Vacuum tube bundle drying system with waste heat for pneumatic drying

A technology of tube bundle drying and airflow drying, which is applied in the direction of dry cargo handling, drying solid materials, non-progressive dryers, etc., to achieve the effects of thorough and uniform drying of materials, reducing energy consumption, and avoiding the phenomenon of burnt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

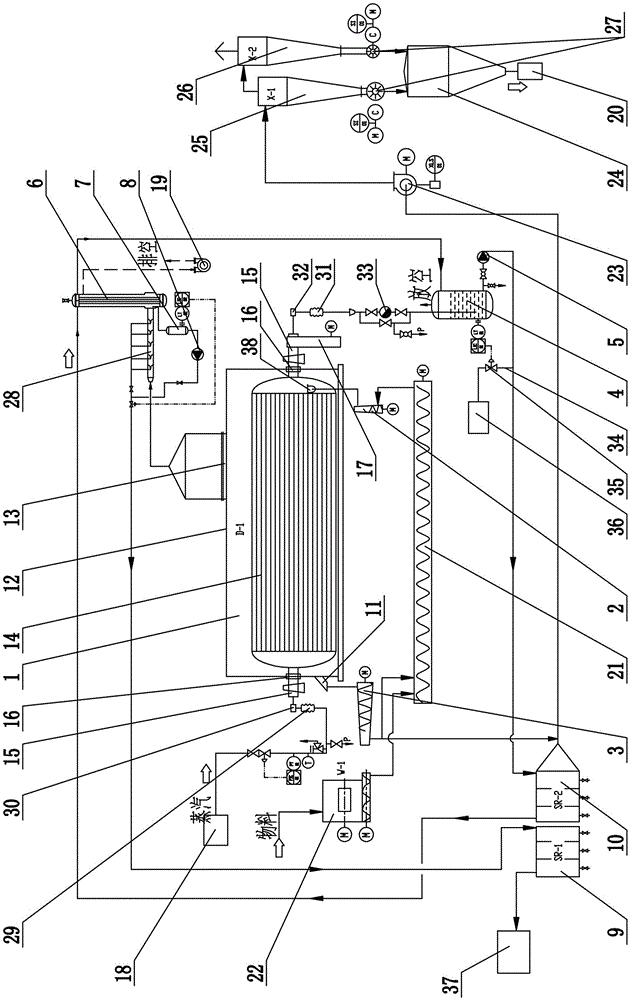

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 1As shown, a vacuum tube bundle drying system in which waste heat is used for air drying, including tube bundle dryer 1, feed auger 2, discharge auger 3, primary condensed water collection tank 4, primary condensed water pump 5, surface condenser 6 , secondary condensed water collection tank 7, secondary condensed water pump 8, primary air heat exchanger 9, secondary air heat exchanger 10 and airflow drying system, one side of the tube bundle dryer 1 is provided with a feed port 38 , the other side is provided with a discharge port 11, and the casing 12 of the tube bundle dryer 1 is provided with a secondary steam outlet 13, and the rotating shafts 15 at both ends of the tube bundle 14 of the tube bundle dryer 1 and the casing 12 are flexibly connected by a mechanical seal 16 One end of the rotating shaft 15 is connected to the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com