Fully-automatic grain drying machine

A dryer, fully automatic technology, applied in dryers, grain drying, drying and other directions, can solve the problems of high construction cost, great weather influence, and unsuitable starting for drying grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

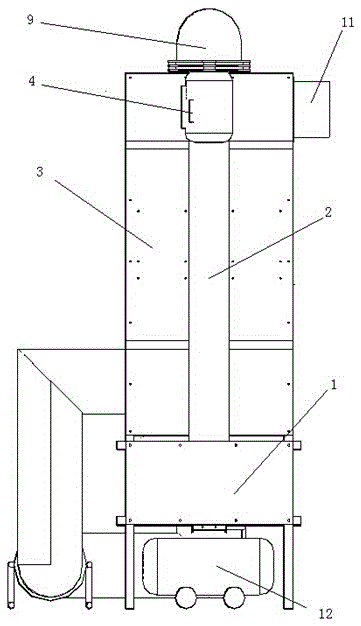

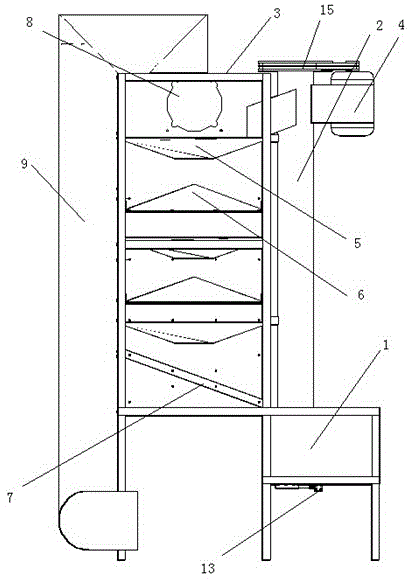

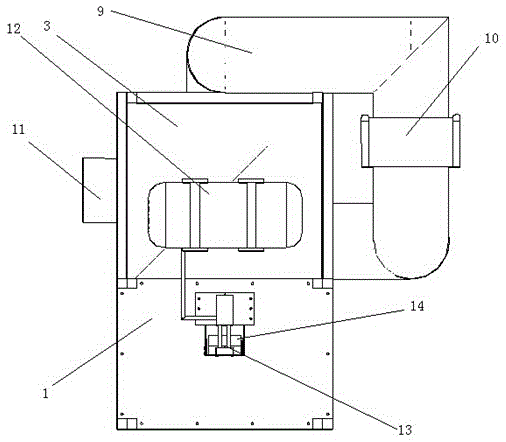

[0023] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0024] The invention provides a fully automatic grain dryer, which is exquisite in structure and adopts a unique mechanical structure design, and the grain drying can be completed indoors through cycle drying, and the whole mechanism can adopt a modular design, which is convenient for assembly and drying The drying temperature and humidity can be controlled, thus improving the drying efficiency and reducing the drying cost.

[0025] As an embodiment of the present invention, the present invention provides a fully automatic grain dryer, including a grain storage bin 1, a grain lifting rod 2, a drying bin housing 3, an auger motor 4, a drying module, and a sliding plate 7. Air supply duct 9, hot air blower 10 and transmission belt 15. The grain storage bin 1 is on the side below the drying bin shell 3, and there is a grain lifting rod 2 on one side of the drying bin shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com