Patents

Literature

49results about How to "Drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

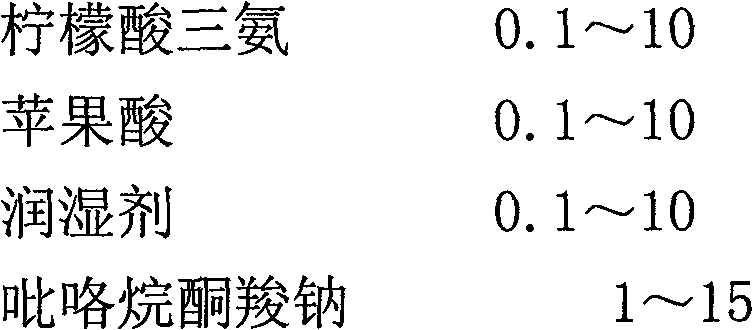

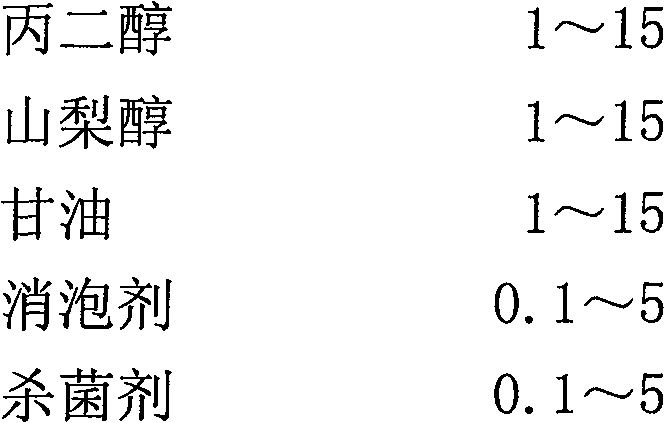

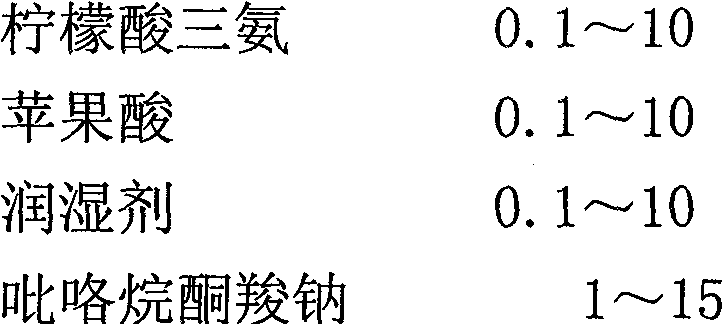

Fountain solution and preparation method thereof

InactiveCN101870213AEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentGermabenPropylene glycol

The invention discloses a fountain solution, which is characterized in that: the fountain solution comprises the following raw materials in percentage by weight: 1 to 15 percent of glycerin, 0.1 to 10 percent of ammonium citrate, 0.1 to 10 percent of malic acid, 0.1 to 5 percent of defoaming agent, 0.1 to 10 percent of wetting agent, 0.1 to 5 percent of bactericide, 1 to 15 percent of L-PCA-Na, 1 to 15 percent of propylene glycol and 1 to 15 percent of sorbierite; and the preparation method comprises the following steps: adding the ammonium citrate, the malic acid, the wetting agent, the L-PCA-Na in a weight percentage ratio, then adding 50 to 80 percent of water, uniformly mixing the materials and the water; and adding the propylene glycol, the sorbierite, the glycerin, the defoaming agent and the bactericide into the obtained mixture and then uniformly stirring the mixture so as to obtain the fountain solution. The fountain solution has the advantages of environmental protection, strong fountain capability, wet non-verbal-visual part, sufficient pH-value buffering, difficult ink emulsification, large electric conductivity, large surface-tension buffering range and easy operating control.

Owner:杜广清

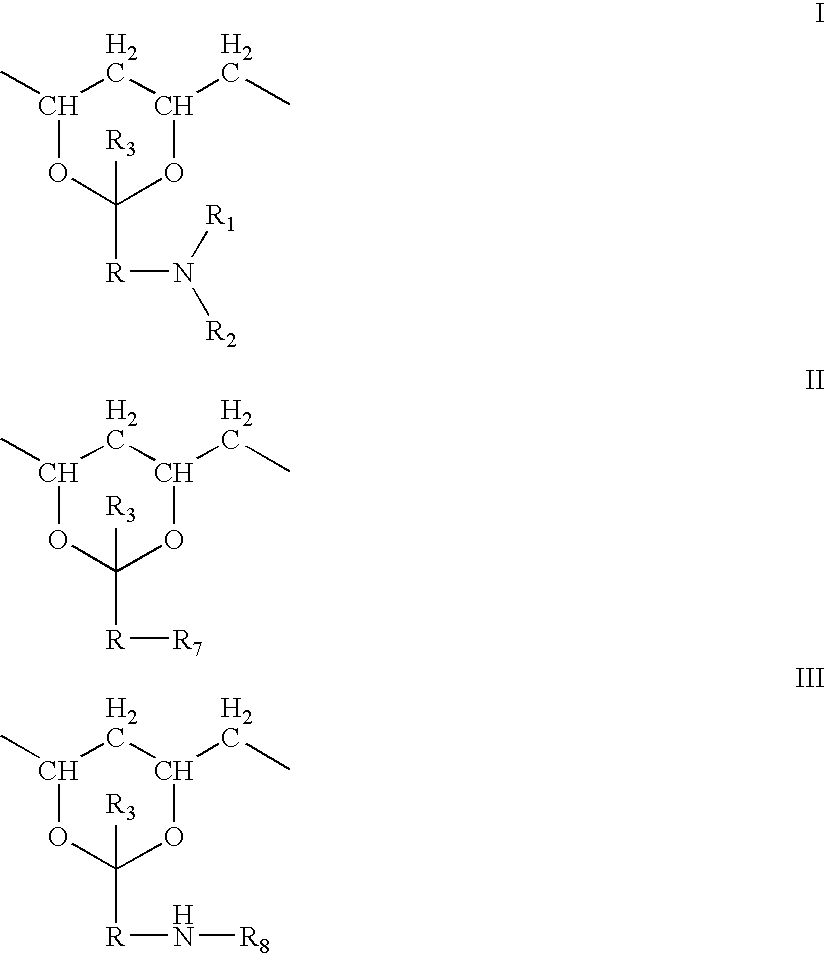

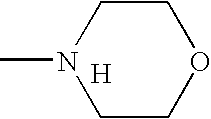

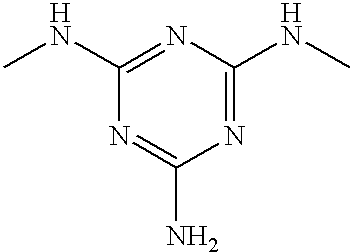

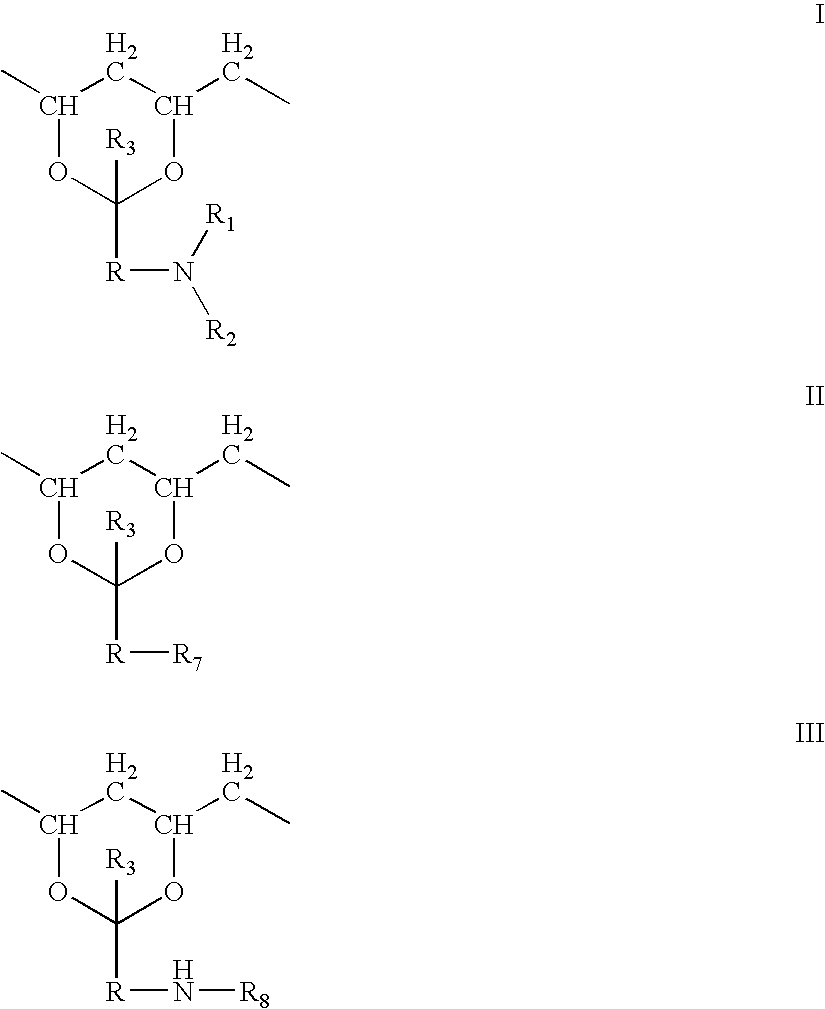

Ink formulations and uses thereof

InactiveUS7411008B2Improve adhesionDrying effectDuplicating/marking methodsInksColor imageSpray nozzle

The present invention provides a chemical ink comprises a solvent, a binder polymer, a colorant and optionally a crosslinker. The ink of the invention has one or more of the following characteristics: a viscosity lower than about 50 centipoises; a surface tension of from about 20 mN / m to about 60 mN / m; a particle size of less than about 5 μm; prolonged stability; an appropriate color level (visible by eye); uniform drop formation; jet stability; good adhesion to contact lenses; good transfer from a mold to a lens made in the mold; and stability of ink in inkjet nozzles. The ink of the invention is useful for inkjet printing of a high-quality color image on a contact lens or a mold so as to produce a colored contact lens.

Owner:ALCON INC

Ink formulations and uses thereof

InactiveUS20070117884A1Improve adhesionDrying effectDuplicating/marking methodsInksColor imageEngineering

The present invention provides a chemical ink comprises a solvent, a binder polymer, a colorant and optionally a crosslinker. The ink of the invention has one or more of the following characteristics: a viscosity lower than about 50 centipoises; a surface tension of from about 20 mN / m to about 60 mN / m; a particle size of less than about 5 μm; prolonged stability; an appropriate color level (visible by eye); uniform drop formation; jet stability; good adhesion to contact lenses; good transfer from a mold to a lens made in the mold; and stability of ink in inkjet nozzles. The ink of the invention is useful for inkjet printing of a high-quality color image on a contact lens or a mold so as to produce a colored contact lens.

Owner:ALCON INC

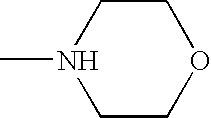

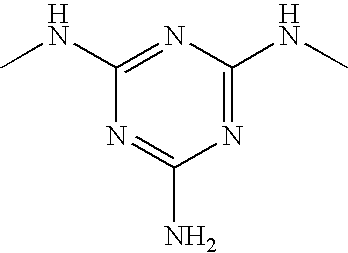

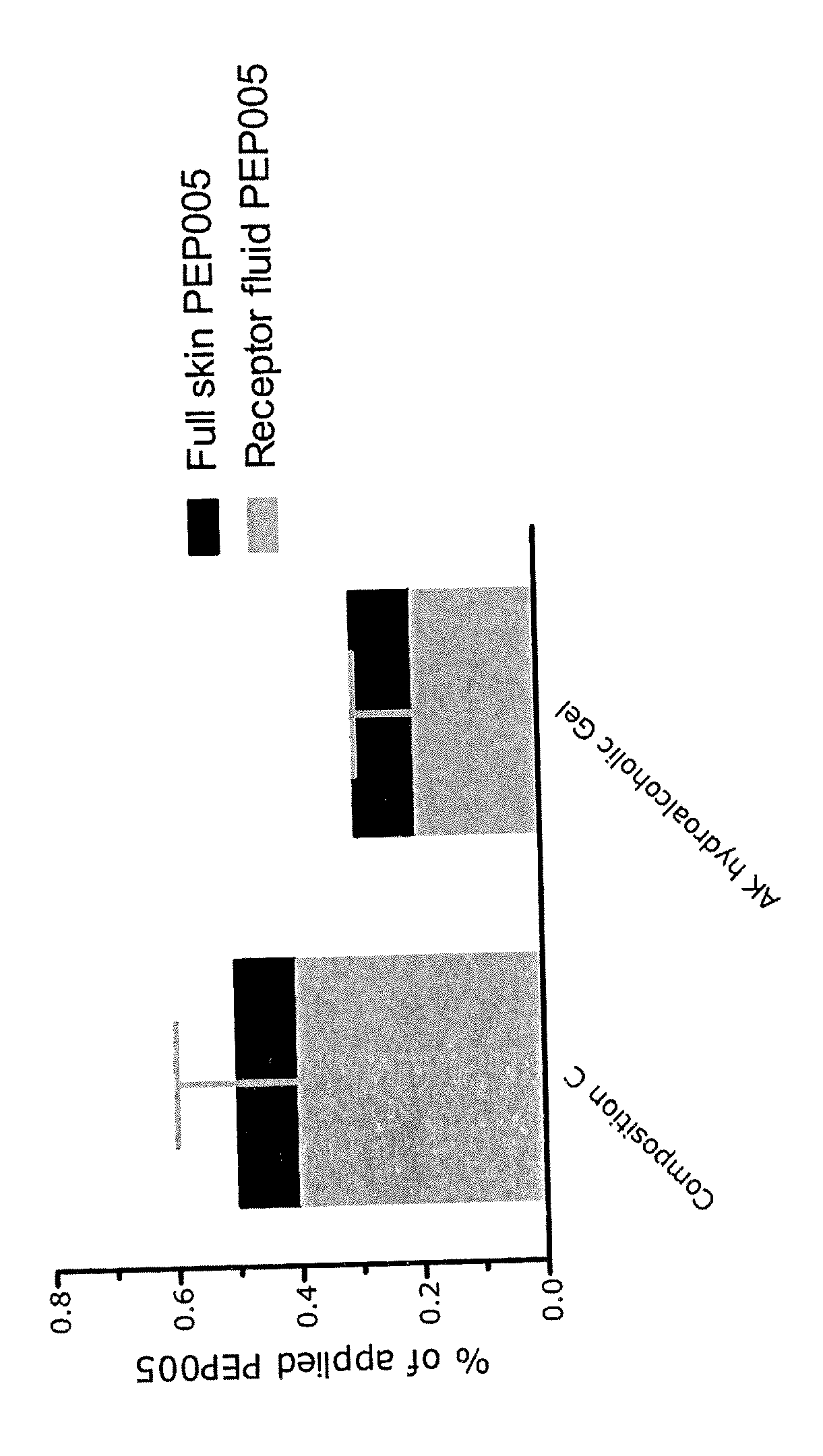

Topical composition comprising an ingenol derivative and a surfactant-cosolvent mixture

InactiveUS20140343141A1Good chemical stabilityImprove stabilityBiocideAnimal repellantsPolyoxyethylene castor oilSucrose

A topical composition for cutaneous application which is a water-in-oil emulsion comprises an oily phase comprising (a) an ingenol derivative in dissolved form; (b) at least one non-ionic surfactant selected from the group consisting of polyoxyl glycerides, polyoxyethylene castor oil derivatives, polyoxyethylene alkyl ethers, polysorbates, or a mixture of acrylamide acryloyldimethyl taurate copolymer, isohexadecane and polysorbate 80, sterols, fatty alcohols, fatty acid phosphonates, mono- or diglycol esters, mono- di- or polyglyceryl esters, mono-, di- or plyglucose esters, sucrose esters or sorbitan esters, the non-ionic surfactant being present in an amount of from about 0.5% by weight to about 10% by weight of the composition; (c) a solvent for the ingenol derivative; and an aqueous phase buffered to a pH of 2.6-3.7.

Owner:LEO LAB

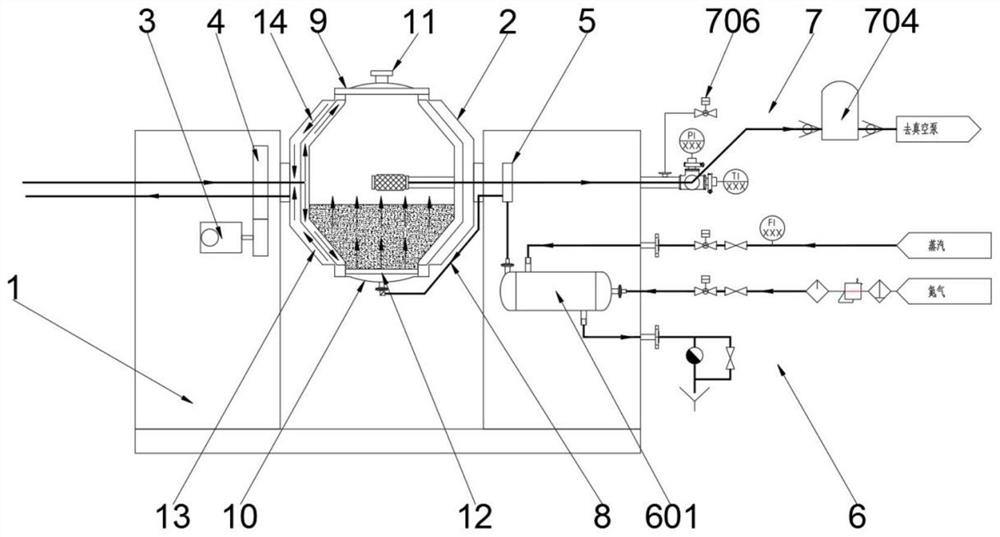

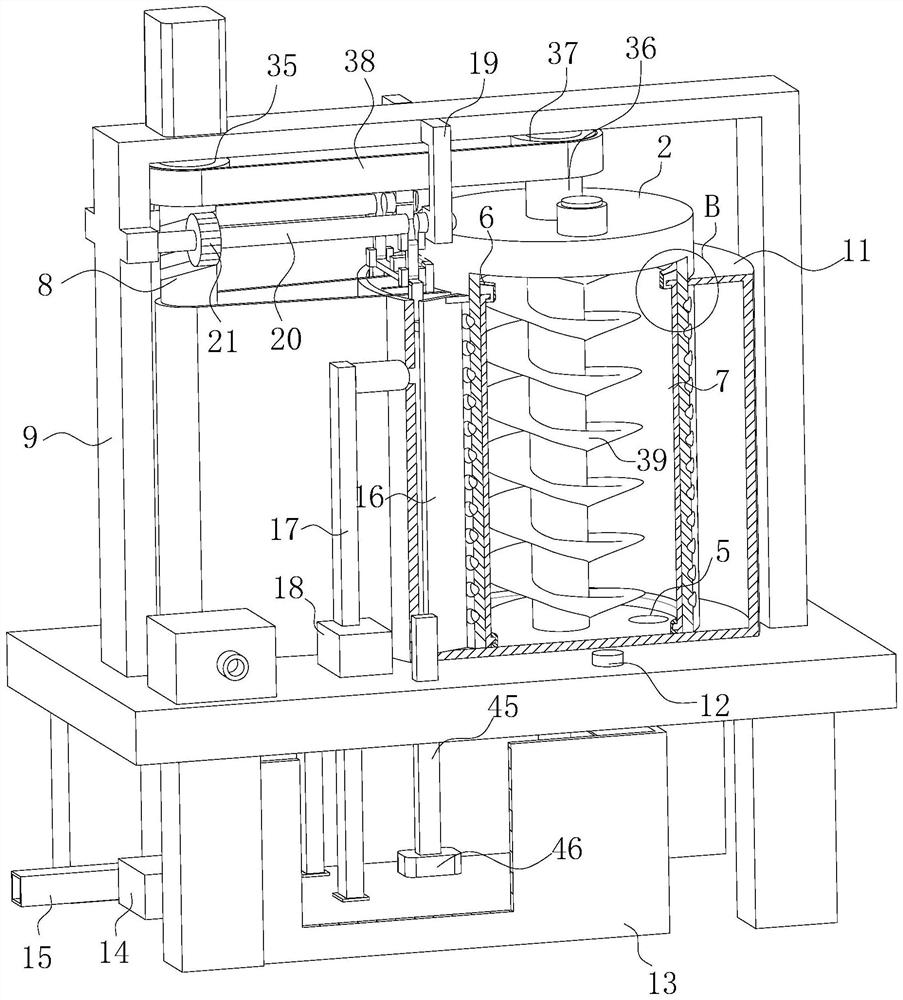

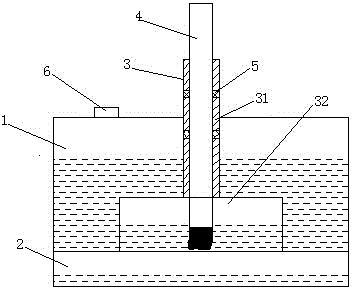

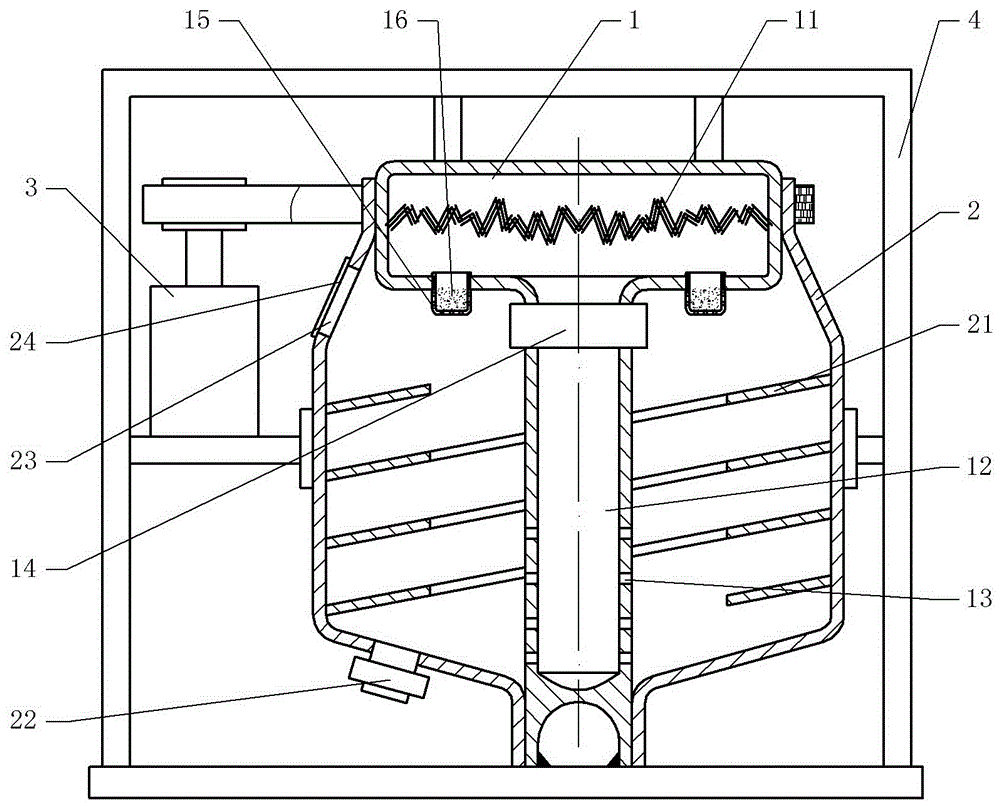

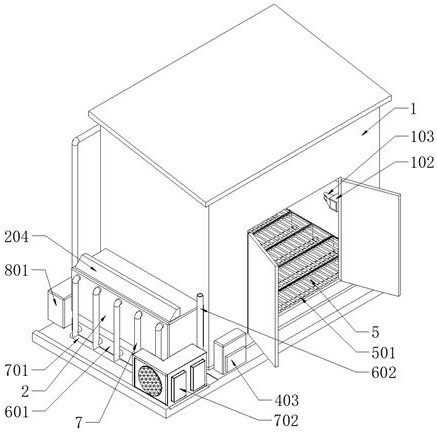

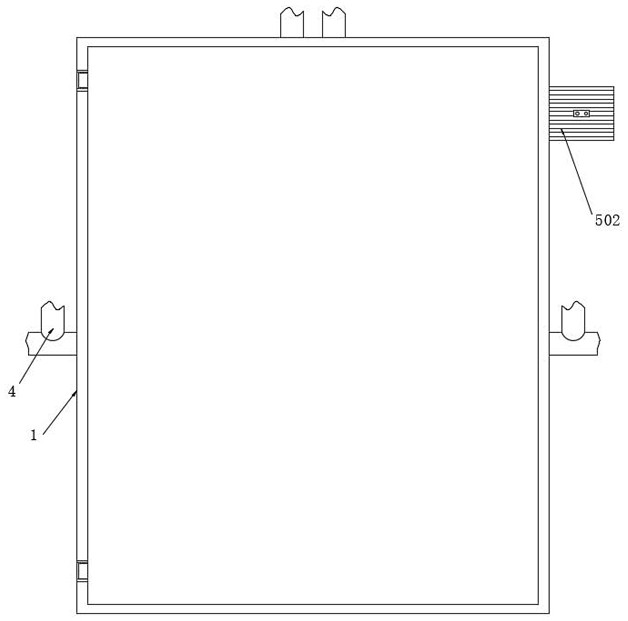

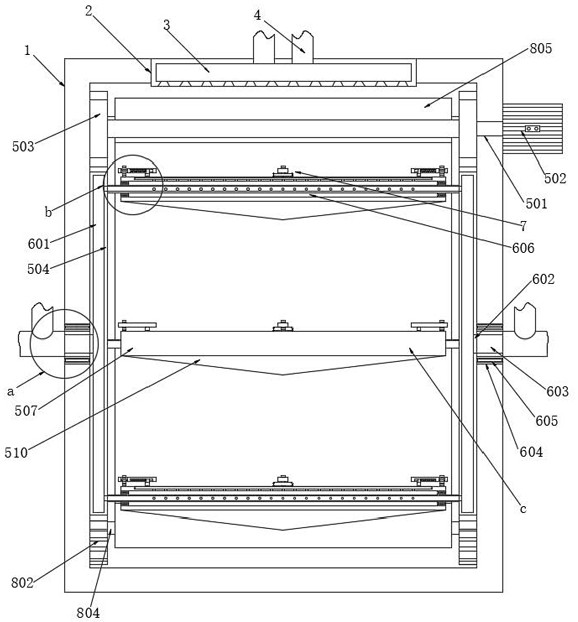

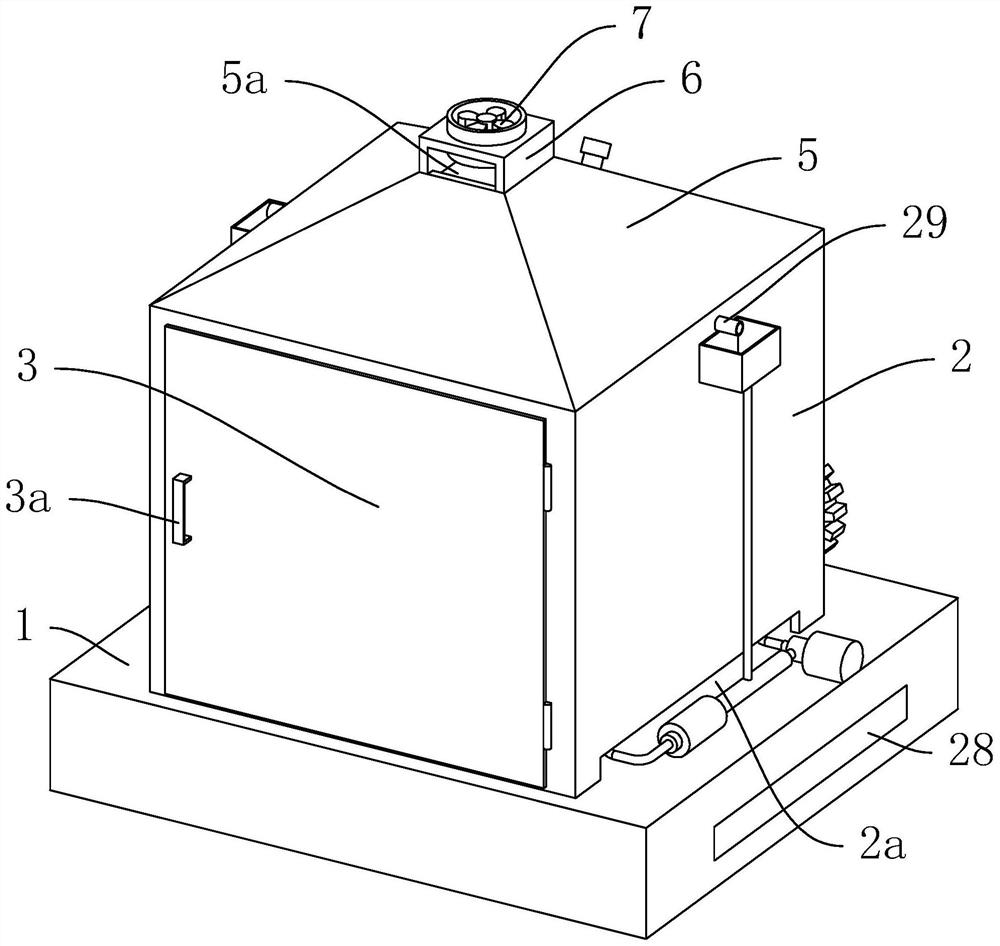

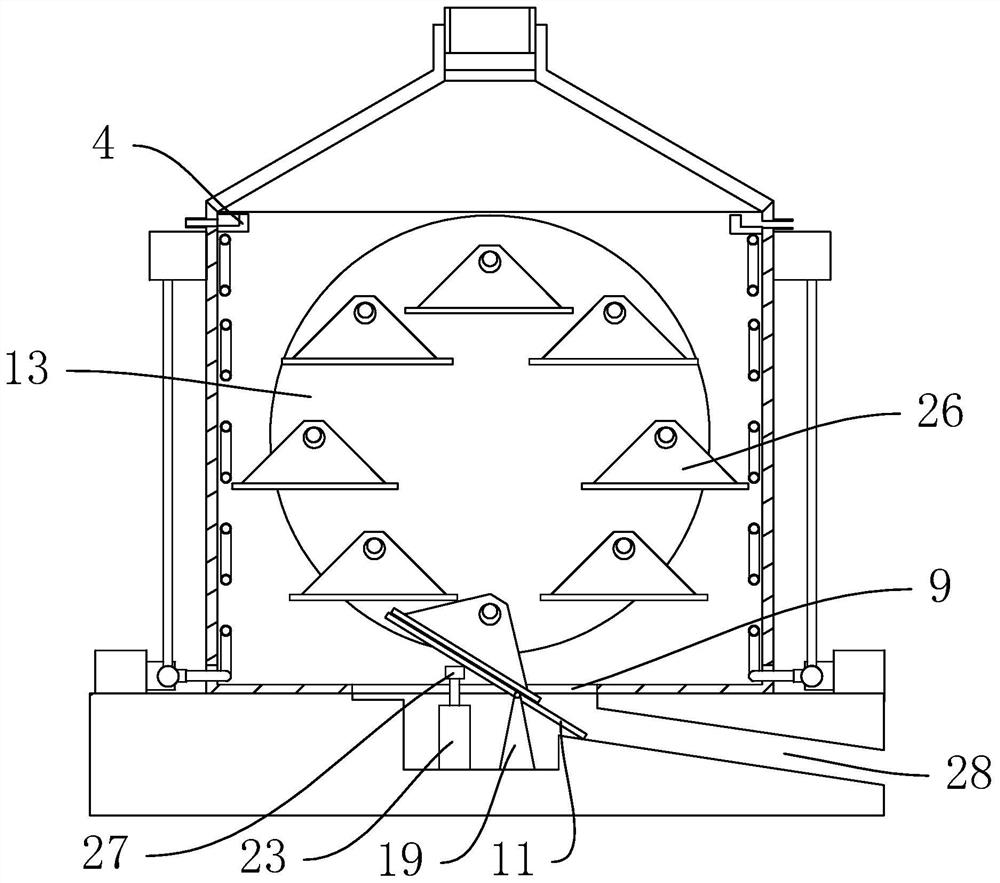

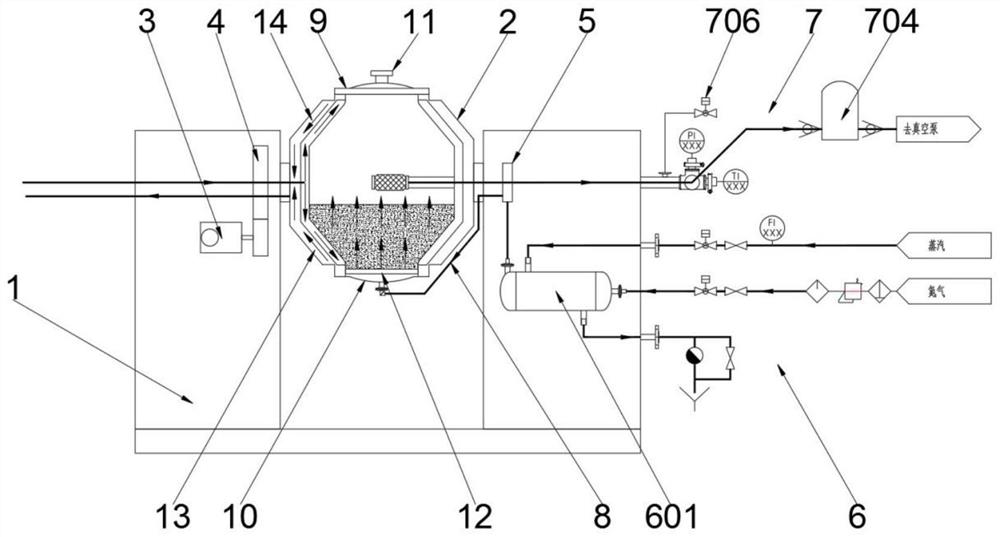

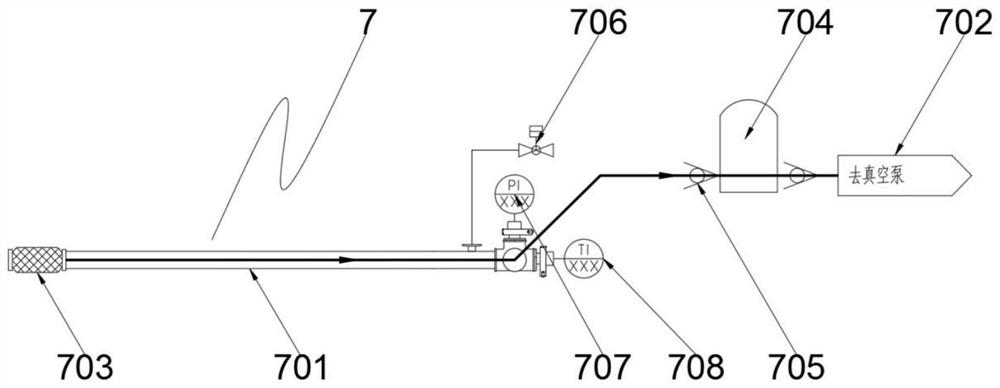

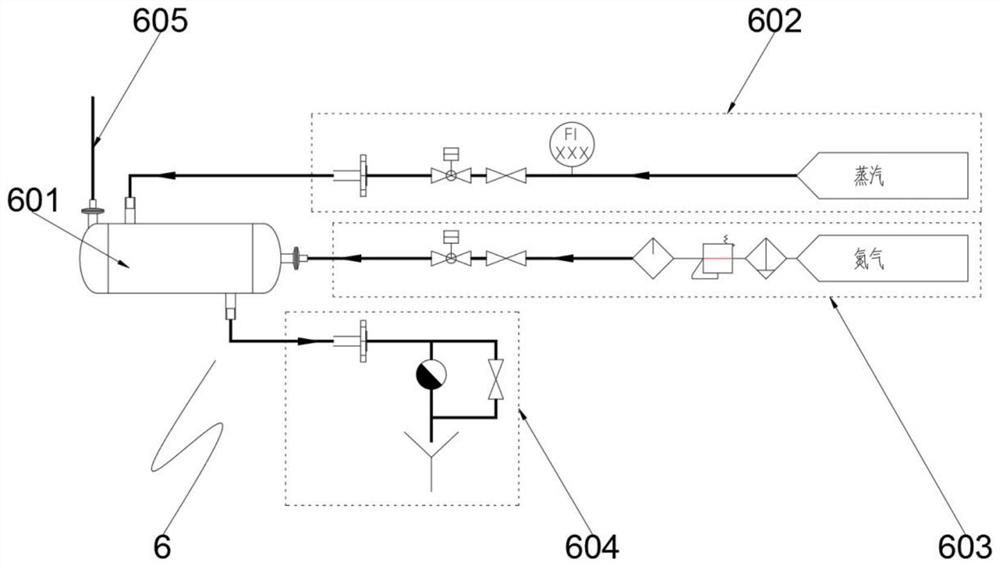

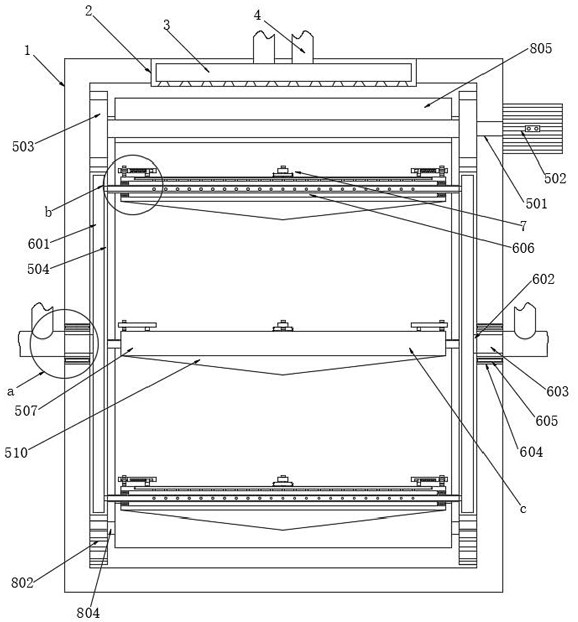

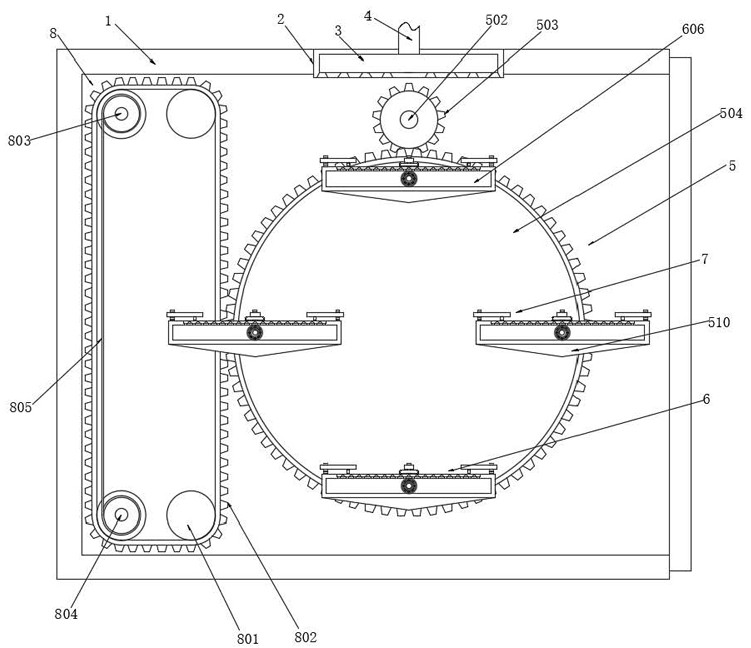

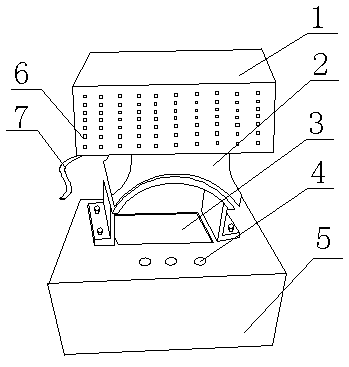

Pulsating replacement type novel vacuum dryer device

ActiveCN111637690AAvoid pollutionImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsThermodynamicsWater vapor

The invention discloses a pulsating replacement type novel vacuum dryer device and belongs to the technical field of material drying. According to the pulsating replacement type novel vacuum dryer device, a rotary tank body is subjected to hanging supporting through a rack, the end, connected with the rack, of the rotary tank body is provided with a rotary air guide device, the rotary air guide device is connected with the rotary tank body and an air supply mechanism, and the end, close to the rotary air guide device, of the rotary tank body is further provided with an air exhausting mechanismused for air exhausting vacuumizing. The pulsating replacement type novel vacuum dryer device is scientific and reasonable and safe and convenient to use, the inner portion of the rotary tank body isheated by utilizing a first clamping sleeve cavity and a heat source, indirect heating is realized, material pollution is avoided, in the material drying process, one path of inert gases heated by aheater is additionally arranged to perform convection current contact with materials inside the tank body through a pulse gas filter plate, heat exchanging is realized, meanwhile, the gases after theheat exchanging are discharged out through the air exhausting mechanism, the heated inert gases are taken as carriers of water vapor discharging after the material drying, and the material drying efficiency is improved.

Owner:CHANGZHOU AOKAI DRYING EQUIP

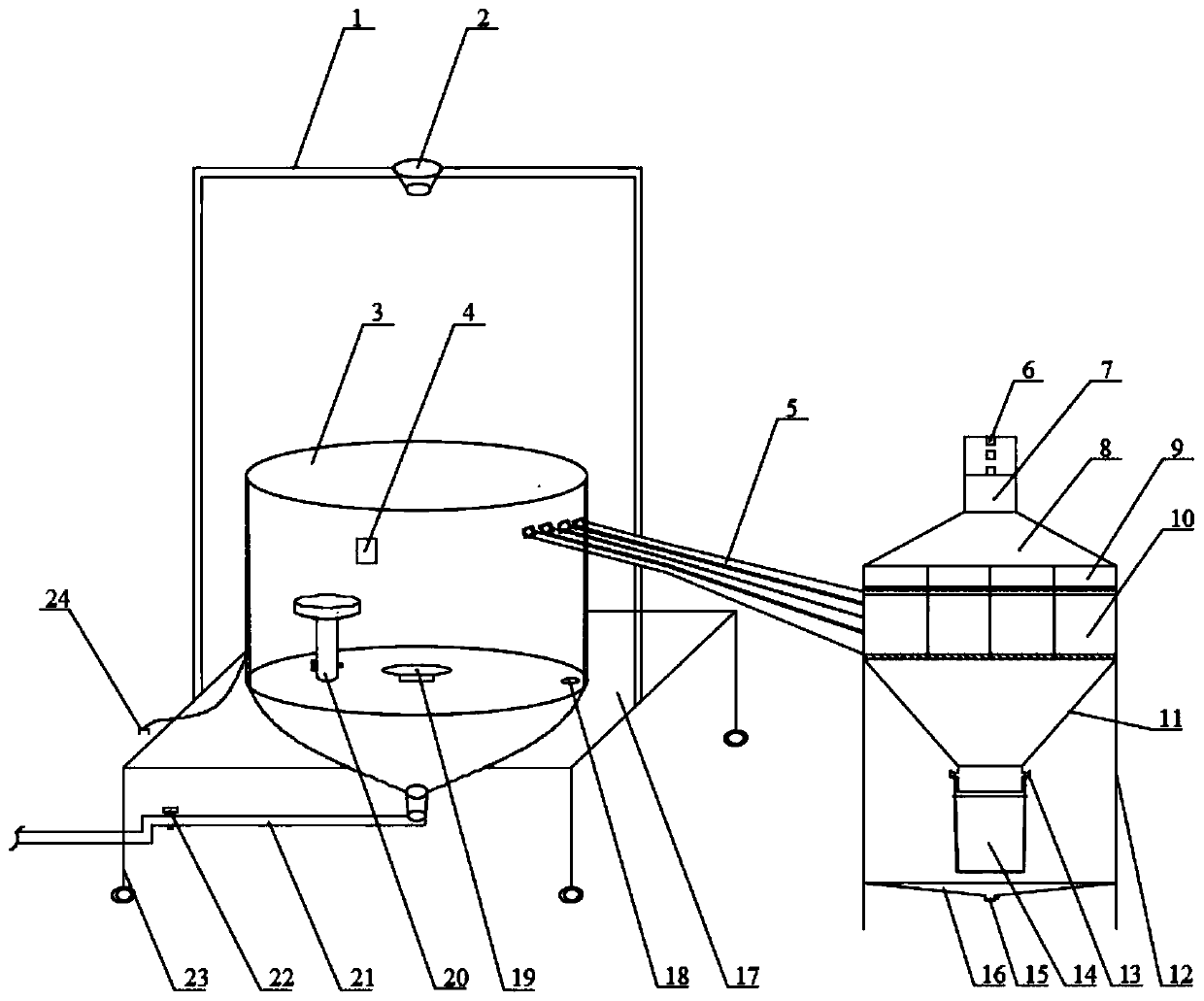

Face cream batching system

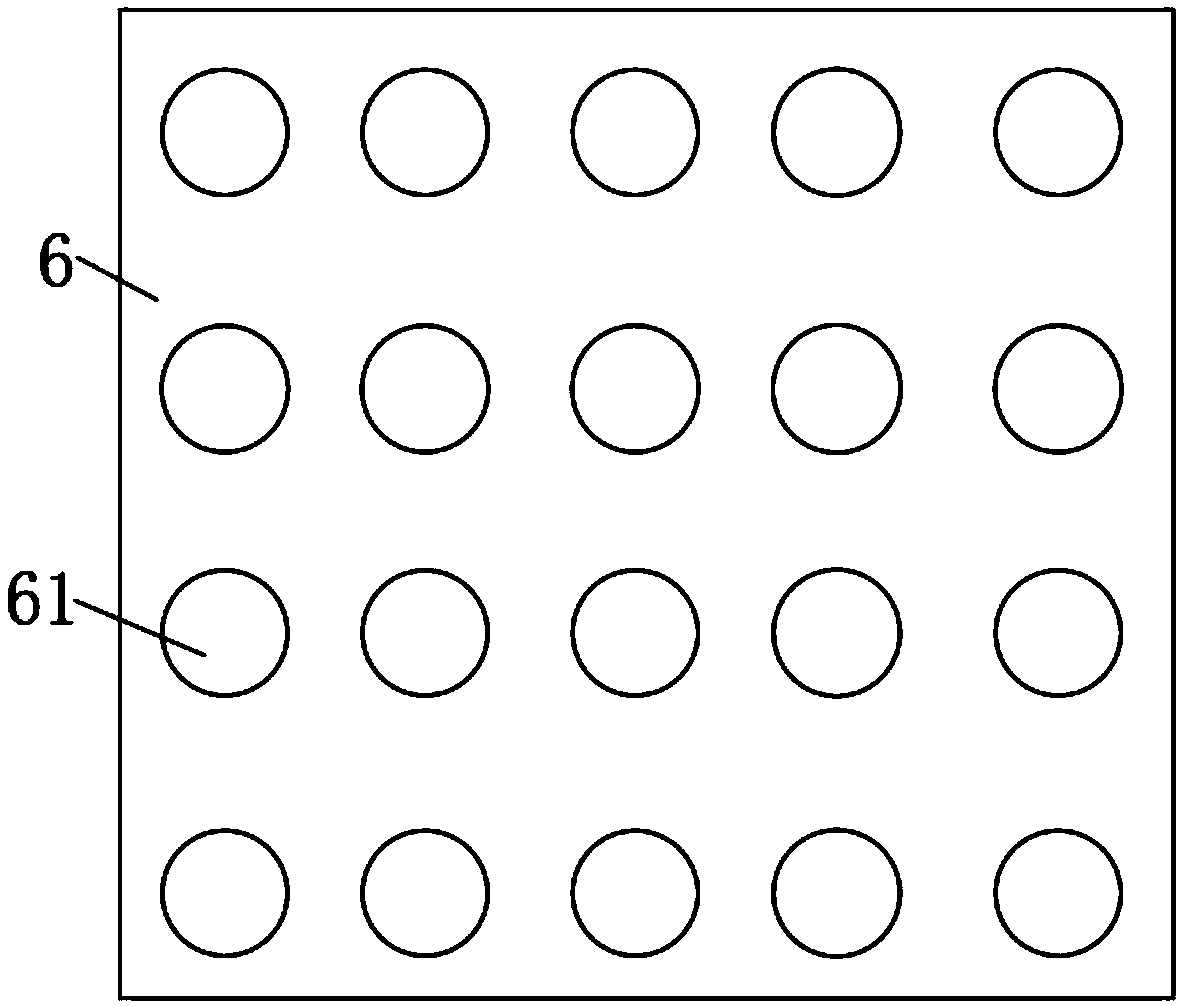

ActiveCN112539617ADrying effectDry evenly and thoroughlyDrying solid materials without heatCleaning using toolsProcess engineeringOil water

The invention discloses a face cream batching system in the technical field of face cream batching systems. The face cream batching system comprises a drying mechanism and a cleaning mechanism, the cleaning mechanism is arranged on the left side of the drying mechanism, the drying mechanism comprises a workbench, the top of the workbench is fixedly connected with a drying cylinder, the side wall of the drying cylinder is provided with a plurality of linearly arrayed water suction holes, and the top of the drying cylinder is fixedly connected with a feeding valve. According to the face cream batching system, when face cream is dried, a stirring mechanism is used for stirring the face cream so that the face cream can be evenly scattered and dried, a first rotating shaft rotates to drive an oil-water separation membrane to rotate, the face cream adhering to the surface of the oil-water separation membrane is scraped and then cleaned, the face cream is prevented from adhering to the surface of the oil-water separation membrane, the cleanliness of the oil-water separation membrane is guaranteed, the face cream adhered to the oil-water separation membrane is prevented from affecting drying of the face cream by the drying cylinder, and thorough and uniform drying of the face cream is guaranteed.

Owner:董凯辉

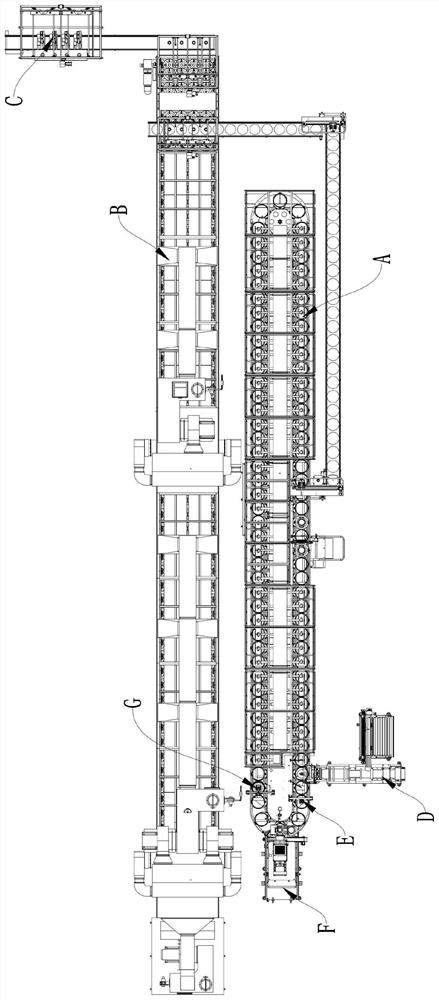

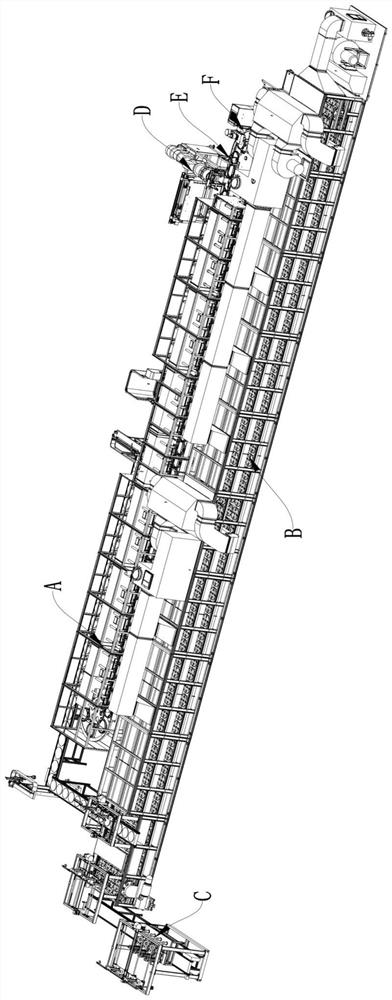

Flexible copper-clad plate electroplating device

The invention relates to the field of copper-clad plate electroplating equipment, in particular to a flexible copper-clad plate electroplating device. The flexible copper-clad plate electroplating device comprises an electroplating tank, an evaporation concentrator, a dryer, a conveying mechanism, a water-washing mechanism, a water absorbing mechanism and a preheating mechanism, wherein the electroplating tank and the water-washing mechanism are arranged adjacent to each other and are both positioned below the conveying mechanism; the evaporation concentrator is positioned besides the electroplating tank; a first liquid inlet pipe is arranged between the water-washing mechanism and the evaporation concentrator; a first liquid inlet pump is arranged on the first liquid inlet pipe; a liquidpassing pipe is arranged on one side of the electroplating tank; a first connecting pipe is arranged between the evaporation concentrator and the liquid passing pipe; the preheating mechanism comprises a recovery assembly and a preheating assembly; the recovery assembly is arranged above the electroplating tank and is connected with the preheating assembly; and the water absorbing mechanism comprises a water absorbing assembly, a first extrusion assembly and a second extrusion assembly. According to the flexible copper-clad plate electroplating device, the waste of raw materials can be effectively reduced, the cost is saved, the environment is protected, the equipment configuration is complete, and the working efficiency is improved.

Owner:铜陵蓝盾丰山微电子有限公司

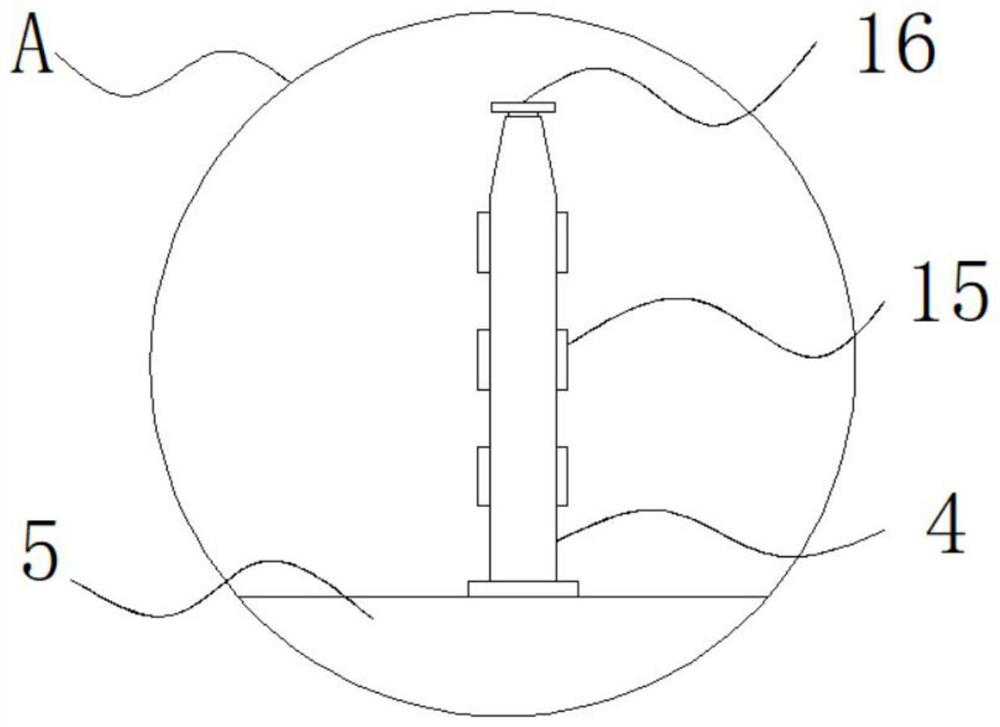

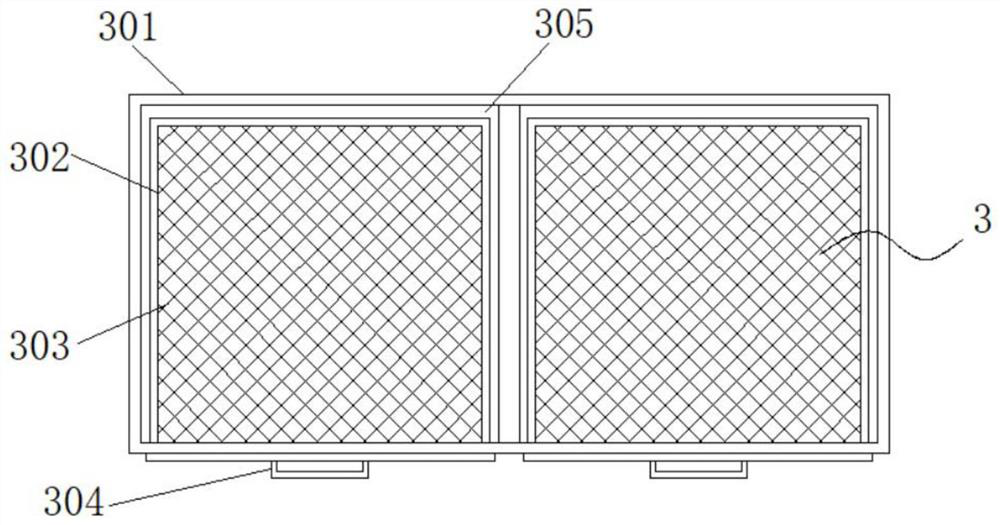

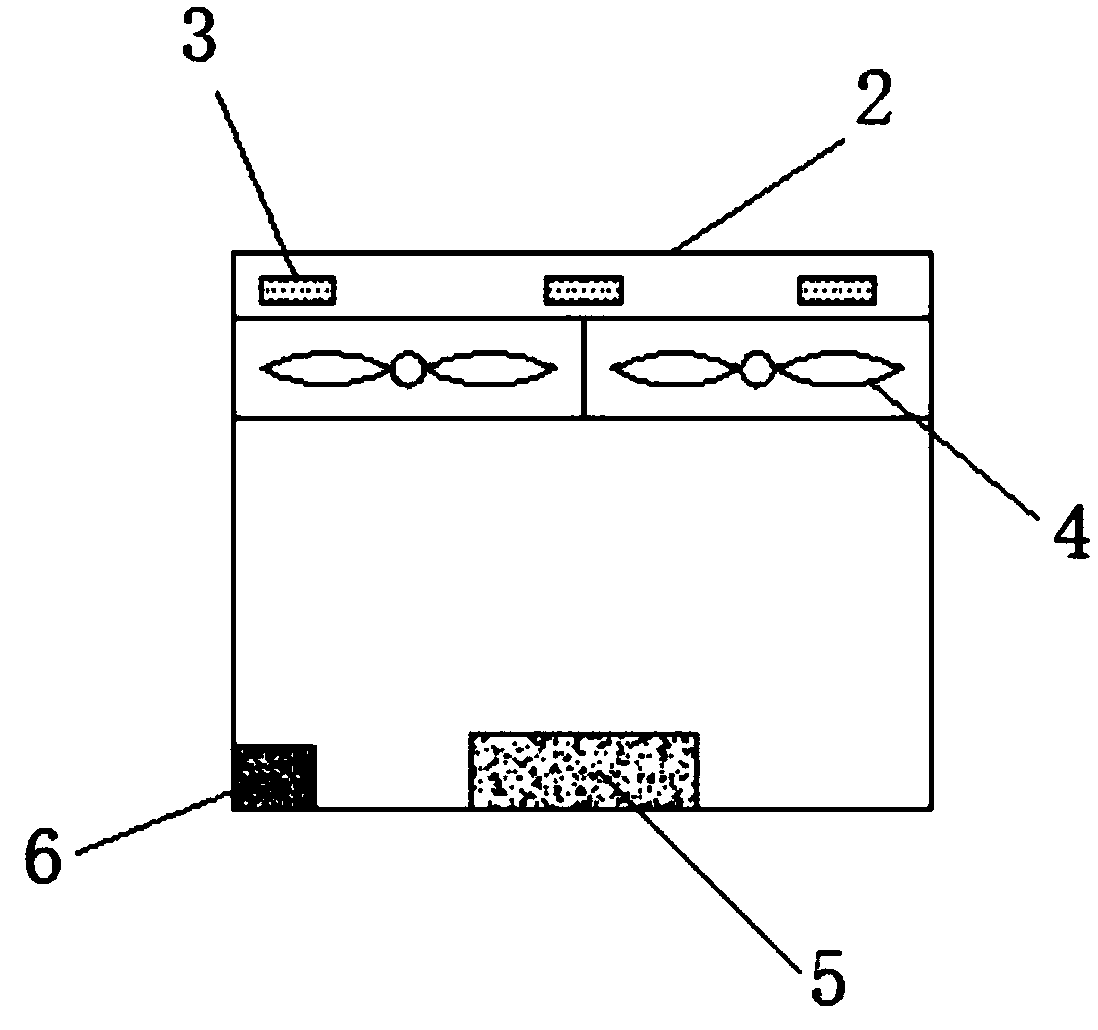

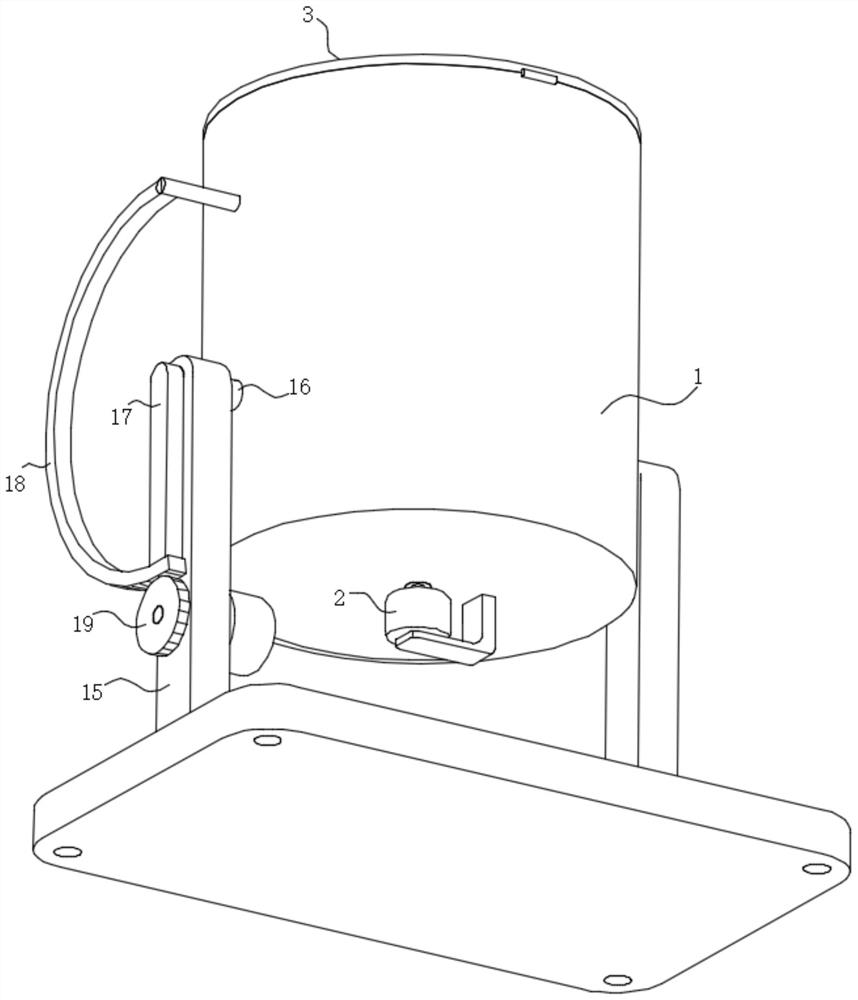

Totally-closed ink brush cleaning device

InactiveCN105291639AImprove cleaning efficiencyEasy to handleNib removersPulp and paper industryEngineering

The invention relates to a totally-closed ink brush cleaning device. The totally-closed ink brush cleaning device comprises a clear water cylinder (1) and a dirty water cylinder (2). An ink brush cylinder (3) communicated with the clear water cylinder (1) is arranged in the clear water cylinder (1) in a sleeved mode, and the ink brush cylinder (3) is communicated with the dirty water cylinder (2). The ink brush cylinder (3) is provided with a fixer (5) used for clamping an ink brush (4). The clear water cylinder (1) is further provided with a controller used for making the ink brush cylinder (3) to rotate on the axis. The totally-closed ink brush cleaning device is simple in structure, the ink brush can be cleaned rapidly, and a good cleaning effect can be achieved.

Owner:黄胡瑞

Wood drying equipment with air humidity auxiliary adjusting structure

ActiveCN113606883AReduce moisture contentIncreased ability to hold water vaporDrying gas arrangementsDrying solid materialsWater vaporSilica gel

The invention discloses wood drying equipment with an air humidity auxiliary adjusting structure, and belongs to the field of wood drying. According to the wood drying equipment with the air humidity auxiliary adjusting structure, through grooves corresponding to knocking sticks are uniformly formed in the outer wall, close to one side of a shaft rod, of a throwing groove, so that the knocking sticks penetrate through the through grooves formed in the throwing groove when rotating, drying balls in the throwing groove can be thrown out, the drying balls which are lighter in weight are arranged to fly in a drying room, a silica gel particle layer can absorb moisture in air in the drying room, the moisture content in the air in the drying room is reduced, the water vapor containing capacity of air is improved, so that the drying efficiency of the device for wet gas in wood is improved, meanwhile, the drying balls can be recycled, the use cost of the device is reduced, and resources are saved conveniently.

Owner:南通市凤杨包装制品有限公司

Energy-saving plastic particle dryer

InactiveCN105953557AImprove liquidityImprove drying efficiencyDrying gas arrangementsDrying chambers/containersElectricityTemperature control

This patent discloses an energy-saving plastic particle dryer, which relates to the technical field of plastic machinery; it includes a drying cylinder, a hot air device and a support frame, and the drying cylinder and the hot air device are connected to the support frame; the hot air device includes a heating chamber, which is located below the heating chamber The air supply pipe, and the fan connected to the heating chamber and the air supply pipe; the drying cylinder is set on the outer periphery of the air supply pipe, and the upper end of the drying cylinder is provided with a feed port, and the cover plate is detachably fixed at the feed port, and the drying The lower end of the cylinder is provided with a discharge port, which is connected with a discharge valve; the heating chamber is provided with a heating wire and a temperature control switch electrically connected with the heating wire, and the bottom of the heating chamber is provided with an air inlet, and the air inlet is also There is a drier, and a desiccant is placed in the drier; several air outlets are arranged at the lower end of the air supply pipe; in this patent, since the hot air can be continuously circulated by the fan, heat loss can be reduced and the utilization rate of heat energy can be improved.

Owner:重庆敏驰塑胶有限公司

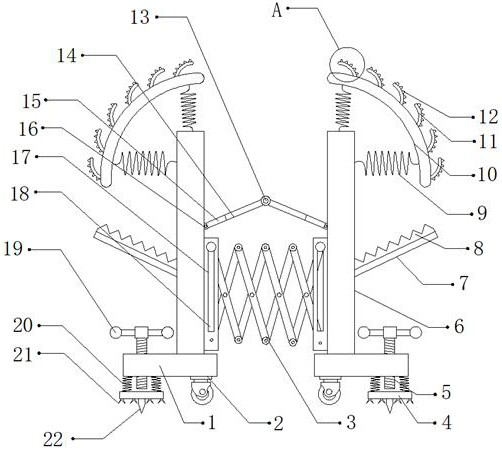

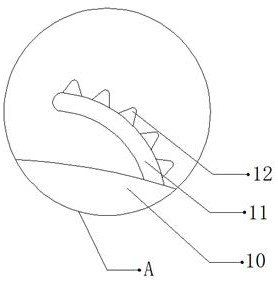

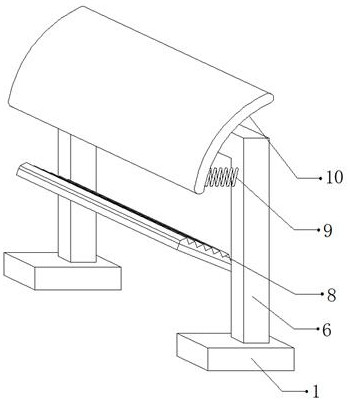

Cloth airing device for textile processing

InactiveCN111780513ADrying effectEasy to drySolar heating energyDrying chambers/containersEngineeringMechanical engineering

The invention discloses a cloth airing device for textile processing. The cloth airing device for textile processing comprises two airing rods, a lifting mechanism is fixedly connected between the outer walls of the opposite sides of the two airing rods, the lifting mechanism is composed of two fixing frames and a plurality of connecting rods, every two adjacent connecting rods are rotationally connected, fixing openings are formed in the outer walls of one sides of the two fixing frames, the fixing openings are in sliding connection with the connecting rods, first springs are fixedly connected to the outer walls of the two airing rods, airing plates are fixedly connected to the outer walls of one sides of the first springs, the two airing plates are each in an arc shape, and a plurality of barbs are fixedly connected to the outer walls of one sides of the two airing plates. According to the cloth airing device, one end of cloth can be prevented from falling on the ground to pollute the surface of the cloth, the cloth can be prevented from sliding down from the device due to the gravity of the cloth, the airing efficiency of the device on the cloth can be conveniently improved, andthe surface of a prism can be cleaned.

Owner:李立志

A wood drying equipment with an auxiliary adjustment structure for humidity in the air

ActiveCN113606883BReduce moisture contentIncreased ability to hold water vaporDrying gas arrangementsDrying solid materialsWater vaporProcess engineering

The invention discloses a wood drying device with an auxiliary adjustment structure for humidity in the air, which belongs to the field of wood drying. The outer wall of the side is evenly provided with a through groove corresponding to the percussion stick, so that when the percussion stick rotates, it passes through the through groove opened on the throwing groove, and the dry ball inside the throwing groove can be knocked out. Setting lighter drying balls to fly inside the drying room can make the silica gel particle layer absorb the moisture in the air inside the drying room, reduce the moisture content in the air inside the drying room, and improve the ability of the air to hold water vapor , so that it is beneficial to speed up the drying efficiency of the device for the humid gas inside the wood. At the same time, by setting the drying ball, it can be recycled and reused, which is beneficial to reduce the cost of the device when it is used, and is convenient to save resources.

Owner:南通市凤杨包装制品有限公司

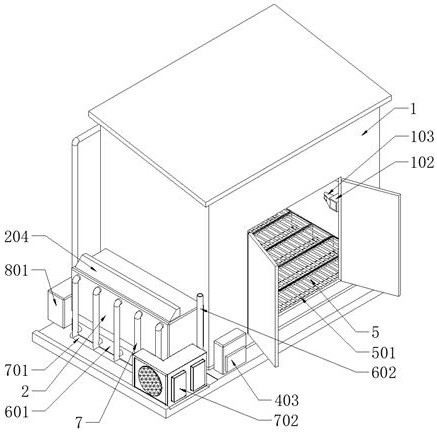

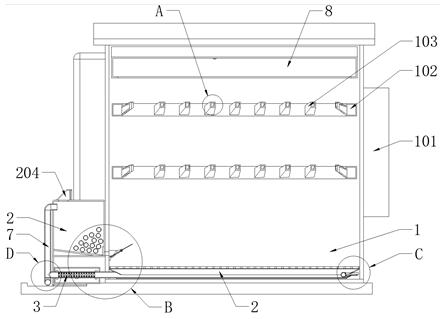

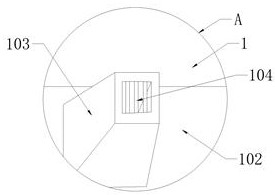

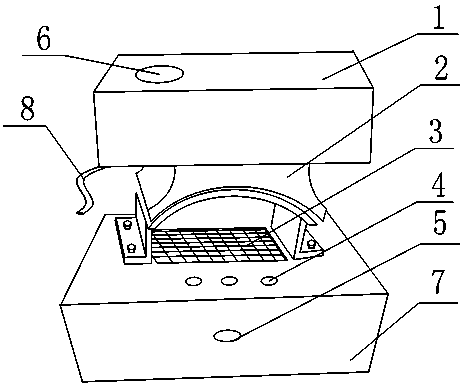

Integrated device for experimental rat water maze experiment

PendingCN110574706AAvoid mutual interferenceEasy to distinguishTaming and training devicesGrooming devicesEngineeringWorkload

The invention relates to an integrated device for an experimental rat water maze experiment. The integrated device comprises an experimental device and a drying device which are connected through a conveying belt. By reasonably combining the experimental device and the drying device of the water maze device, rats can be directly conveyed from the experimental device into the drying device after entering the water maze experiment, the rats do not need to leave the water maze environment on the premise of not influencing the carrying out of the experiment, water on the rats cannot fall onto theground of a laboratory even when the rats move back and forth, the cleanliness of the laboratory environment is kept, the operations of an experimental operator are convenient, and the experimental efficiency is effectively improved; through the design of a unit drying cage and a telescopic plate, the technical problems are solved that the experimental drying operation is difficult and the counting and managing of experimental rats are disordered, the workload of the experimental operators is greatly reduced, the distinguishing of the experimental rats is facilitated, the experimental time isshortened, and the experimental accuracy is improved.

Owner:TIANJIN KANGTING BIOLOGICAL ENG GRP CO LTD

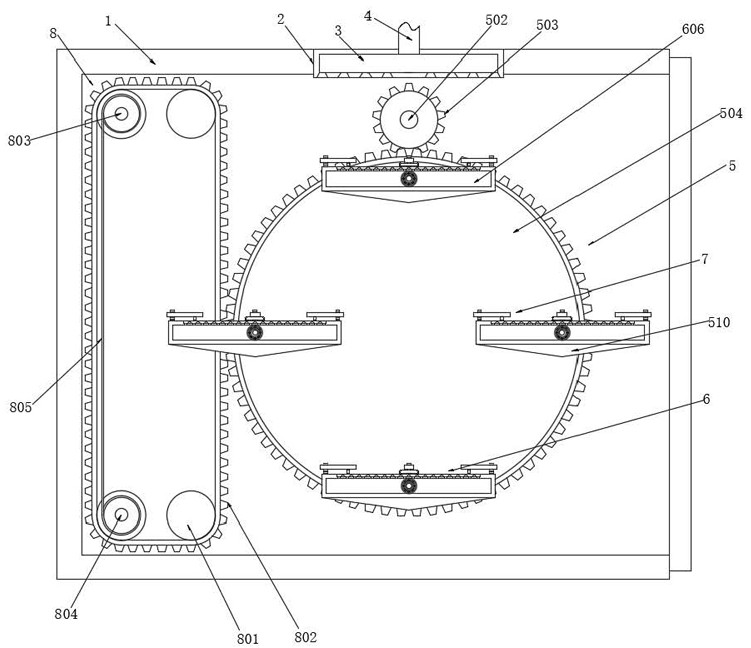

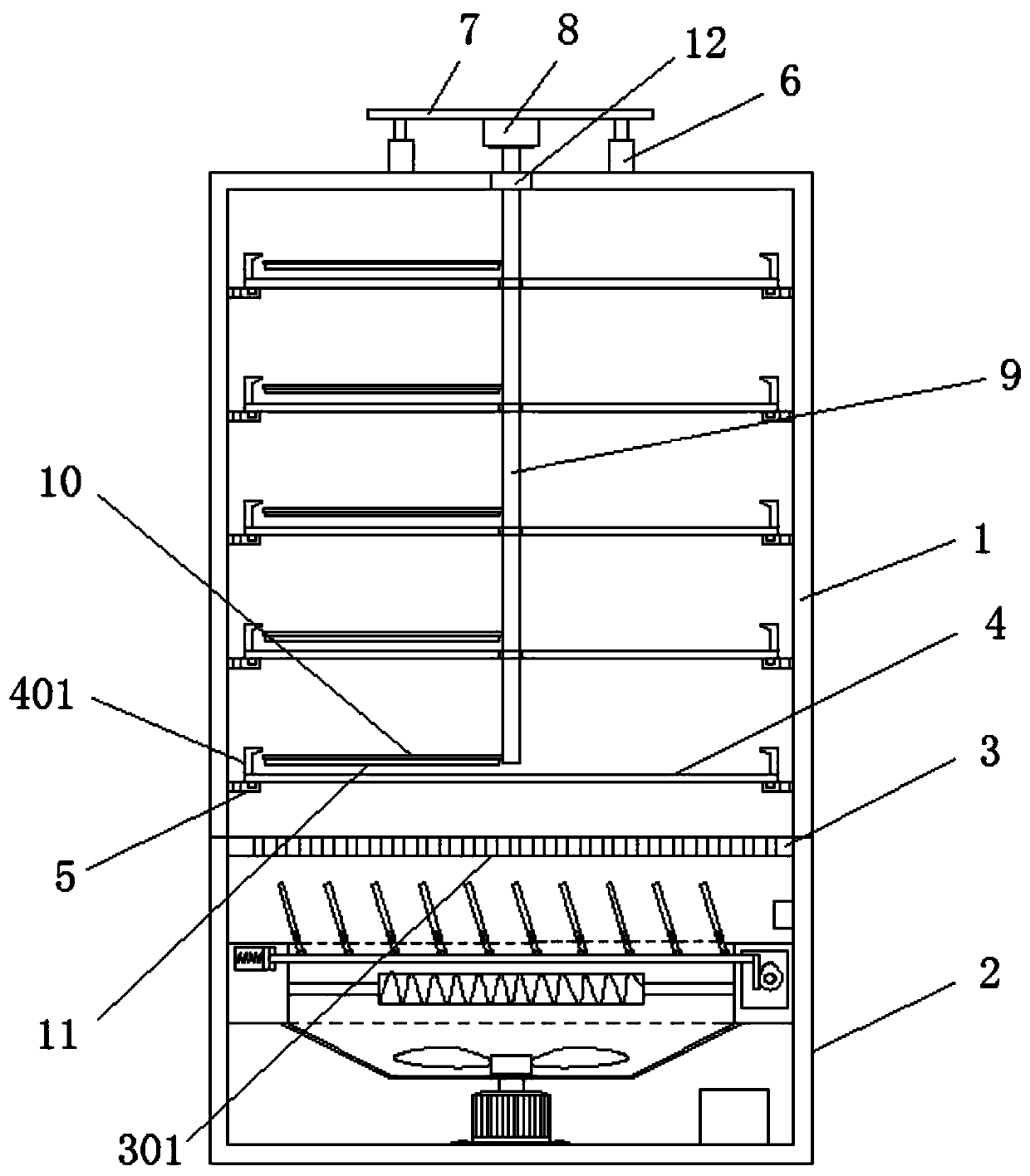

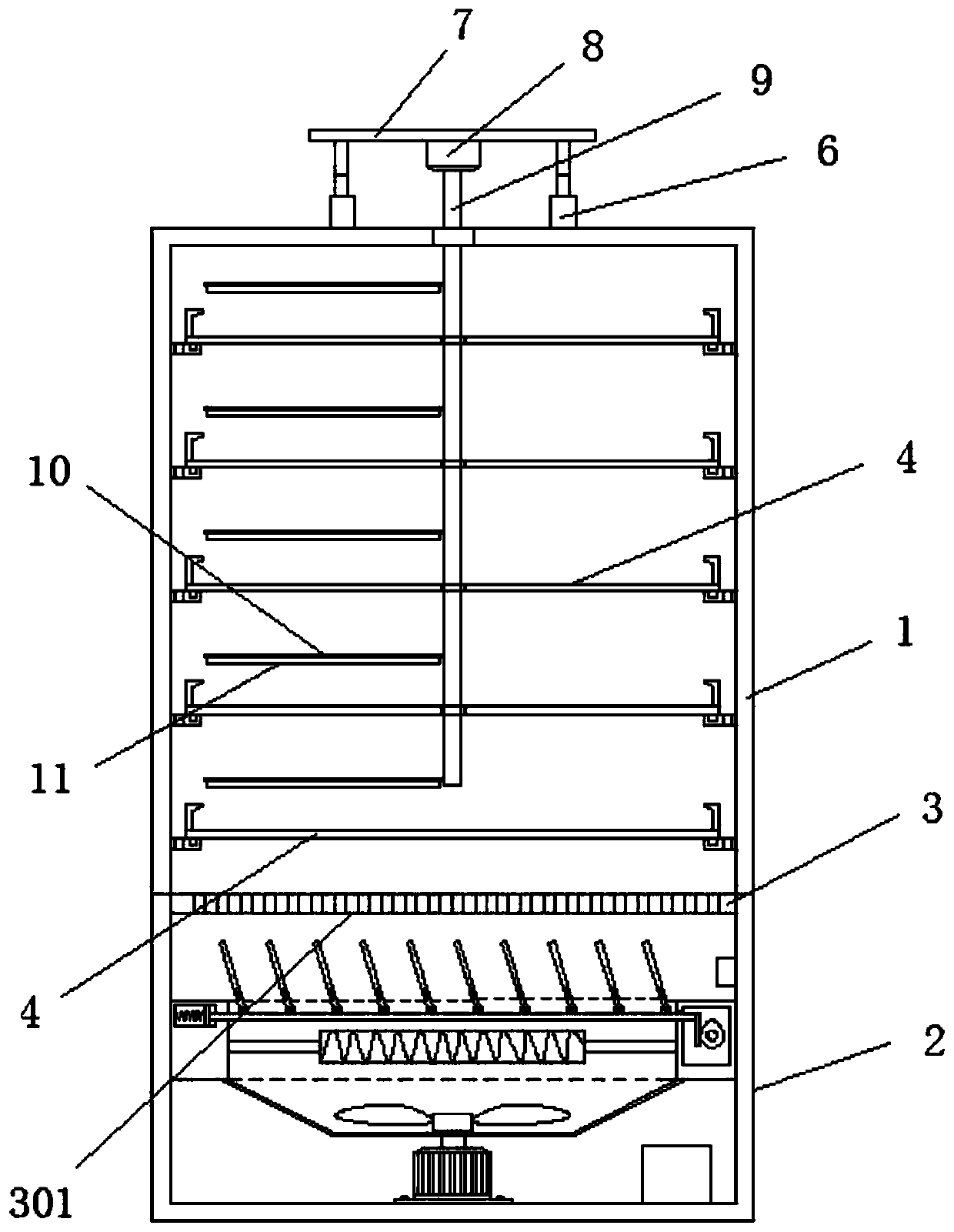

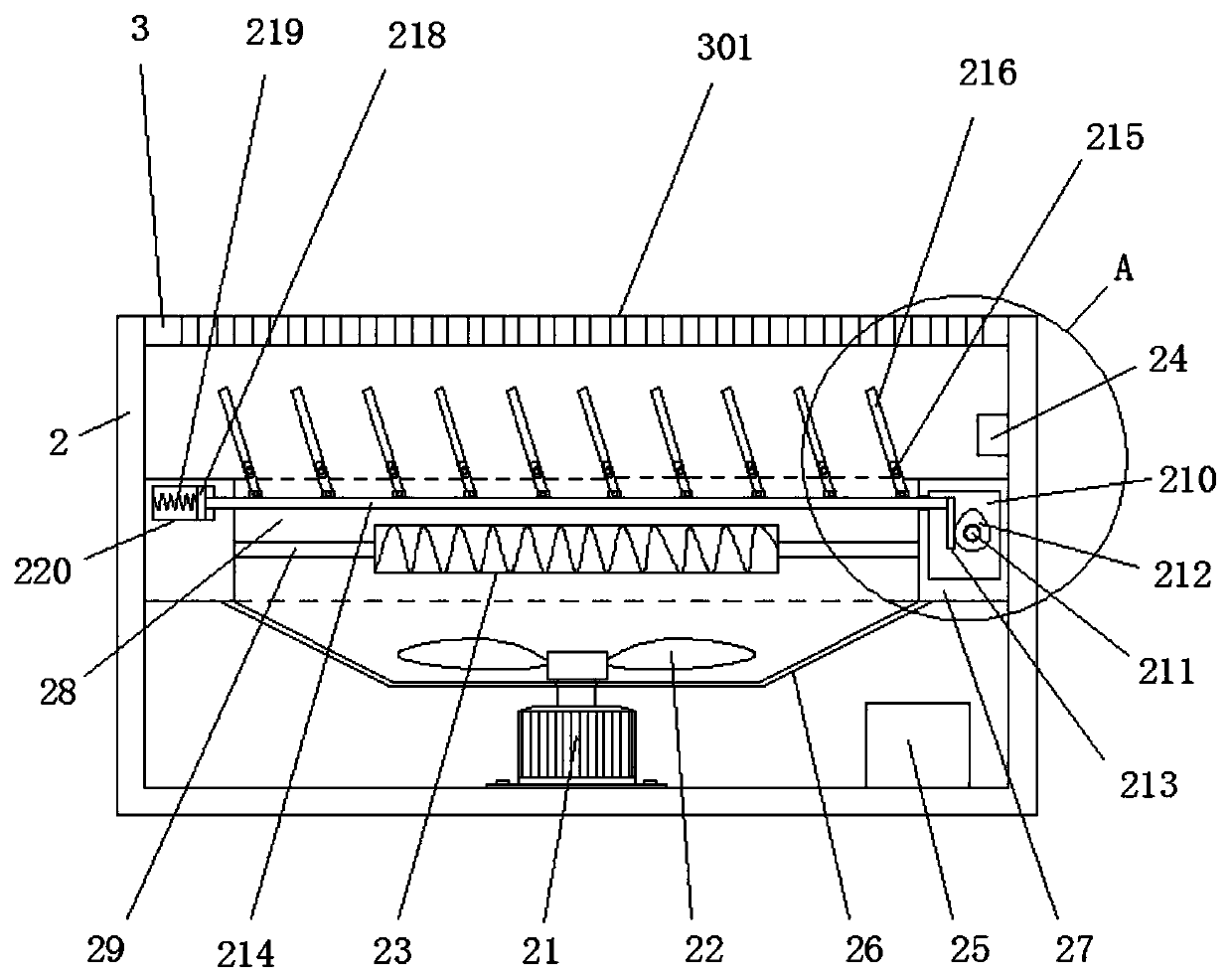

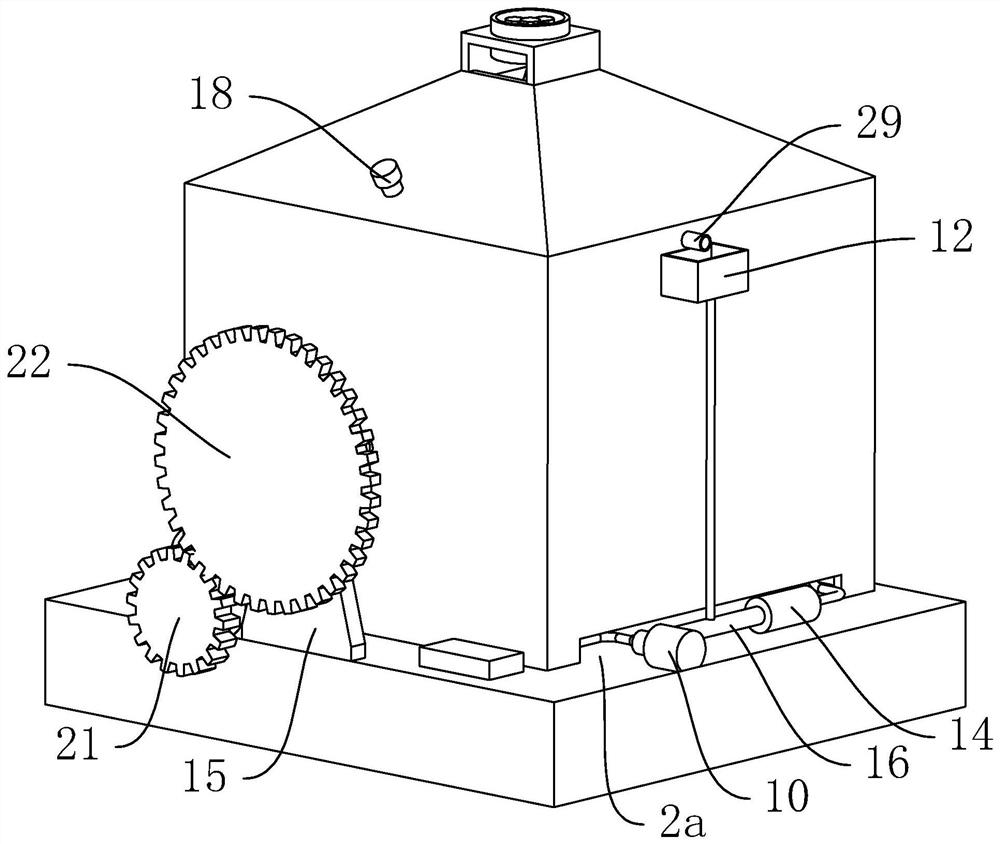

A multi-layer intelligent drying kiln for the production of ceramic tiles

ActiveCN113446835BAvoid different degrees of drynessAvoid uneven heatingDrying gas arrangementsDrying chambers/containersBrickGear wheel

The invention relates to the technical field of ceramic drying mechanical equipment for ceramic production, in particular to a multi-layer intelligent drying kiln for producing ceramic tiles, including a kiln, a uniform drying component, and a drying enhancement component. The uniform drying component is fixedly installed in the kiln , the uniform drying component is provided with a drying enhancement component. When the brick is dried in the kiln, the drive motor is started, so that the main gear drives the gear disc to rotate synchronously in the kiln. Since the gear disc is connected with a fixed pipe, thus The connecting pipe drives the mounting plate to rotate, so that the hot air jetted from the exhaust pipe can dry the bricks on the mounting plate, and is conducive to the rapid rise of the room temperature as a whole. At the same time, the connecting pipe can enter the air cavity through the connecting hole In the first chamber, with the influx of hot air in the first air chamber, the hot air can enter the fixed pipe through the communication hole, then enter the second air chamber through the air seepage hole, and finally flow out through the air outlet hole, which can dry the bottom of the brick effect.

Owner:佛山市景鑫达陶瓷机械有限公司

Energy-saving drying device for inner wall of pipeline

PendingCN112815682ACan be dried coarseRealize the collectionDrying gas arrangementsDrying chambers/containersThermodynamicsEngineering

The invention discloses an energy-saving drying device for the inner wall of a pipeline, and particularly relates to the technical field of pipeline drying. The energy-saving drying device comprises a machine body and a first cavity, wherein the first cavity, a second cavity and a third cavity are formed in the machine body, the bottom end in the third cavity is fixedly connected with a fan, and the output end of the fan is fixedly connected with a heater. According to the energy-saving drying device, drying pipes, air conveying pipes, a second exhaust pipe, air outlets and silica gel sheets are arranged, the inner walls of some pipelines with small pipe orifice diameters are difficult to dry, the drying pipes are arranged in several sets on the to-be-dried drying pipeline, the drying pipes are sleeved with the pipeline firstly, then the fan and the heater convey hot air into the conveying pipes, and the hot air in the conveying pipes is conveyed into the drying pipes through the second exhaust pipe and then is discharged from the air outlets of the drying pipes to dry the inner wall of the pipeline. According to the structure, the inner wall of the pipeline is directly dried, and the situation that the inner wall of the pipeline is insufficiently dried is avoided.

Owner:住重福惠动力机械有限公司

Environment-friendly printing and drying device for green printing of paperboards

PendingCN108645134AIncrease temperatureReduce wind speedDrying gas arrangementsDrying solid materialsPaperboardPulp and paper industry

The invention discloses an environment-friendly printing and drying device for green printing of paperboards, and relates to the technical field of printing. The drying device comprises a drying device body, the drying device body comprises a conveying frame, a drying box, an air inlet, a heating plate, an air guide plate, a cold fan, an air separation plate, air suction ports and a dust collection box, wherein the drying box is fixedly arranged on the upper side of one end of the conveying frame, the air inlet is fixedly arranged on one side of the upper end of the drying box, and the heatingplate is located below the air inlet. According to the environment-friendly printing and drying device for green printing of paperboards, on one hand, the heating plate can heat air blown into the air inlet, the hot air is used for drying the printed paper board, on the other hand, the air guide plate can guide hot air to uniformly dry the paper board, air guide holes in the air guide plate are provided with two layers, the wind speed can be slowed down when the hot air is evenly blown to the lower end, and the wind speed can be prevented from being too high, in addition, the dried paper canbe blown and aired by the cold fan, and the temperature of the dried paper is prevented from being too high.

Owner:湖州新天地印刷有限公司

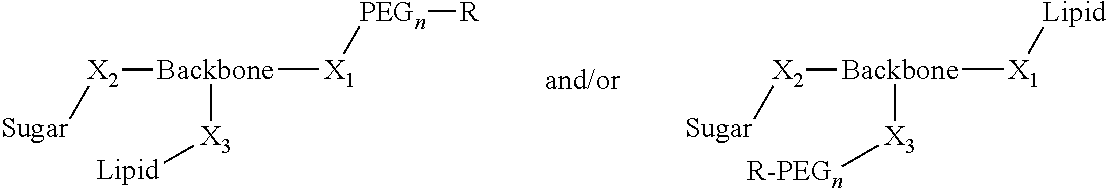

Mouth wash compositions for denture adhesive removal

InactiveUS20150023892A1Process cleaningSmooth moisture feelingCosmetic preparationsToilet preparationsMouth washLipid formation

An antiseptic, polymer-lipid or emulsification agents-based aqueous composition can be used for intraoral removal of denture adhesive residuals. More particularly, the present invention relates to employing a polymer-lipid based or a mixture of polymer-lipids and emulsification agents or a mixture of emulsification agents and Co-emulsification agents for convenient and effective removing the denture adhesive residuals intra mouth or a combination of two ore more polymer-lipids or emulsification agents or Co-emulsification agents thereof.

Owner:UKRAINIAN INDEPENDENT INFORMATION AGENCY

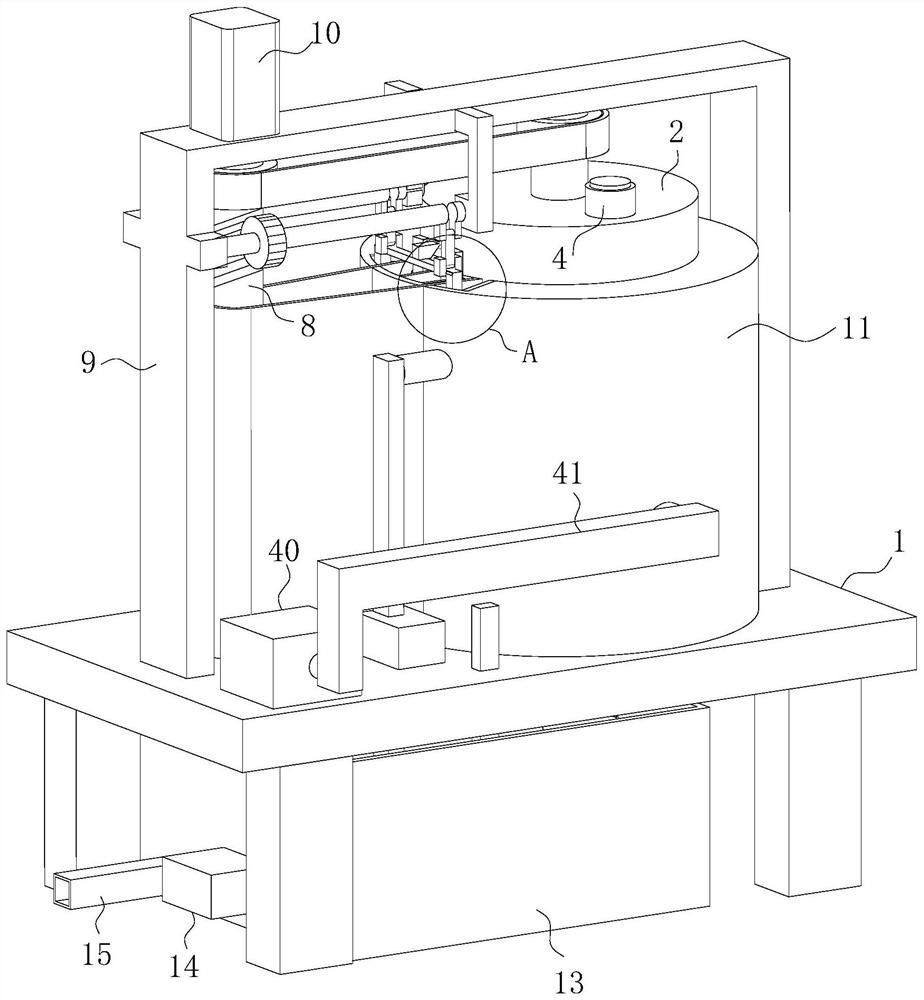

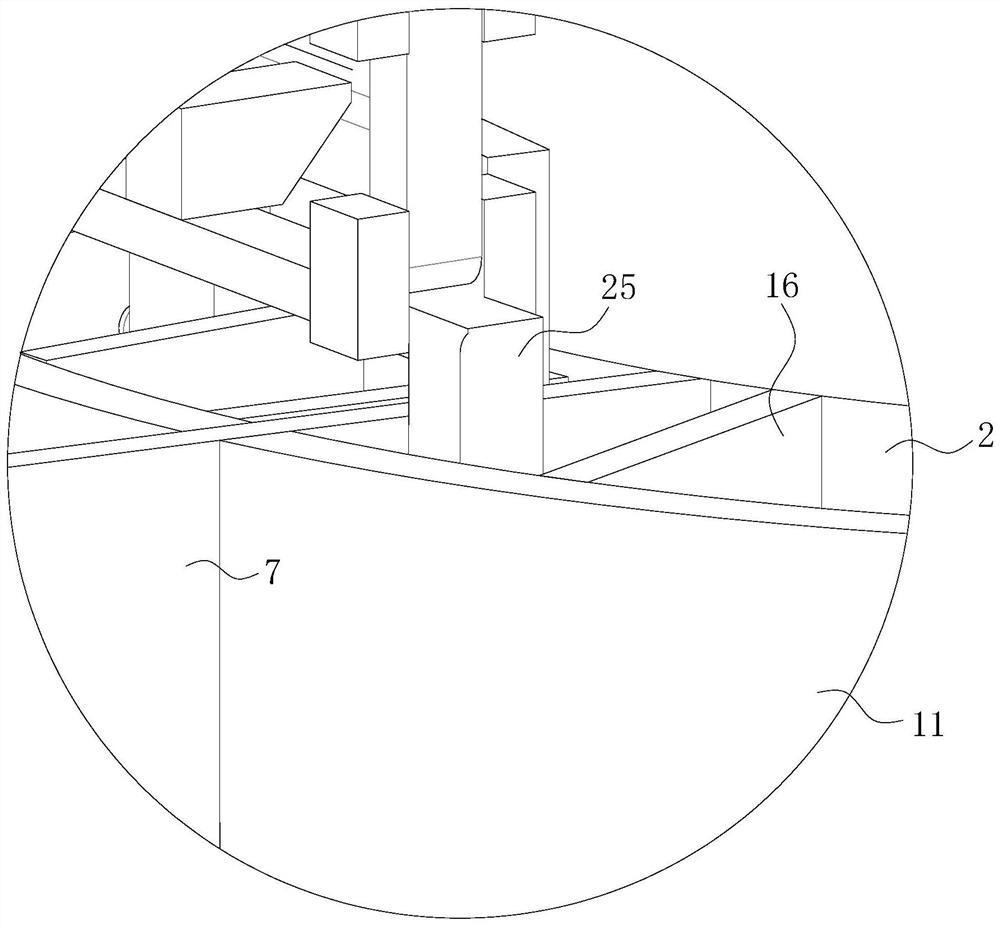

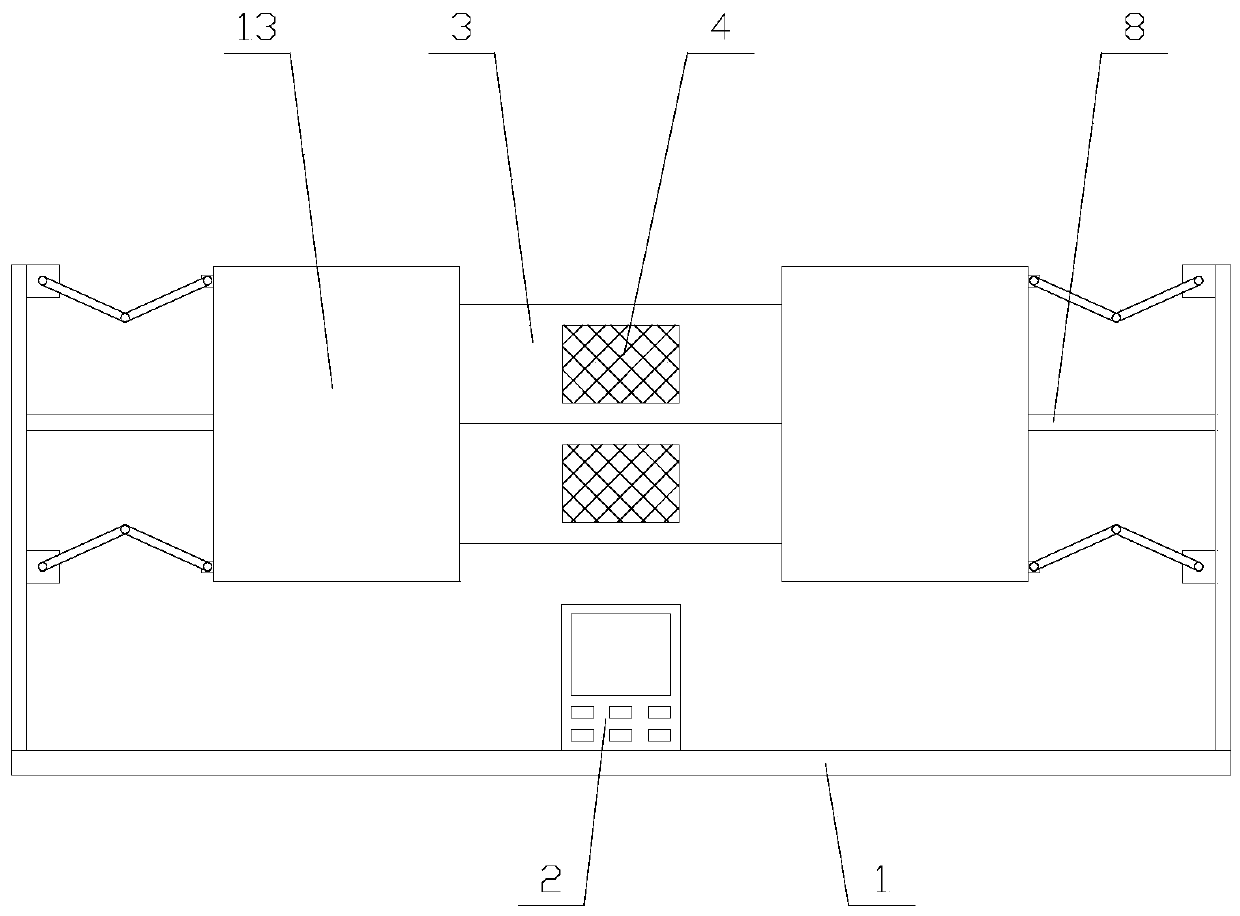

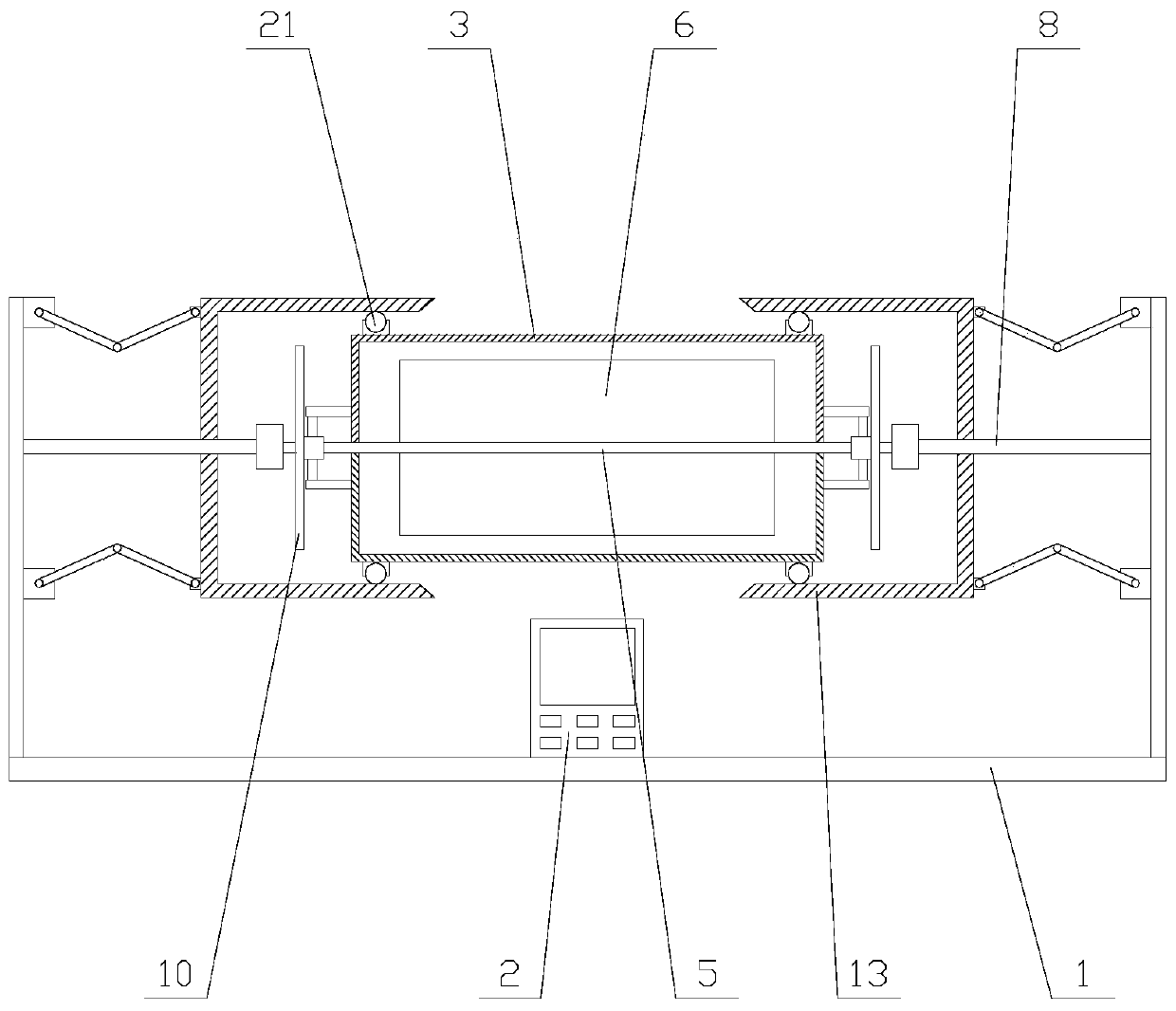

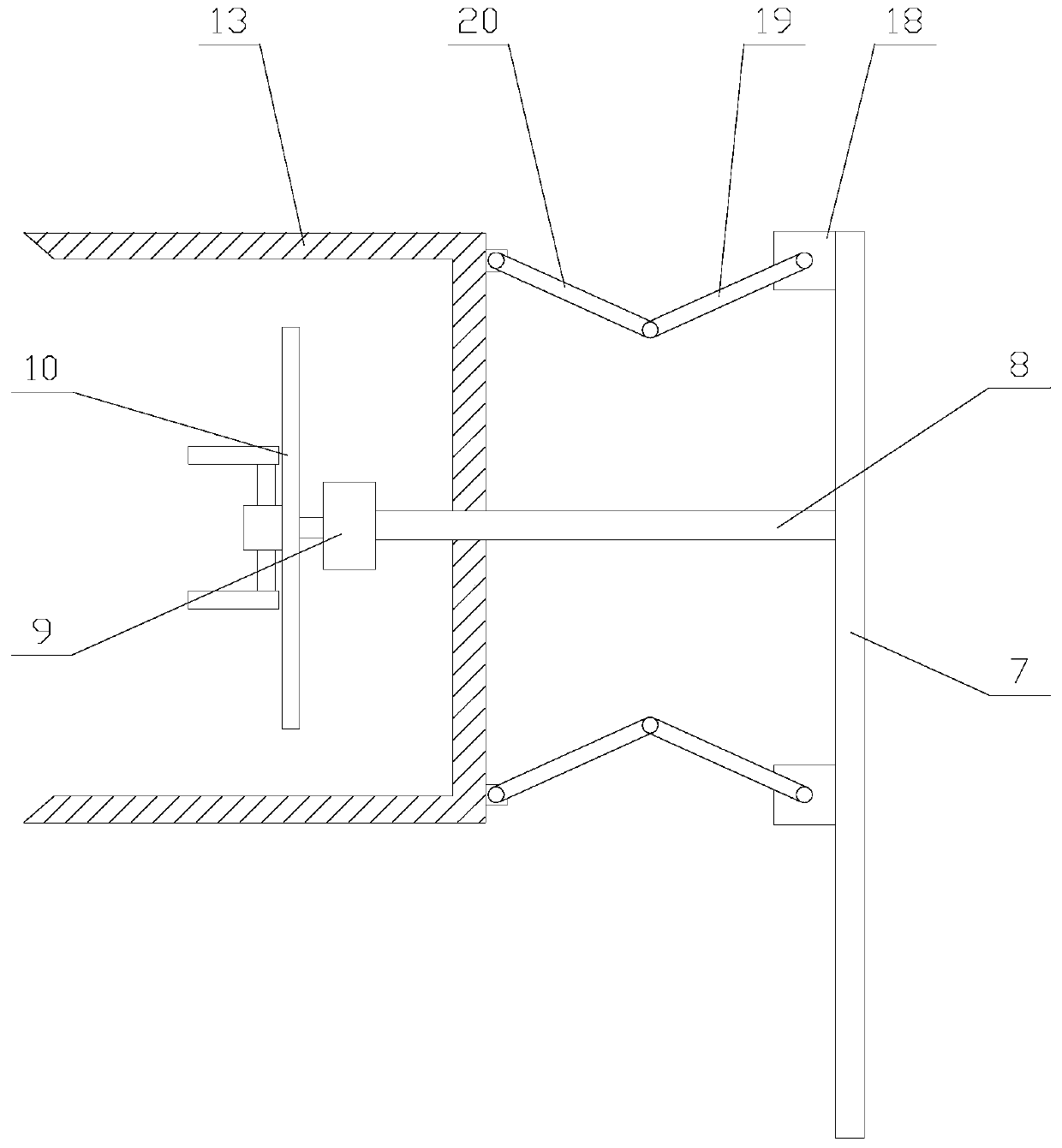

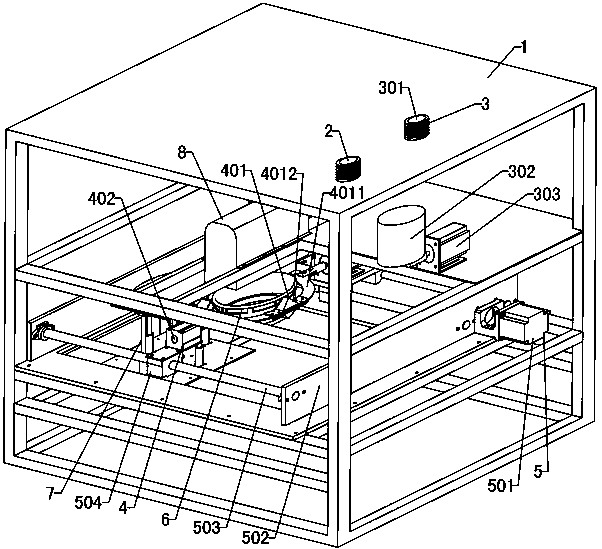

Rotary drum dryer facilitating material loading and unloading and cleaning

ActiveCN111365965ADrying effectDrying smoothlyDrying chambers/containersDrying machines with non-progressive movementsElectric machineryStructural engineering

The invention relates to a rotary drum dryer facilitating material loading and unloading and cleaning. The rotary drum dryer comprises a base, a control cabinet, two drum bodies and two supporting devices, each supporting device comprises a supporting plate, a transverse shaft, a first motor, a rotating disc, a reinforcing mechanism and an aggregation mechanism, each aggregation mechanism comprises a drive assembly and two aggregation assemblies, each aggregation assembly comprises a connecting plate and two supporting rods, and each reinforcing mechanism comprises a reinforcing pipe and two stretching and retracting assemblies. According to the rotary drum dryer facilitating material loading and unloading and cleaning, the two drum bodies can be driven to get close to or far away from each other through the aggregation mechanisms, when the two drum bodies are separated, materials can be conveniently loaded and unloaded, the interiors of the drum bodies can be conveniently cleaned, inaddition, after the two drum bodies stay close together, the reinforcing pipes can be driven through the reinforcing mechanisms to move to sleeve the two drum bodies, the sutiation that drying of thematerials is influenced by the separation of the two drum bodies is avoided, drying of the materials in the two drum bodies is ensured to be smoothly carried out, and therefore the practicability of the equipment is improved.

Owner:临沂振峰化工有限公司

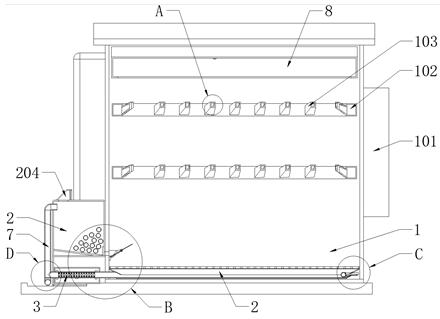

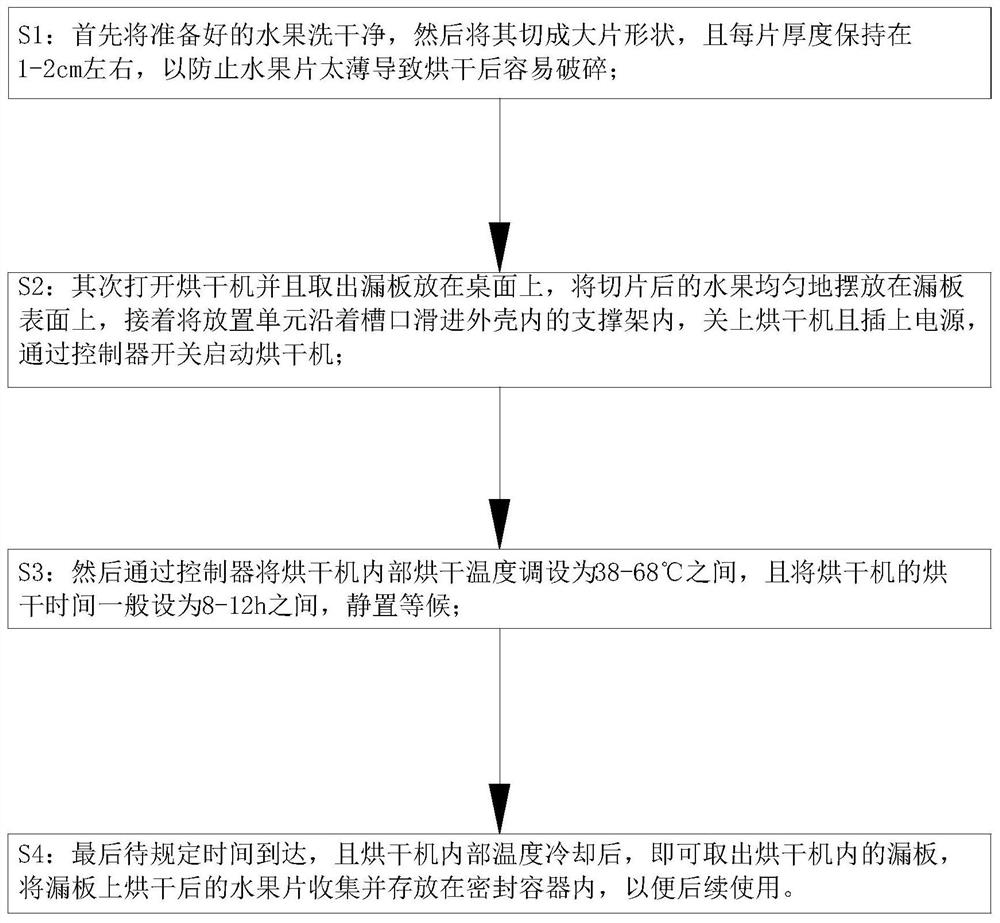

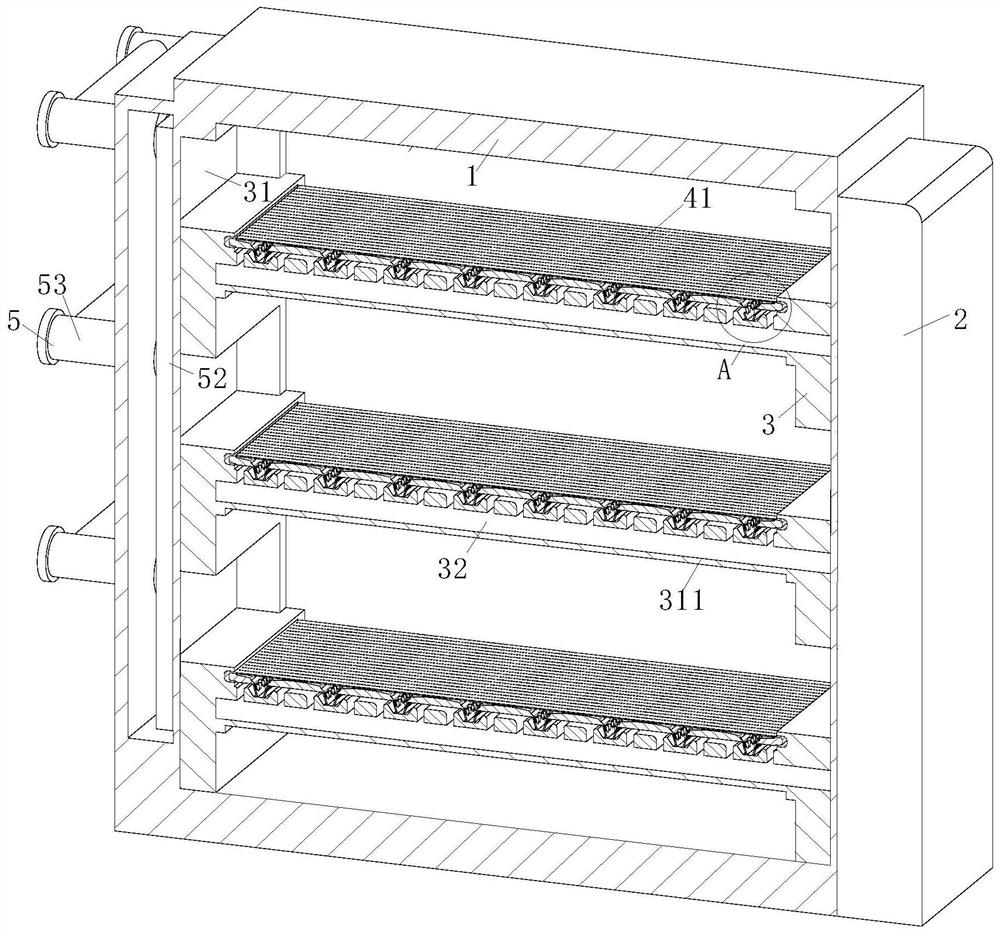

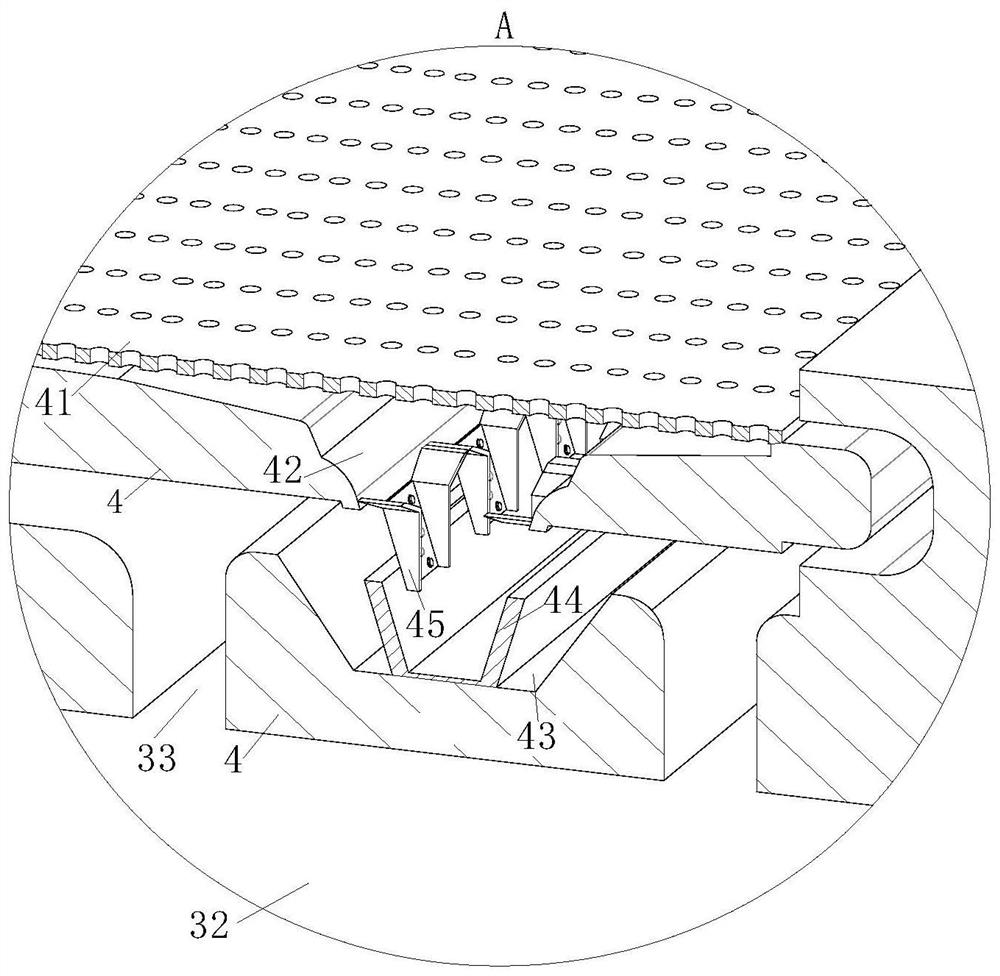

Fruit tea processing equipment and method

ActiveCN113974185AFully dryImprove drying efficiencyTea substituesFood treatmentBiotechnologyEngineering

The invention relates to the technical field of fruit tea drying, in particular to fruit tea processing equipment and method. The equipment comprises a shell and an air heater, wherein the air heater is installed on the outer wall of the right side of the shell and used for continuously injecting dry hot air into the shell, the interior of the shell comprises a bracket unit, a placing unit and a circulation unit, and the placing unit comprises a leakage plate. According to the invention, by arranging a first notch, a long hole, a second notch, a placing unit, a fifth notch, a collecting container and a leakage plate, one part of hot air directly passes through the first notch to dry the surfaces of fruit slices, the other part of hot air moves in the long hole, the hot air is diffused to the bottom of the placing unit through the second notch, along with diffusion of the hot air, and the hot air diffuses into the collecting container through the fourth notch, and moves upwards in the collecting container, so that the hot air dries the bottoms of the fruit slices through the vent holes in the leakage plate so as to ensure the effect of fully drying the fruit slices.

Owner:上海臻敬实业有限公司

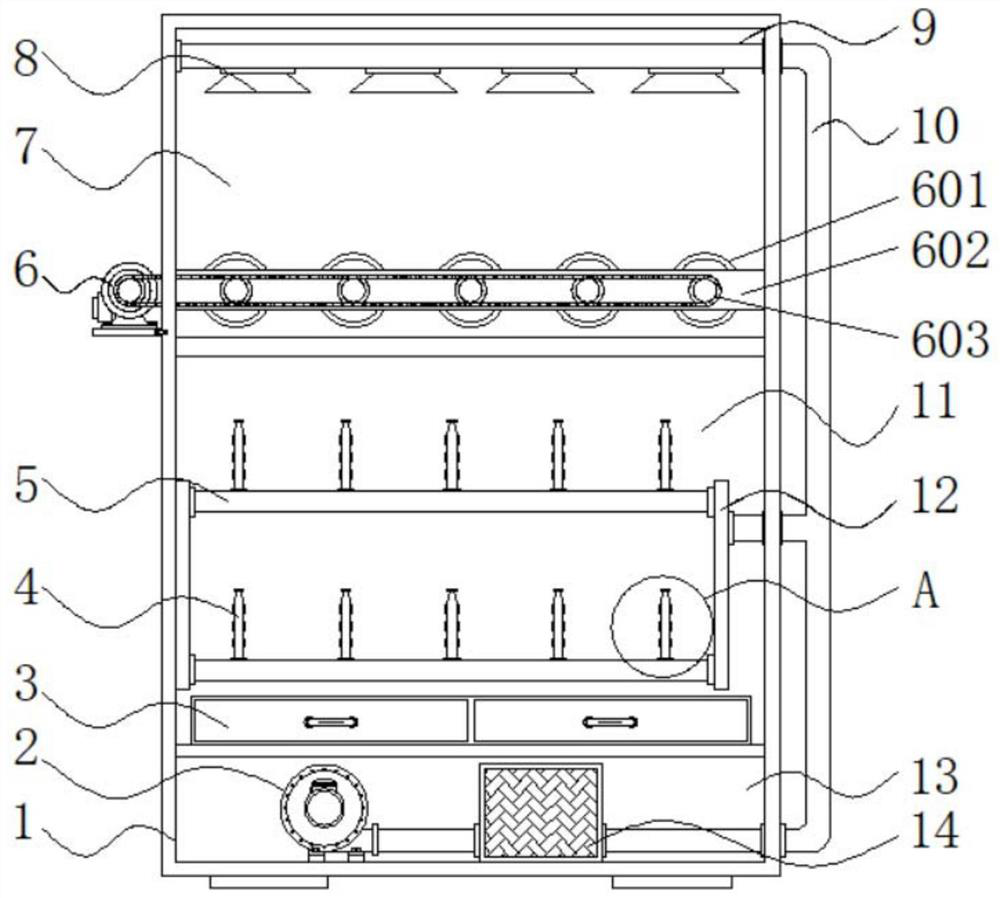

Drug drying box of automatic pharmaceutical machine

InactiveCN111504029AAvoid the hassle of manually dispensing medicationEasy to operateDrying gas arrangementsDrying chambers/containersThermodynamicsHeat flow

The invention discloses a drug drying box of an automatic pharmaceutical machine. The drug drying box comprises a drying box body and a bottom box arranged at the bottom of the drying box body. A heating and drying mechanism is arranged in the bottom box. A heat radiation plate is arranged between the drying box body and the bottom box, and multiple heat radiation holes are formed in the heat radiation plate. In the drug drying device, drugs placed on drying trays can be rotated and evenly spread, so that drugs are prevented from being gathered at a certain position of the drying trays, the trouble that previously, drugs need to be spread manually is avoided, and operation is quite simple and sanitary; through left-and-right swing of a hot flow guide plate, hot airflow generated during heating can be subjected to overall left-and-right flow guide and heat radiation; and thus, the hot flow, generated after heating, in the drying box body can be subjected to even heat radiation, the boundedness that the hot flow heat radiation area is small is avoided, the arrange of hot flow heat radiation is widened, the overall drying efficiency can be improved easily, and then the overall dryingspeed of drugs is increased.

Owner:山东药品食品职业学院

Drying and winding equipment for leather fabric

PendingCN108165675AReduce workloadEfficient dryingSkins/hides/leather/fur manufacturing apparatusLeather dryingPulp and paper industryConductor Coil

The invention discloses drying and winding equipment for a leather fabric. The drying and winding equipment comprises a worktable and a drying box. The top end of the worktable is fixedly connected with the drying box, heating pieces are fixedly arranged at the top end in the drying box, and fans are fixedly arranged at the bottom ends of the heating pieces; the bottom end in the drying box is fixedly connected with a dehumidifier, and a temperature sensor is fixedly arranged on one side of the dehumidifier; a discharging roller is fixedly arranged on one side of the worktable; supporting columns are fixedly arranged on the two sides of the drying box, and the inner side walls of the supporting columns are rotatably connected with a pressing roller; and a winding roller is arranged on theinner side wall of one end of the worktable. The design is novel, and the structure is simple; firstly, the leather fabric can be rapidly wound while dried, and the capability of well protecting the leather fabric is achieved, so that the leather fabric is not liable to be damaged; and secondly, operators can conveniently operate the drying and winding equipment, and the overall processing efficiency of the leather fabric is improved.

Owner:杭州德洋高分子材料有限公司

A kind of drying equipment for granular materials

ActiveCN110631354BHeating evenlyEvenly heatedDrying gas arrangementsDrying chambers/containersExpansion tankThermodynamics

The invention provides a drying device for granular materials, which belongs to the technical field of machinery. It solves technical problems such as uneven heating of materials during drying in existing drying devices. The drying equipment for granular materials includes a frame, which is characterized in that a drying box is fixed on the frame, the side of the drying box has an operation port, and the drying box is also hinged to be operated. The box door with the closed mouth is provided with a handle, the bottom of the drying box has a feeding structure, the top of the drying box is connected with a box cover, and the box cover is provided with an air outlet. A number of air inlets, a rotary placement mechanism for placing granular materials on the drying box, and a number of water heating mechanisms that can heat the drying box are also installed on the rack. The water heating mechanism includes water heat pipes, water pumps, Expansion tank, heater, connecting pipe and thermometer. The invention has the characteristics of uniform heating of materials and high drying efficiency.

Owner:沅陵县家其农业有限责任公司

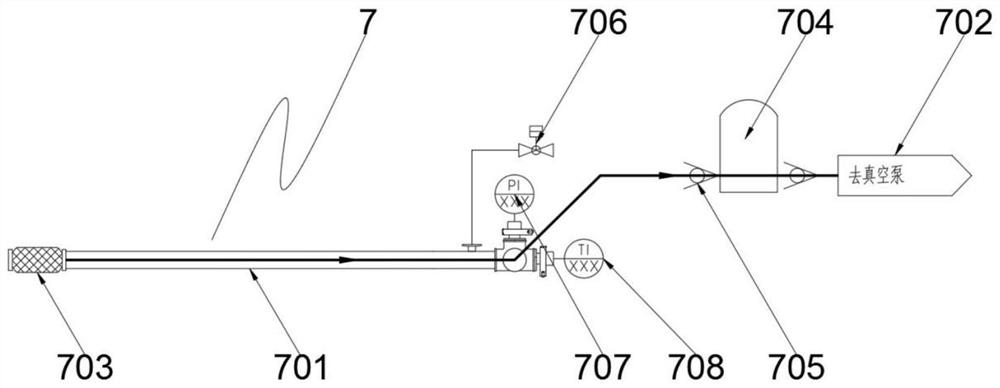

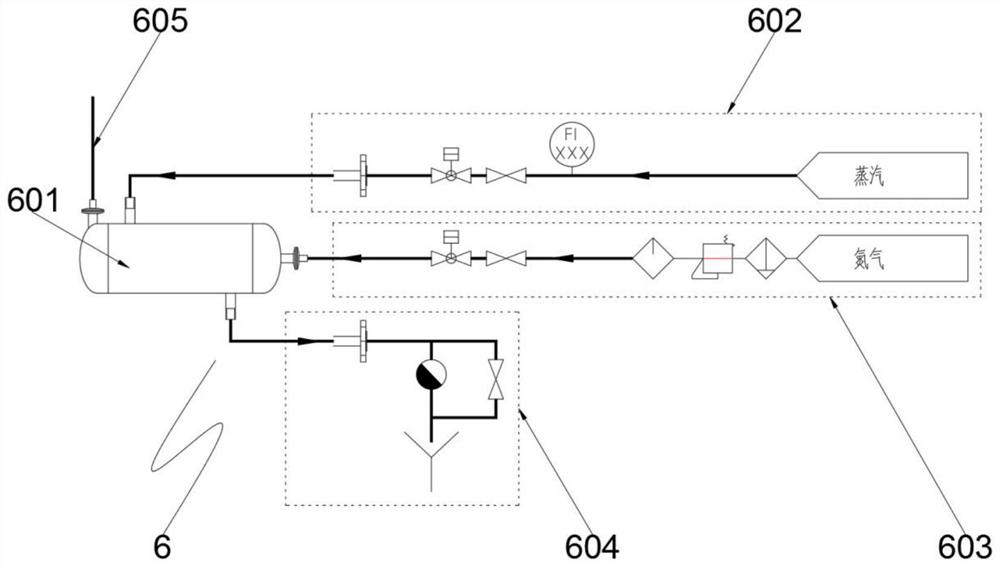

A pulsating displacement vacuum dryer device

ActiveCN111637690BAvoid pollutionImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsThermodynamicsWater vapor

The invention discloses a pulsating displacement vacuum dryer device, which belongs to the technical field of material drying. The rotary tank body is supported in the air by a frame, and a rotary air guiding device is arranged at one end of the rotary tank body connected to the frame , the rotary air guide device is connected to the rotary tank body and the air supply mechanism, and the end of the rotary tank body close to the rotary air guide device is also provided with an exhaust mechanism for exhausting and vacuuming. The invention is scientific and reasonable, safe and convenient to use , using the cavity of the first jacket and the heat source to heat the inside of the rotary tank to realize indirect heating and avoid polluting the material. The materials in the tank are in convective contact to realize heat exchange. At the same time, the gas after heat exchange is discharged through the exhaust mechanism, and the heated inert gas is used as the carrier for the water vapor discharge after the material is dried, so as to improve the drying efficiency of the material.

Owner:CHANGZHOU AOKAI DRYING EQUIP

Multi-layer intelligent drying kiln for ceramic tile production

ActiveCN113446835AAvoid different degrees of drynessAvoid uneven heatingDrying gas arrangementsDrying chambers/containersGear driveGear wheel

The invention relates to the technical field of ceramic drying mechanical equipment for ceramic production, in particular to a multi-layer intelligent drying kiln for ceramic tile production. The multi-layer intelligent drying kiln comprises a kiln body, a uniform drying assembly and drying enhancing assemblies, wherein the uniform drying assembly is fixedly arranged in the kiln body, and the drying enhancing assemblies are arranged on the uniform drying assembly. When tile billets are dried in the kiln body, a driving motor is started, a main gear drives gear discs to synchronously rotate in the kiln body, and fixing pipes are connected between the gear discs, so that mounting plates are driven to rotate through connecting pipes, the tile billets on the mounting plates can be dried by hot air flow jetted by an exhaust pipe, and the overall room temperature favorably rises rapidly; and meanwhile, the hot air flow can enter air cavities I via connecting holes through the connecting pipes, as a large amount of hot air flow flows into the air cavities I, the hot air flow can enter the fixing pipes through communicating holes, then enters air cavities II through air permeation holes and finally flows out through air outlet holes, and the bottoms of the tile billets can be dried.

Owner:佛山市景鑫达陶瓷机械有限公司

Drying tooling

The invention discloses a drying tooling, comprising a leather storage chamber and a steam discharge box fixed on the leather storage chamber, wherein the leather storage chamber is communicated with the internal part of the steam discharge box; the bottom of the steam discharge box sinks inwards; a drain-pipe is arranged at the bottom; and an exhaust port is formed in the steam discharge box. The drying tooling has the advantages that the bottom of the steam discharge box sinks inwards, and water drops are discharged through the drain pipe, so that the water drops can be effectively prevented from returning back to the leather storage chamber to affect drying of the leather.

Owner:CHENGDU LIXIN SCI & TECH

Drying tool set

The invention discloses a drying tool set which comprises an operating desk and a heater positioned in the operating desk, wherein a leather storage chamber is arranged on the operating desk; a steam discharge box is fixed to the leather storage chamber; the inside of the steam discharge box is communicated with the inside of the leather storage chamber; the bottom of the leather discharge box sinks to the inside; the edge of the bottom of the steam discharge box is provided with a drainage pipe; the heater comprises a controller, a heating block and a control button; the heating block and the control button are connected to the controller; and the heating block is positioned below the leather storage chamber. The bottom of the leather discharge box sinks to the inside, so that the liquefied water can not flow back into the leather storage chamber, thereby avoiding the influence of water backflow on the drying of the leather.

Owner:CHENGDU LIXIN SCI & TECH

Fountain solution and preparation method thereof

InactiveCN101870213BEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentPropylene glycolDefoaming Agents

Owner:杜广清

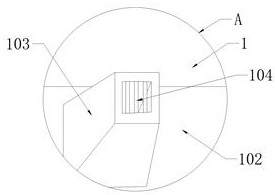

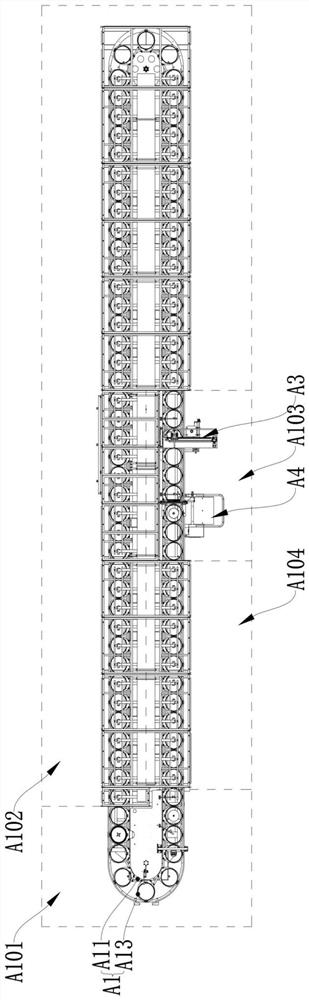

Production line of domestic ceramics

ActiveCN113664976AGuaranteed drynessGuaranteed low moisture contentDischarging arrangementCeramic shaping plantsProduction lineMolding machine

The invention relates to the technical field of domestic ceramic production equipment, in particular to a production line of domestic ceramics, which comprises a primary drying system, a secondary drying system and an edge washing machine, wherein the primary drying system comprises a closed-loop conveying device, a heat circulation device, a blank turning device and a rolling forming machine, and the closed-loop conveying device comprises a rolling section, a blank drying section, a demolding section and a mold drying section which are connected in sequence; and the heat circulation device comprises a fan, an air pipe, an air supply branch pipe, an air return box and a combustion chamber, the air pipe is located above the closed-loop conveying device, the air pipe is provided with a first air duct and a second air duct which not communicate with each other, and an air outlet of the air supply branch pipe is located above the blank drying section and the mold drying section. According to the production line of the domestic ceramics, it can be effectively guaranteed that mud blanks are smoothly demolded, and the technical problem that in the existing mud blank demolding process, due to the fact that moisture of the mud blanks can be absorbed by a forming mold, mud blank demolding is difficult is solved.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

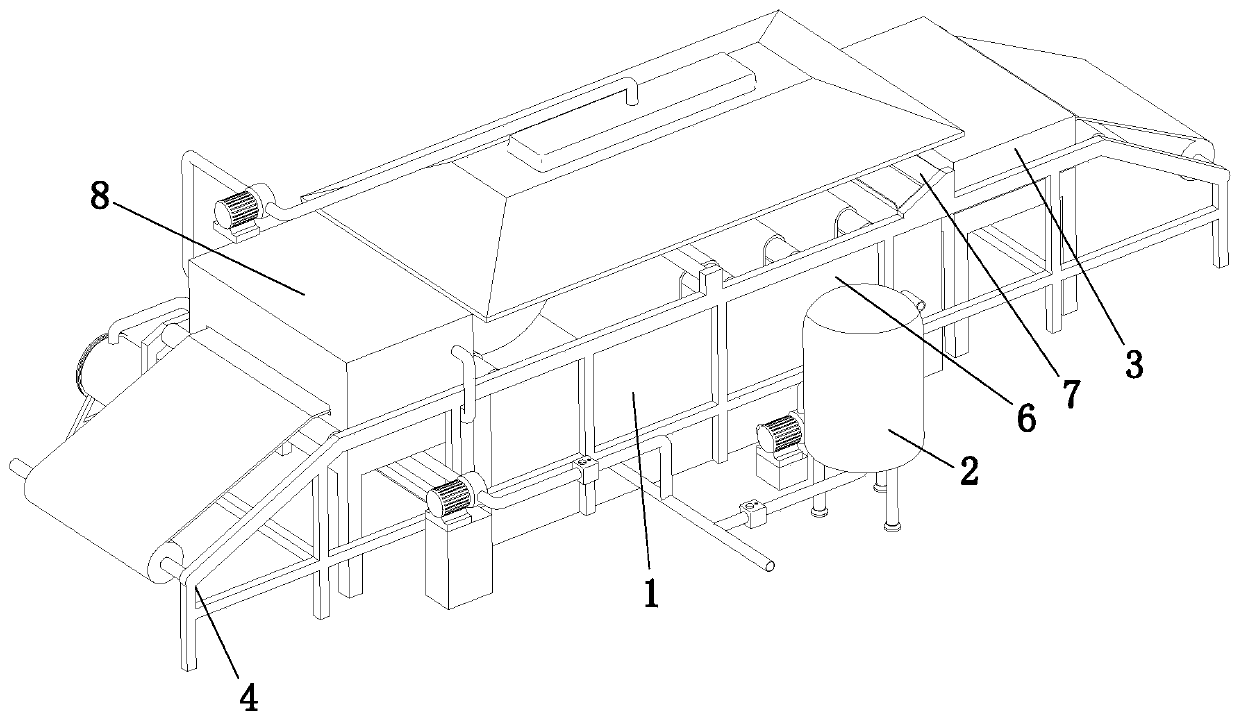

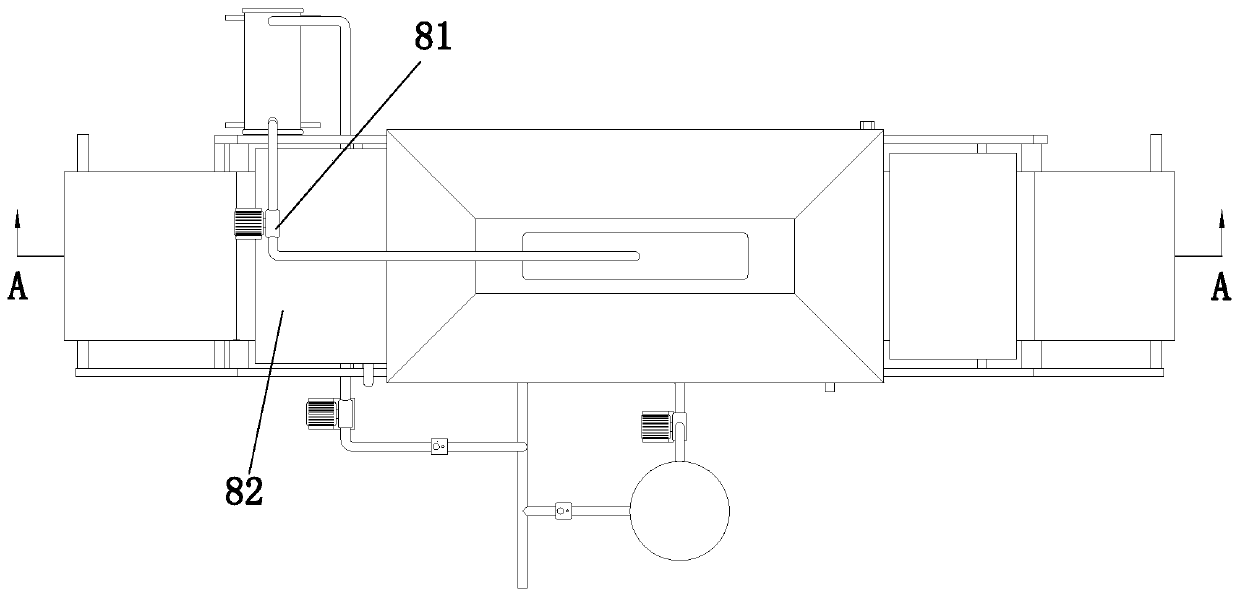

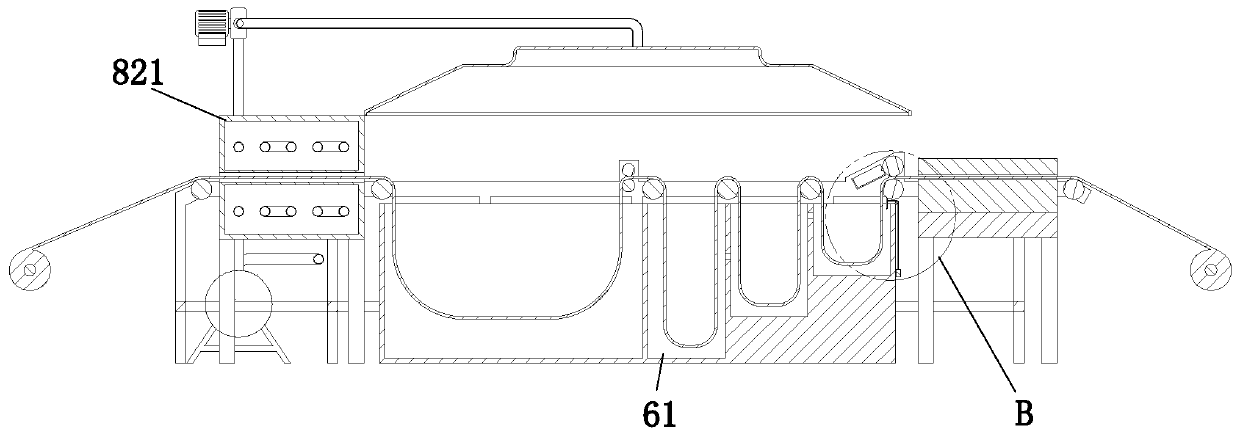

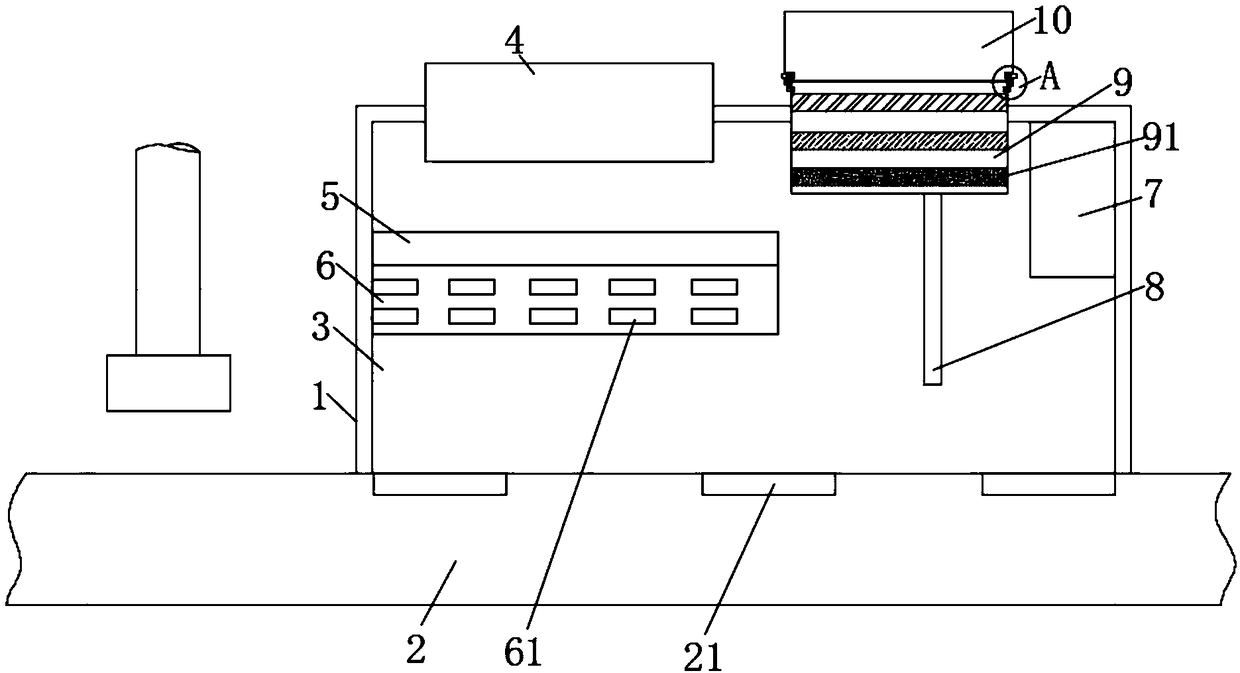

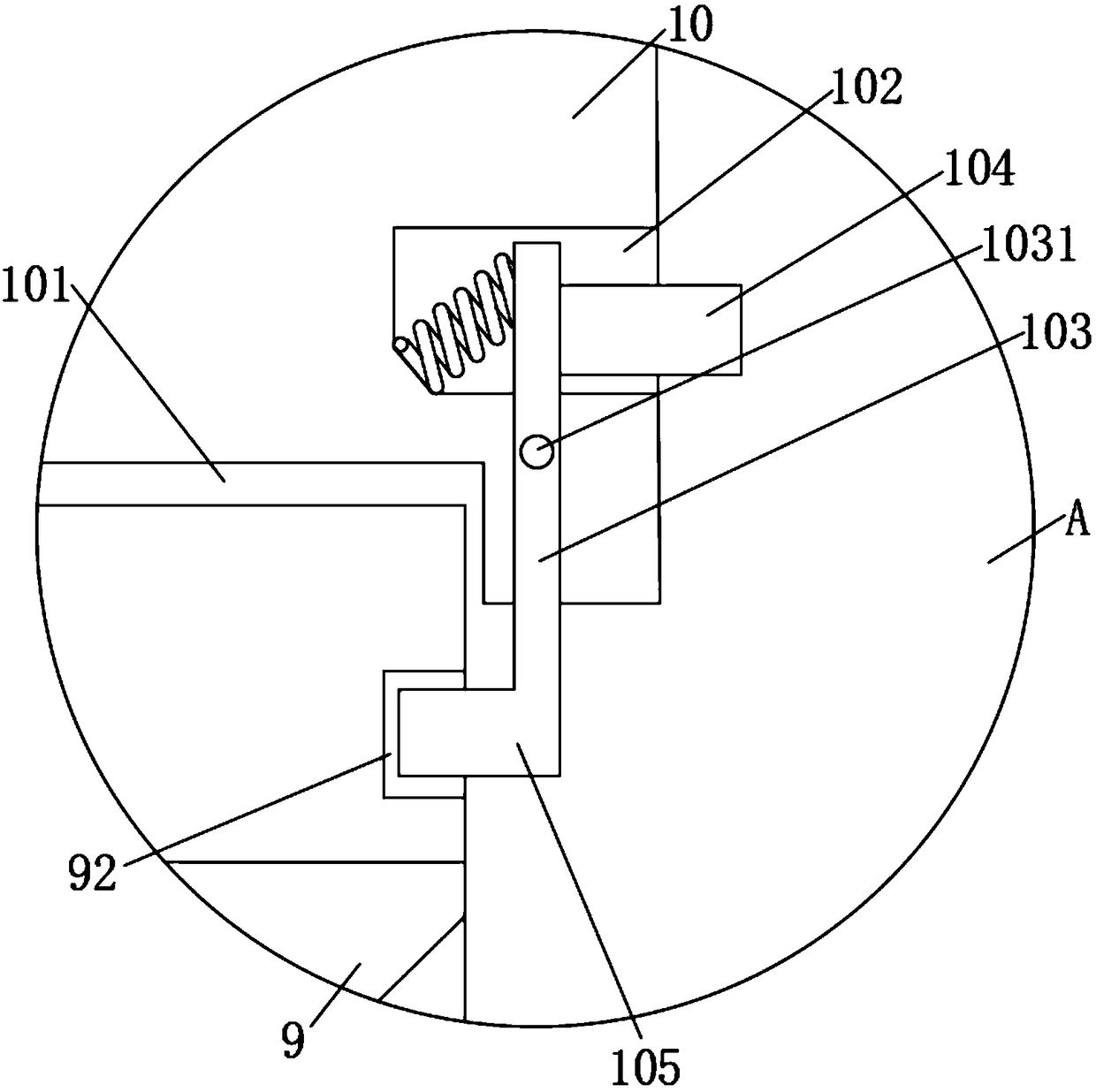

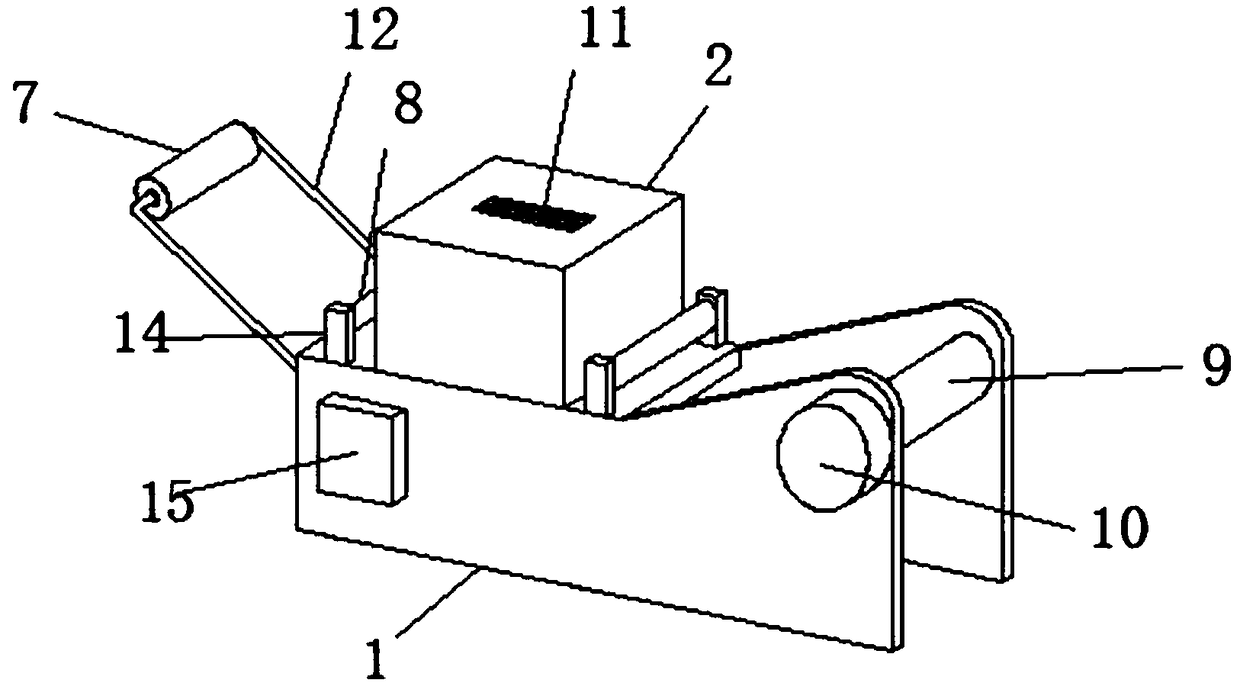

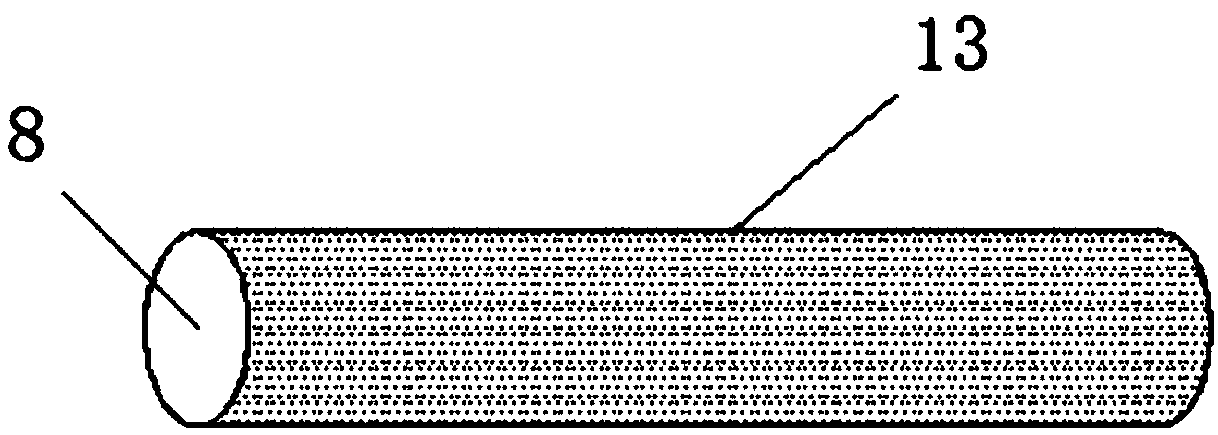

Wet ball mill discharge detection device

InactiveCN106248519BImprove the phenomenon of uneven particle sizeGuaranteed accuracyPreparing sample for investigationParticle size analysisEngineeringMechanical engineering

The utility model relates to a discharge detection device of a wet ball mill, which belongs to the field of ball mill wet material detection equipment. It is characterized in that it includes a frame (1), a feeding mechanism (3), a washing mechanism, a drying mechanism (8), a weighing mechanism (7) and a mobile conveying mechanism installed in the frame (1). The mechanism can be horizontally slidably installed in the middle of the frame (1), the feeding mechanism (3) and the flushing mechanism are respectively arranged above the moving conveying mechanism, the weighing mechanism (7) is arranged below the moving conveying mechanism, and the weighing mechanism (7) and the feeding mechanism (3) are respectively arranged on both sides of the frame (1), and a drying mechanism (8) is arranged between the weighing mechanism (7) and the feeding mechanism (3). The present invention can conveniently and timely control the feeding amount of the ball mill and the grinding time of the stones through the discharge detection of the discharge port of the ball mill, thereby improving the phenomenon of uneven particle size in the working process of the ball mill.

Owner:SHANDONG UNIV OF TECH

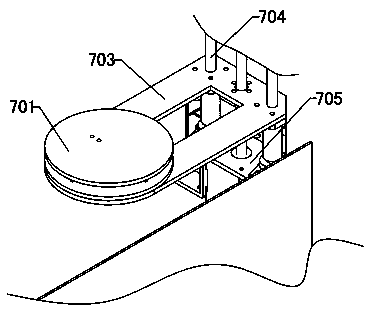

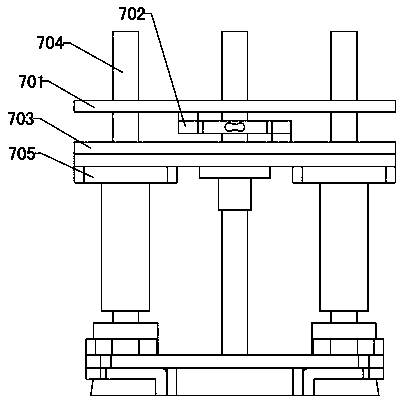

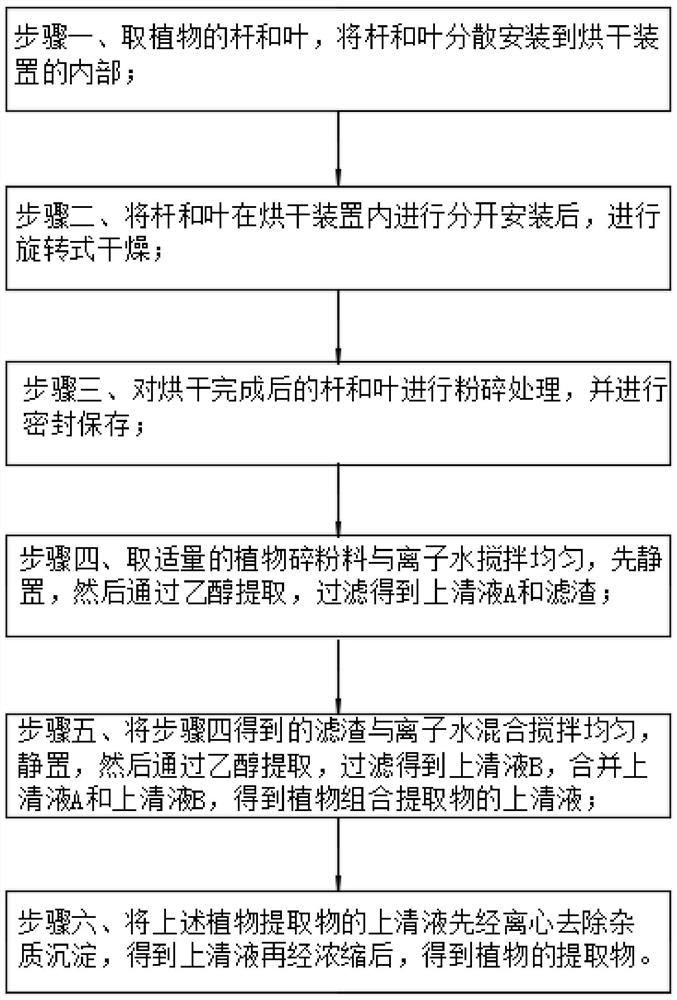

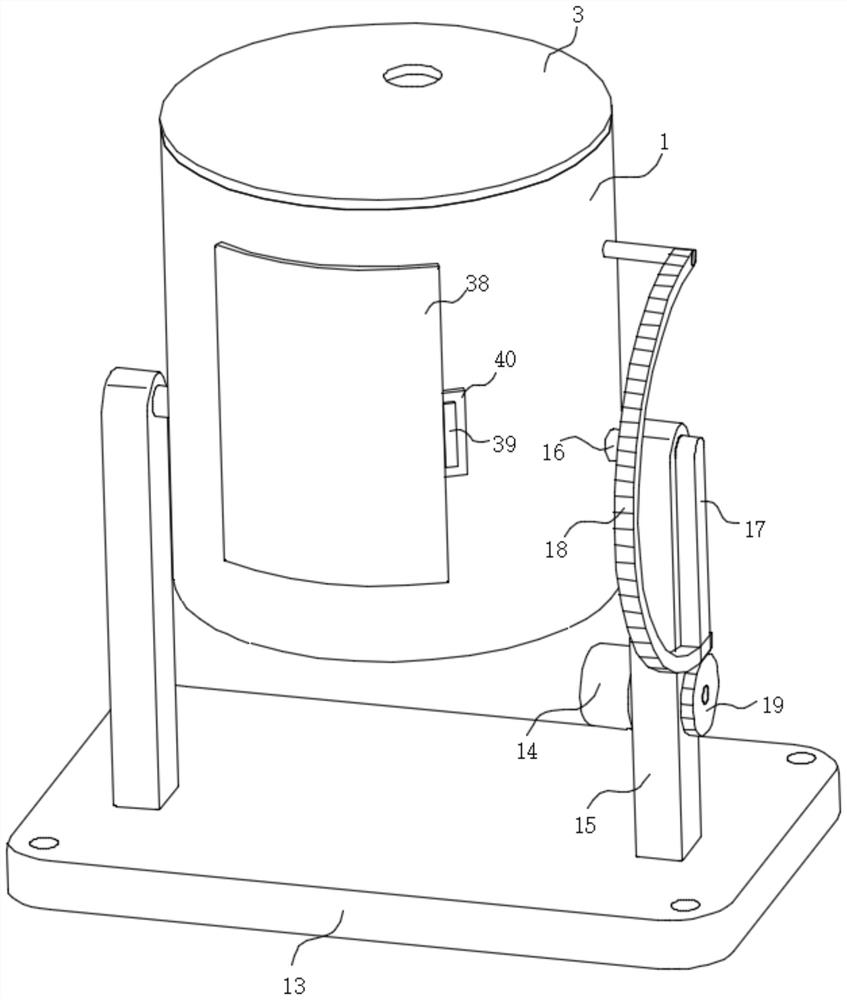

Method for extracting active ingredients of natural plants

ActiveCN114543463AEasy accessAvoid concentrated accumulationDrying gas arrangementsDrying chambers/containersAgricultural engineeringMechanical engineering

The invention relates to the technical field of natural plant active ingredient extraction methods, in particular to a natural plant active ingredient extraction method which comprises the following steps: step 1, taking stems and leaves of a plant, and dispersedly mounting the stems and the leaves in a drying device; 2, the stems and the leaves are separately installed in a drying device, and then rotary drying is conducted; thirdly, the dried stems and leaves are smashed and stored in a sealed mode; in the moving process of the connecting base, the linkage mechanism can be in linkage with the connecting base to rotate, the connecting base can rotate while moving, the connecting base drives the connecting rod and the drying net barrel to rotate together, then branches and leaves in the whole drying net barrel can get close to a heating plate with the same opportunity, and therefore it is guaranteed that heating and drying are uniform; the situation that branches and leaves are dried unevenly due to concentrated accumulation is avoided, and thorough and even drying of the branches and leaves is facilitated.

Owner:山东聚胜生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com