Continuous peanut drying device

A drying device and peanut technology, applied in the application, food processing, food science and other directions, can solve the problems of uneven drying, mildew, incomplete drying, etc., achieve uniform and thorough drying, convenient use and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

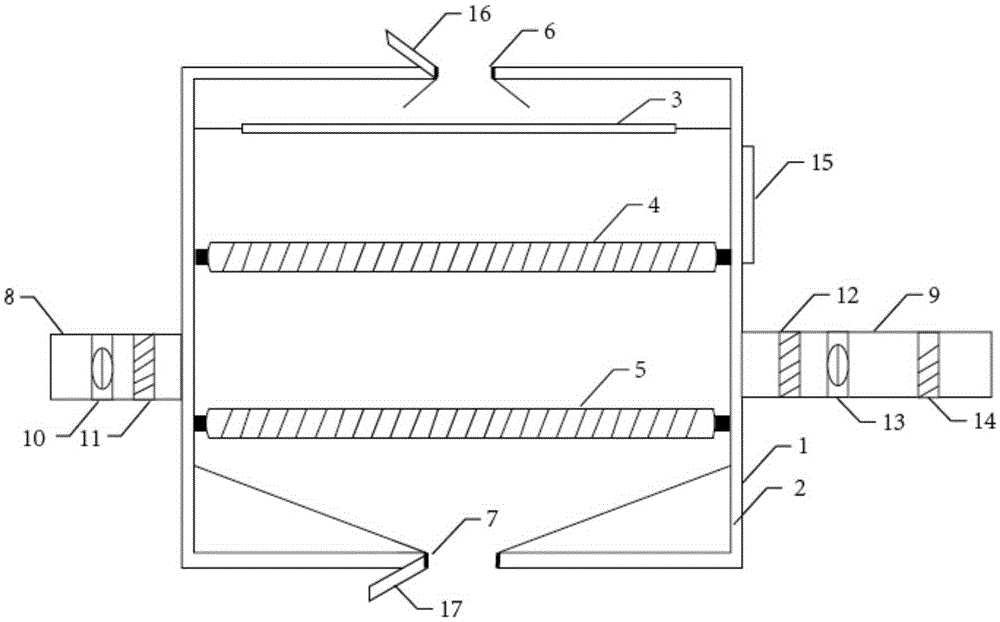

[0014] Such as figure 1 The structure shown in the present embodiment is a peanut continuous drying device, which includes a body 1, the body 1 is provided with a thermal insulation layer 2, and the upper end of the body 1 is provided with a drying irradiation lamp 3, and the drying irradiation lamp 3. The first drying layer 4 and the second drying layer 5 are arranged below. The first drying layer 4 and the second drying layer 5 are conveying equipment with a vibrating device, which can convey materials downward after drying , the body 1 is provided with a material inlet 6 and a material outlet 7, the left side of the second drying layer 5 is provided with an air inlet 8, and the right side of the second drying layer 5 is provided with an air outlet 9, so The air inlet 8 is provided with a blower 10 and a heat source 11 sequentially from left to right, and the air outlet 9 is provided with a moisture removal device 12 , an exhaust fan 13 and a dust removal device 14 sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com