Cloth airing device for textile processing

A drying device and cloth technology, applied in the field of textile processing, can solve problems such as surface pollution of cloth, and achieve the effects of improving the distribution range, improving the reflectivity, and improving the drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

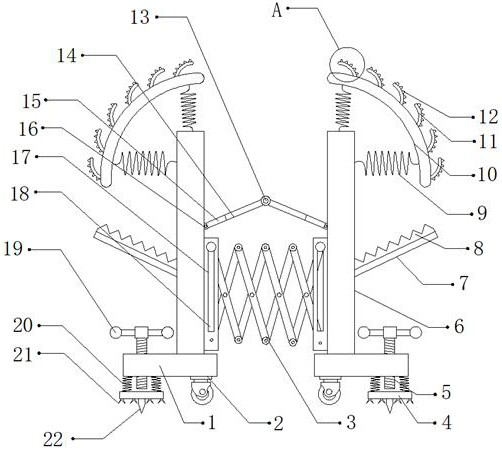

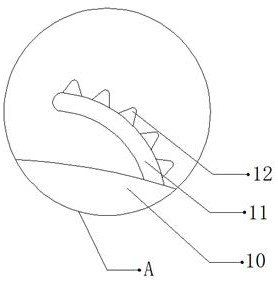

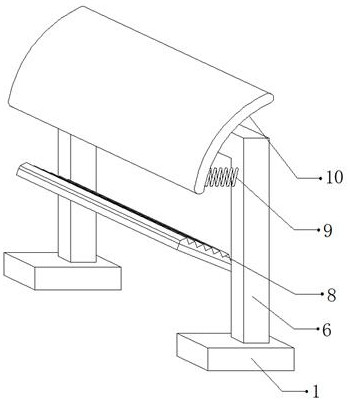

[0029] refer to Figure 1-3 , a cloth drying device for textile processing, comprising two drying rods 6, a lifting mechanism 3 connected by bolts between the outer walls of the opposite side of the two drying rods 6, and the lifting mechanism 3 consists of two fixing frames 17 and a plurality of Composed of connecting rods, and a rotational connection is formed between two adjacent connecting rods. One side outer wall of the two fixing frames 17 is provided with a fixing port 18, and the fixing port 18 forms a sliding connection with the connecting rods. The two drying rods 6 The outer wall of the first spring 9 is connected with a first spring 9 by bolts, and one side of the outer wall of the first spring 9 is connected with a drying board 10 by bolts. The bolts are connected with a plurality of barbs 11, and one side of the outer wall of the barbs 11 is provided with a plurality of tooth blocks 12, and the shape of the barbs 11 is arc.

[0030] Wherein, a hinge 16 is conne...

Embodiment 2

[0038] refer to Figure 4 , a cloth drying device for textile processing. Compared with Embodiment 1, the two ends of the outer walls on one side of the two drying rods 6 are connected with damping bearings 23 by bolts, and the outer walls on one side of the damping bearings 23 are rotationally connected. Sleeve 24 is arranged, and the inwall of sleeve 24 is plugged with sleeve rod 26, and one side outer wall of sleeve 24 is provided with threaded opening, and the inwall of threaded opening is threadedly connected with limit bolt 25, can jack-up the top of cloth, so that The utility model is used for drying the bottom of the cloth, which improves the drying efficiency of the device for the cloth.

[0039] Working principle: when in use, the device is moved to a suitable position through the moving wheel 2. After the movement is completed, the distance between the two drying rods 6 is adjusted through the lifting mechanism 3. After the adjustment is completed, the handle 19 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com