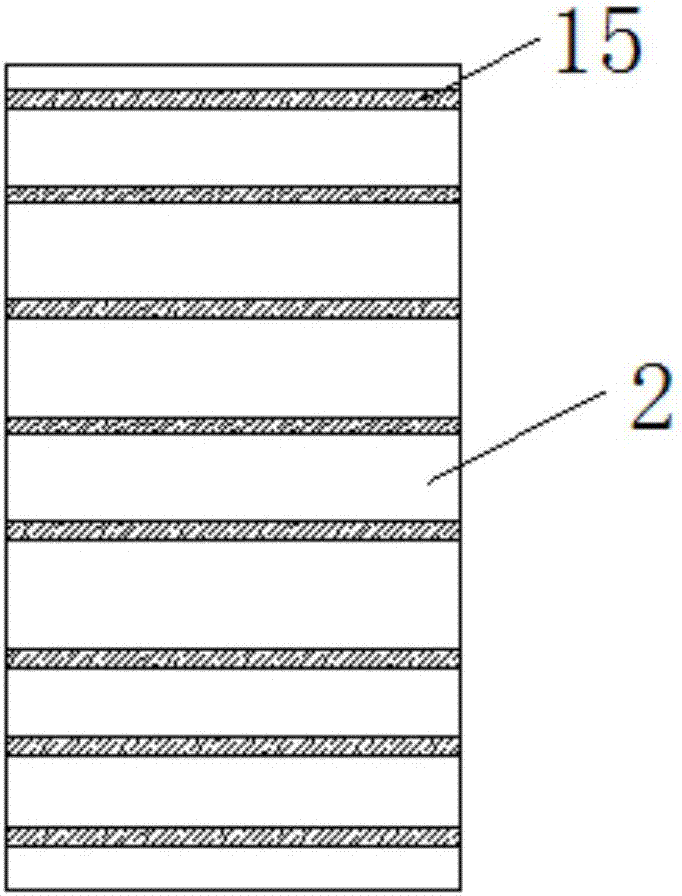

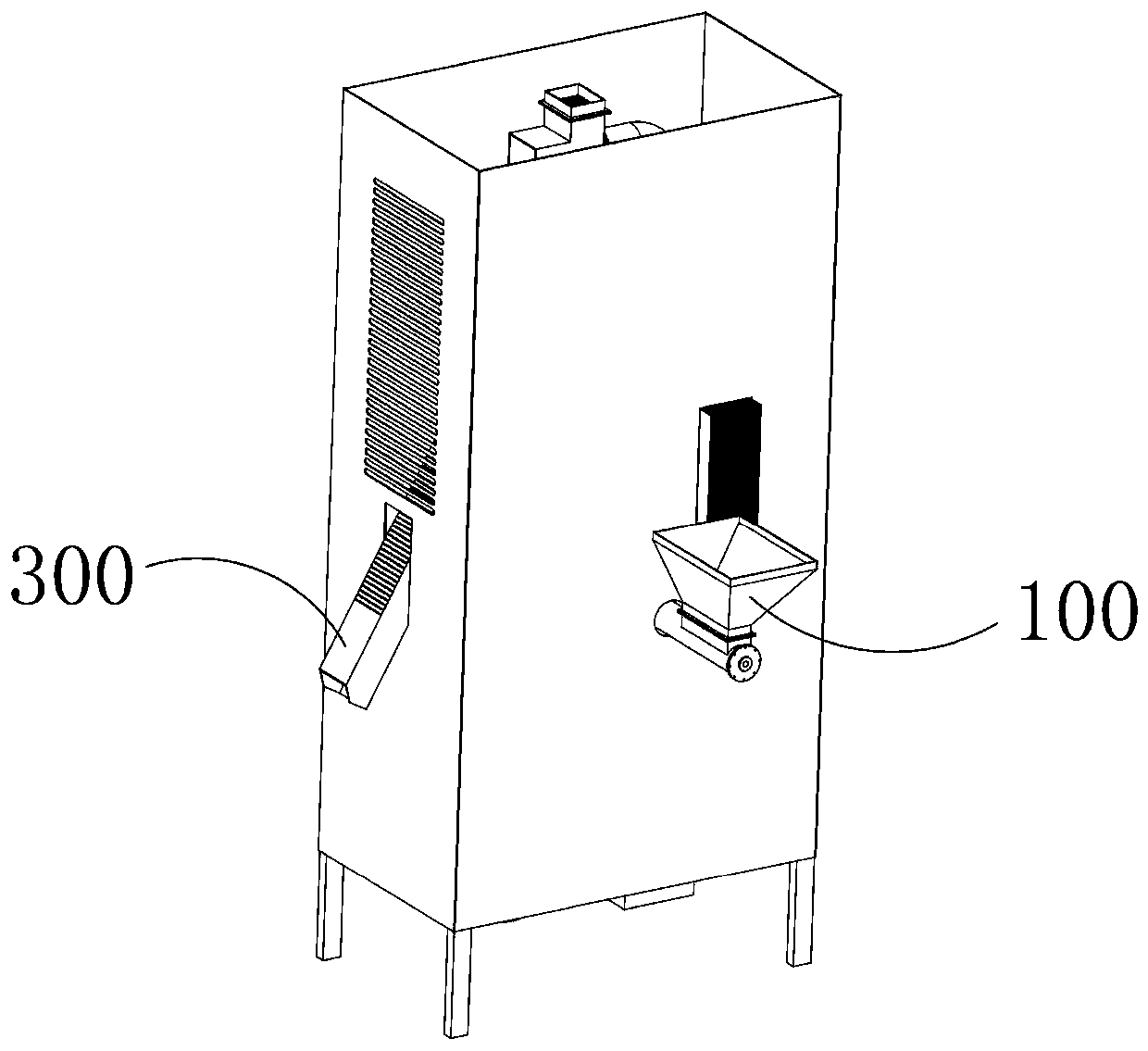

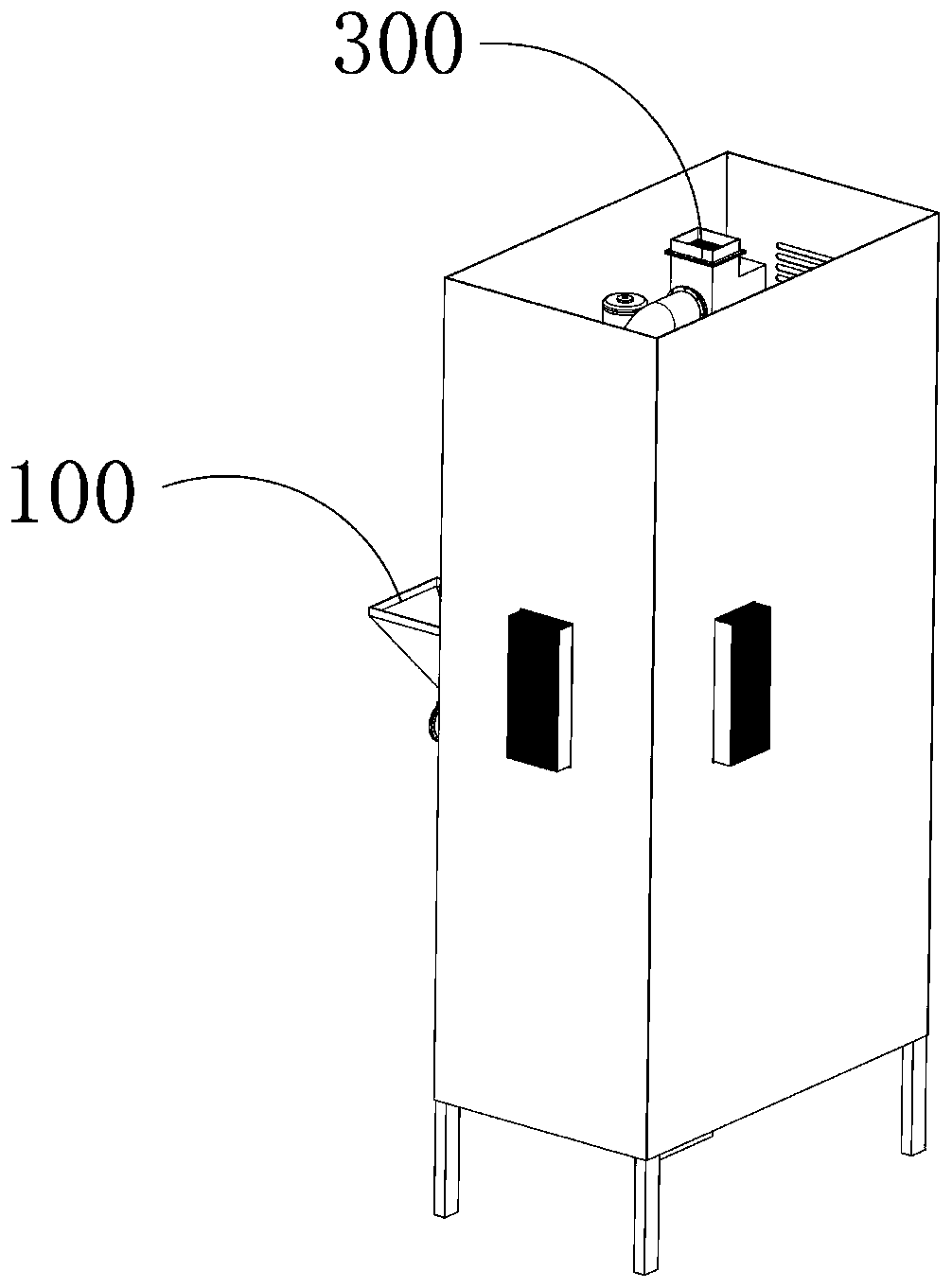

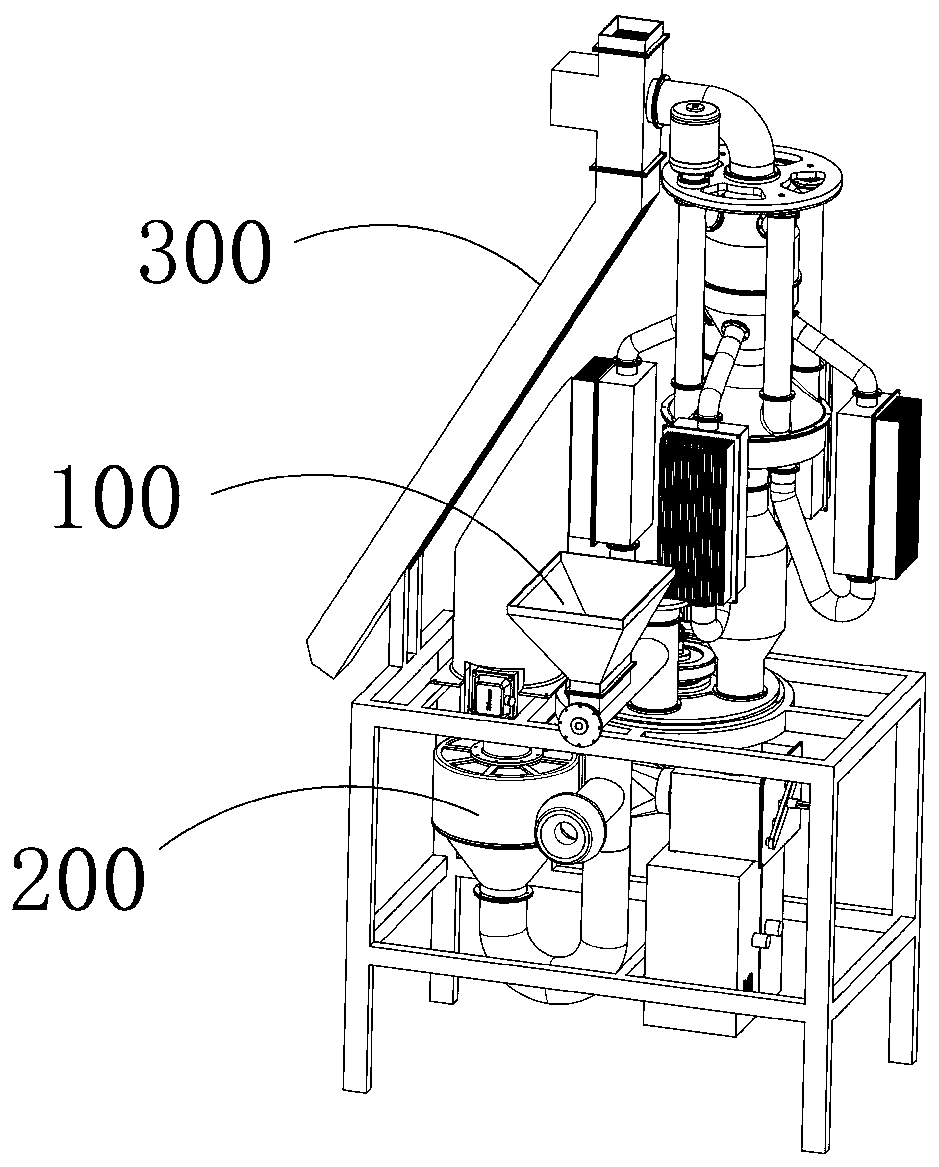

Tea dryer with high uniformity

InactiveCN107990632AKeep dryDry evenly and thoroughlyPre-extraction tea treatmentTea dryingHeat conductingEngineering

The invention discloses a tea dryer with high uniformity. The tea dryer comprises a main body; a first conveying net belt and a second conveying net belt are aslant mounted in an inner cavity of the main body in sequence from top to bottom; the main body is provided with a preheating cylinder above the first conveying net belt; an air sucker is fixedly mounted on the side, opposite to the preheating cylinder, of the top end of the main body; a first electric heating resistance wire is fixedly mounted on the inner wall of the main body; a ventilation fan is fixedly mounted in the inner cavity of the main body; a heat conducting layer is arranged on the inner wall of the preheating cylinder; a second resistance heating wire is embedded in the side wall of the preheating cylinder; and guide fins are staggered and downwards inclined on the inner wall of the preheating cylinder. Through arrangement of the preheating cylinder, tea is primarily preheated; and meanwhile, the tea is scattered to uniformly fall onto the first conveying net belt to prevent reduction of the overall quality of the tea due to halfway drying caused by local accumulation of the tea.

Owner:重庆牧宇农业发展有限公司

Continuous peanut drying device

The invention belongs to an agricultural device and relates to a continuous peanut drying device. The continuous peanut drying device comprises a machine body; the machine body is provided with a thermal insulation layer; a drying irradiation lamp is arranged at the upper end inside the machine body; a first drying layer and a second drying layer are arranged under the drying irradiation lamp; each of the first drying layer and the second drying layer is conveying equipment provided with a vibration device and conveys materials downwards after the completion of drying; the machine body is provided with a feeding port and a discharging port; an air inlet is formed in the left side of the second drying layer; an air outlet is formed in the right side of the second drying layer; an air blower and a heat source are sequentially arranged at the air inlet from left to right; a dehumidifying device, an exhaust fan and a dust removal device are sequentially arranged at the air outlet from left to right. The continuous peanut drying device provided by the invention is simple in structure and convenient to use, and not only can realize multilayer feeding to achieve final collection and intelligent regulation and control, but also can achieve uniform and thorough drying.

Owner:CHONGQING YANYU FOOD CO LTD

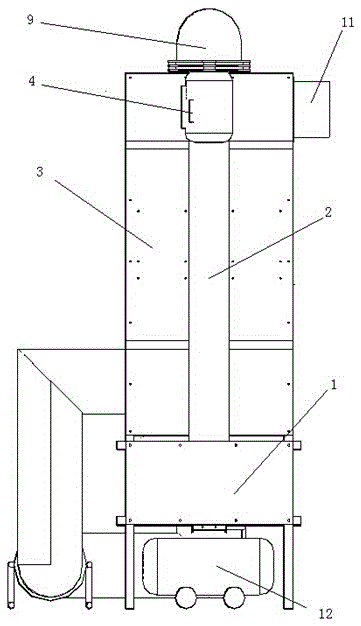

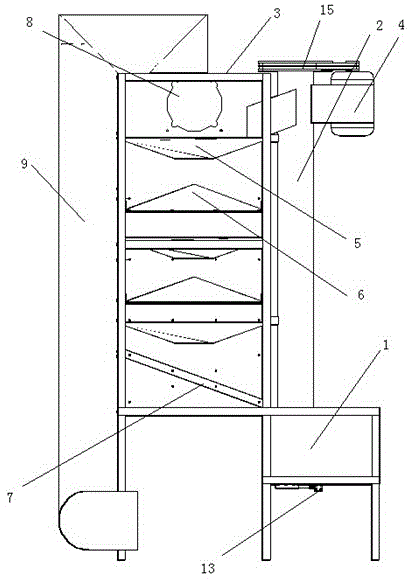

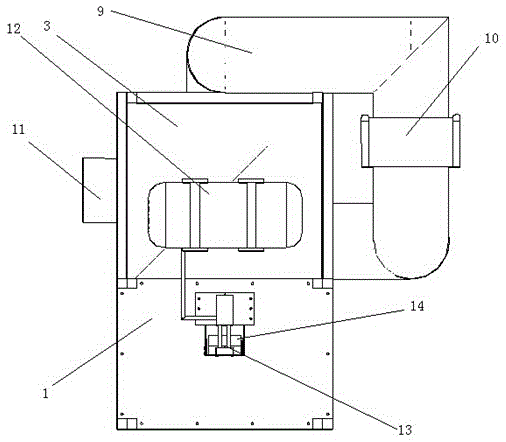

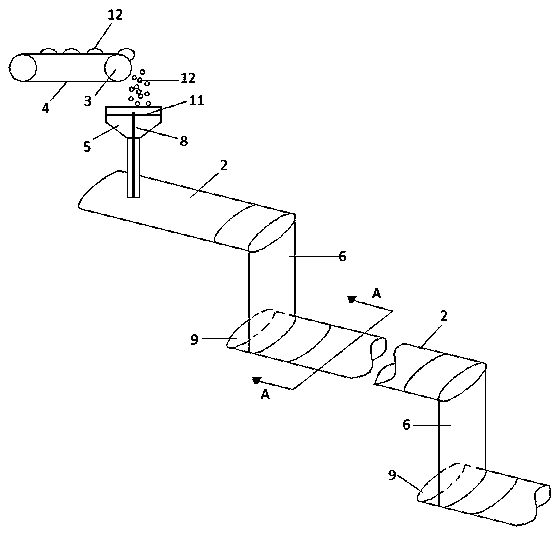

Fully-automatic grain drying machine

ActiveCN105486067ADry evenly and thoroughlyReduce damage rateSeed preservation by dryingDrying solid materialsGrain storageModular design

The invention provides a fully-automatic grain drying machine. A grain storage bin is arranged on one side below a drying bin shell. A grain lifting rod is arranged on one side of the drying bin shell. An auger motor is arranged on one side of the grain lifting rod. The upper end of a rotary shaft of the auger motor and the upper end of a rotary shaft of an auger of the grain lifting rod are sleeved with a driving belt. An air heater is arranged on the other side below the drying bin shell. Two connectors of the air heater are connected with connecting holes in the top of the drying bin shell and one side below the drying bin shell through an air supply pipeline respectively. The drying bin shell is internally provided with one to five drying modules and a material sliding plate. The material sliding plate is arranged below a drying mechanism located on the lowest portion, and an opening is formed in one side below the drying bin shell. The fully-automatic grain drying machine is exquisite in structure, unique mechanical structural design is adopted, grain can be dried in a room in a circulating drying manner, modular design can be adopted for the whole mechanism, assembly is convenient, and both the drying temperature and humidity can be controlled, so that drying efficiency is improved, and drying cost is lowered.

Owner:JINLING INST OF TECH

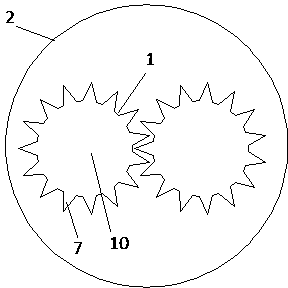

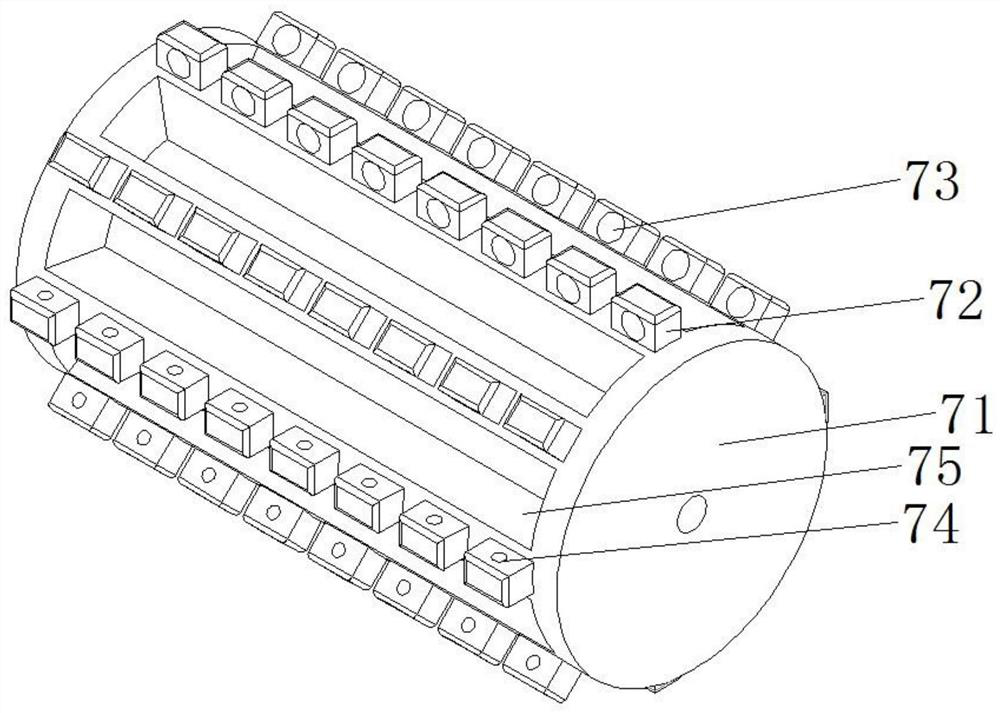

Rolling drum dryer internally provided with toothed rolling wheels for treating molding sand

InactiveCN104215047AAvoid churnExtension of timeDrying machines with non-progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a rolling drum dryer internally provided with toothed rolling wheels for treating molding sand. The rolling drum dryer comprises the plurality of rolling wheels, a plurality of rolling drums, two conveying rollers, a conveying belt, a huge hopper body and a connecting section, wherein bulged racks are arranged on the surface of each rolling wheel obliquely and spirally, and rotate for 180 degrees from one end of the corresponding rolling wheel to the other end of the corresponding rolling wheel; every two rolling wheels are arranged in the corresponding rolling drum; the bulged racks are arranged on the surface of each rolling wheel; the bulged racks on the surfaces of every two rolling wheels in the same rolling drum are engaged with each other, and the rolling wheels rotate oppositely; a through hole through which a central line penetrates is formed inside each rolling wheel; a forward extension section extending forwards is arranged at the lower end of the connecting section. The rolling drum dryer has the advantages that the rolling drums are simple in structure; the drying efficiency is high; the rolling drum dryer is efficient and uniform in drying, and low in energy consumption.

Owner:焦桂春

Rotary drying device for seed storage

InactiveCN112013652ADry evenly and thoroughlyExtend the movement timeDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention relates to the field of agriculture, and particularly discloses a rotary drying device for seed storage. The rotary drying device comprises a box body, a base, a sealing cover, a hinge,a heating box and a fan; a horizontal rotating roller for raising cereal seeds is mounted in the box body; first swing plates are rotationally connected to the left end and the right end of a fixed bottom plate through horizontal first pin shafts correspondingly; and the other ends of the first swing plates incline upwards and are rotationally connected with second swing plates through horizontalsecond pin shafts, the other ends of the second swing plates incline upwards, sliding rods are slidably arranged in supporting sleeves in a penetrating mode, push plates perpendicular to the sliding rods are fixedly mounted at the upper ends of the sliding rods, and the push plates face the second pin shafts. Through the multiple arranged swing plates and the jacking direction of the sliding rodsswinging for extending and retracting, the swing plates are driven to move up and down, the cereal seeds falling on the swing plates are turned over, the cereal seeds make contact with hot air conveniently, the cereal seeds are pushed to move towards the rotating roller, and the seeds are raised under the action of the rotating roller.

Owner:王莹莹

Face cream batching system

ActiveCN112539617ADrying effectDry evenly and thoroughlyDrying solid materials without heatCleaning using toolsProcess engineeringOil water

The invention discloses a face cream batching system in the technical field of face cream batching systems. The face cream batching system comprises a drying mechanism and a cleaning mechanism, the cleaning mechanism is arranged on the left side of the drying mechanism, the drying mechanism comprises a workbench, the top of the workbench is fixedly connected with a drying cylinder, the side wall of the drying cylinder is provided with a plurality of linearly arrayed water suction holes, and the top of the drying cylinder is fixedly connected with a feeding valve. According to the face cream batching system, when face cream is dried, a stirring mechanism is used for stirring the face cream so that the face cream can be evenly scattered and dried, a first rotating shaft rotates to drive an oil-water separation membrane to rotate, the face cream adhering to the surface of the oil-water separation membrane is scraped and then cleaned, the face cream is prevented from adhering to the surface of the oil-water separation membrane, the cleanliness of the oil-water separation membrane is guaranteed, the face cream adhered to the oil-water separation membrane is prevented from affecting drying of the face cream by the drying cylinder, and thorough and uniform drying of the face cream is guaranteed.

Owner:董凯辉

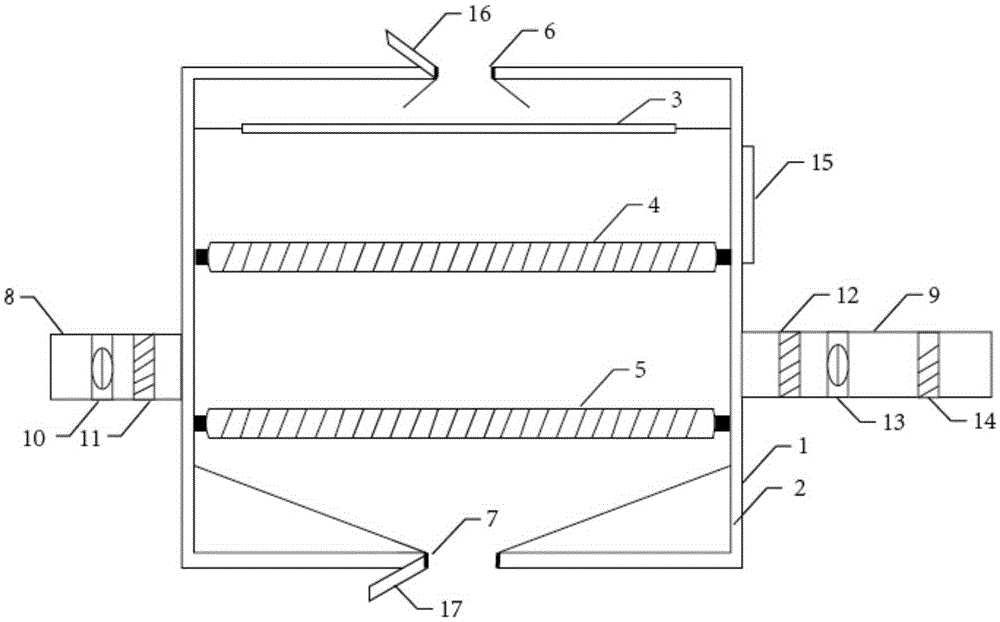

Double-barrel grain dryer

PendingCN107702508AQuality assuranceImprove efficiencyDrying solid materialsGrains dryingEngineeringInsulation layer

The invention discloses a double-barrel grain dryer. The double-barrel grain dryer comprises a first barrel body, a baseplate, a base and an air sucking pipe orifice; insulation layers are mounted onthe inner walls of the first barrel body and the second barrel body; heaters are fixed on the inner walls of the insulation layers; the upper end of the first barrel body is connected with a loading pipe; a first air pump is mounted on the loading pipe; the bottom end of the loading pipe is connected with the pipe orifice; a motor is arranged between the first barrel body and the second barrel body; the left end of the motor is connected with a rotating shaft; stirring blades are mounted on the rotating shaft; the second barrel body is arranged below the stirring blades; a support rod is fixedin the second barrel body; the outer wall of the support rod is connected with a baffle plate through the rotating shaft; the bottom end of the baffle plate is connected with a spring; and the secondbarrel body is arranged above the baseplate. The double-barrel grain dryer is provided with the first barrel body and the second barrel body, so that grains can be primarily heated by the first barrel body, and then, are cooled by the second barrel body with lower temperature.

Owner:安徽金谷机械科技有限公司

Calcium hypochlorite filter cake drying device

InactiveCN105021010ADry evenly and thoroughlyDrying using combination processesDrying machinesPulp and paper industryCalcium hypochlorite

The invention provides a calcium hypochlorite filter cake drying device. The calcium hypochlorite filter cake drying device comprises a machine body, a draught fan at the upper end of the machine body and a control device outside the machine body. The calcium hypochlorite filter cake drying device further comprises heating plates on the inner walls of the two sides of the machine body and a conveying net belt at the lower end of the machine body. A water trough with the upper end open is formed at the bottom of the conveying net belt, and the superficial area of the water trough is equivalent to the superficial area of the conveying net belt. A plurality of suction nozzles are arranged on the side, close to the upper end, of the water trough. Each suction nozzle is connected with an air pump. The calcium hypochlorite filter cake drying device has the beneficial effects that water in filter cakes can be sucked away through the air pumps while ventilating and drying are carried out, and even and thorough drying can be achieved.

Owner:TIANJIN YUFENG CHEM

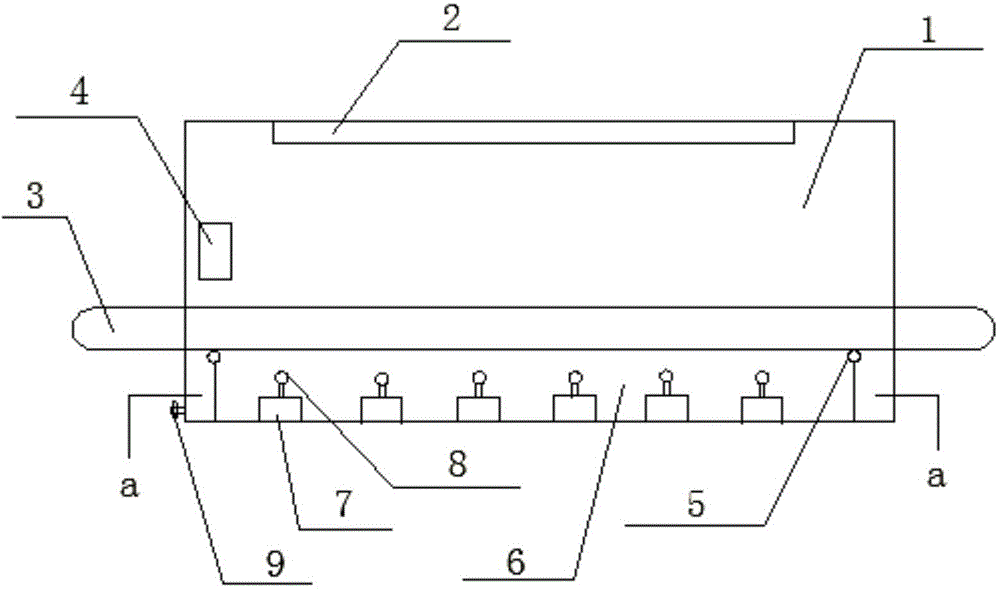

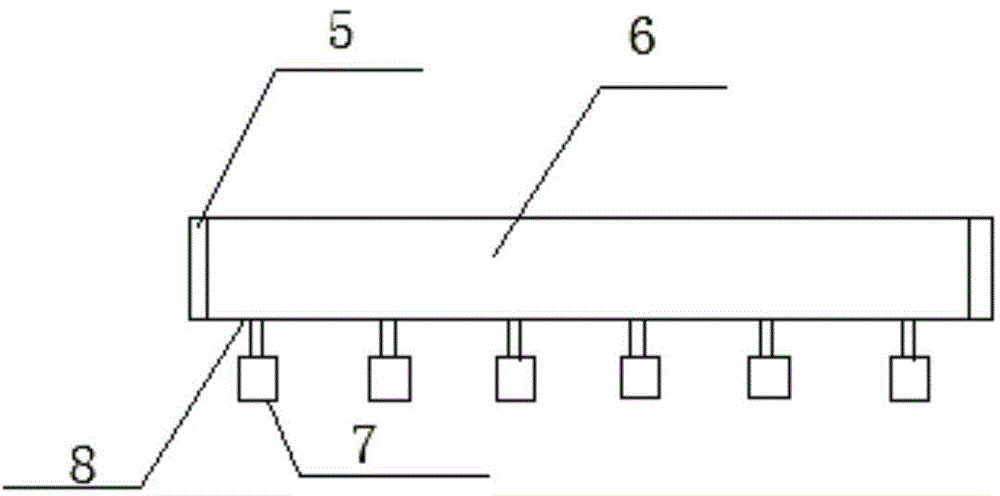

Intermittent conveying equipment of food production line

ActiveCN109703991ADry evenly and thoroughlyEasy accessThrowing machinesPackagingProduction lineDrive motor

The invention relates to the field of food production, in particular to intermittent conveying equipment of a food production line. The intermittent conveying equipment comprises a sliding device, a conveying plate, a swinging device and a control device, and one side of the intermittent conveying equipment is provided with a mounting plate, wherein the sliding device includes a telescopic rod, arod sleeve and a main slider; the swinging device is arranged on the right side of the telescopic rod; the swinging device comprises a first turntable, a first skateboard, a second turntable, a secondskateboard and a drive belt; the control device is located behind the second turntable; and the control device comprises a stop, a connecting shaft, a third slider, a sleeve, a tooth block, a clockwork spring, a gear, a transmission and a drive motor. The swinging device fits with the sliding device to make food continuously thrown by the conveying plate so that the drying of the food can be uniform and thorough. As the food is continuously moved to the left in the conveying equipment, the control device stops the conveying plate in the gap of the completion of the swinging process for a short time, so that workers can take and package the food at the tail end of the conveying equipment.

Owner:江西博展自动化科技有限公司

Cereal drying technology adopting hot wind drying manner

ActiveCN110542301AImprove drying effectConditions to avoid cracksSievingDomestic cooling apparatusAgricultural engineeringHigh pressure

The invention discloses a cereal drying technology adopting a hot wind drying manner. The technology comprises the steps that a worker pours grain into a conveying mechanism, and a power mechanism operates and drives the conveying mechanism to convey the grain into a storing area of a transition mechanism; after the grain is conveyed into the transition mechanism, a high-pressure fan operates andsucks water attached to the surface of the grain through a wind sucking pipe, a cooling wind pipe or a wind blasting pipe blows wind to the outside, wind power of the wind blasting pipe is blown intothe transition mechanism after being heated through a heater, then the grain in the transition mechanism is blown into a drying tank through the hot wind, the grain is the dried in the drying tank ina suspension ascending turnover drying manner with the hot wind as a drying source, the dried grain is blown into a separation mechanism through the hot wind, and the grain and the hot wind are separated and output to a cooling discharging device through different channels; and the grain in the separation mechanism is discharged after being cooled through the cooling discharging device in a multi-stage cooling manner and then carried away by the worker.

Owner:黑龙江北纯农产品开发有限公司

Tartary buckwheat drying device

InactiveCN110044156ADry evenly and thoroughlyAvoid excessive heatSeed preservation by dryingDrying machines with non-progressive movementsElectric heatingEngineering

The invention discloses a tartary buckwheat drying device. The drying device comprises a device casing, an electric heating wire and a rotating motor; the device casing is internally provided with a drying cavity; the bottom of the drying cavity is provided with the electric heating wire; a rotating shaft is arranged in the drying cavity; a driven gear is fixedly connected with the outer end of the rotating shaft; a driving gear is fixedly connected with the rotating shaft of the rotating motor; the driving gear and the driven gear are connected through a chain; a plurality of sets of stirringblades are fixedly connected at the tail end, located in the drying cavity, of the rotating shaft; the front end of a sampling plate is embedded in a sampling port; and a temperature sensor is embedded in the drying cavity. The drying device has the advantages of being uniform in drying, visible in drying temperature and adjustable in drying temperature, and is mainly used for drying tartary buckwheat.

Owner:安徽省钗源苦荞麦制品有限责任公司

Dryer for petroleum coke processing

InactiveCN109442934AEasy accessDry evenly and thoroughlyDrying gas arrangementsDrying machines with non-progressive movementsThermodynamicsElectric machine

The invention belongs to the field of petroleum coke processing, and particularly relates to a dryer for petroleum coke processing. The dryer for petroleum coke processing aims to achieve the technical effect that drying is uniform and thorough. The dryer for petroleum coke processing comprises a bottom plate, a supporting rod, a cutting device, a drying cylinder, a feeding hopper, a cover plate,a first fixing sleeve, a fixing rod, a second fixing sleeve, a bearing block, a mounting plate, a motor, a rotating shaft, an air inlet pipeline, an electric heating wire, a mounting frame, an air blower, a hollow rotating cylinder and a circular ring; the supporting rod is fixedly connected to one end of the top of the bottom plate, an air cylinder is hinged to the other end of the top of the bottom plate, and the two ends of the drying cylinder are hinged to the supporting rod and the air cylinder correspondingly. According to the dryer, the effect that drying is uniform and thorough is achieved.

Owner:张红艳

Microwave drying upgrading equipment for low-rank coal

InactiveCN105509450AReduce utilizationDry evenly and thoroughlyDrying solid materials with heatSolid fuelsSulfurCoal

The invention belongs to the technical field of coal upgrading and particularly relates to microwave drying upgrading equipment for low-rank coal. The microwave drying upgrading equipment comprises a microwave drying chamber, a microwave generator, microwave radiators, a pneumatic device and a support device, wherein the support device is mounted below the microwave drying chamber; the microwave generator and an exhaust port are mounted at the upper part of the microwave drying chamber; the microwave generator is connected with the microwave radiators; the microwave radiators are mounted at the inner top of the microwave drying chamber; the exhaust port is connected with a purifying and recycling device; a feed opening and a discharge opening are formed in two ends of the microwave drying chamber respectively; and a sloping slideway is arranged at the bottom of the microwave drying chamber. According to the microwave drying upgrading equipment, low-rank coal in the microwave drying chamber is dried and subjected to removal of sulfur, magnesium and other substances by a microwave heating technology, the energy consumption is low, the desulphurization efficiency is high, drying is complete, the heat efficiency is high, and treated coal slides under the action of gravity from an inlet end to an outlet end along the sloping slideway. A traditional conveying mechanism is omitted in the technology so that the manufacturing cost and running cost are reduced, and the microwave drying upgrading equipment is simple, efficient and reliable low-rank coal drying upgrading equipment.

Owner:NANTONG JINGHUAN ENERGY TECH CO LTD

Floating type grain dryer

ActiveCN110500875AImprove drying effectConditions to avoid cracksDrying gas arrangementsDrying solid materialsSurface moistureMechanical engineering

The invention provides a floating type grain dryer which comprises a mounting frame body. The mounting frame body is provided with a feeding device, a hot air drying device and a cooling and discharging device; the feeding device is used for conveying grains into the hot air drying device; and the hot air drying device is used for heating and drying the grains in a hot air drying method, and the cooling and discharging device is used for transporting the dried grains away and adopting a multi-stage cooling manner to reduce the temperature of the grains in the removal process. The hot air is used as a drying source, suspension rising overturning is adopted as the drying manner, and before the grains are blown into a drying tank for drying treatment, an air blowing mechanism can perform surface moisture suction treatment on the grains, so that the follow-up grain drying effect is better; when the grains are dried in the drying tank, wind is used for blowing upwards, the grains rise in atumbling manner, and drying is more uniform and thorough.

Owner:绥化市嘉禾米业有限公司

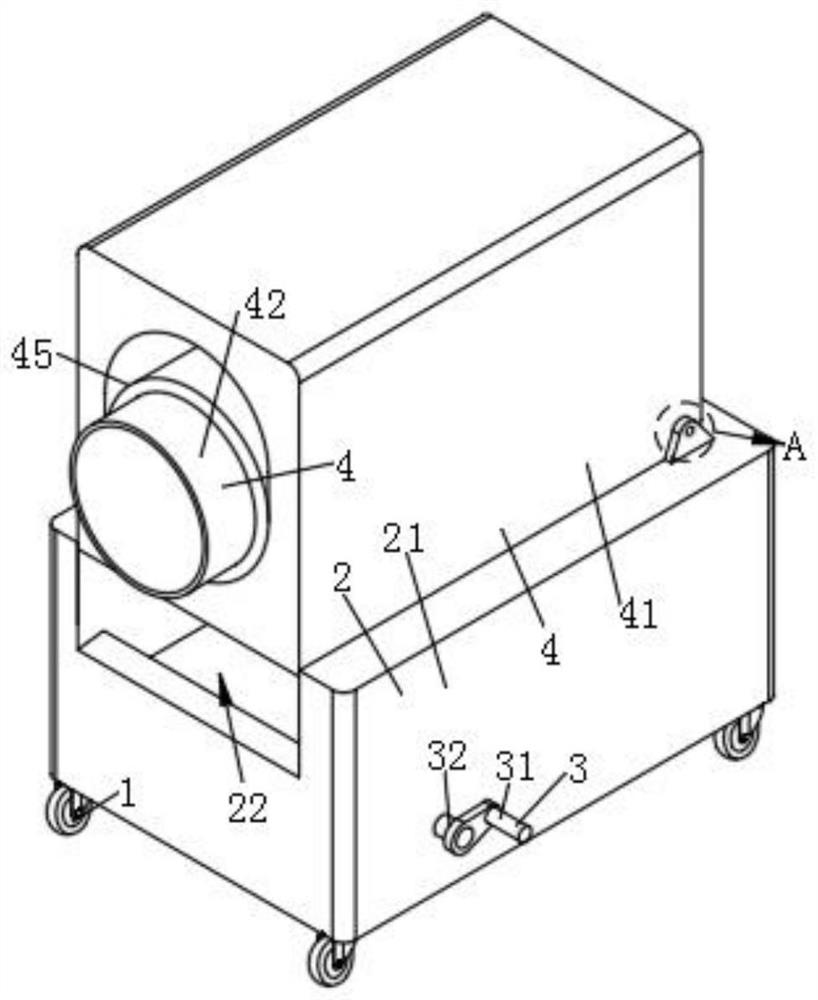

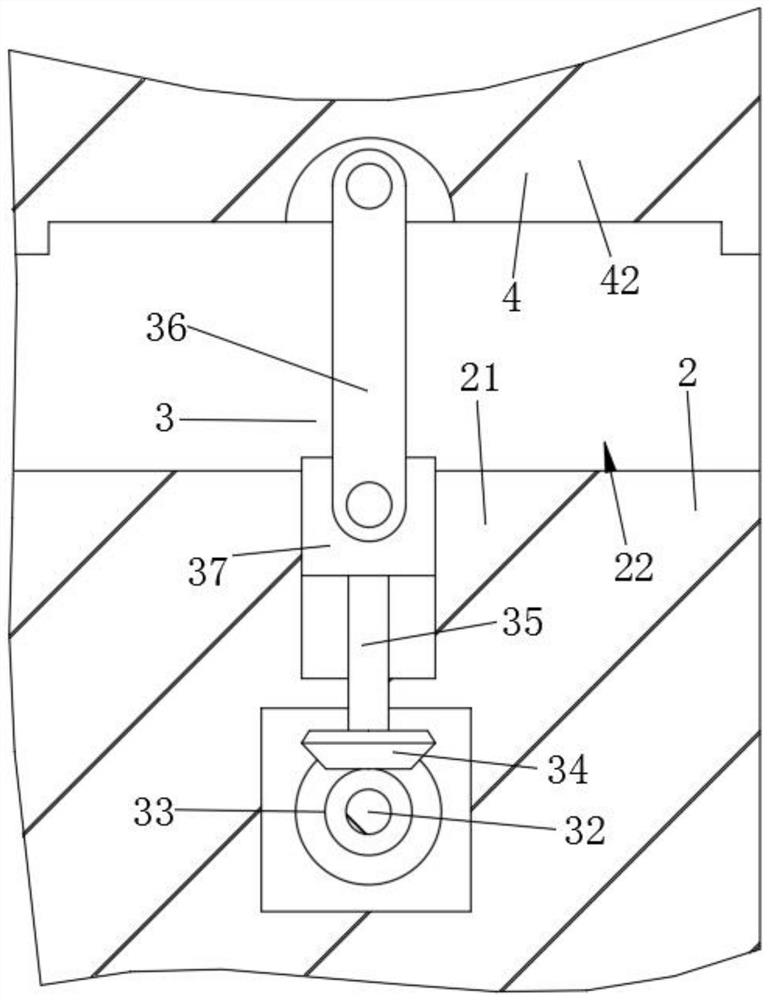

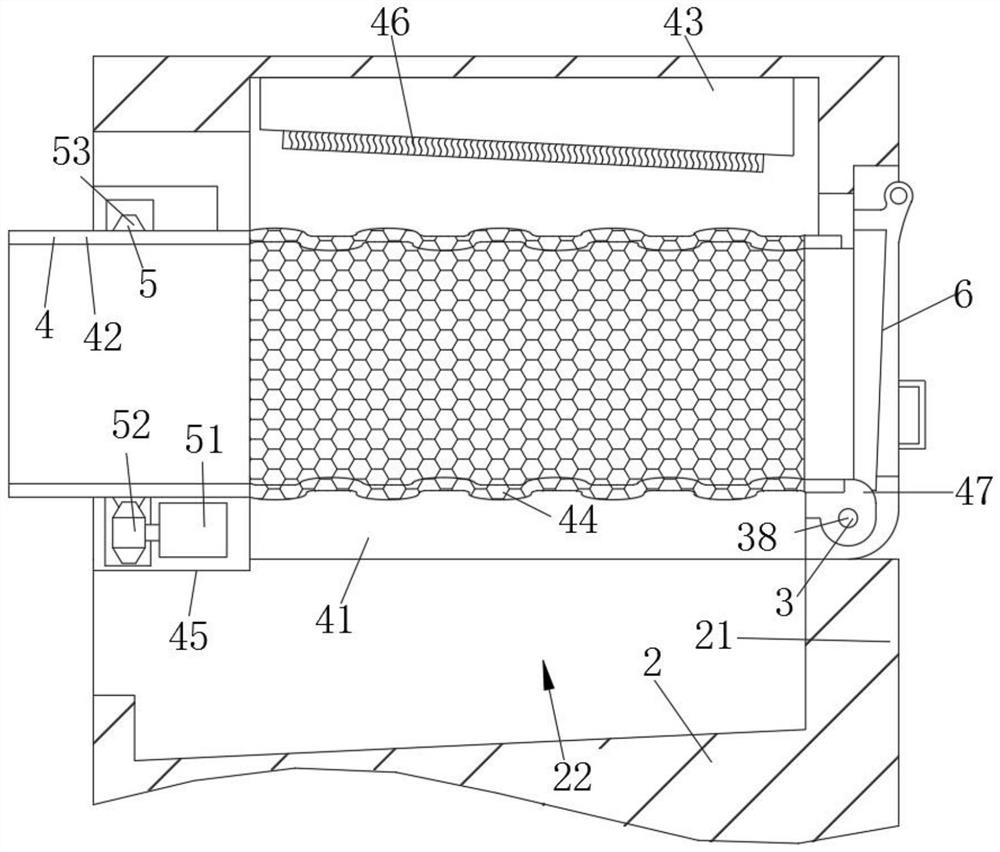

Draining and air-drying device with auxiliary drying function for Chinese herbal medicine processing

PendingCN112378204AIncrease the drying areaEfficient dryingDrying gas arrangementsDrying chambers/containersEngineeringMechanical engineering

The invention discloses a draining and air-drying device with an auxiliary drying function for Chinese herbal medicine processing. The draining and air-drying device with the auxiliary drying functionfor Chinese herbal medicine processing comprises universal wheels, a supporting structure, a lifting structure, an air-drying structure, an outer cover, a roller, a fan, a filter screen and a drivingstructure. The draining and air-drying device with the auxiliary drying function for Chinese herbal medicine processing provided by the invention has the beneficial effects that the driving structureis arranged in the outer cover, the outer cover is rotatably connected to the supporting structure, the fan is connected to the top end of the outer cover, the roller is rotatably connected into theouter cover and is connected to the driving structure, the filter screen is connected to the roller, the section of the filter screen is in a wave shape, and the air-drying area of Chinese herbal medicines needing to be air-dried is increased through the wave shape, so that air-drying of the Chinese herbal medicines is more efficient; and then the roller is driven by the driving structure so as torotate in the outer cover, the roller rotates to drive the filter screen to rotate, and the filter screen rotates to disperse the stacked Chinese herbal medicines, so that the Chinese herbal medicines can be air-dried more uniformly and thoroughly under the action of the fan.

Owner:翁妹华

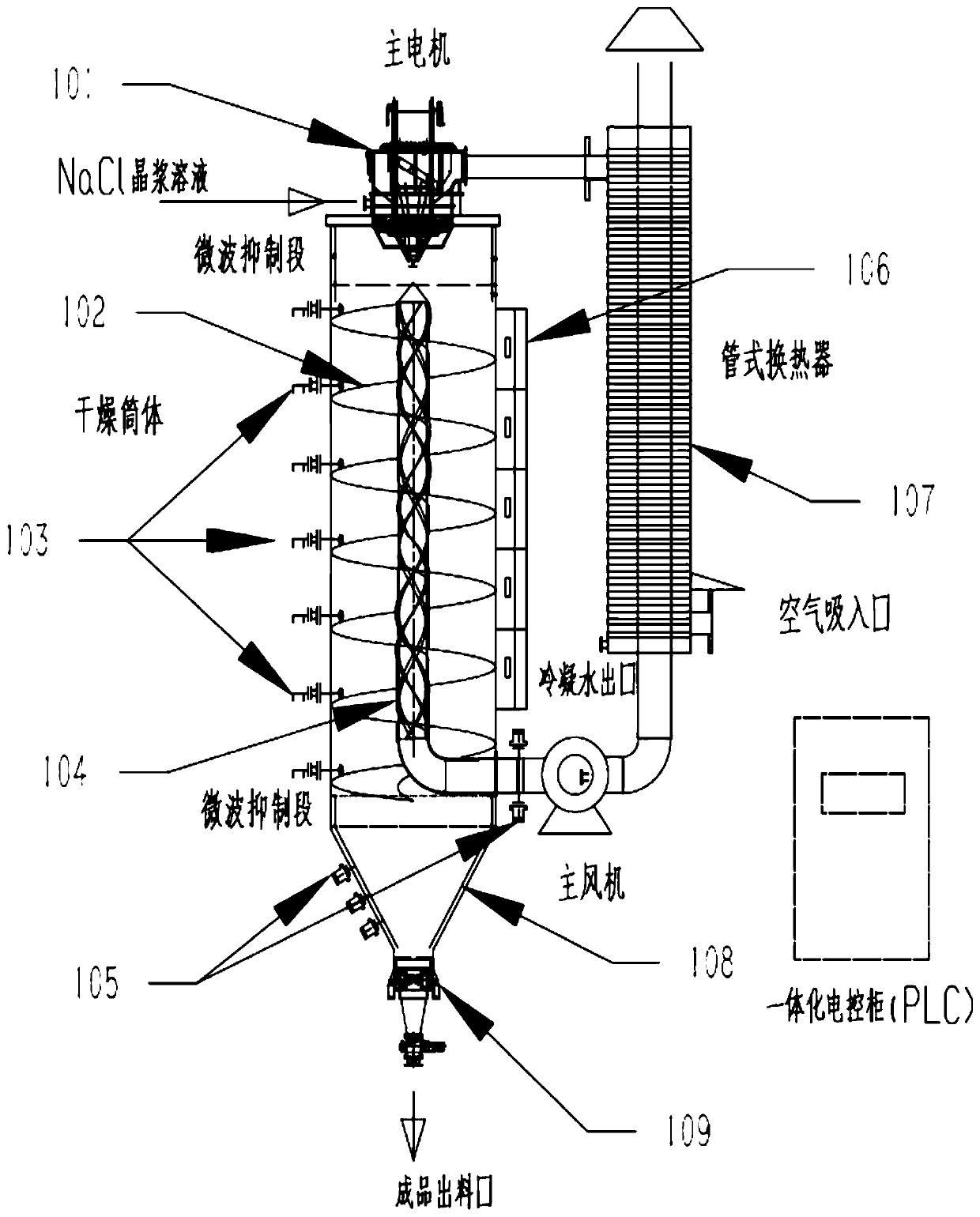

Microwave crystal oscillator drying device for zero emission of desulfurization wastewater

PendingCN110947349AThe overall structure is simple and reliableDry evenly and thoroughlyEnergy based chemical/physical/physico-chemical processesEvaporation by sprayingWastewaterSlurry

The invention relates to a microwave crystal oscillator drying device for zero emission of desulfurization wastewater. According to the microwave crystal oscillator drying device, a spray end of a rotary spray head faces downwards and extends into a drying cylinder, a liquid inlet end is communicated with a crystal slurry solution, an air inlet end is communicated with one end of a heat exchanger,and the other end of the heat exchanger is provided with an air suction inlet communicated with the heat exchanger; the drying cylinder is vertically arranged, a spiral guide groove is formed in theinner wall of the drying cylinder from top to bottom, and a finished product discharging port is formed in the bottom of the drying cylinder; a magnetron device for emitting microwaves to the center is arranged around the drying cylinder, a vertical nested vibrating screen pipe corresponding to the magnetron device is arranged in the center of the drying cylinder, the outer ring of the nested vibrating screen pipe is a microwave scattering surface with a breathable film clamped inside, the inner ring of the nested vibrating screen pipe is a crystal oscillator element, and an air interlayer isreserved between the outer ring and the inner ring; the nested vibrating screen pipe extends out of the drying cylinder and is connected with a fan, air is exhausted outwards through an air exhaust pipeline, the air exhaust pipeline penetrates through a heat exchanger, and air sucked in through an air suction inlet is heated through the heat exchanger.

Owner:SHANGHAI TIANXIAO ENVIRONMENTAL PROTECTION ENG CO LTD

Adjustable drying equipment capable of performing stirring in barrel-shaped structure and for feed processing

InactiveCN108477646AEasy to storeFull and even contactFeeding-stuffTransportation and packagingEngineeringFeed processing

The invention discloses adjustable drying equipment capable of performing stirring in a barrel-shaped structure and for feed processing. The adjustable drying equipment comprises a housing, a stirringmotor, a feeding opening and a stirring shaft, wherein the housing is divided into a drying cavity at the upper part of the housing and a heating cavity at the lower part of the housing by partitionboards; a fixing column is coaxially fixed to the outer side of the stirring shaft; horizontal supporting boards are respectively fixed to the upper end and the lower end of the fixing column throughscrews; air bags and a moving barrel are sequentially arranged on the outer side of the fixing column in a sleeving manner; a vertical stirring barrel is fixedly connected to connecting rods; a plurality of stirring blades are fixed to the inner wall of the stirring barrel; a fan is mounted on the side wall of the heating cavity; and a heating cabinet communicates with the inner part of the fan. According to the adjustable drying equipment disclosed by the invention, the air bags are arranged, so that the moving barrel can conveniently move from left to right, and during moving, the moving barrel rotates; two baffles are in contact, so that after the moving barrel moves, the moving barrel can have enough thrust to perform rotating; and an adjusting roller manually moves, and is pressed onthe stirring barrel, so that the integral position of the stirring barrel is changed.

Owner:毕超

Efficient and quick rose petal separation and drying device

InactiveCN108826862AImprove drying effectResolve the breakDrying gas arrangementsDrying chambers/containersPetalEngineering

The invention discloses an efficient and quick rose petal separation and drying device. The device comprises a base, a fixed rod, a box, a first servo motor and a second servo motor; the fixed rod andthe box are fixedly mounted on the two sides of the top end of the base; the bottom end of the fixed rod is vertically welded with the base; the box is fixedly connected with the base through a bracket; a horizontal ejector rod is welded on the side surface, towards the box, of the top end of the fixed rod; the first servo motor is mounted at the top end of the ejector rod; a turntable is arranged at the bottom end of the ejector rod rightly under the first servo motor; the first servo motor is rotationally connected with the turntable through engagement of gears; and a vertical positioning rod is arranged at the bottom end of the ejector rod on the right side of the turntable. The efficient and quick rose petal separation and drying device effectively improves the drying efficiency, reduces the breakage of petals in the drying process, is convenient to separate receptacles from the petals after drying, and guarantees the petal discharge quality.

Owner:湖南亲亲庄园农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com