Cereal drying technology adopting hot wind drying manner

A technology of hot air drying and drying process, applied in grain drying, drying, dryer and other directions, can solve the problems of prolonged storage period, uneven drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

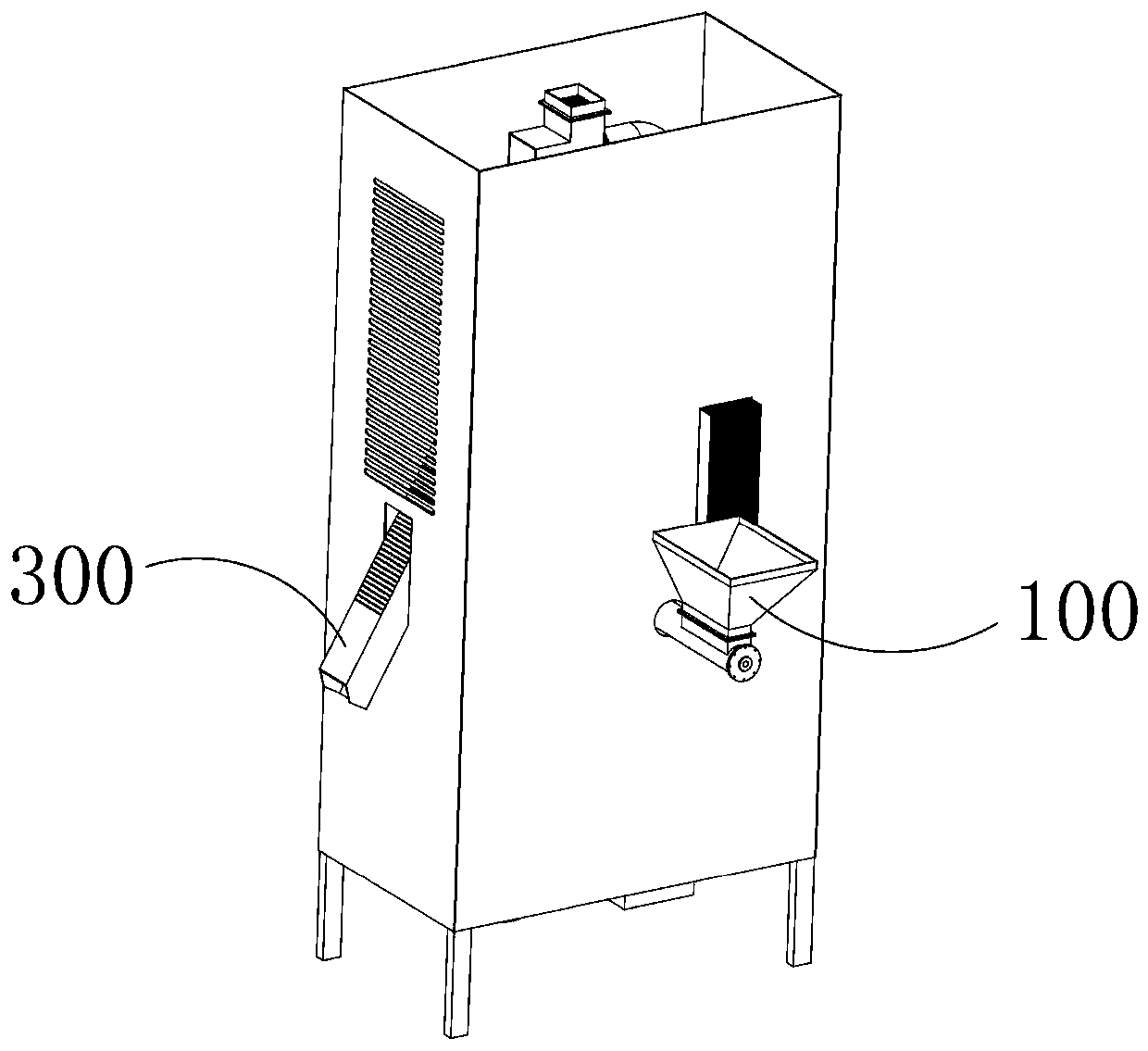

[0073] The drying process of grains by means of hot air drying, the steps are as follows:

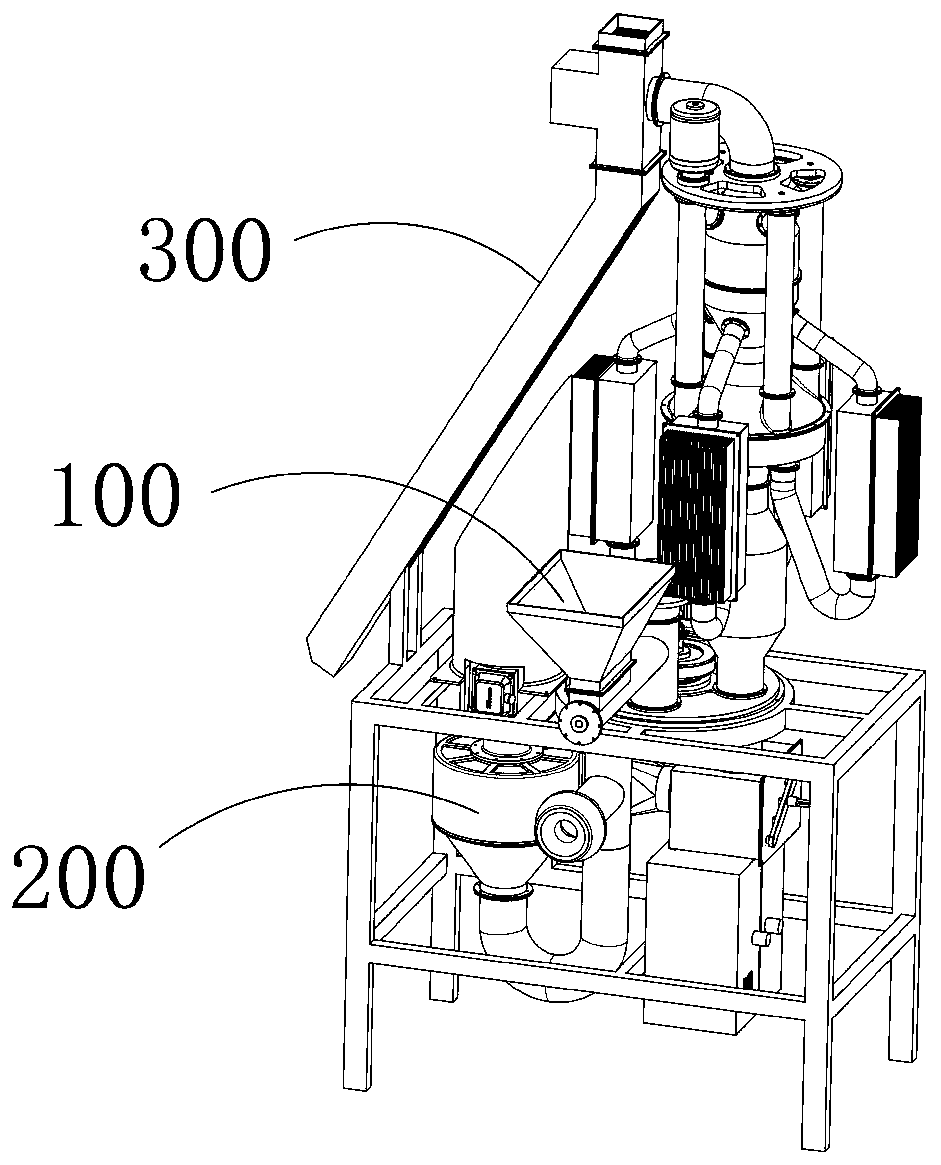

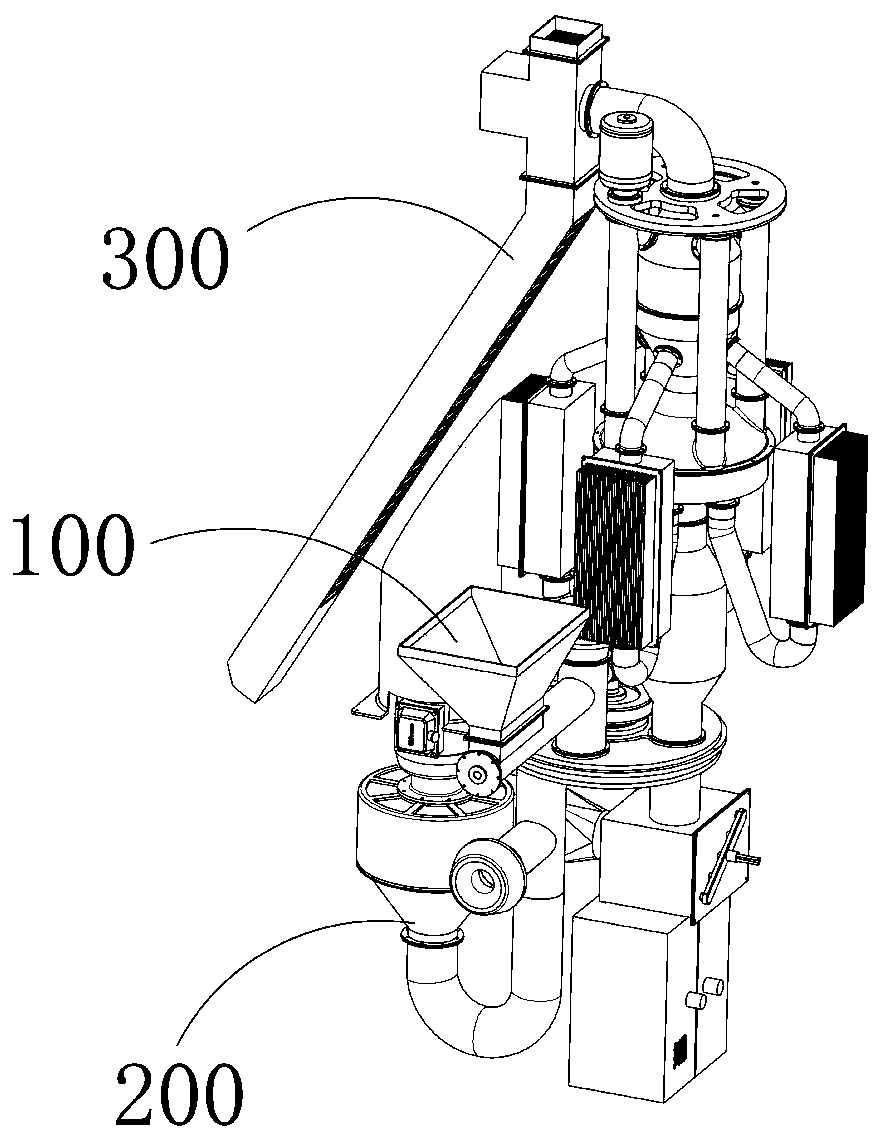

[0074] S1: the feeding device 100 operates and carries out grain transportation;

[0075] The feeding device 100 includes a power mechanism 110, a feeding mechanism 120, and a transition mechanism 130. The power mechanism 110 is used to provide power for the operation of the feeding mechanism 120. transported to the transition mechanism 130;

[0076] The transition mechanism 130 includes a transition housing 131, a rotating shaft 133, a screen 134, and a separation bracket 135. The transition housing 131 is a circular shell structure with one end open, one end closed and horizontally fixed on the mounting frame body. The transition housing 131 The open end is located below the closed end and the open end is matched with a closed end cover 132. The closed end of the transition shell 131 is provided with a suction hole 1311, a discharge hole 1312, and a feed hole 1313. The closed end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com