Drug drying box of automatic pharmaceutical machine

A technology of drying oven and medicine, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc. It can solve the problems of difficult heat flow, low drying efficiency, limited range of heat flow and heat dissipation, and avoid heat flow heat dissipation area Small, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

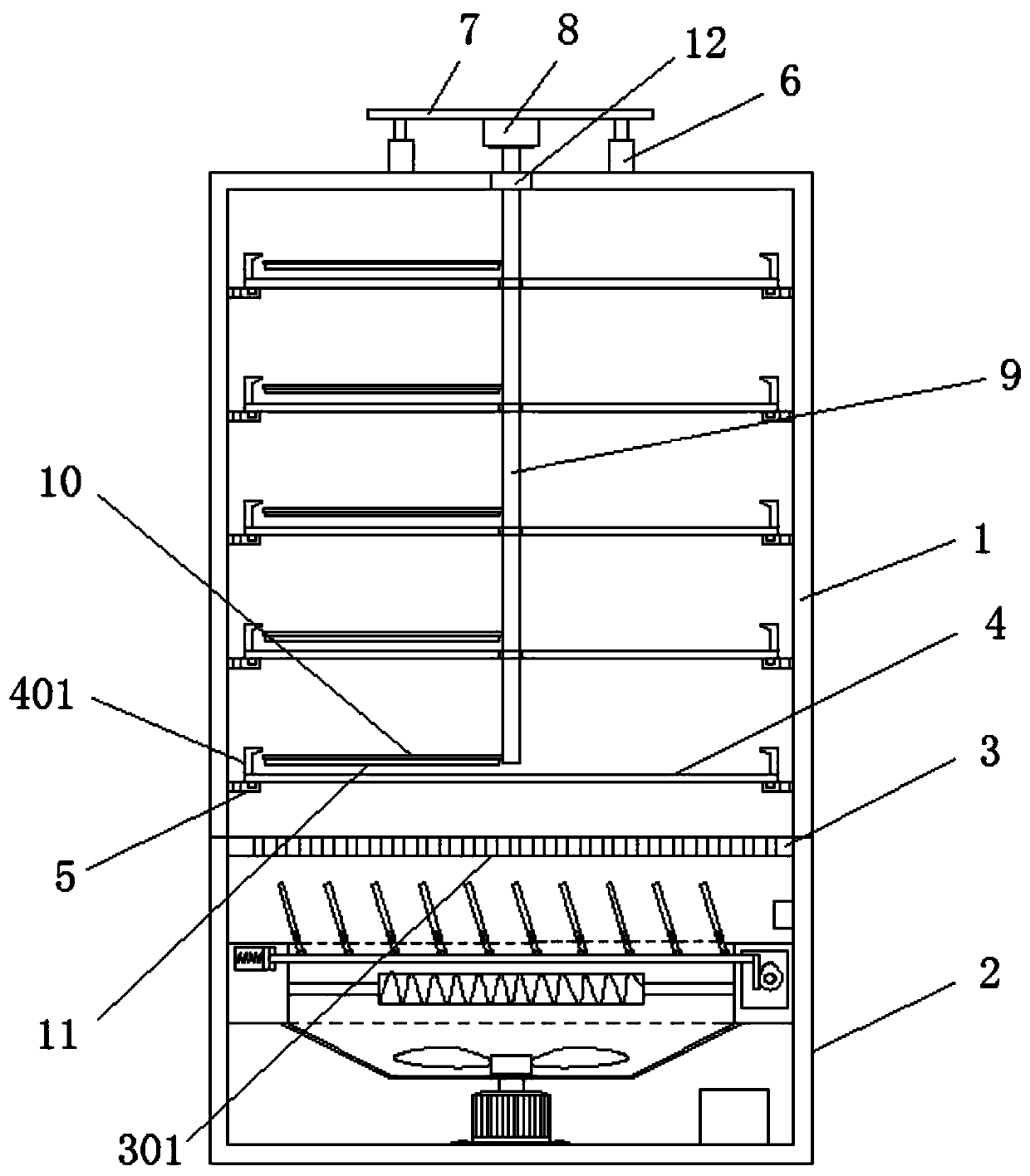

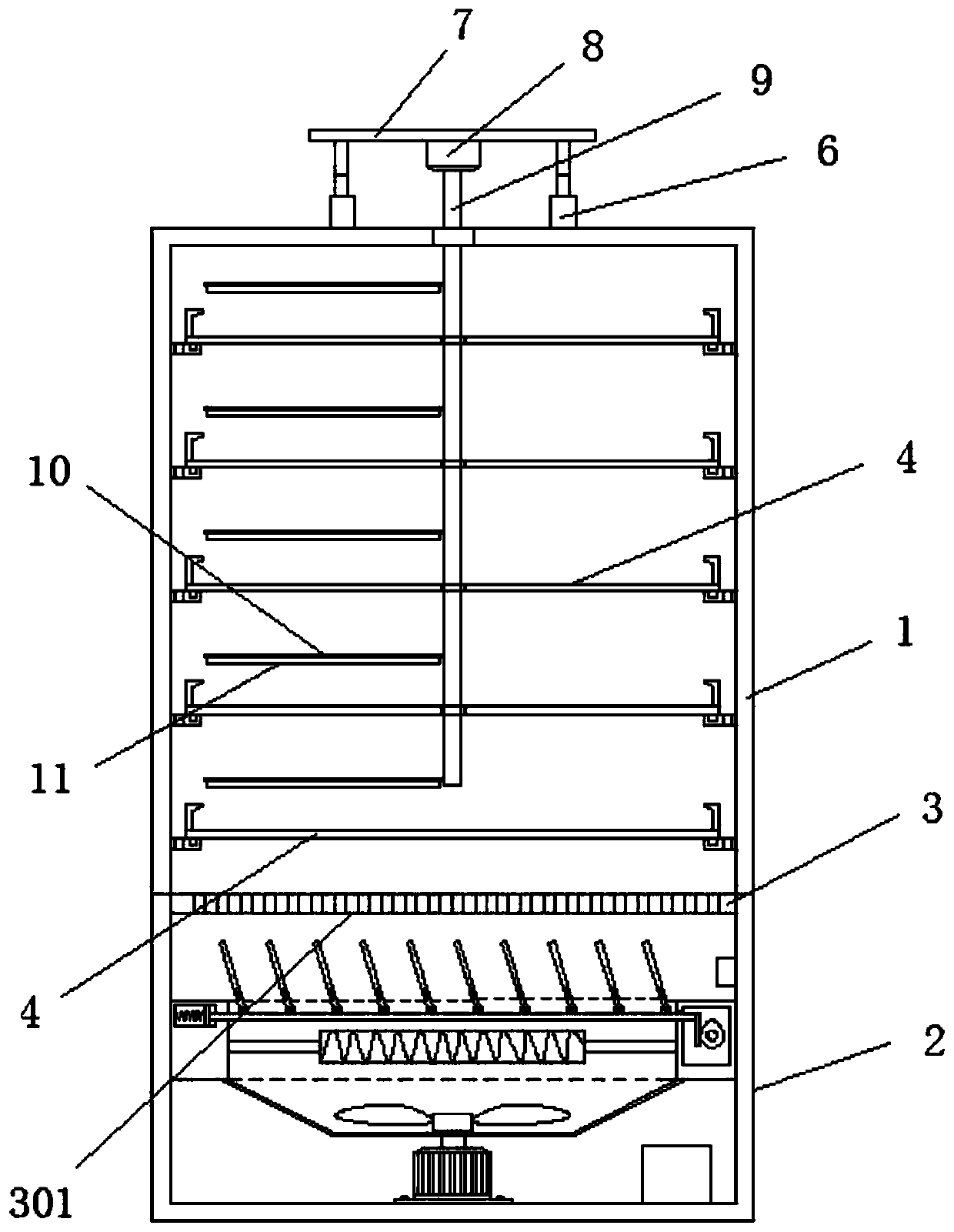

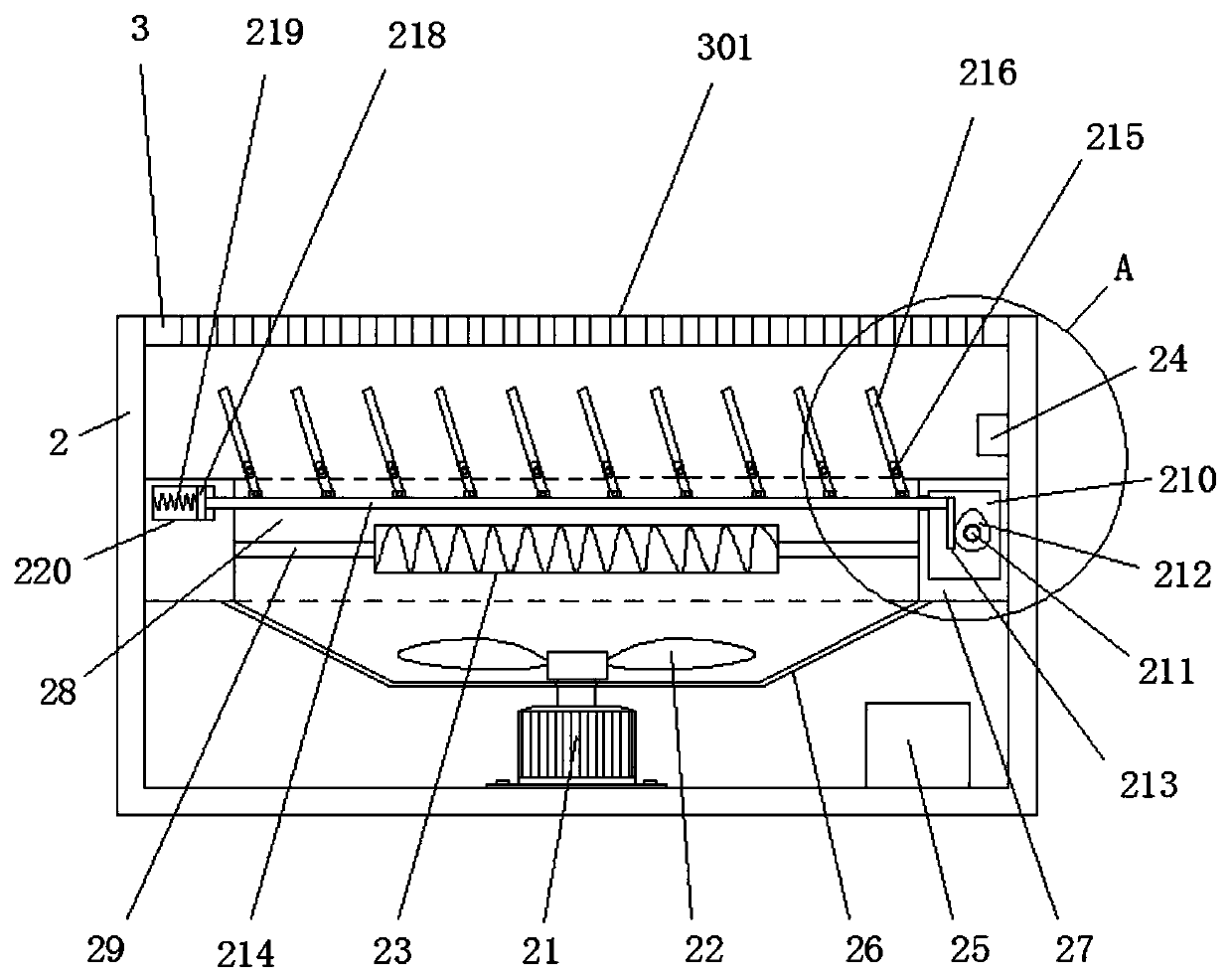

[0029] refer to Figure 1-6 In this embodiment, an automatic pharmaceutical machinery medicine drying box is proposed, comprising a drying box main body 1 and a bottom box 2 arranged at the bottom of the drying box main body 1, a heating and drying mechanism is arranged inside the bottom box 2, and the drying A heat dissipation plate 3 is arranged between the box main body 1 and the bottom box 2, and a plurality of heat dissipation holes 301 are arranged on the heat dissipation plate 3. A plurality of drying trays 4 are arranged in the drying box main body 1 from bottom to top, and the drying tray 4 It is used to place the medicine that needs to be dried, and the drying tray 4 is installed in the main body 1 of the drying box through the bracket 5. The main body 1 of the drying box is provided with a plurality of spreading bars 10 and a spreading plate 11 arranged on the bottom side of the spreading bars 10 , and the spreading board 11 is located above the drying tray 4 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com