Microwave crystal oscillator drying device for zero emission of desulfurization wastewater

A technology for desulfurization wastewater and drying equipment, which is applied in chemical/physical/physicochemical processes of energy application, spray evaporation, chemical/physical/physicochemical processes, etc. It can solve the problems of inability to convert economic benefits, secondary pollution of crystal slurry components, Low volumetric heat transfer coefficient and other issues, to achieve the effect of uniform and thorough drying process, simple and reliable structure, and less rotating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

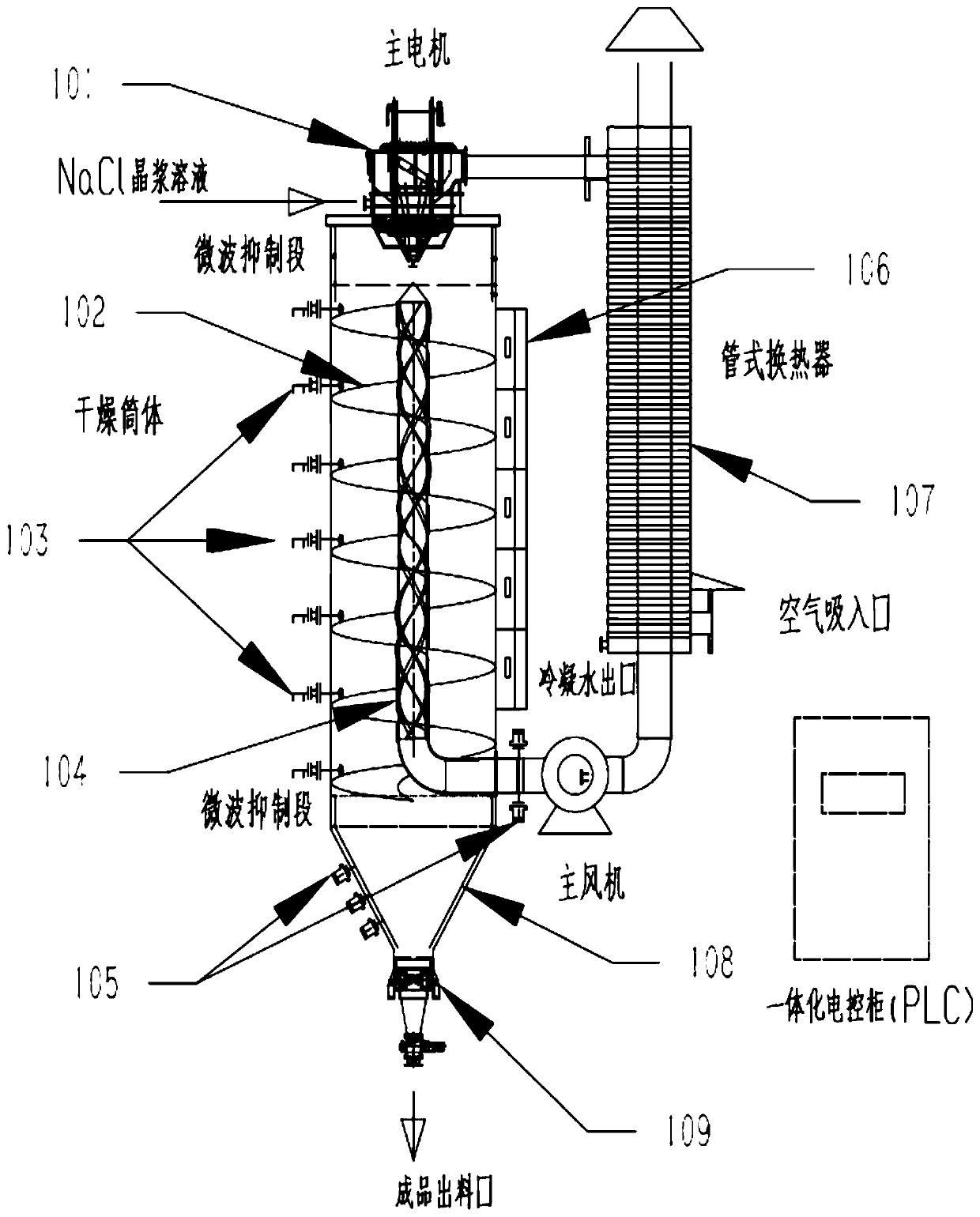

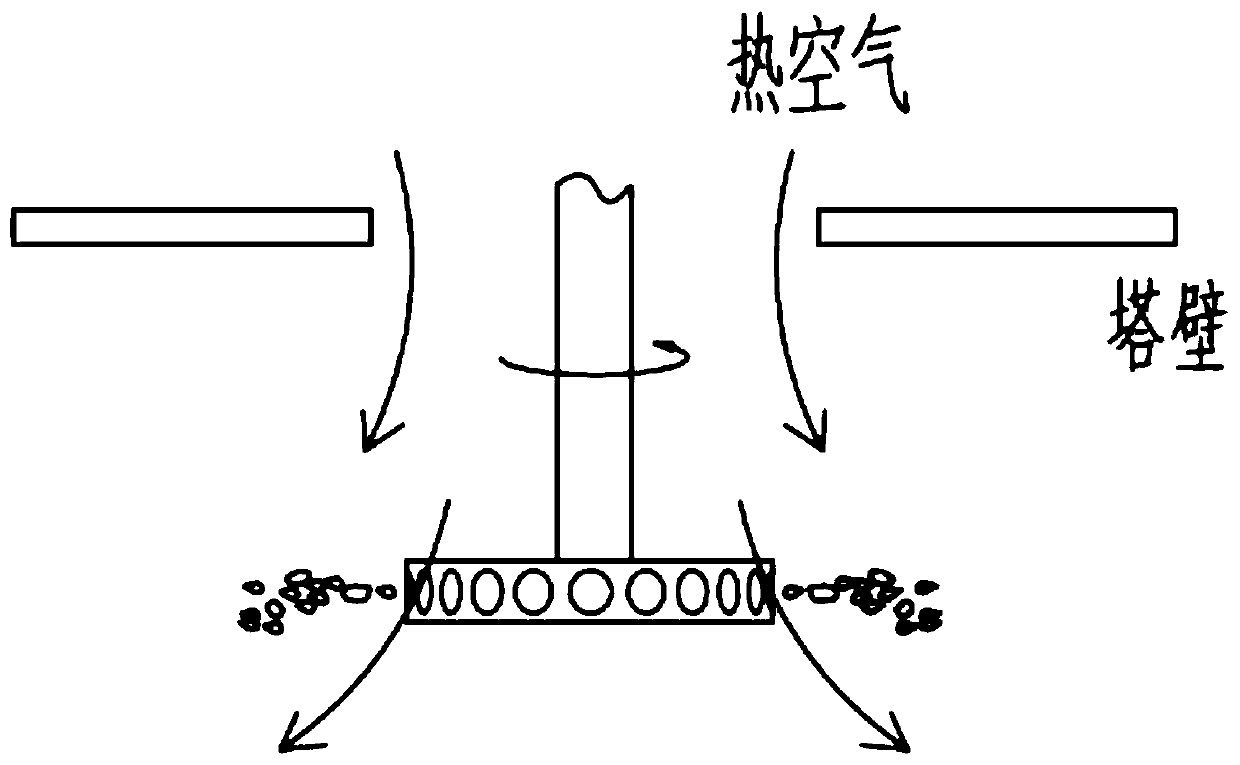

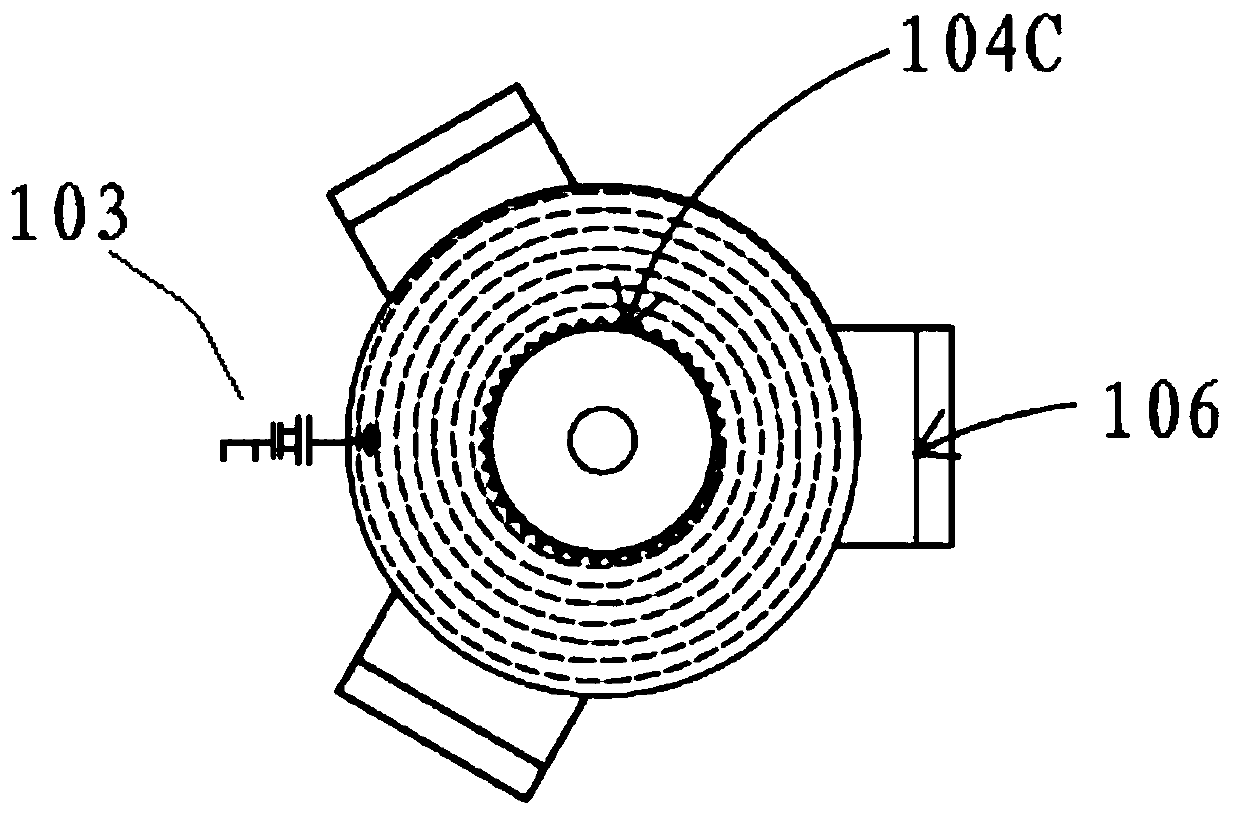

[0035] see Figure 1-Figure 4 , a microwave crystal oscillator drying device for zero discharge of desulfurization wastewater, including two parts: a drying cylinder and a tubular heat exchanger. The top of the drying cylinder is equipped with a high-speed rotating spray head 101, the straight pipe section is equipped with a spiral guide groove 102, the center is equipped with a nested vibrating screen 104, and the outer wall is layered with ultrasonic crystal oscillators according to the spiral guide groove. At the same time, a magnetron device is installed on the circumference according to the direction of 120° to generate microwaves for drying. The nested vibrating screen tube is equipped with a polymer breathable membrane. The high-temperature moisture generated by microwave drying passes through the vibrating screen tube, is drawn out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com