Rotary drying device for seed storage

A rotary drying and seeding technology, which is applied in the agricultural field, can solve the problems of water vapor cannot be quickly discharged, hot air seeds are difficult, and the drying time is long, so as to achieve the effects of uniform and thorough drying, shortening the drying time, and improving the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

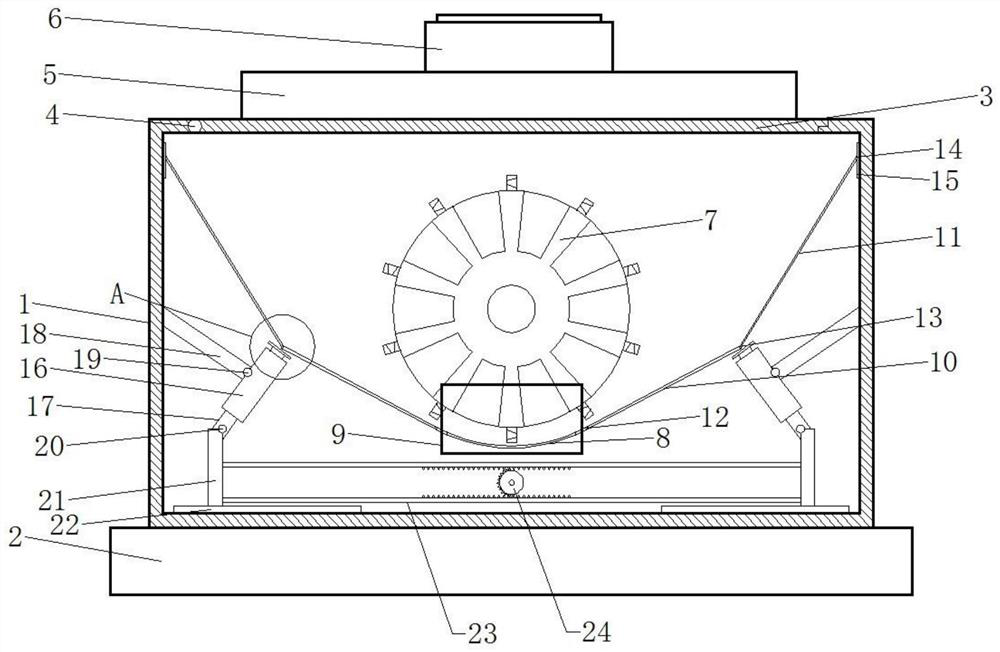

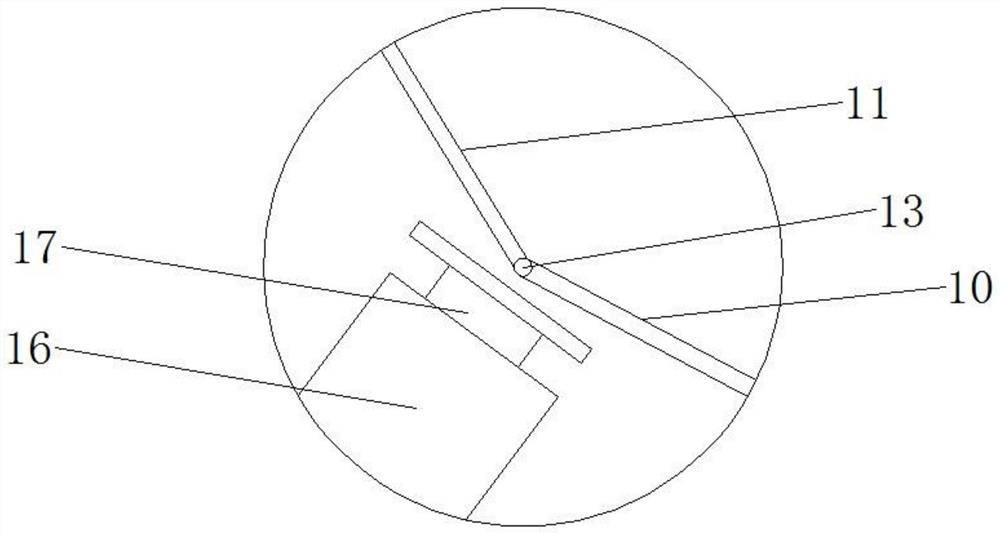

[0020] Please refer to the figure, in the embodiment of the present invention, a rotary drying device for seed storage includes a box body 1, a base 2, a sealing cover 3, a hinge 4, a heating box 5 and a fan 6; the box body 1 is fixedly installed on On the base 2, a sealing cover 3 is arranged on the top of the box body 1, and the sealing cover 3 is connected to the box body 1 through a hinge 4, so that the sealing cover 3 can be opened outwards, and the grain seeds are packed into the box body 1 Inside: a heating box 5 is fixedly installed on the outer surface of the sealing cover 3, and several blowing holes extending to the lower surface of the sealing cover 3 are provided on the heating box 5, and the hot air in the heating box 5 is sent into the box body 1 Inside, a heating element is installed in the heating box 5 to heat the air entering the interior and provide hot air for drying. A fan 6 is installed on the top of the heating box 5, and the fan 6 sends the external air...

Embodiment 2

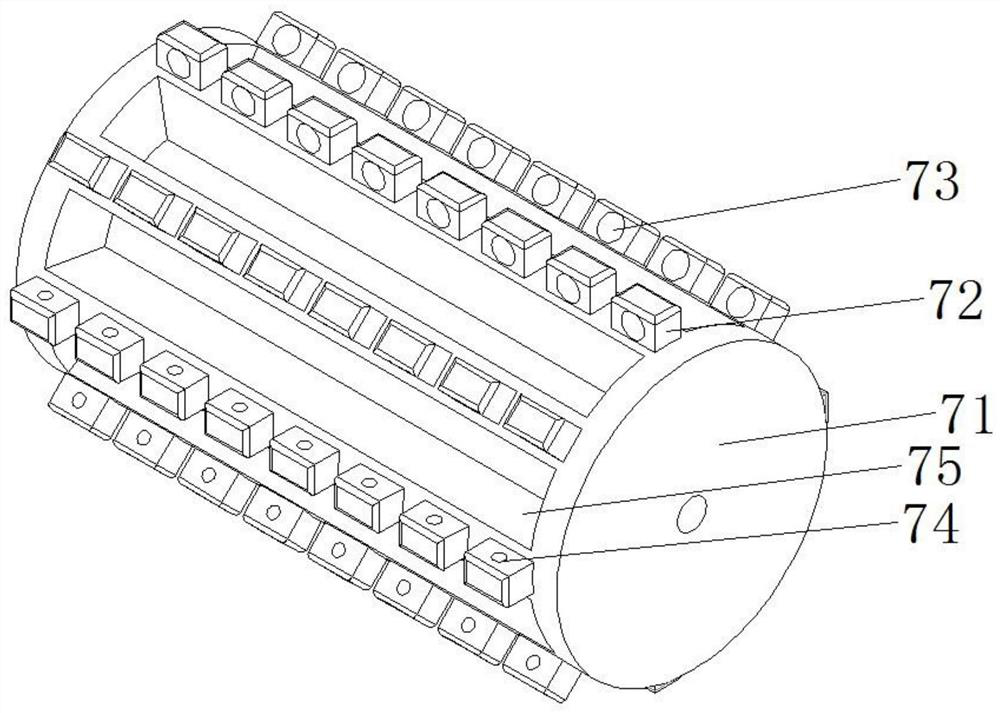

[0023] On the basis of Embodiment 1, the rotating roller 7 includes a rotating roller 71 with a cylindrical structure, and several toggle blocks 72 are fixedly installed on the side wall of the rotating roller 71, and the toggle block 72 is a rectangular block structure. The toggle block 72 is provided with a feed port 73 facing the direction of rotation and a discharge port 74 on the other side, and the feed port 73 communicates with the discharge port 74, and the diameter of the feed port 73 is greater than the diameter of the discharge port 74 , preferably, the diameter of the feed port 73 is 1.5-2 times the diameter of the discharge port 74, forming a cavity with a circular truncated structure, so that the grain seeds enter the interior from the feed port 73, store them inside, and pass through the opening smaller The discharge port 74 flows out downwards, so that the grain seeds follow the roller 71 and slowly fall from the shifting block 72; preferably, the shifting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com