Adjustable drying equipment capable of performing stirring in barrel-shaped structure and for feed processing

A technology of feed processing and drying equipment, which is applied to lighting and heating equipment, mixers with rotating stirring devices, feed, etc. It can solve the problems of difficult air-drying of pellet feed, insufficient drying of feed, and influence on air-drying effect, and achieve uniform contact Sufficient, easy to store for a long time, reduce the effect of internal dry dead space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

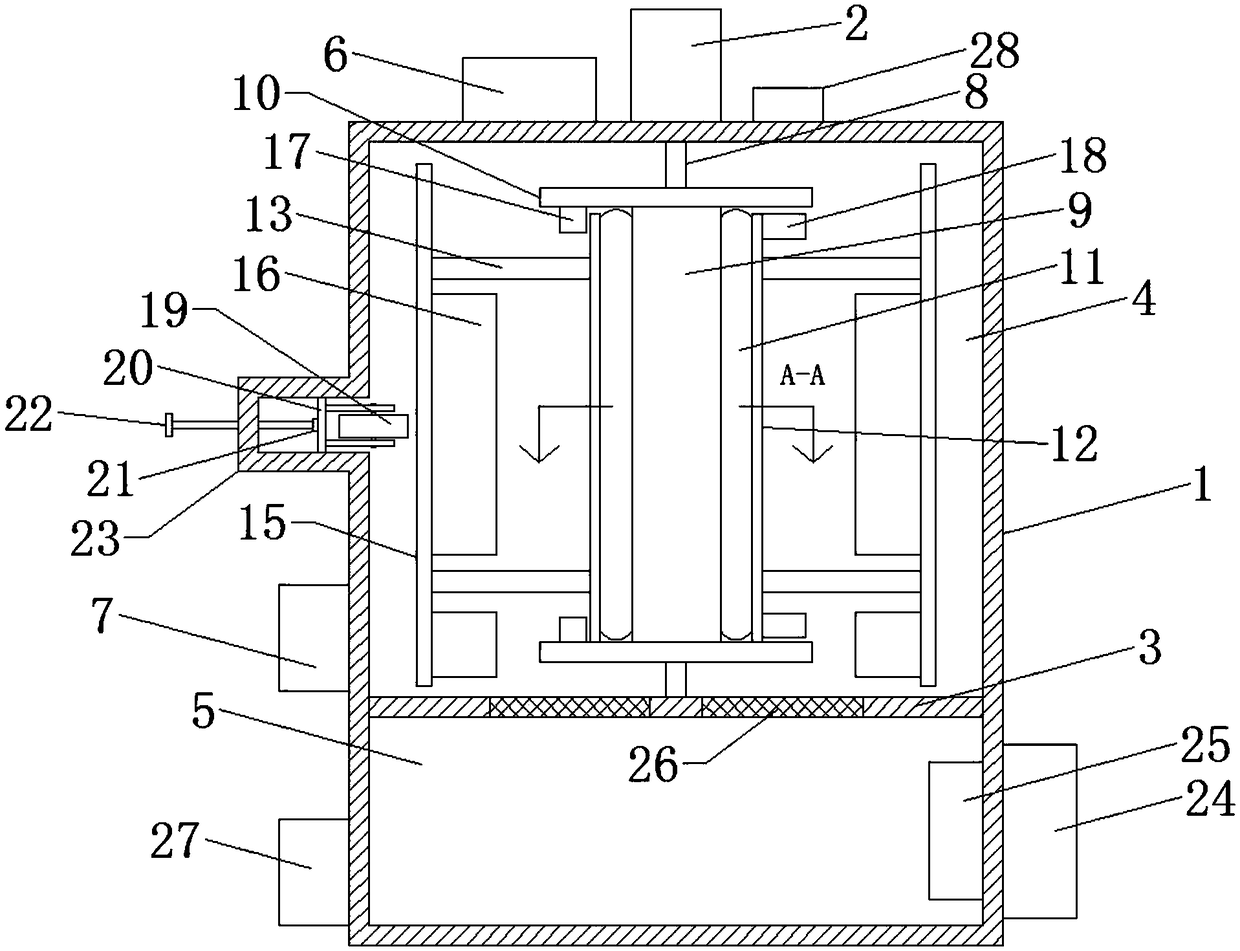

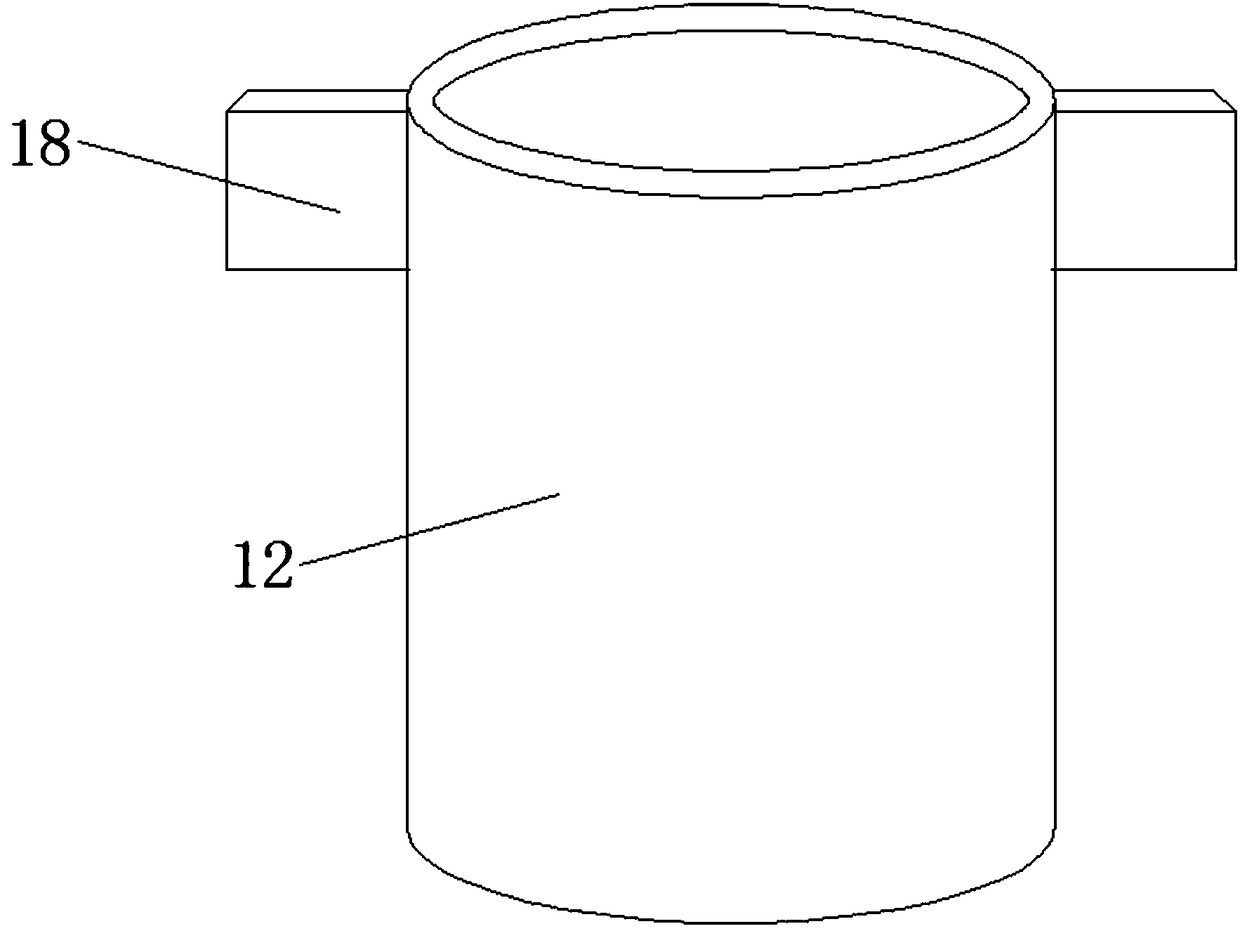

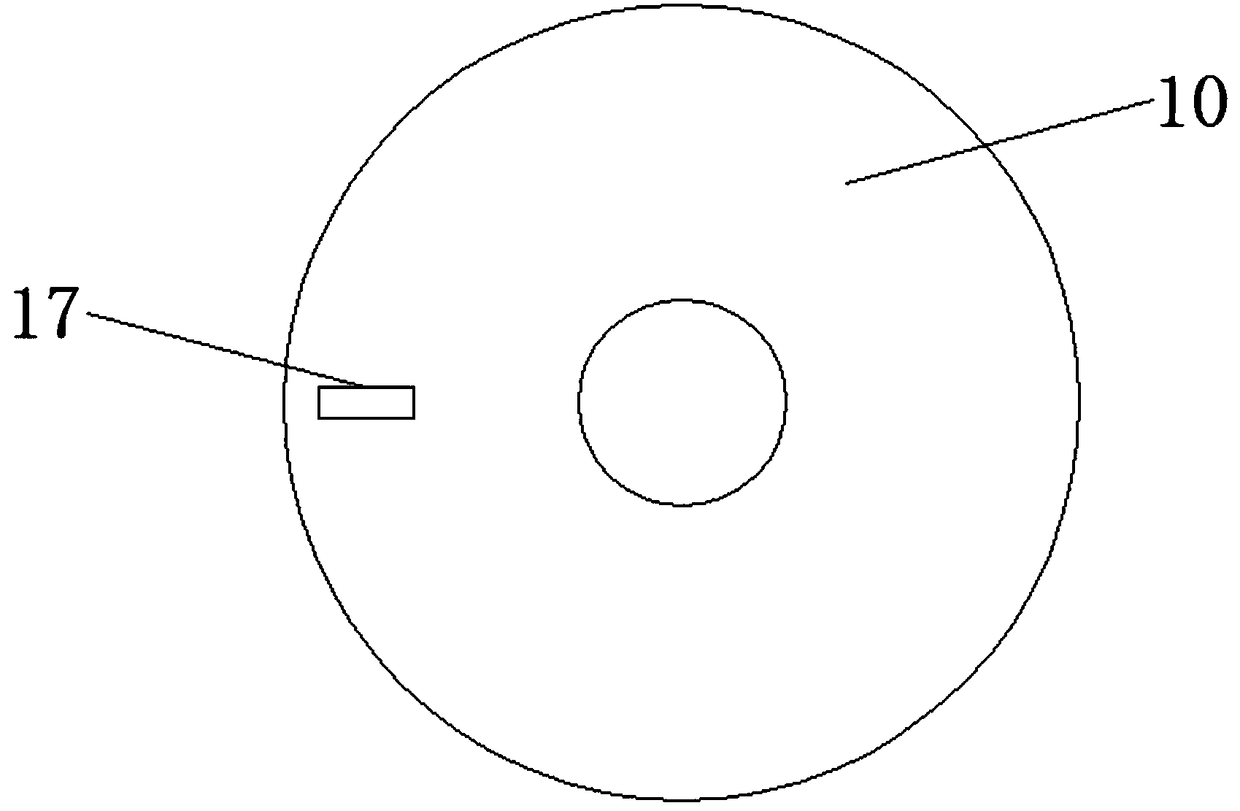

[0018] Referring to the figure, in the embodiment of the present invention, a drying device for feed processing with adjustable cylindrical structure stirring includes a casing 1, a stirring motor 2, a feeding port 6 and a stirring shaft 8; the feeding port 6 is connected to On the top of the housing 1, a horizontal partition 3 is fixed at the lower part of the housing 1. The partition 3 divides the housing 1 into an upper drying chamber 4 and a lower heating chamber 5. The feed is in the drying chamber 4. After stirring and drying, a ventilating mesh 26 is embedded in the separator 3, and the hot air below is transported upward.

[0019] The stirring motor 2 is fixedly installed on the top of the casing 1, the output shaft of the stirring motor 2 extends vertically downward into the drying chamber 4 in the casing 1, and a vertical shaft is fixedly connected to the output shaft of the stirring motor 2. The lower end of the stirring shaft 8 is rotatably connected to the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com