Patents

Literature

51results about How to "Avoid concentrated accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

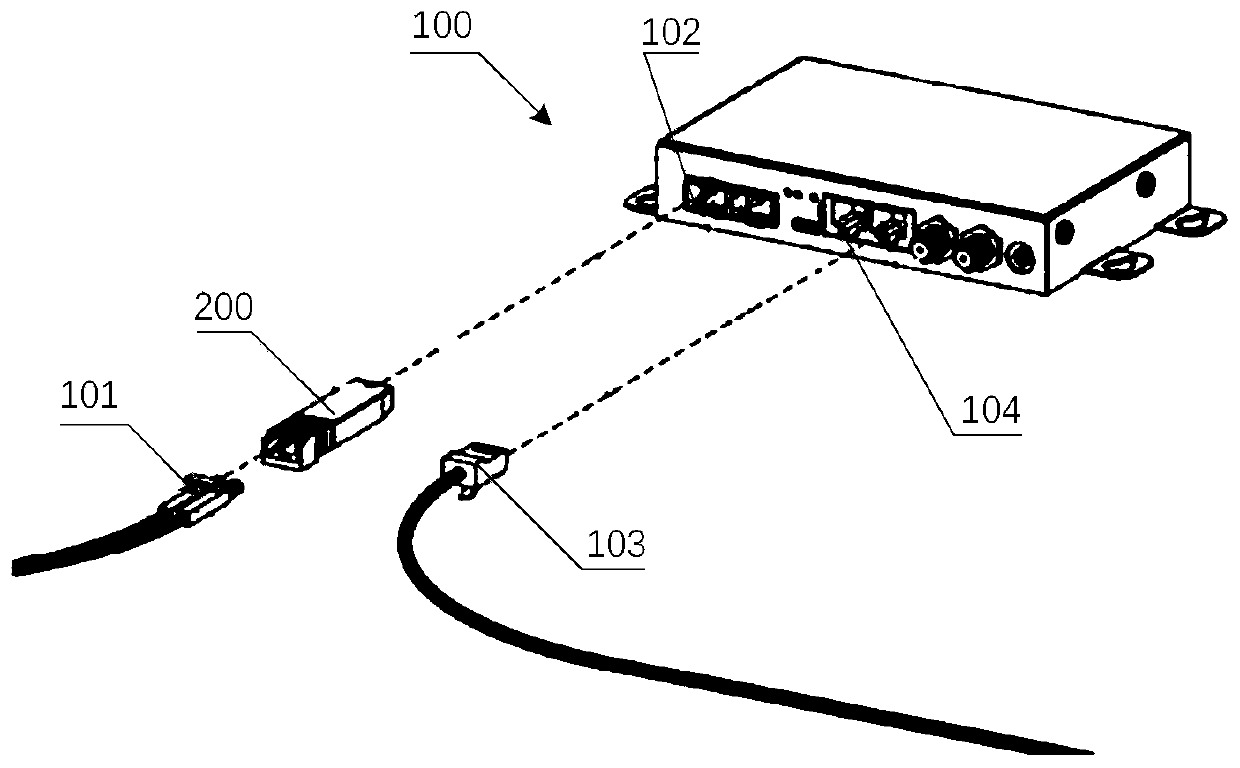

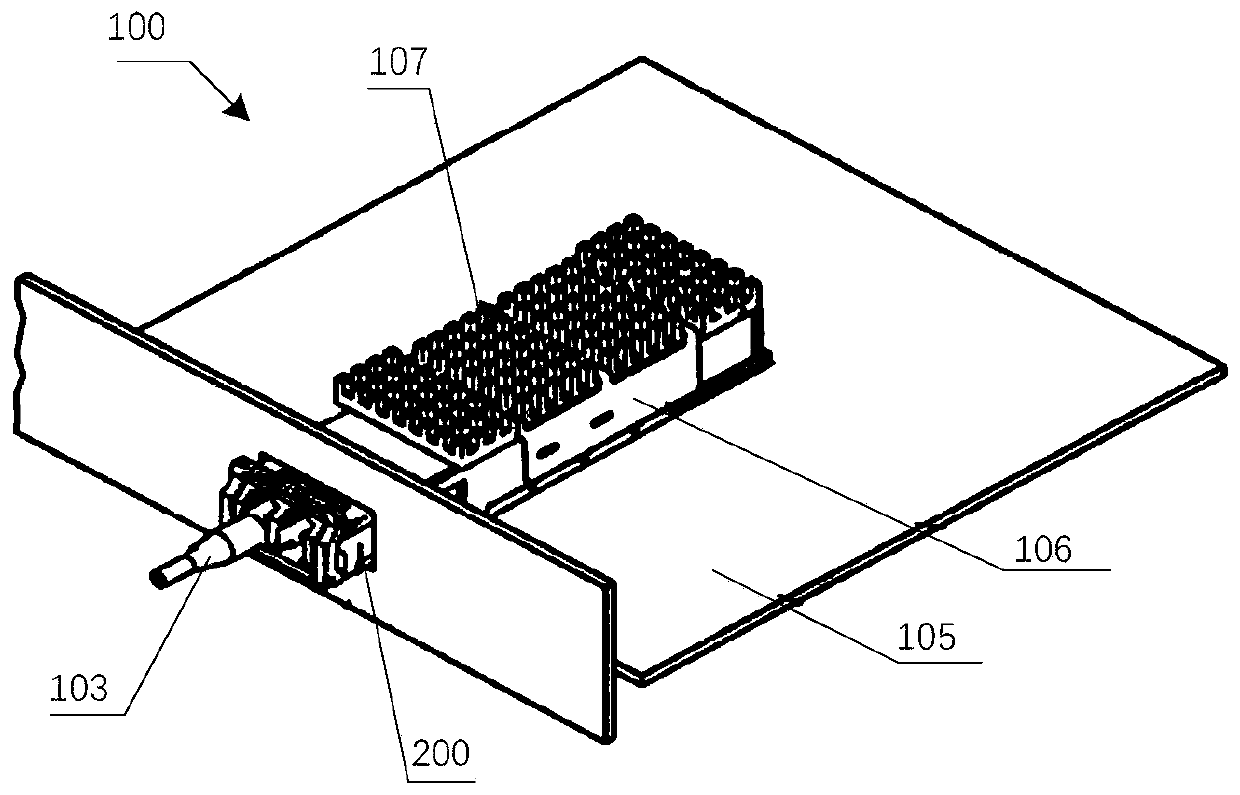

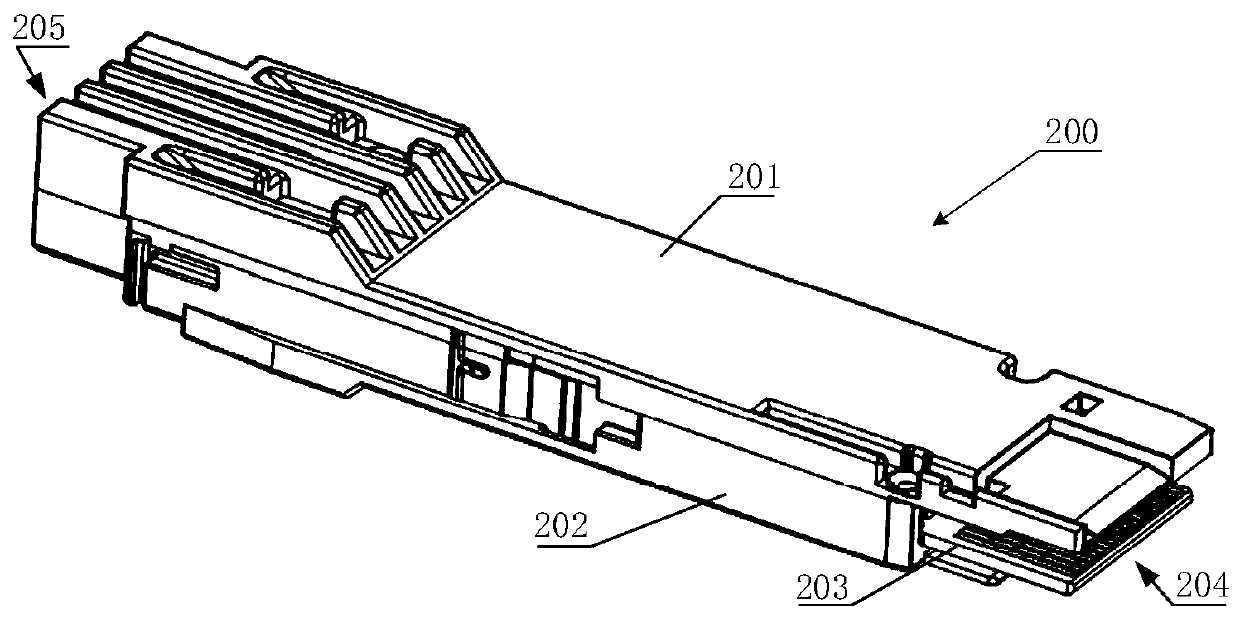

Optical module

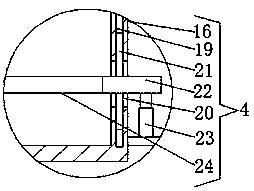

ActiveCN111338039AAvoid heat accumulationGood optical alignment stabilityCoupling light guidesPhysicsErbium lasers

An optical module provided by the invention comprises a circuit board; a base embedded in the circuit board; a laser assembly attached to the base and used for emitting light without carrying signals;a silicon optical chip attached to the base, wherein a third light hole is formed in the silicon optical chip, and light which is emitted by the laser assembly and does not carry signals is receivedthrough the third light hole; and a laser upper cover, wherein the bottom of the laser upper cover is fixedly connected with the base, and the laser upper cover is used for covering the laser assemblyand sealing the laser assembly between the laser upper cover and the base. The invention provides the optical module. The laser assembly and the silicon optical chip are arranged on the base, the laser assembly is sealed through the laser upper cover, and the laser assembly and the silicon optical chip are directly cooled through the base, so that internal heat dissipation of the optical module is facilitated, concentrated accumulation of internal heat of the optical module is avoided, the laser assembly arranged on the base is directly wrapped by the laser upper cover, packaging of the laserassembly is omitted, and packaging of the laser assembly is facilitated.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

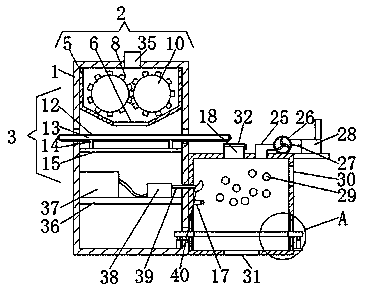

Environment-friendly garbage incineration device

InactiveCN109595560AImprove incineration efficiencyImprove practicalityIncinerator apparatusChamber safety arrangementEnvironmentally friendlyEngineering

The invention discloses an environment-friendly garbage incineration device. The environment-friendly garbage incineration device comprises a first box, a crushing structure is fixedly connected to the top of the interior of the first box, a conveying structure is fixedly connected to the interior of the first box, and an incineration structure is fixedly connected to the right side of the first box. According to the environment-friendly garbage incineration device, through arrangement of the first box, the crushing structure, the conveying structure and the incineration structure, the garbageincineration device has the advantages of being environmentally friendly and high in incineration efficiency, the practicability and the incineration efficiency of the garbage incineration device areimproved, the pollution degree of the garbage incineration device to the environment is reduced, the environment is protected, and meanwhile the problems that a traditional garbage incineration device is not environmentally friendly and low in incineration efficiency are solved; and through cooperative use of a second box, a circulating groove, a first motor, a first crushing roller, a second motor and a second crushing roller, garbage needing to be incinerated can be crushed, therefore, the garbage incineration contact area is increased, and incineration is faster and more comprehensive.

Owner:单卫光

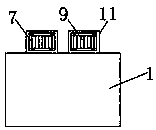

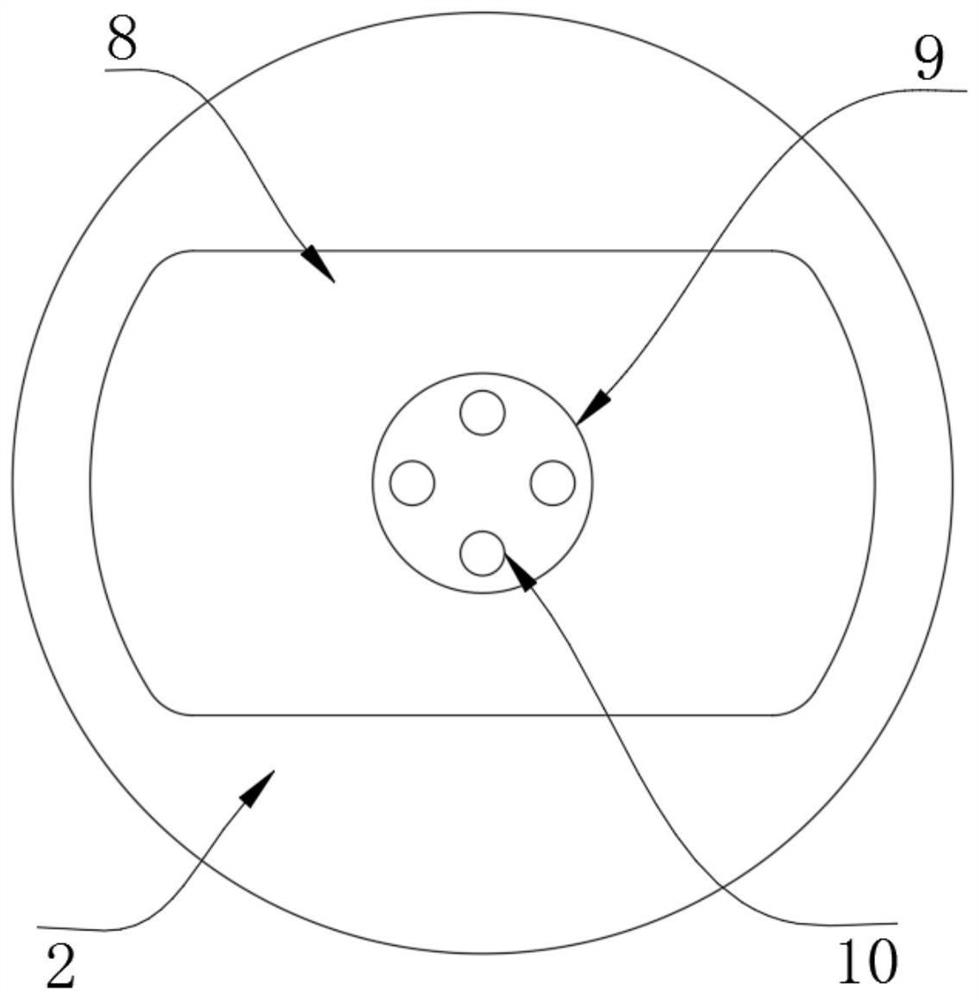

Efficient air filter

InactiveCN107185311AImprove filtration efficiencyHigh dust capacityDispersed particle filtrationTransportation and packagingAir filterArchitectural engineering

The invention discloses an efficient air filter. The efficient air filter comprises an outer shell, a first filtering assembly and a second filtering assembly, wherein the first filtering assembly and the second filtering assembly are arranged inside the outer shell, an air inlet is formed in the top of the outer shell, and an air outlet is formed in the bottom of the outer shell, the first filtering assembly is located on the side close to the air inlet and comprises a rotary shaft which is horizontally arranged below the air inlet and a rectangular hinge which is arranged at the outer circumference surface of the rotary shaft, and the outer surface of the rectangular hinge is coated with a fluff layer, the second filtering assembly is located on the side, close to the air outlet, of the first filtering assembly, and comprises a filtering core, an upper end cover and a lower end cover, and the upper end cover and the lower end cover are fixedly installed at the two ends of the filtering core; the filtering core comprises a center pipe and filtering paper, the outer edge of the upper end cover abuts against the inner wall of the outer shell, and a sealing surface is formed at the contact surface of the outer edge and the inner wall, an air inlet is formed in the upper end cover, and the lower end cover is provided with an air outlet channel which is communicated with the air outlet and a cavity of the center pipe. The efficient air filter is large in ash accommodation volume, high in filtering efficiency and good in filtering effect.

Owner:王雨

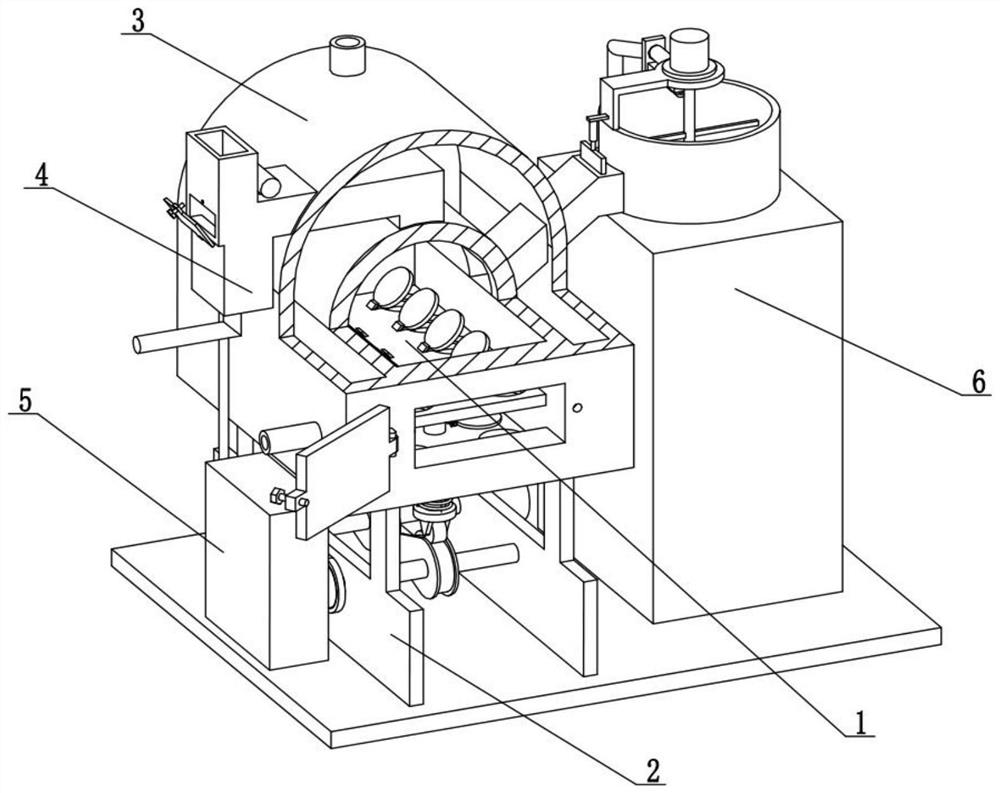

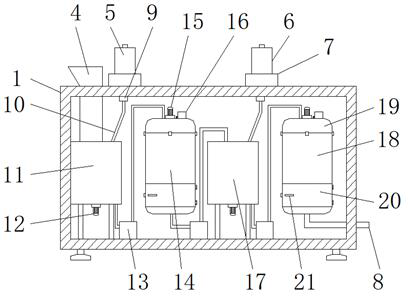

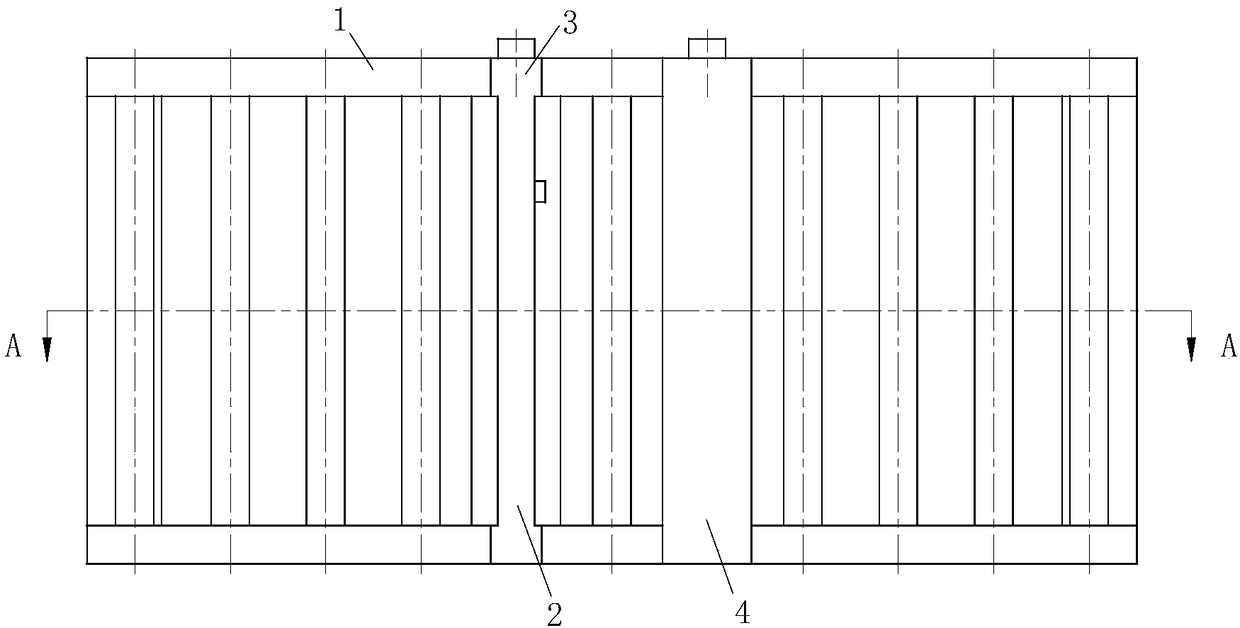

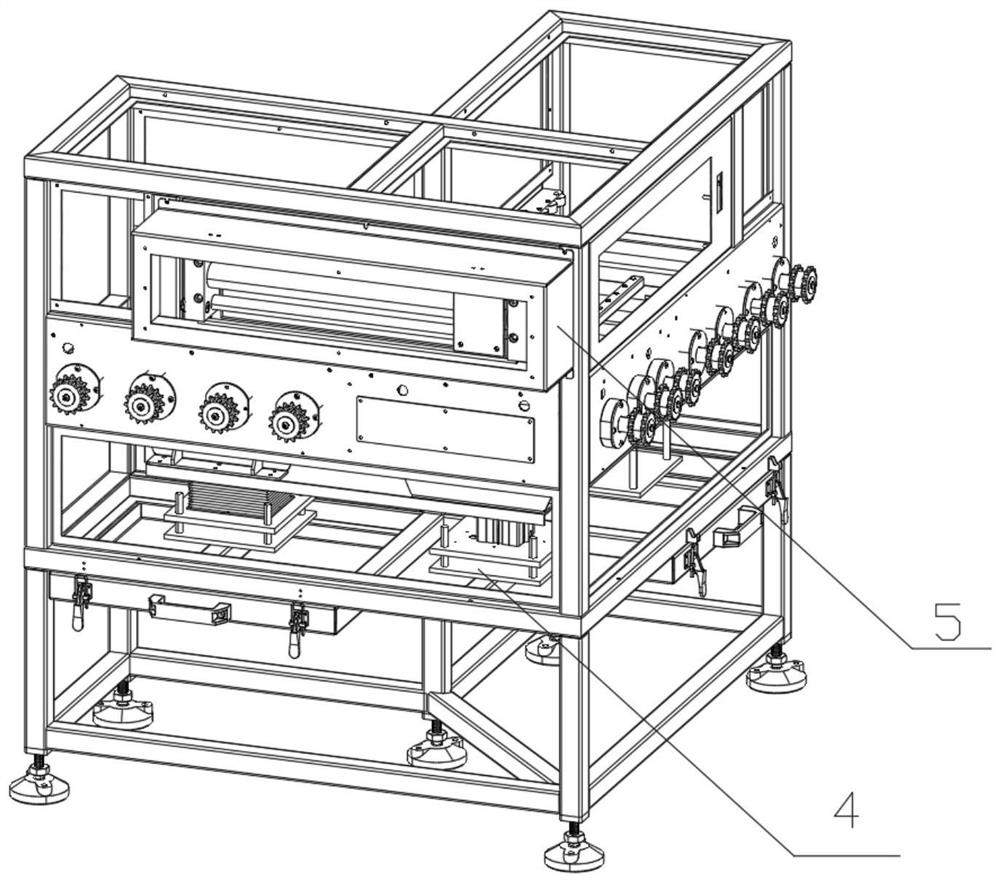

Production line for silver paste

PendingCN108079884AImprove production efficiencyReduce the number of replacementsTransportation and packagingRotary stirring mixersSilver pasteManufacturing line

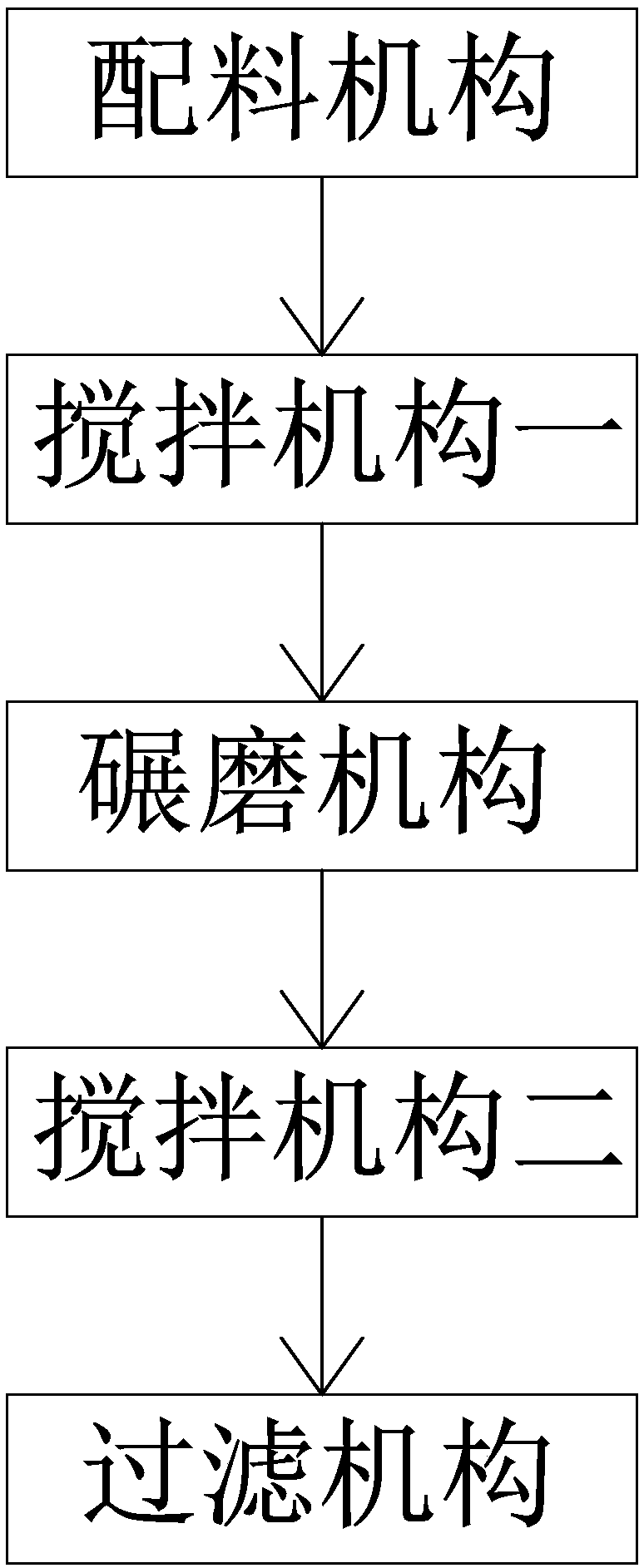

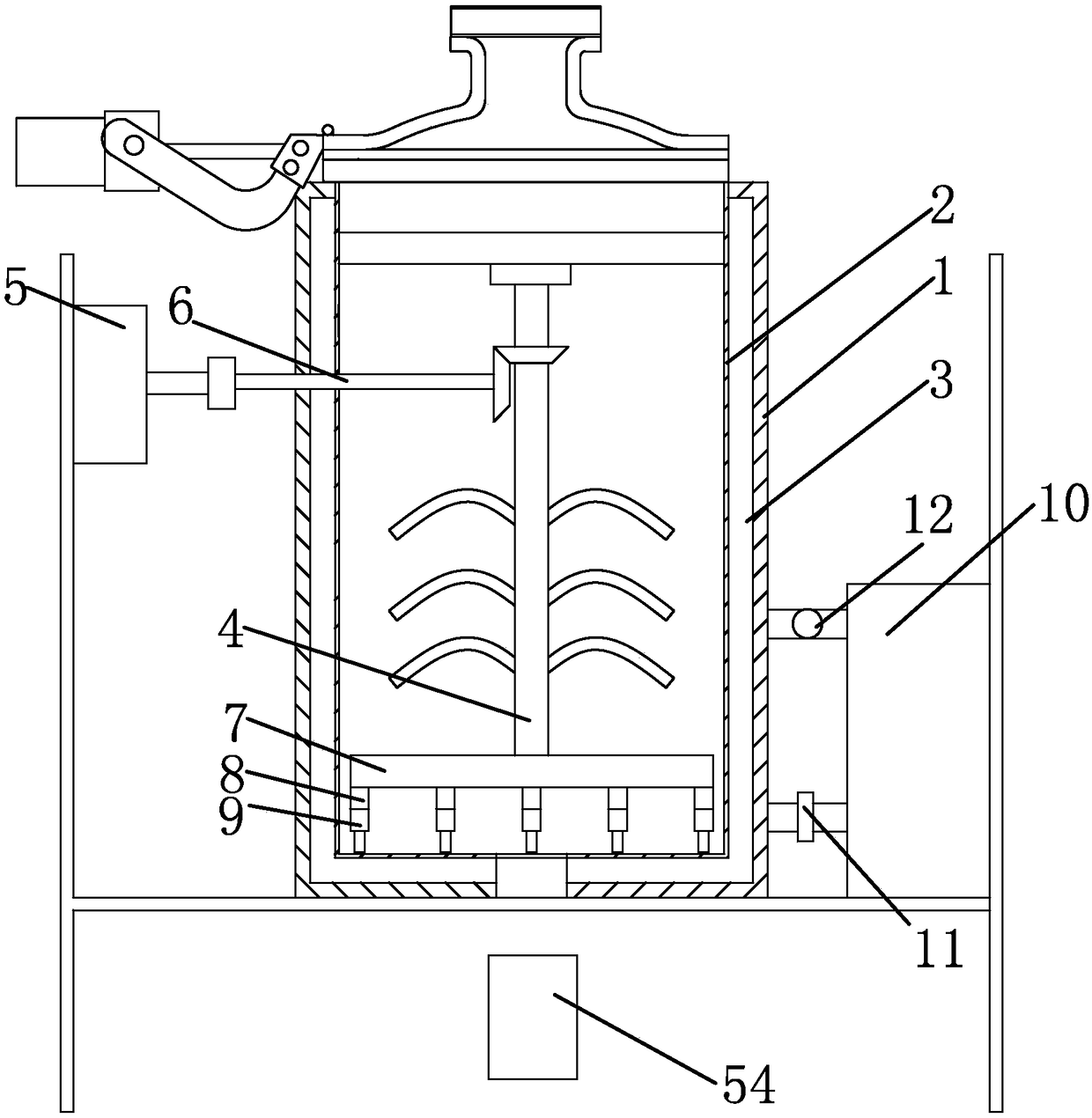

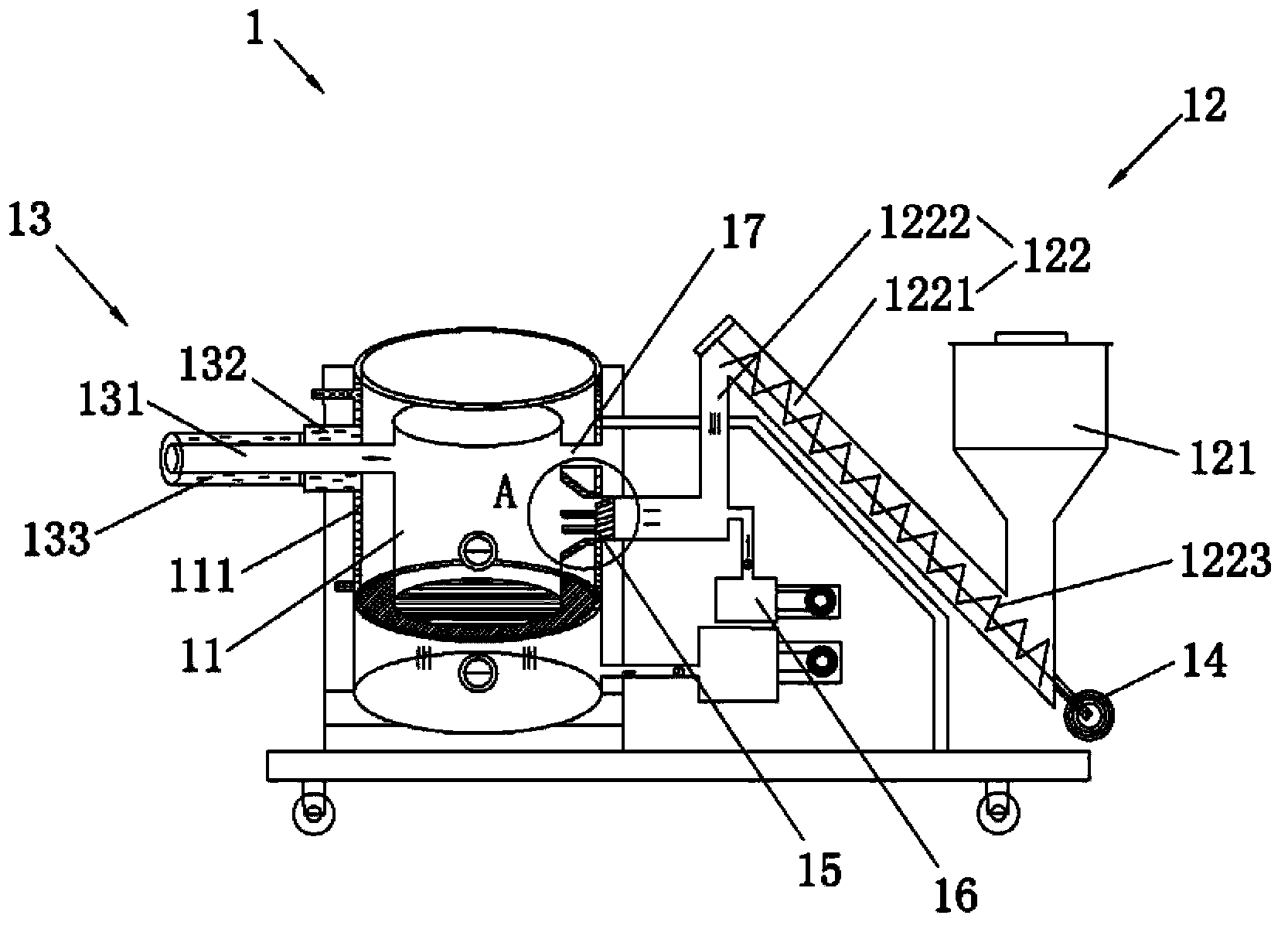

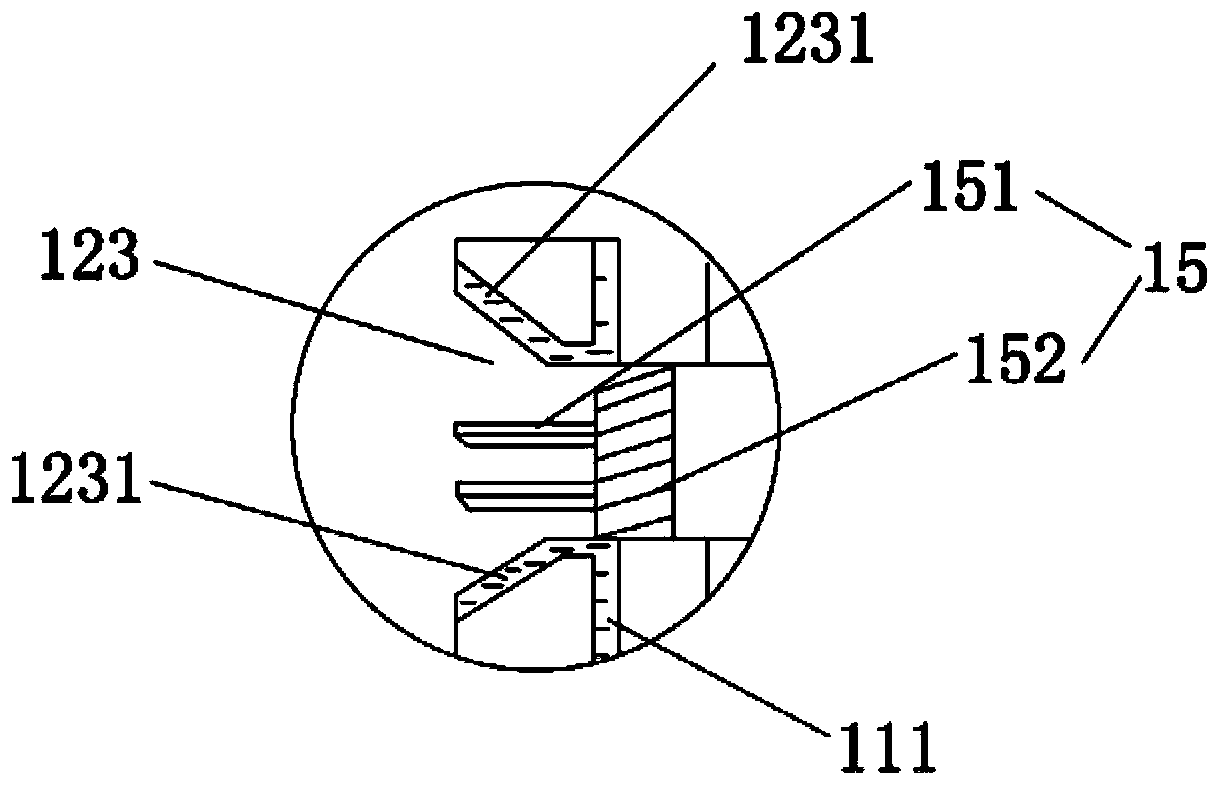

The invention provides a production line for silver paste, and belongs to the technical field of silver paste preparation. The production line solves a problem of low productivity in the prior art. The production line for the silver paste comprises a frame, the frame is provided with a feeding end and a discharging end, and a proportioning mechanism capable of preparing the silver paste, a stirring mechanism1 capable of stirring the silver paste, a grinding mechanism capable of grinding the silver paste, the stirring mechanism 2 capable of stirring the silver paste, and a filtering mechanism capable of filtering the silver paste are arranged from the feeding end to the discharging end sequentially. The production line for the silver paste has the advantages of high production efficiency.

Owner:ZHEJIANG KAIYING NEW MATERIAL

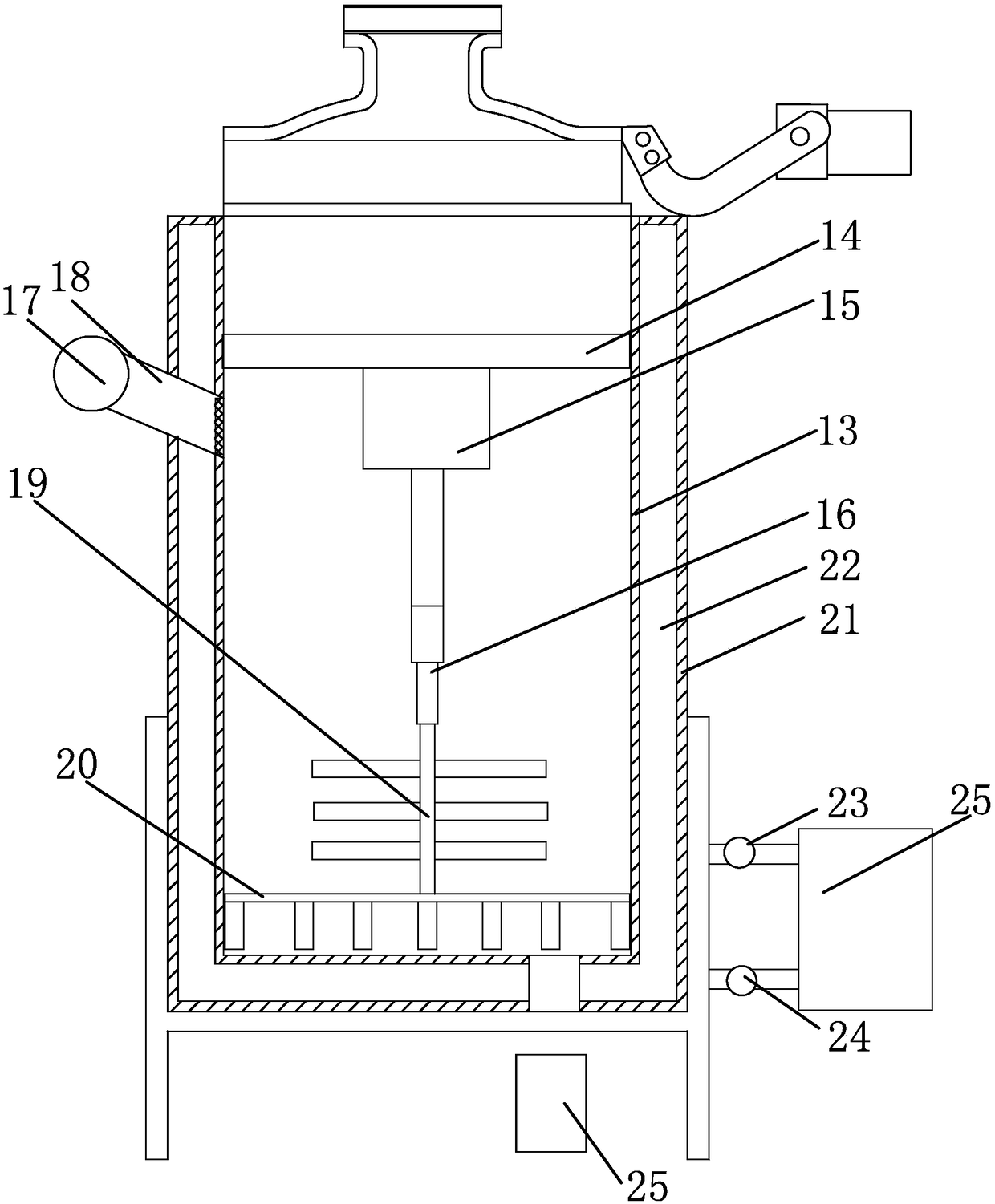

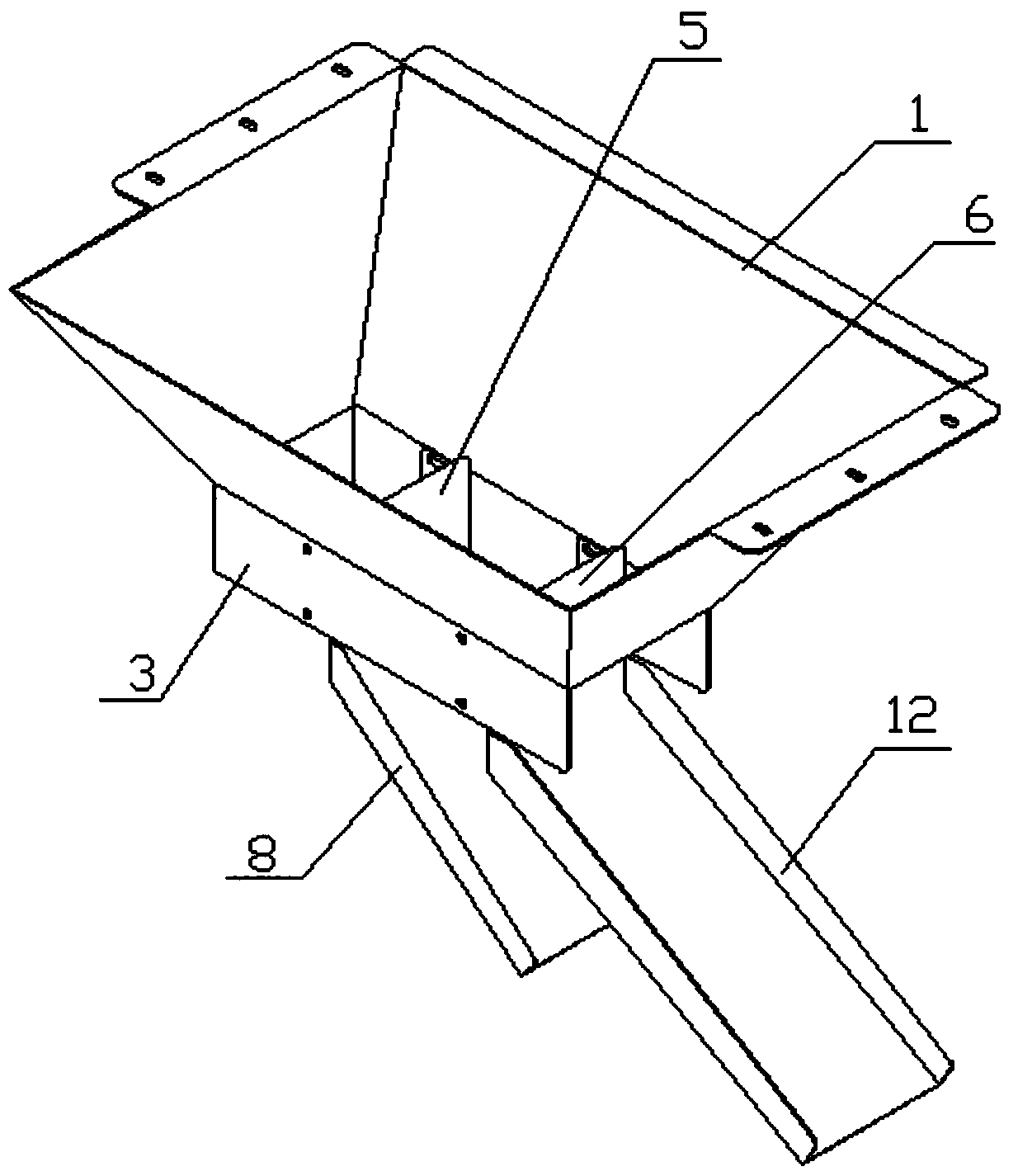

Biomass combustion machine

ActiveCN104279553AReduce the temperatureExtended service lifeSolid fuel combustionBlast-producing apparatusLiquid layerCombustion chamber

The invention provides a biomass combustion machine which comprises a combustion chamber, a feeding device communicated to one side of the combustion chamber and a flame outlet device communicated to the other side of the combustion chamber. The flame outlet device comprises a flame outlet pipe communicated with the combustion chamber and a cooling pipe installed on the periphery of the flame outlet pipe, wherein the cooling pipe is communicated with a liquid layer arranged on the outer wall of the combustion chamber and used for reducing the temperature of the flame outlet pipe so as to carry away heat, and the service life of the flame outlet pipe can be prolonged. The feeding device comprises a raw material hopper, a feeding pipe connected with the raw material hopper and a blanking port, wherein the blanking port is connected between the feeding pipe and the combustion chamber, one end of the feeding pipe is connected with an air distribution machine, and a blanking baffle capable of controlling biomass fuel to be evenly distributed in the combustion chamber is assembled in the blanking port. The biomass fuel falls into the combustion chamber through the blanking baffle and can be evenly distributed in the combustion chamber by adjusting the blanking baffle, the phenomenon that the biomass fuel is centralized and piled together in the prior art is avoided, the fuel can be efficiently combusted, and energy conversion rate is improved.

Owner:中山市兴和生物能源科技有限公司

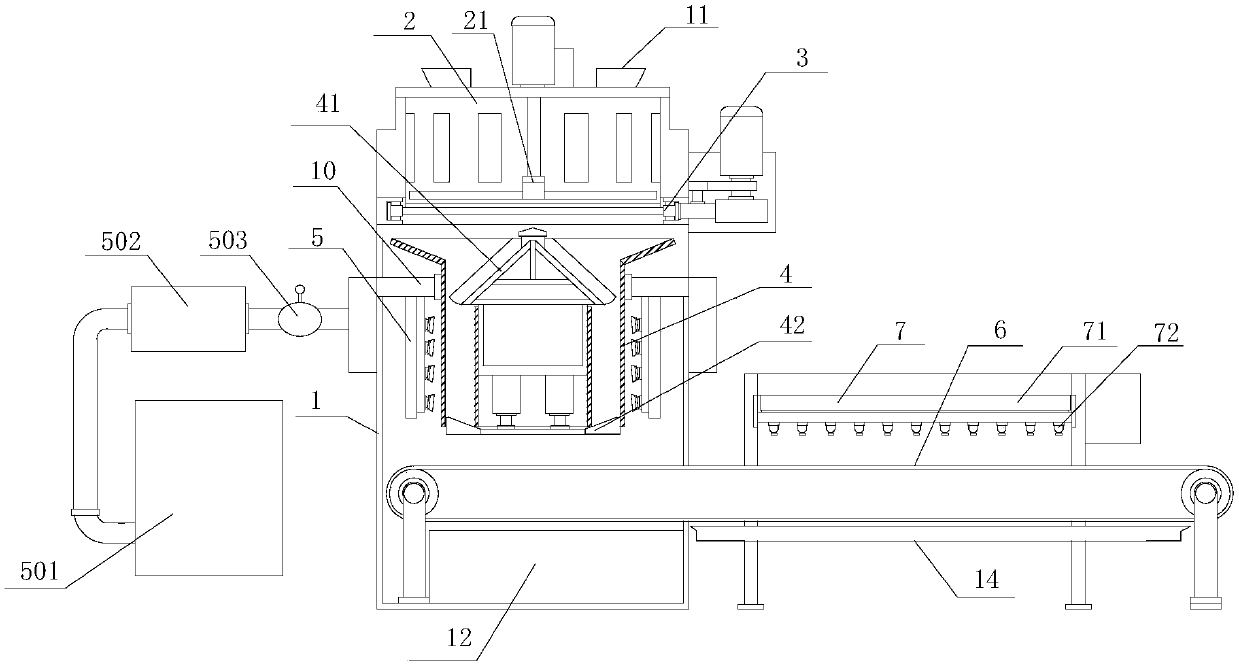

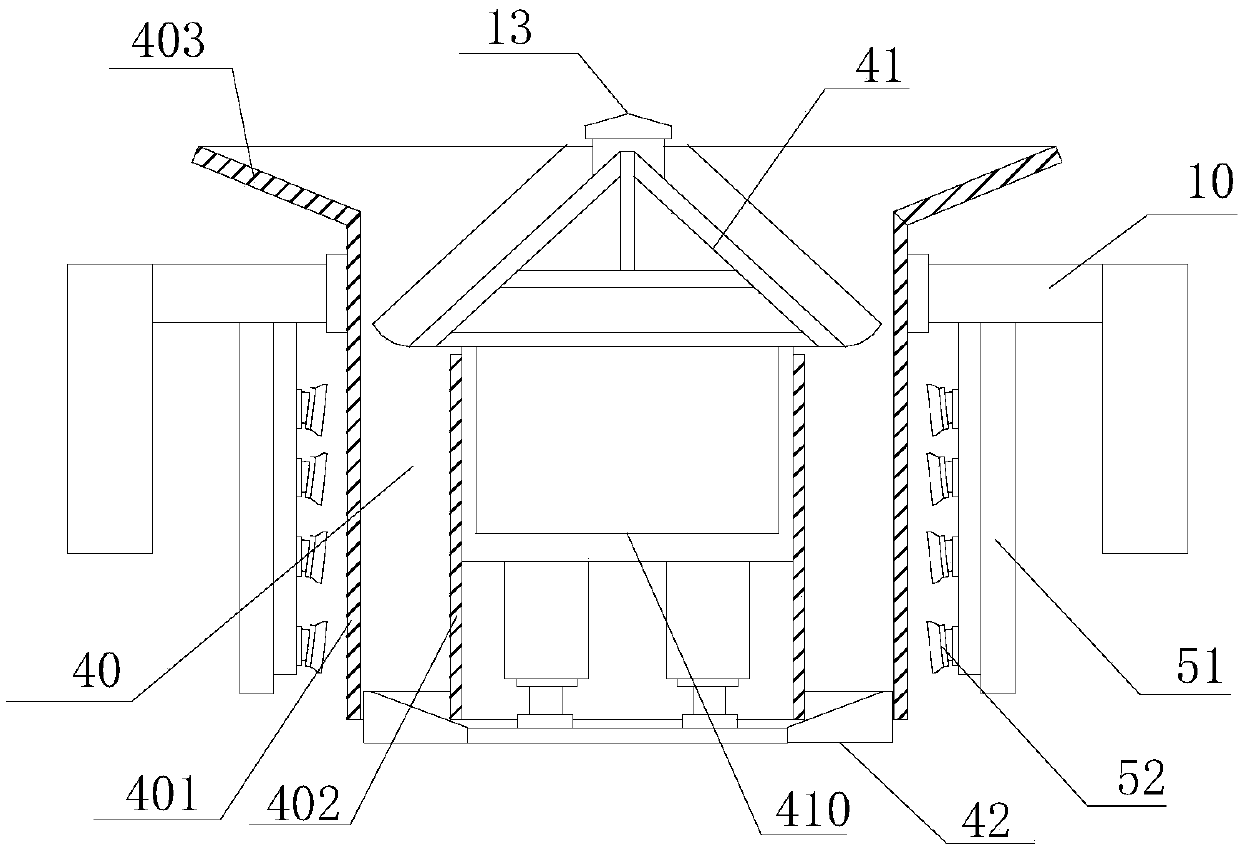

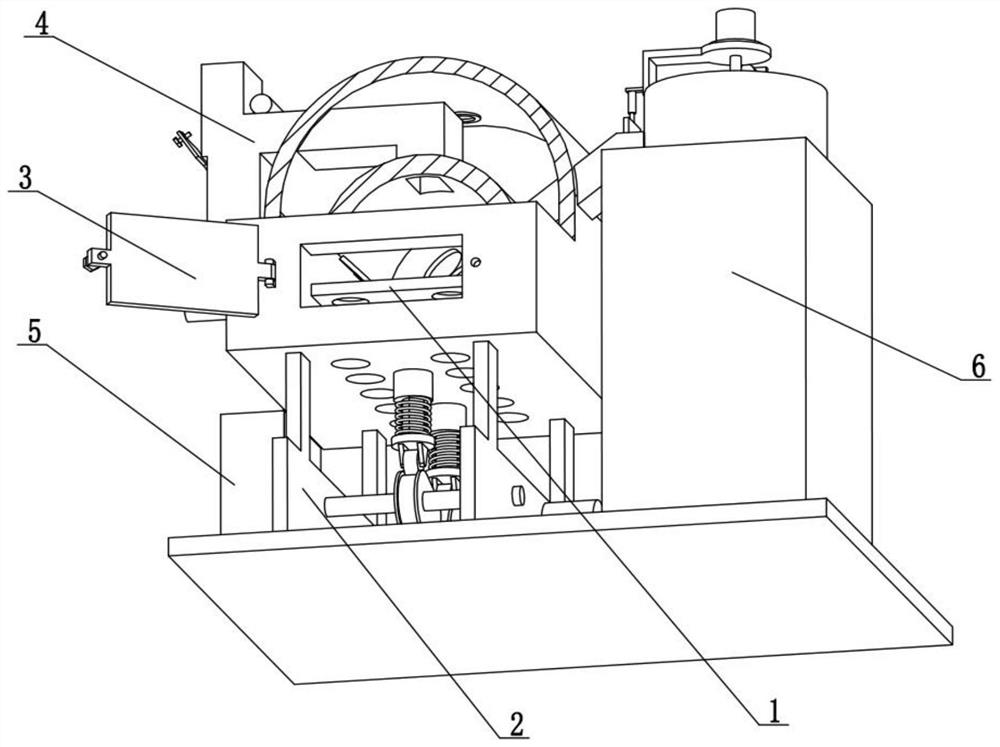

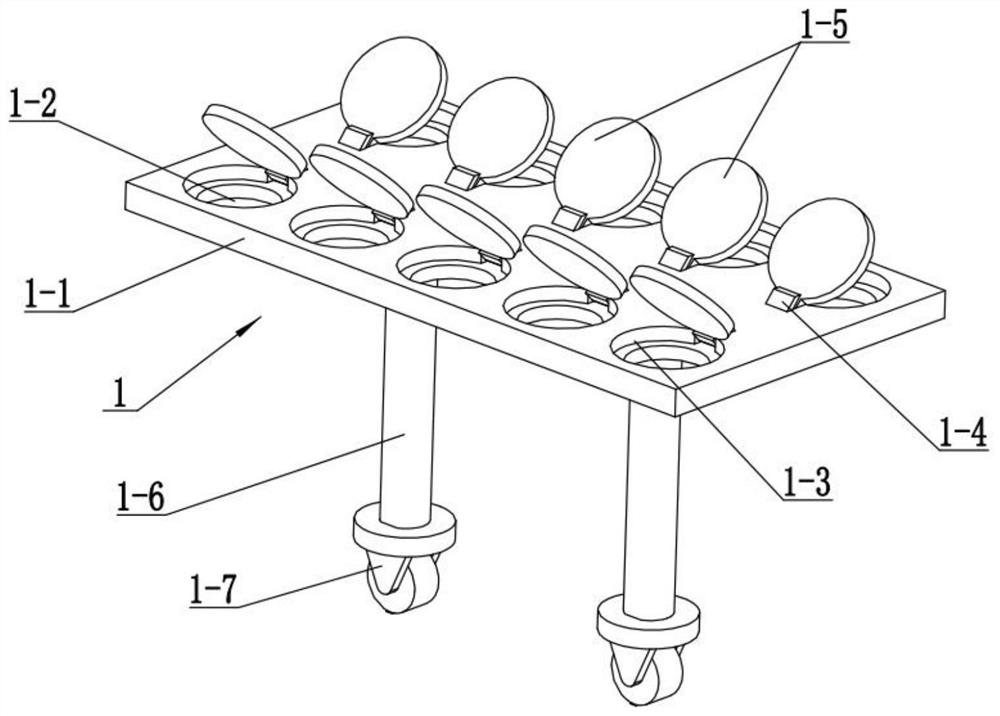

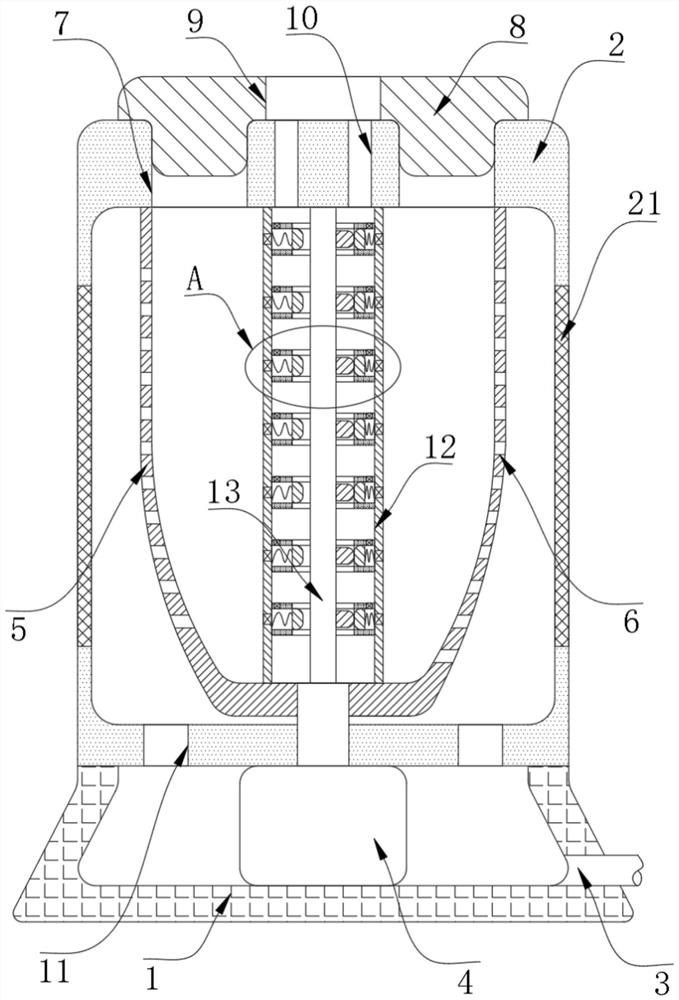

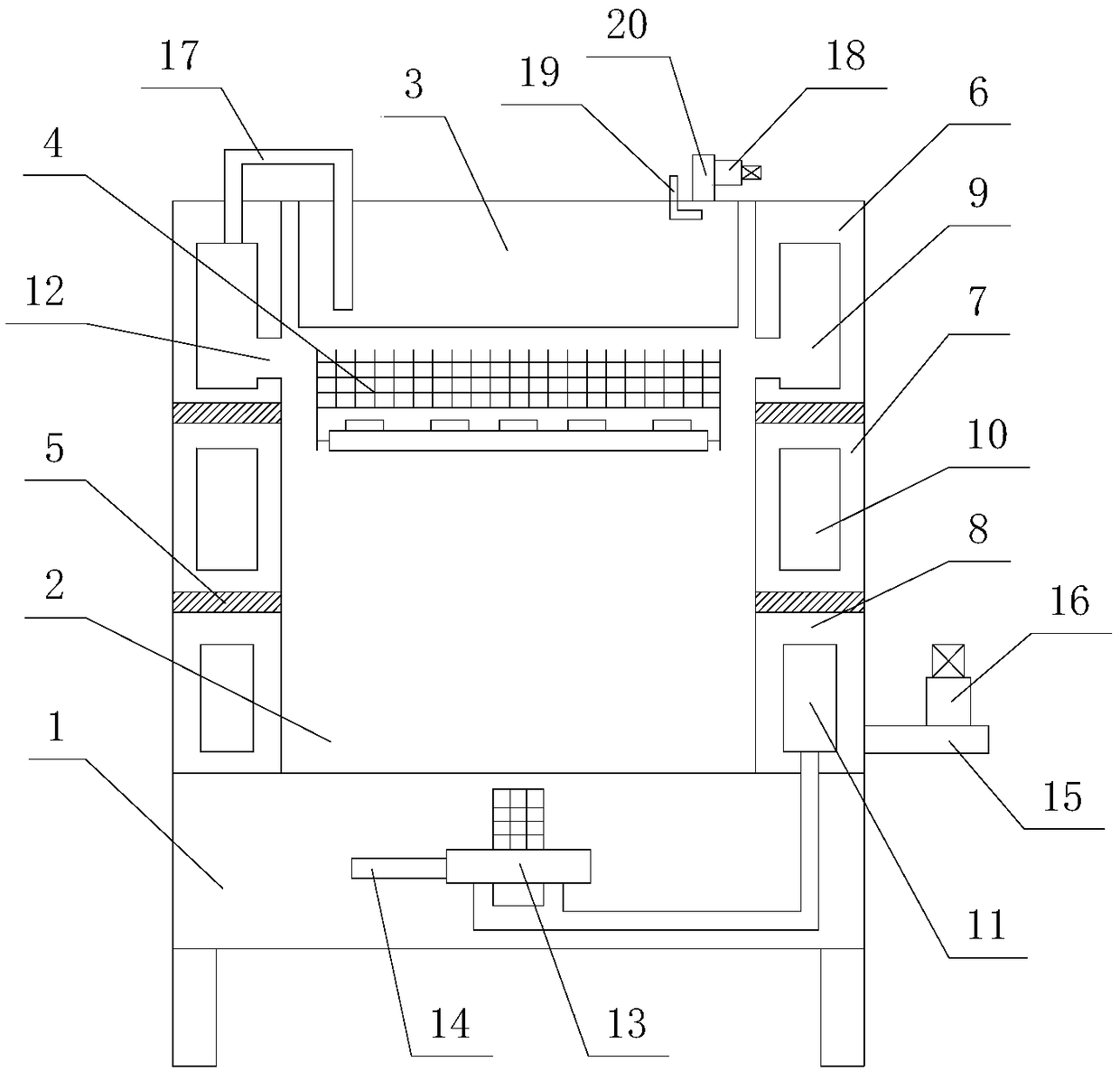

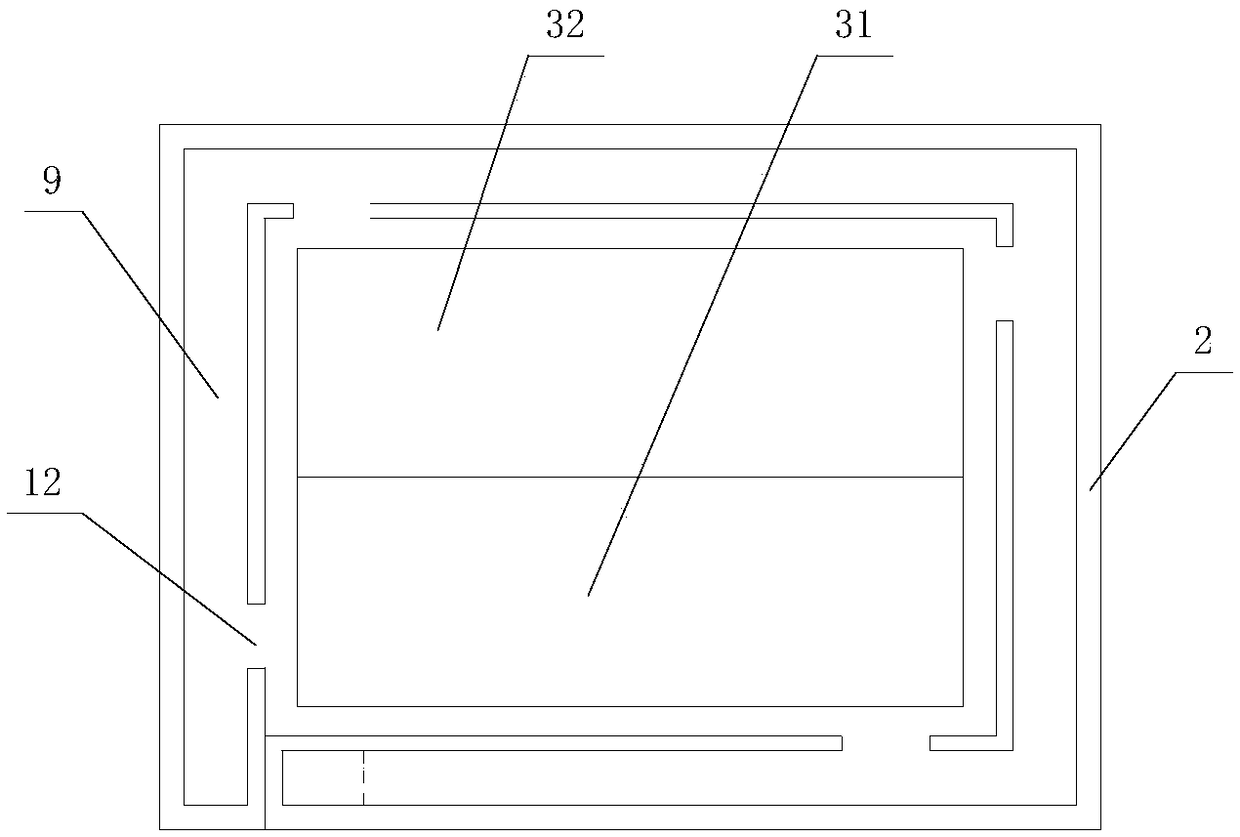

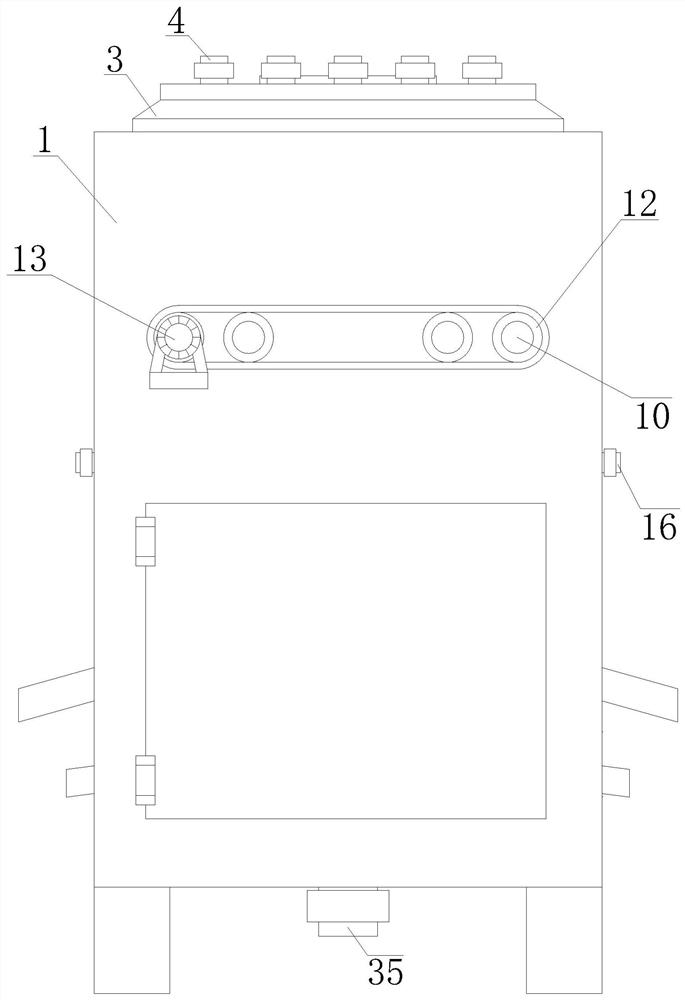

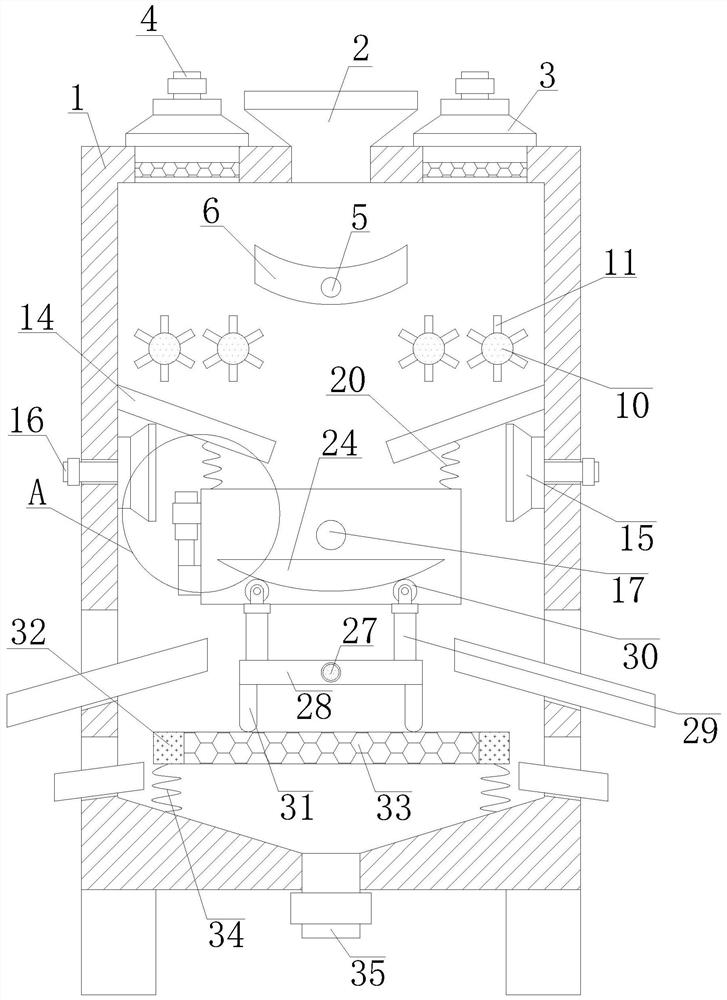

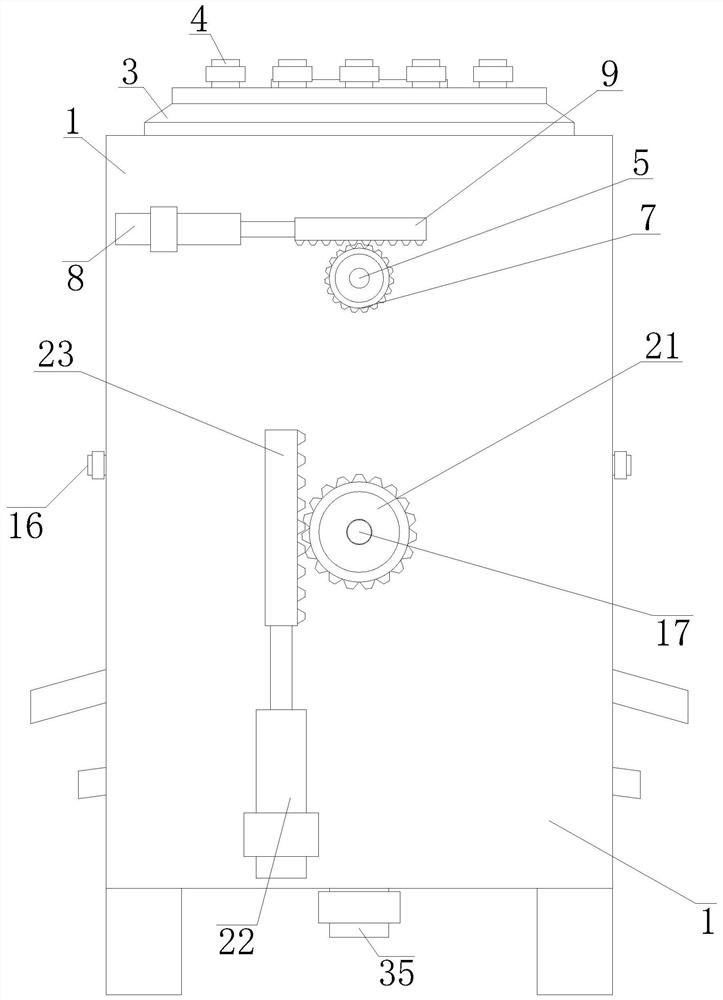

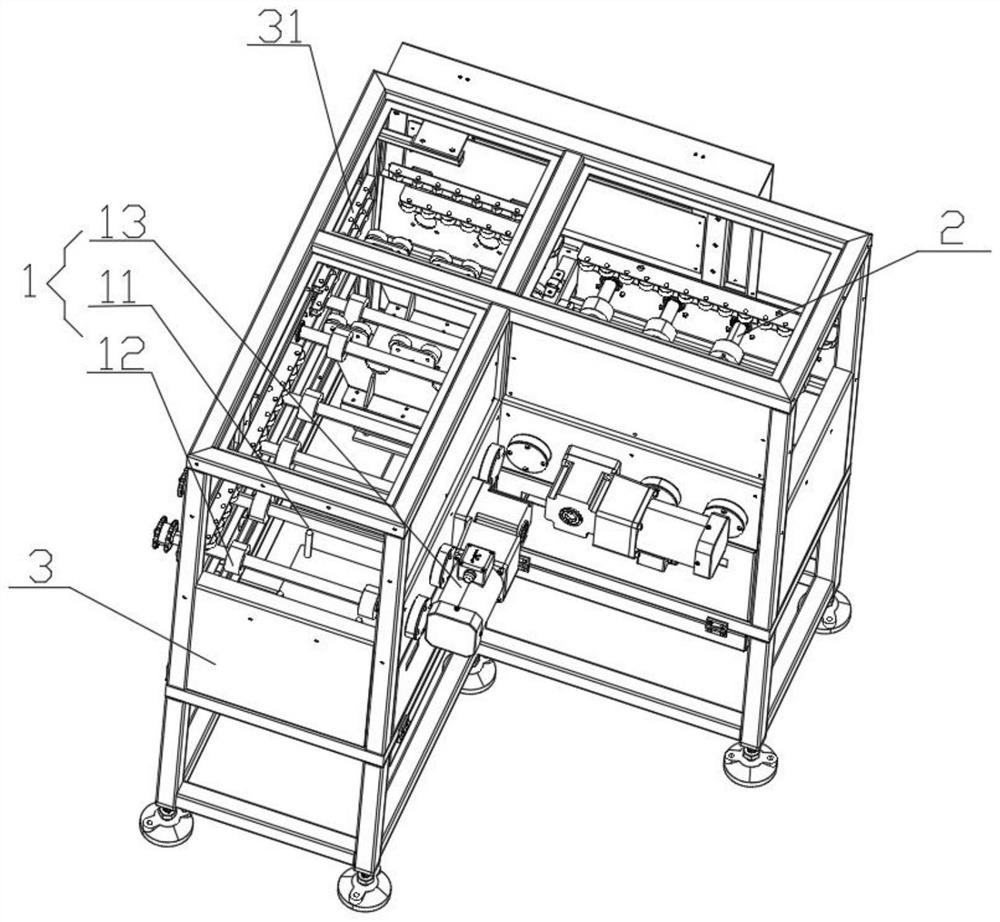

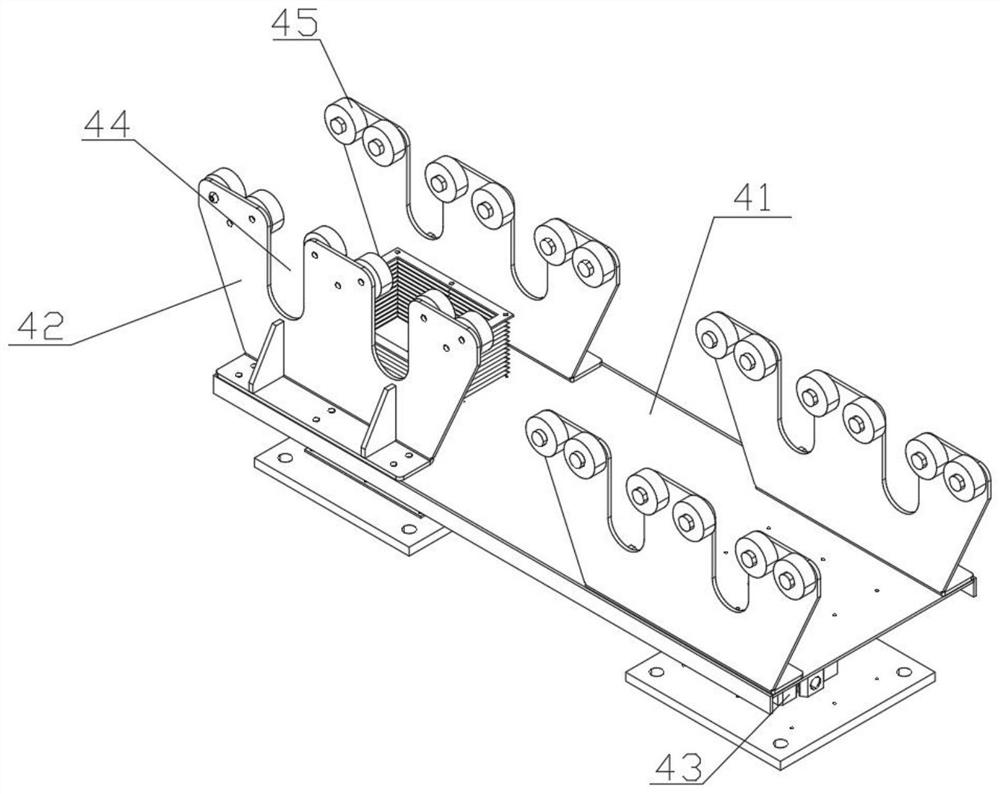

Fastener quenching treatment equipment

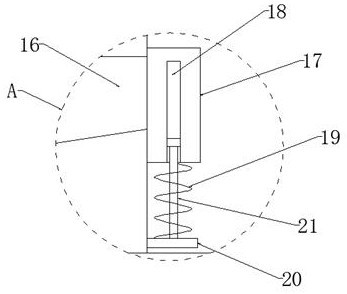

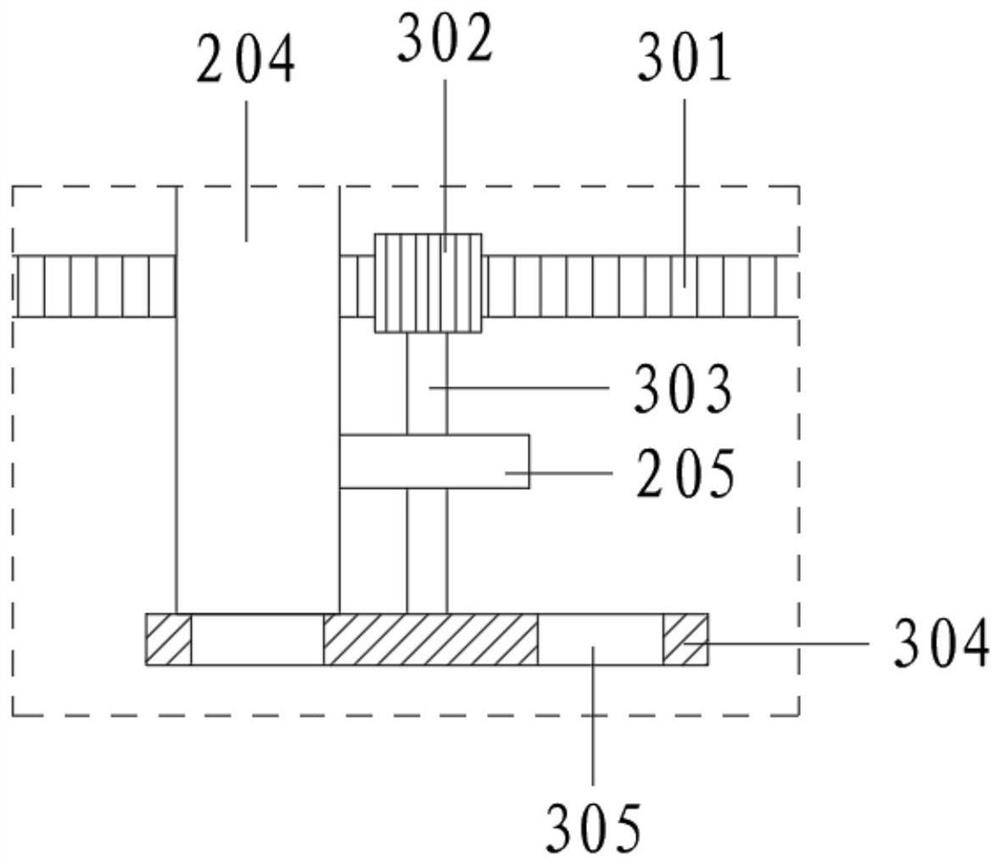

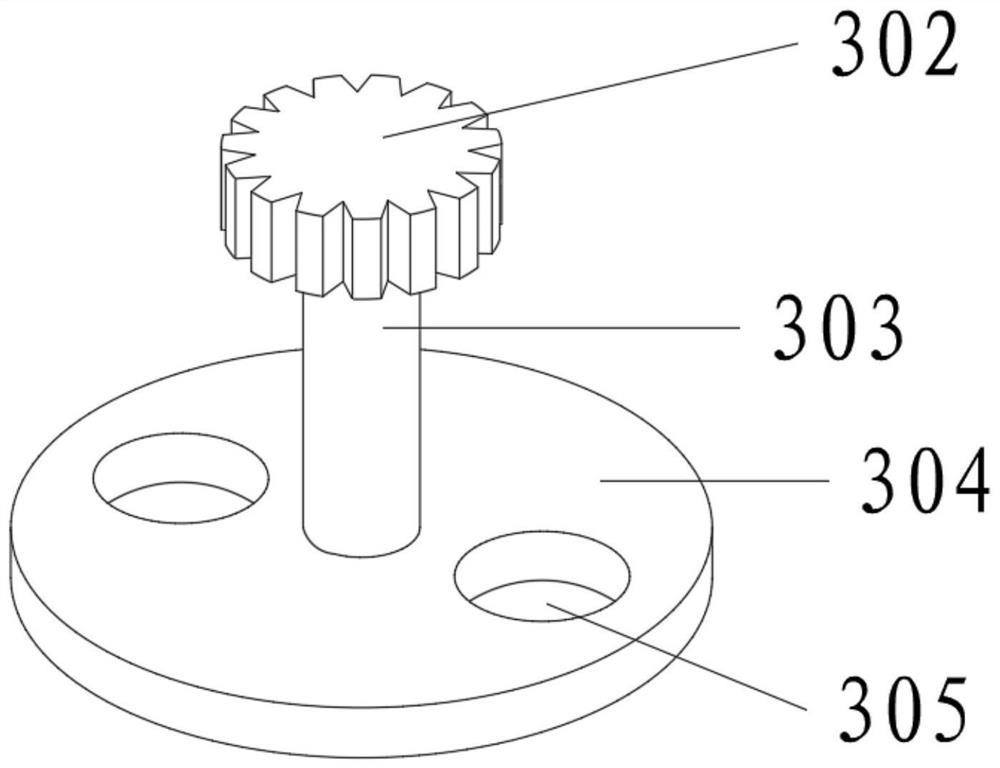

InactiveCN109554522AAvoid concentrated accumulationEven contactFurnace typesProcess efficiency improvementCooling effectEngineering

The invention provides fastener quenching treatment equipment which comprises a rack, a heating room, a first blanking device, a quenching tank, a cooling spraying device, a conveying device and an air blast drying device, wherein the heating room, the first blanking device, the quenching tank and a first waste liquid recycling tank are sequentially arranged in the rack from top to bottom; the quenching tank comprises an outer cylinder and an inner cylinder; a distributing mechanism is arranged above the inner cylinder; an accommodating cavity is formed between the outer cylinder and the innercylinder; a second blanking device is mounted at the bottom of the accommodating cavity; a baffle frame used for blocking the bottom of the accommodating cavity is mounted on the second blanking device; the cooling spraying device comprises a plurality of spraying brackets which are circumferentially distributed on the periphery of the quenching tank; the input end of the conveying device is positioned right below the quenching tank; the air-blast drying device is arranged above the output end of the conveying device; and a plurality of air-blast nozzles are uniformly mounted on the air-blastdrying device. The fastener quenching treatment equipment is convenient to operate, good in cooling effect and high in quenching efficiency.

Owner:浙江明铖金属科技股份有限公司

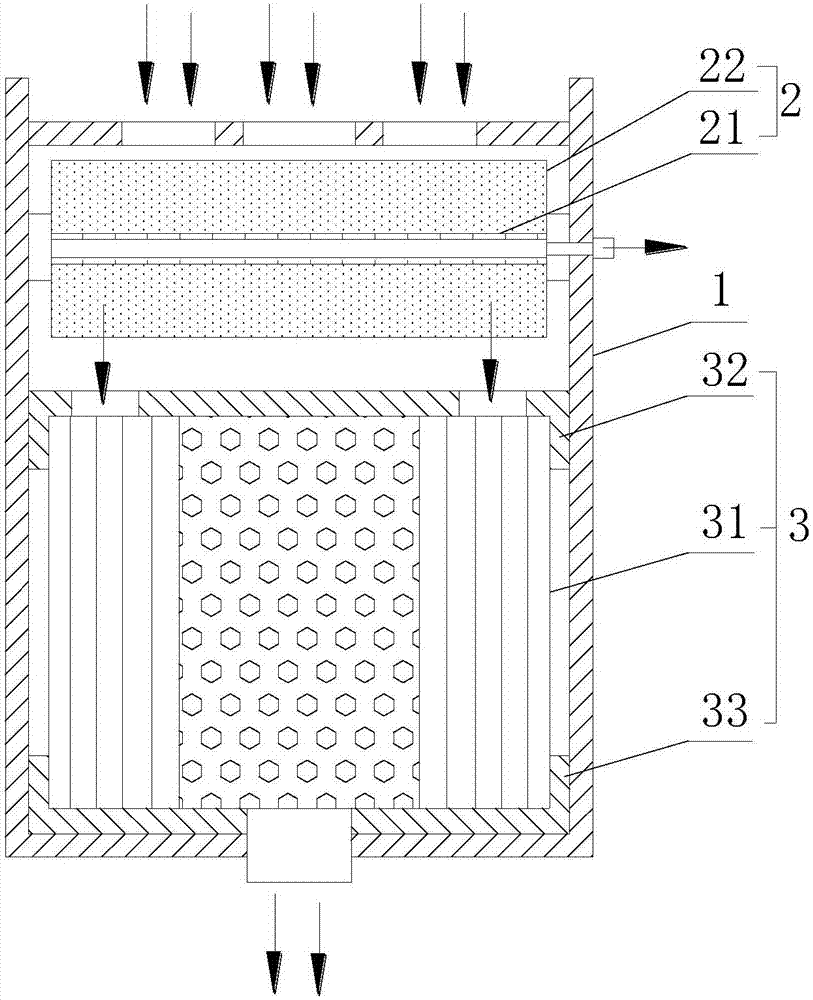

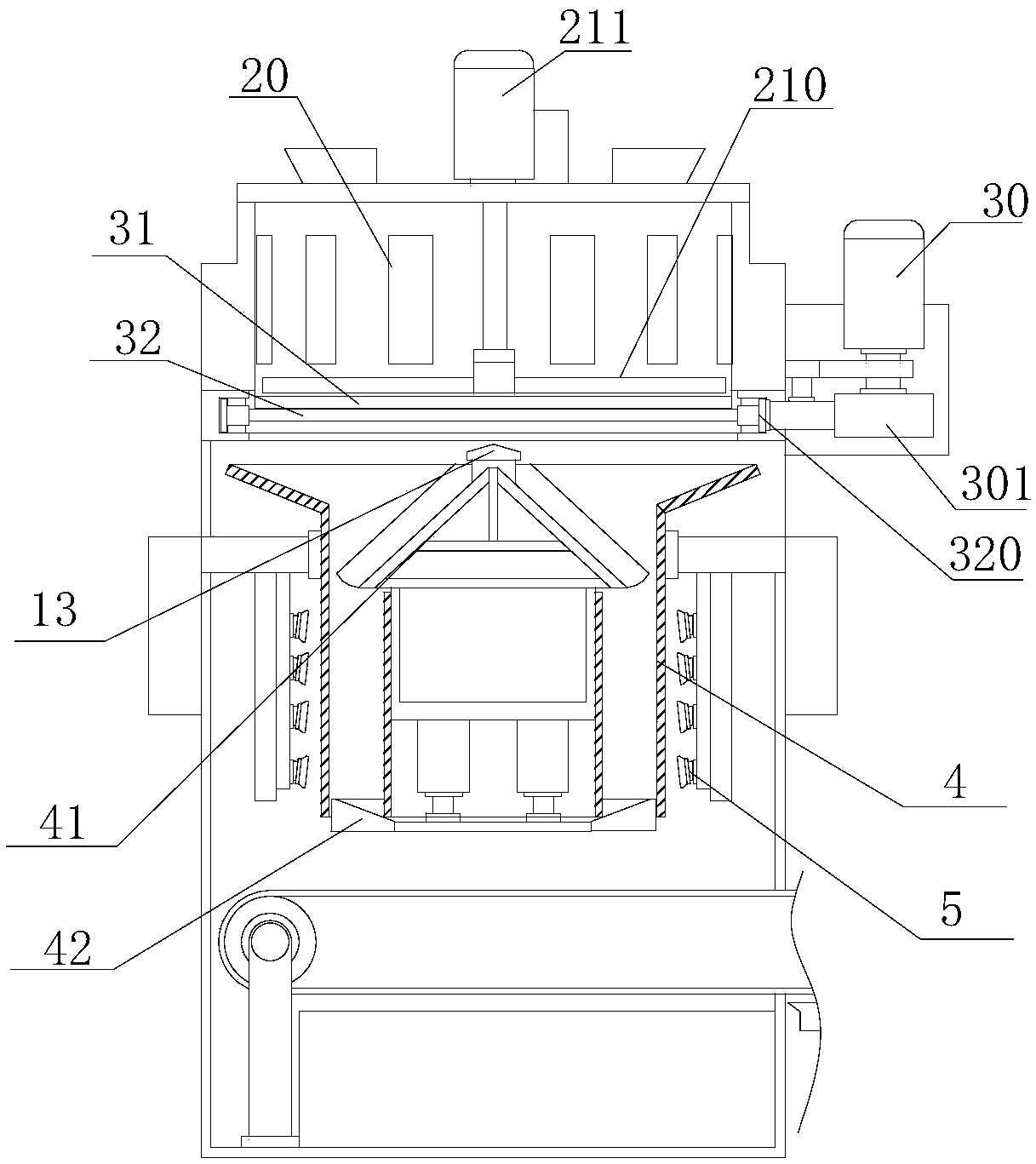

Wet dust removal type energy-saving coal-fired boiler

InactiveCN112066361AAutomatic flatteningAvoid concentrated accumulationFuel feeding arrangementsUsing liquid separation agentElectric machineDust control

The invention relates to the technical field of coal-fired boilers, in particular to a wet dust removal type energy-saving coal-fired boiler. Added coal can be automatically flattened. The coal-firedboiler comprises a floating oxygen supply leveling mechanism, a floating driving mechanism, a boiler body mechanism, a dust removal chimney mechanism, a dust removal spraying mechanism and a coal wetting and feeding mechanism; a rotating shaft and a driving cam on the rotating shaft are driven by a driving motor to rotate for driving two synchronous chain wheels to rotate synchronously; the otherdriving cam is driven by the other rotating shaft to rotate, so that two sliding rods and two contact wheels are driven by the the two driving cams to move up and down simultaneously; a fluctuating plate is driven by the two sliding rods to move up and down, and in the up-and-down moving process of the fluctuating plate, pulverized coal on the fluctuating plate can be driven to throw up and then fall down; and the pulverized coal falls onto the fluctuating plate, and is automatically laid flat, and the situation that the pulverized coal is concentrated and accumulated at a certain position, and consequently combustion is slow is avoided.

Owner:金丽颖

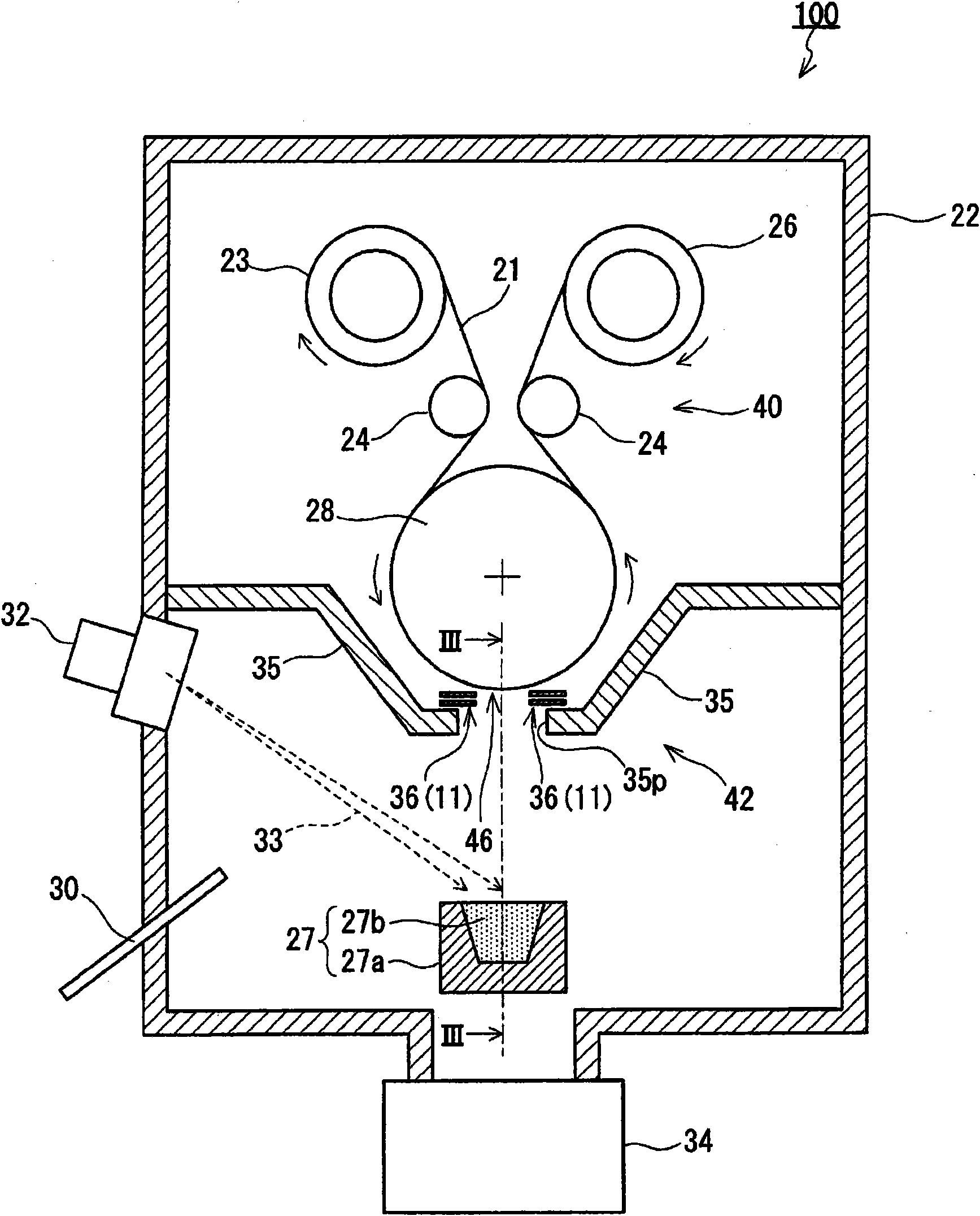

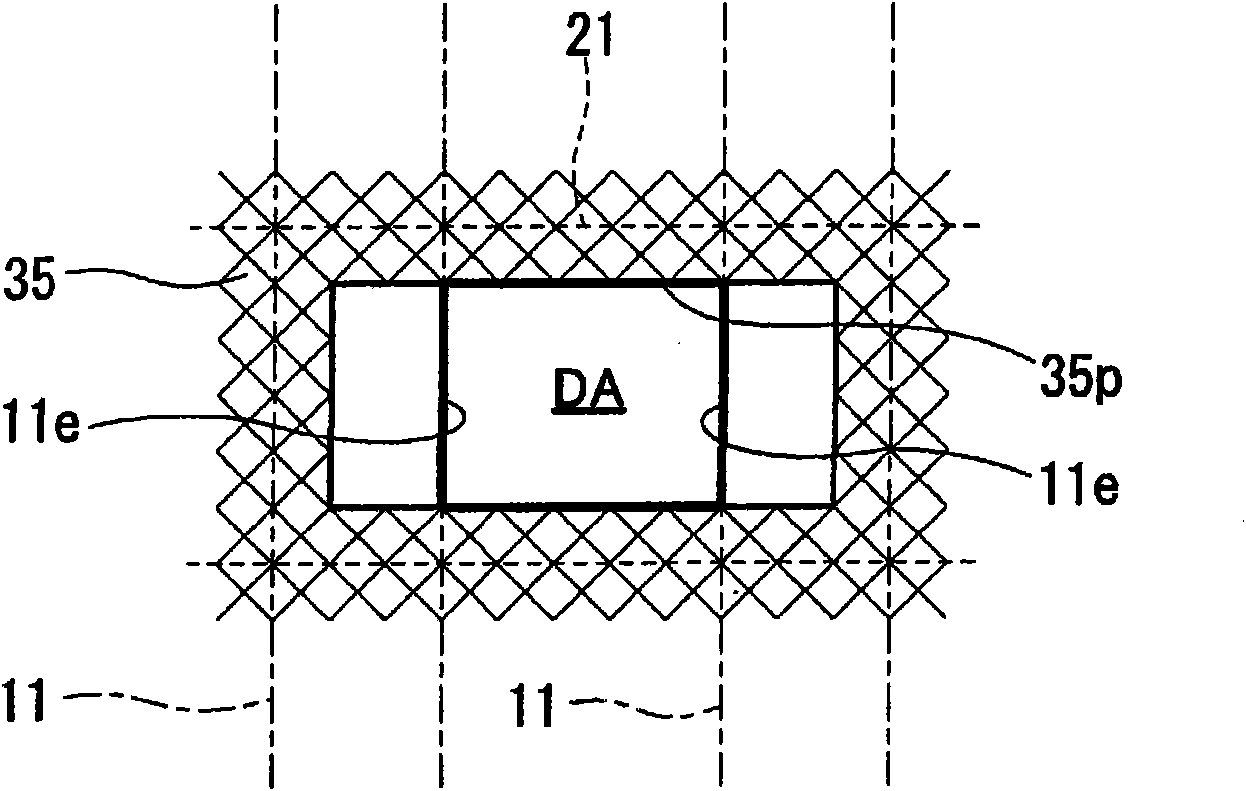

Thin film forming method and film forming apparatus

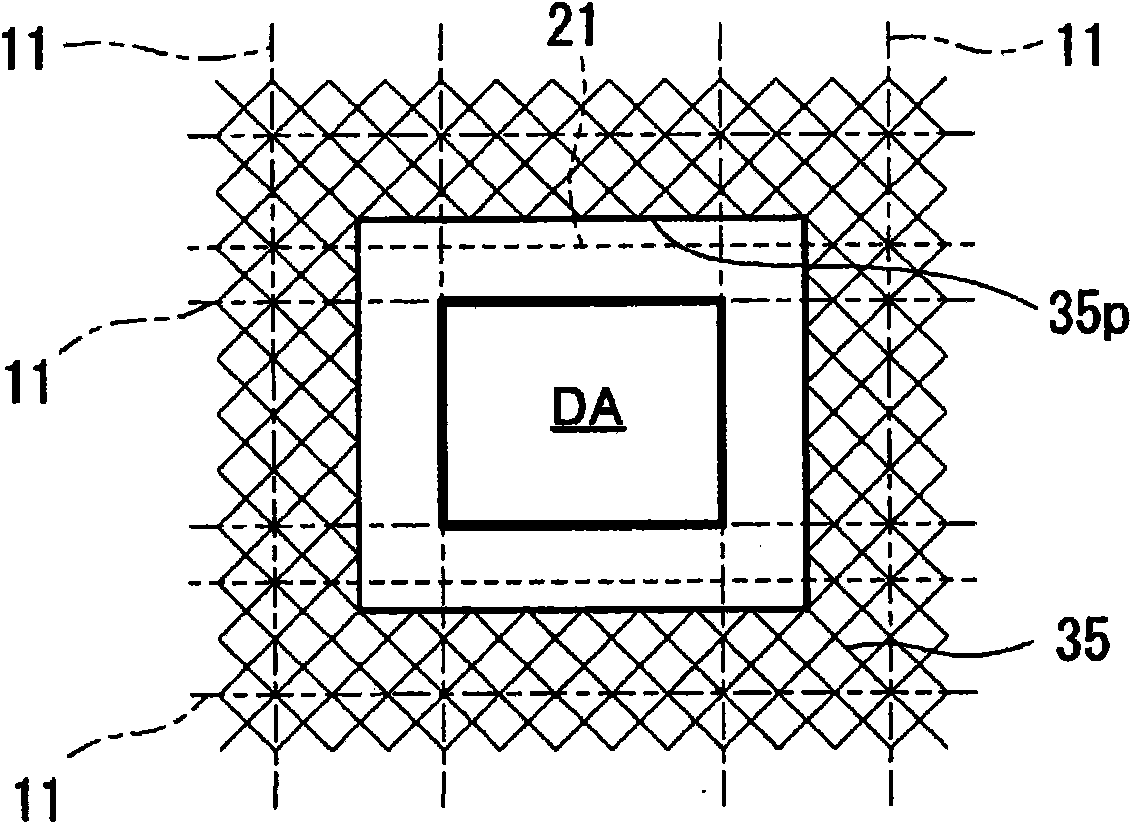

InactiveCN102016103AAccurateAvoid concentrated accumulationVacuum evaporation coatingSputtering coatingEngineering

Provided is a method for forming a thin film by depositing on a substrate (21) particles sputtered in vacuum from a film forming source (27). Specifically, the particles are deposited on the substrate (21) in a state where a movable endless strip (11) is arranged between the film forming source (27) and the substrate (21) so that a film forming region (DA) is defined on a surface of the substrate (21) by the movable endless strip (11) of which the approach route and the return route are set between the film forming source (27) and the substrate (21). The substrate (21) is typically a long substrate having flexibility. The particles are deposited on the substrate (21) while the substrate is being transferred from a feeding roller (23) to a take-up roller (26).

Owner:PANASONIC CORP

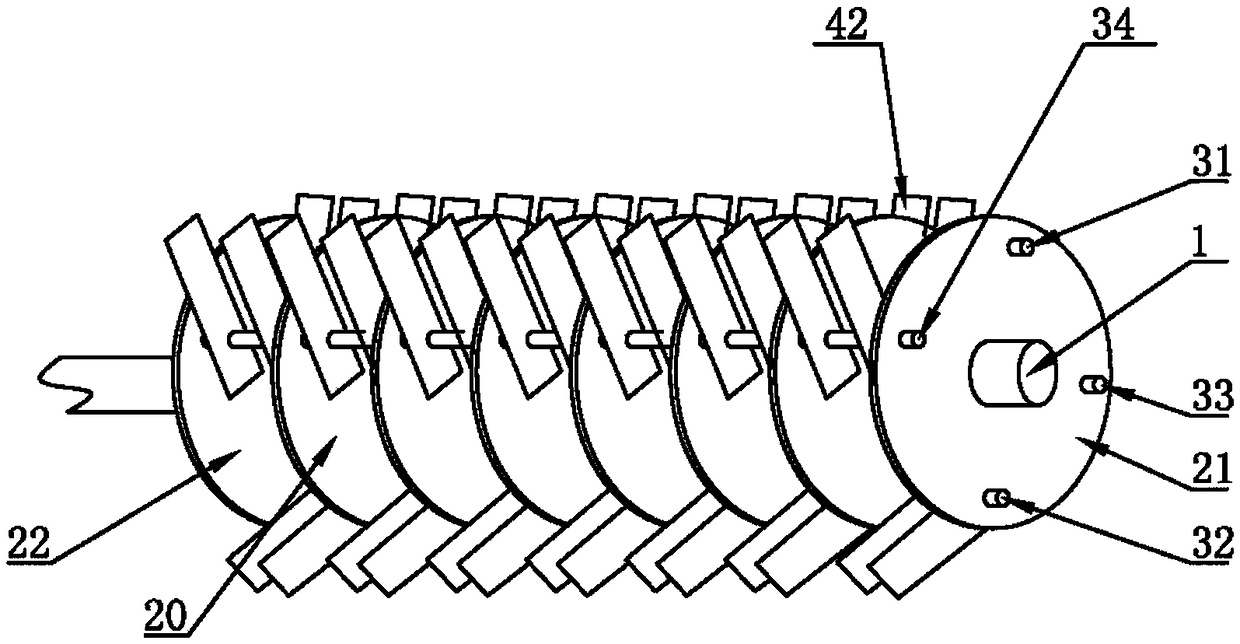

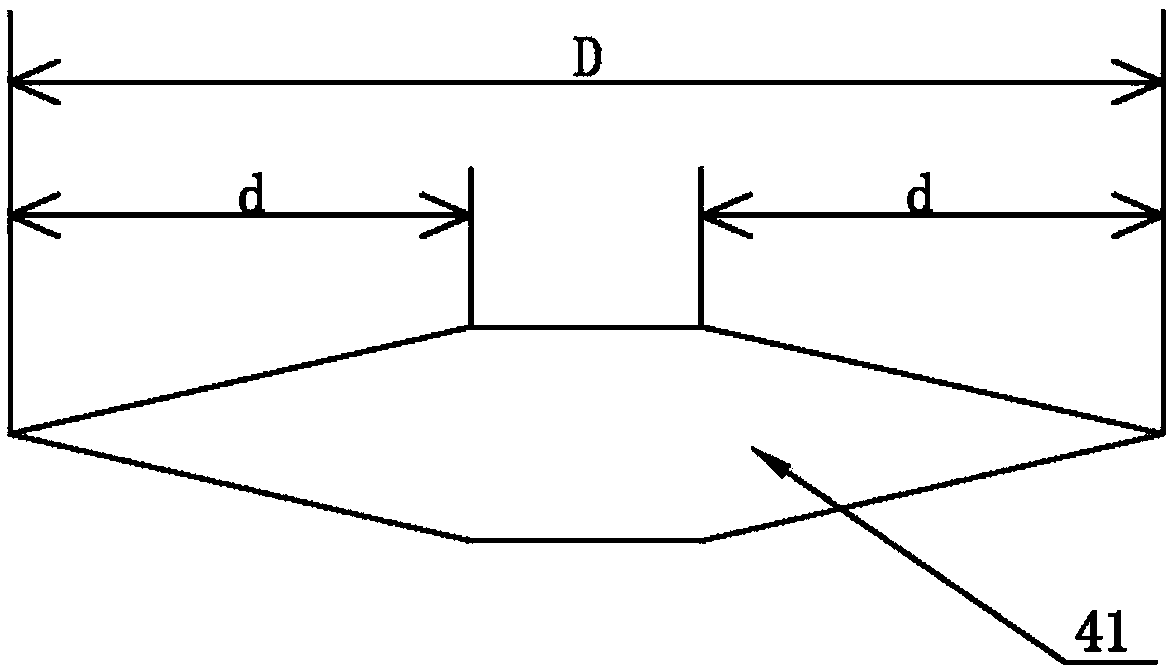

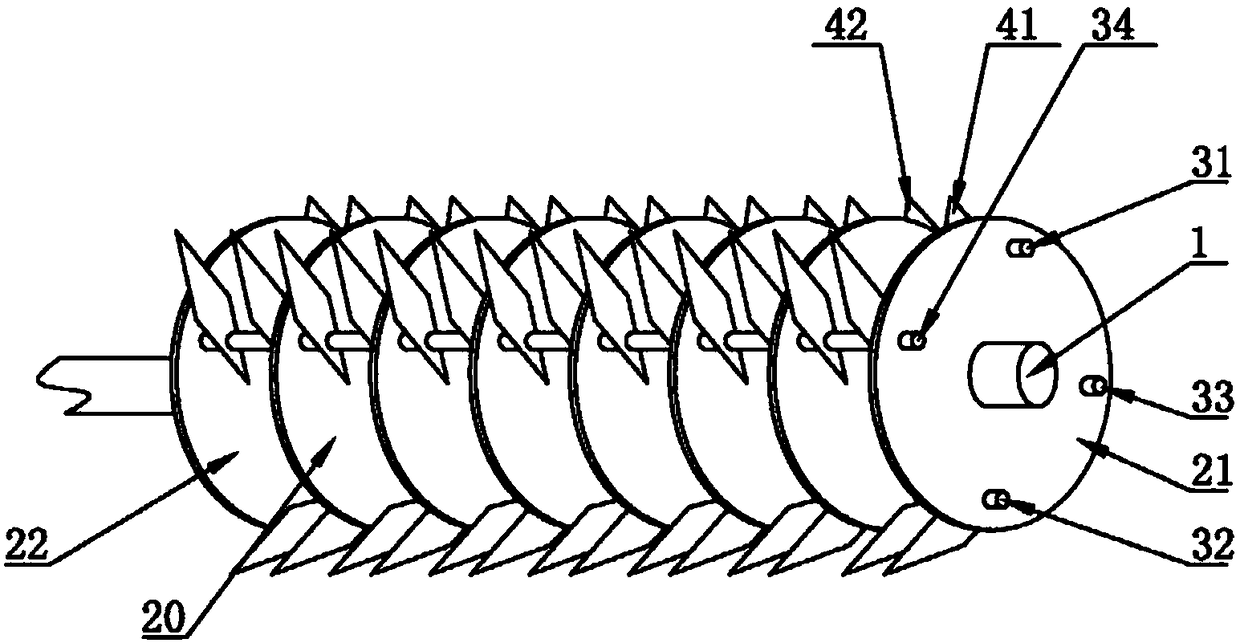

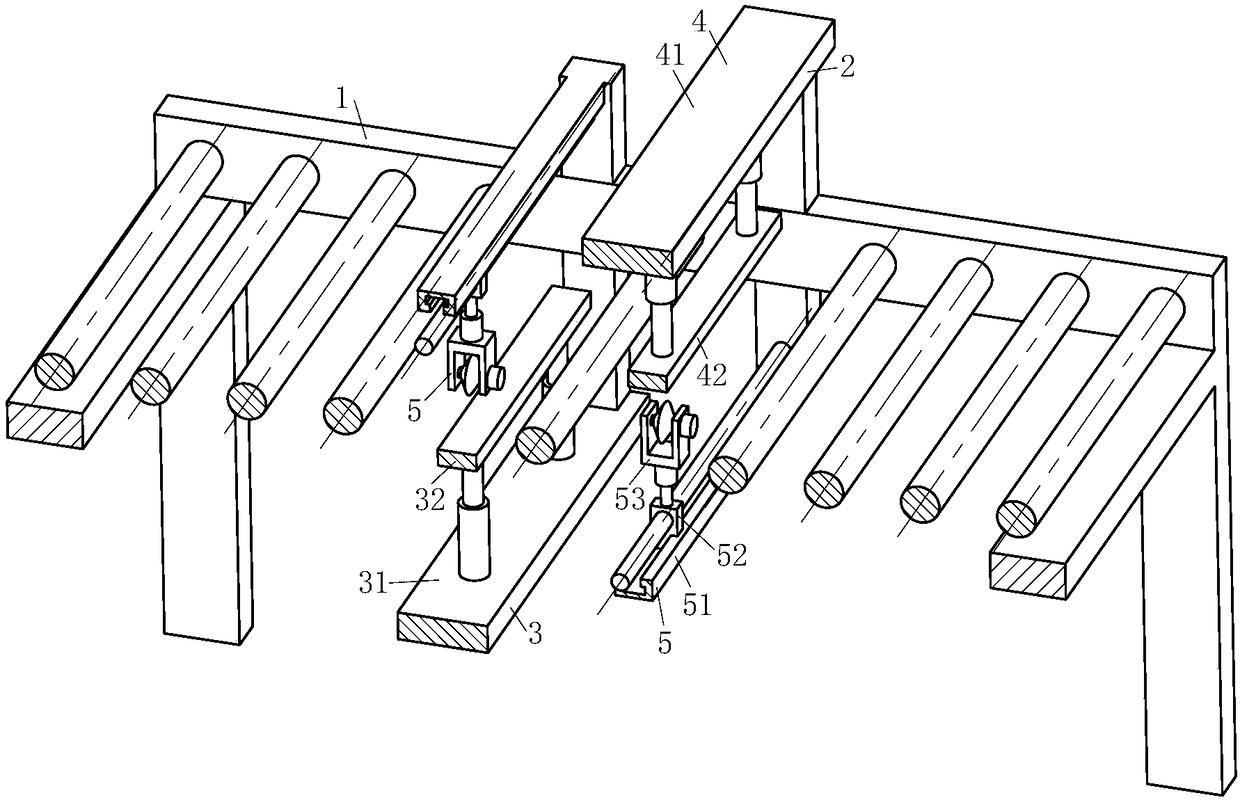

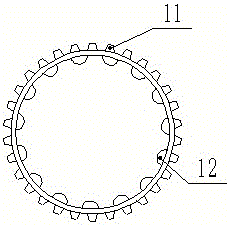

Pulverizing cutting head and pulverizer

The invention relates to the field of cutting tools, in particular to a pulverizing cutting head and a pulverizer. The pulverizing cutting head comprises a rotating shaft, a fixing disc, cutting bladeshafts and cutting blades; the cutting blade shafts are fixedly connected into two oppositely-formed fixing holes correspondingly and parallel to the rotating shaft; each cutting blade shaft is provided with the M pulverizing cutting blades, and M is positive integral; the rotating shaft drives the fixing disc to rotate, and the fixing disc drives the cutting blade shafts to move; the pulverizercomprises a shell and further comprises a cutting head and a sieve net arranged in the shell body; the sieve net is annularly arranged on the outer side of the pulverizing cutting head, the shell bodyis divided into a pulverizing cavity and a discharging cavity through the sieve net, and the pulverizing cutting head is arranged in the pulverizing cavity; and the shell body is provided with a feeding opening and a discharging opening, the feeding opening is formed in the upper portion of the shell body, the discharging opening is formed in the lower portion of the shell body, the feeding opening is connected with one end of a feeding channel, the sieve net is closely connected with the feeding channel, and the rotating shaft is connected with a motor. According to the pulverizing cutting head and the pulverizer, material temperature rising during pulverizing can be reduced, the pulverizing efficiency is improved, and the congestion problem of the pulverizer is solved.

Owner:郭国杉

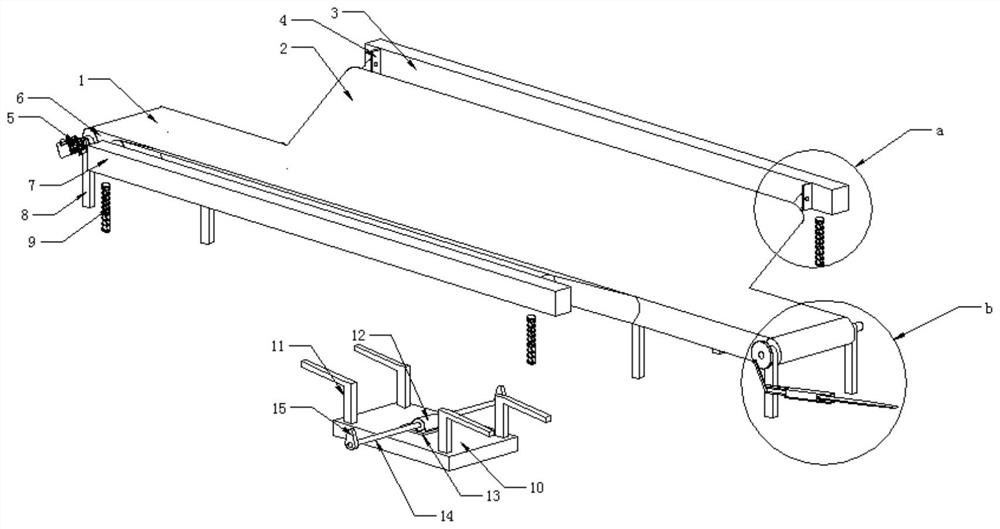

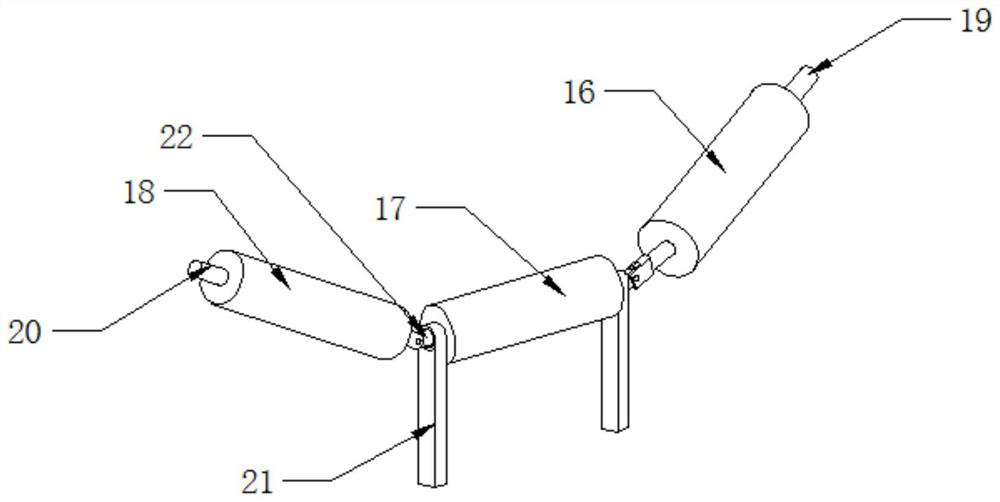

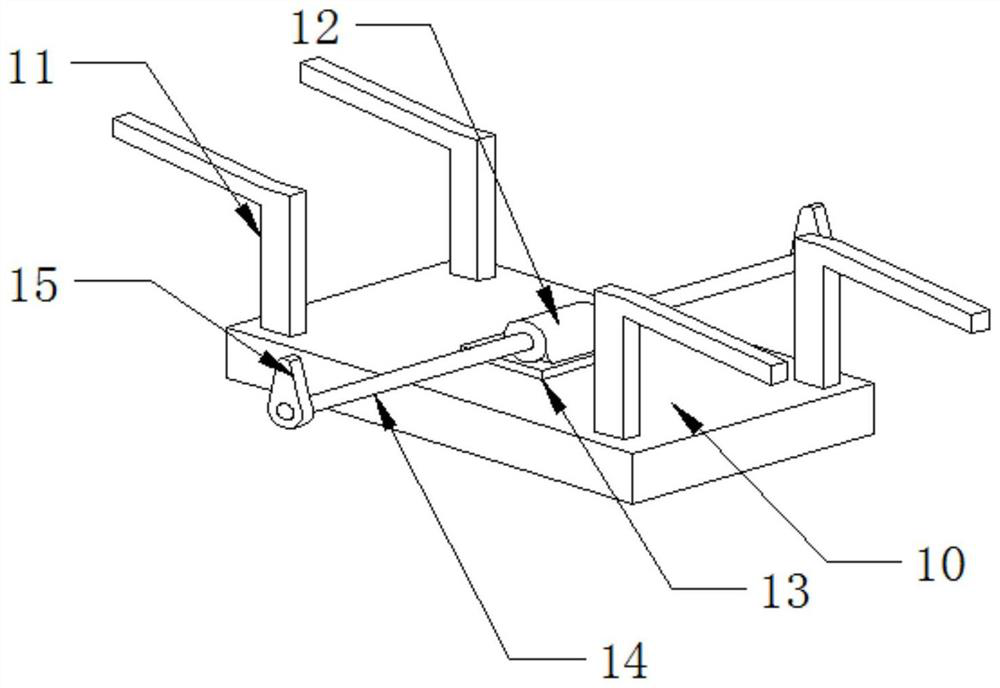

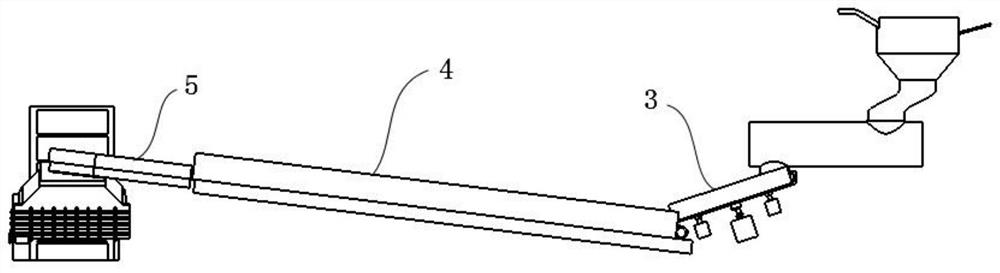

Belt conveyor for boiler fire coal conveying

ActiveCN111891630AAvoid scatterRealize the sorting functionConveyorsLump/pulverulent fuel feeder/distributionElectric machineProcess engineering

The invention discloses a belt conveyor for boiler fire coal conveying, and belongs to the technical field of belt conveyors. A double-head motor is started to drive a fifth rotating rod to rotate, the fifth rotating rod drives a special-shaped cam to rotate, and the special-shaped cam continuously impacts a second side strip-shaped rod and is matched with a vibration supporting assembly to drivea first side driven roller and a second side driven roller to vibrate, so that the problem that coal is scattered everywhere is avoided by centering on the top middle portion of a first conveying beltthrough vibration in the coal conveying process; and a rotating plate is started to drive a first hinge rod to move, the first hinge rod drives a second hinge rod to slide back and forth, the secondhinge rod drives a limiting sliding block to slide back and forth on the inner side of a limiting side U-shaped seat, and arranging of the coal in a boiler is achieved through an arranging shovel, sothat the problem of concentrated accumulation during coal feeding is avoided, and the arranging function is achieved through the arranging shovel.

Owner:长春市华宇机电输送设备有限公司

A bagasse cellulose and lignin centrifugal separation synchronous processing and screening equipment

ActiveCN111298749BImprove separation efficiencyImprove work efficiencyProductsReagentsCelluloseElectric machinery

Owner:ZHANJIANG EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

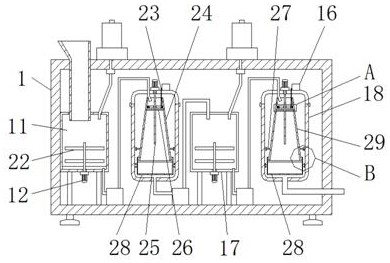

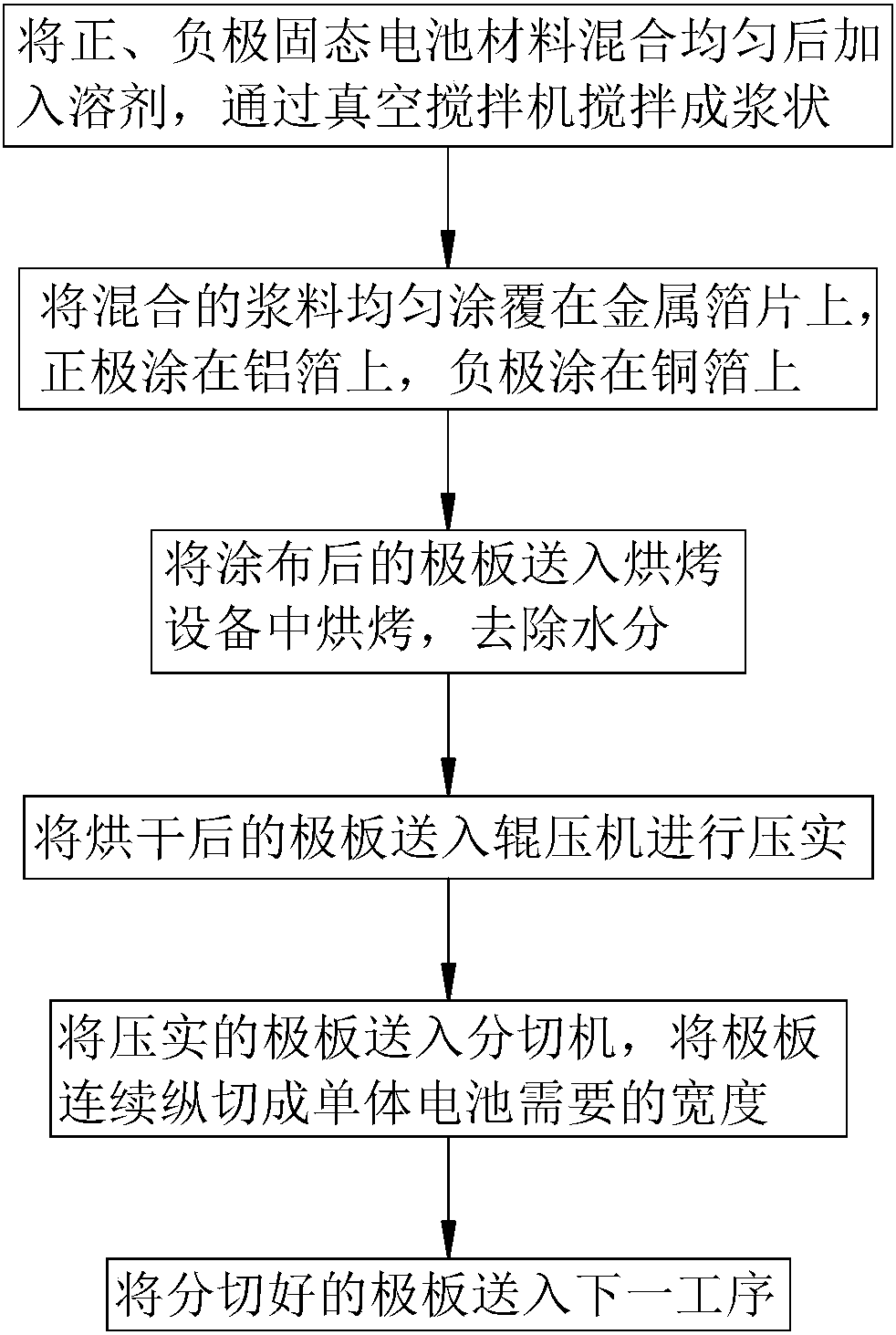

Lithium battery production process

ActiveCN108511808AReduce shear deformationQuality improvementFinal product manufactureElectrolyte accumulators manufactureEngineeringShearing deformation

The invention belongs to the technical field of lithium batteries, and in particular, relates to a lithium battery production process; the process adopts a slitter; the slitter comprises a worktable and a shearing mechanism, and the shearing mechanism comprises a preliminary shearing unit and a re-shearing unit; the preliminary shearing unit is arranged in the middle of the worktable, comprises alower support plate, a lower press plate and a cutting assembly and is used for nicking a polar plate; the re-shearing unit is arranged on one side of the preliminary shearing unit and is arranged onthe worktable; the re-shearing unit comprises an upper support plate, an upper press plate and a cutting assembly; the re-shearing unit is used for cutting off the polar plate; the bottom of the upperpress plate is provided with a groove notch, and the groove notch is internally provided with an adjusting unit; the adjusting unit comprises a left sliding block, a right sliding block and a lead screw. A way of nicking one face of the polar plate and then cutting off from the other face of the polar plate is adopted, the shearing deformation quantity of the polar plate is reduced, the quality of the polar plate slices is improved, subsequent winding slice leakage of the polar plate is avoided, and the internal short circuit caused by the contact between a positive electrode and a negative electrode is avoided.

Owner:自贡市泰威科技有限公司

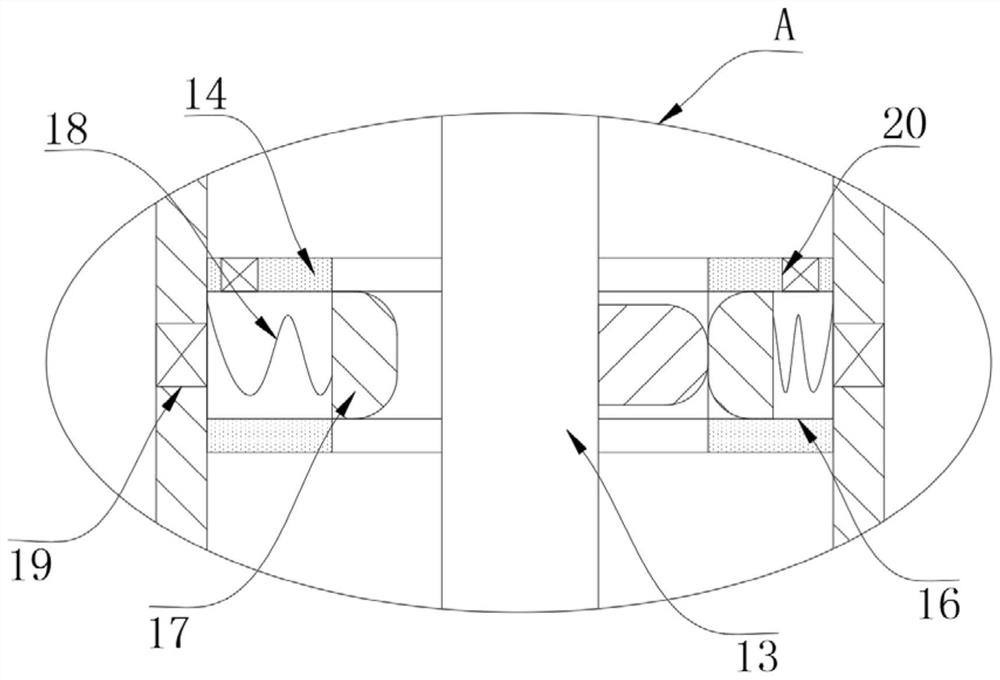

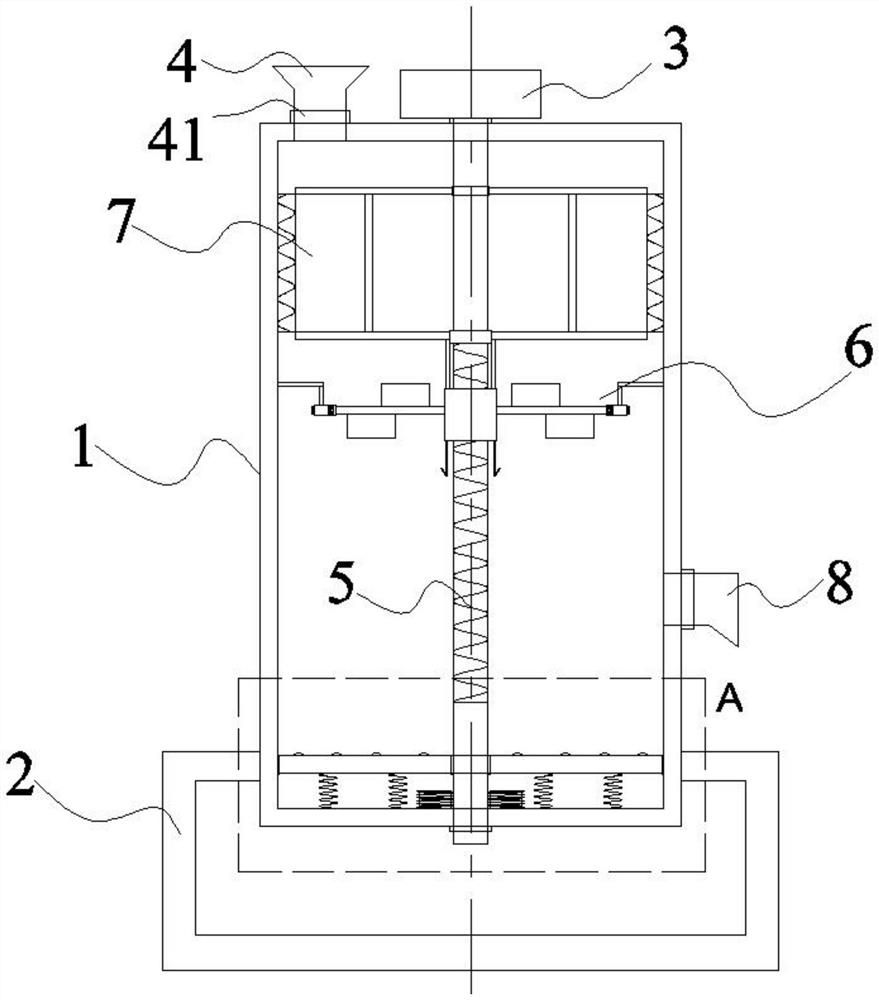

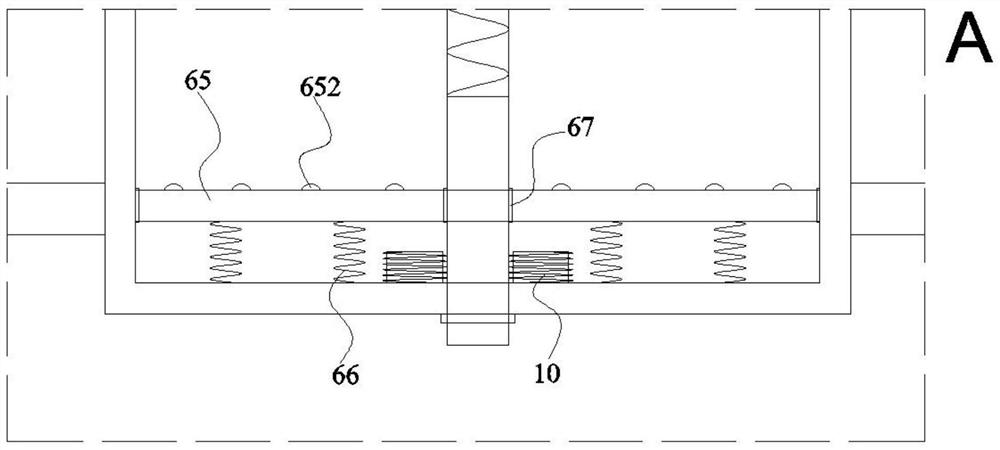

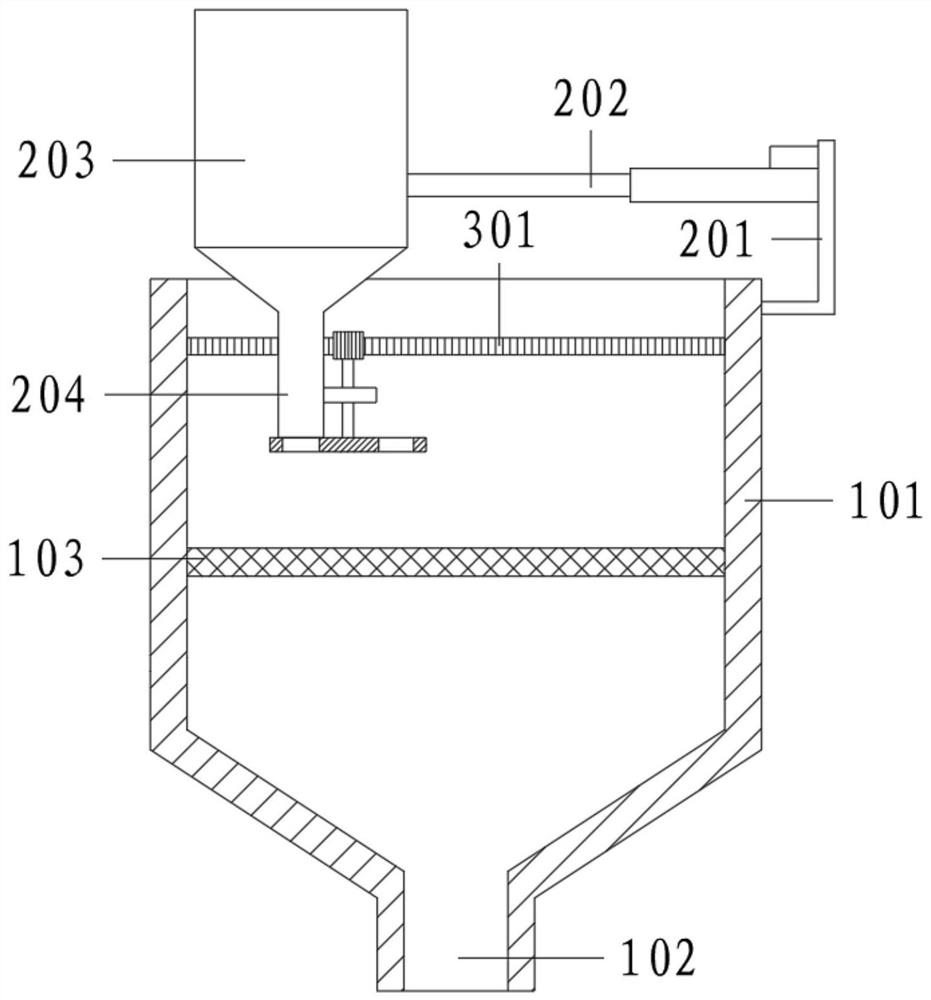

A kind of dehydration processing method of down and down anti-caking

ActiveCN112268430BAvoid concentrated accumulationImprove dehydration efficiencyDrying solid materials without heatDrying machines with non-progressive movementsElectric machineProcess engineering

The invention discloses an anti-caking down dehydration processing method, which comprises the following processing steps: feeding, dehydration, and collection. The processing equipment used in the above-mentioned dehydration processing method for anti-caking down down includes a collection box and a fixed The processing box at the upper end of the collection box, the side wall of the collection box is inserted with a water outlet pipe, the inner bottom of the collection box is fixed with a motor, the output shaft of the motor runs through the bottom of the processing box and is fixed with a drum, A plurality of water outlet holes are opened through the side wall of the drum. The advantage is that: in the present invention, by setting the lower end of the drum to be narrow and the upper end wide, and the inner wall of the lower part is arc-shaped, so that when the drum rotates at high speed, the down accumulated at the bottom will quickly move along the inner wall of the drum under the action of centrifugal force. Move upwards, so that it is relatively evenly distributed on the inner wall of the drum, so as to avoid the concentrated accumulation of a large amount of down and make the dehydration process more efficient.

Owner:杭州金弘三鸟羽绒制品有限公司

Multistage condensation miniature hot water stove

PendingCN109084343AHigh thermal efficiencyShorten burn timeWater heating stoves/rangesAir heatersCombustion chamberCombustor

The invention discloses a multistage condensation miniature hot water stove, comprising a stove body and a combustor. A heating tank is mounted in the upper portion of the stove body; a heating grateis mounted in the combustor; the inside of the stove body is divided by two horizontal partitions which are circular into a primary waste heat exchange area, a secondary waste heat exchange area and atertiary waste heat exchange area sequentially from top to bottom; a plurality of high-temperature tail gas inlets communicated with the combustor are arranged evenly in the primary waste heat exchange area in spaced manner; an intensive exhaust fan is externally connected to the tertiary waste heat exchange area and is connected with a tail gas discharge pipe; a water incoming pipe is also connected with the tertiary waste heat exchange area; a hot water outgoing pipe is connected to the top of one side of the primary waste heat exchange area; a water outlet of the hot water outgoing pipe ispositioned in the heating tank. The multistage condensation miniature hot water stove has the advantages that high-temperature tail gas generated by the combustor is subjected to efficient heat exchanging, hot water produced by heat exchanging is delivered into the heating tank, energy consumption for heating is reduced, and application cost is reduced.

Owner:南充烽英堂厨房电器设备科技有限公司

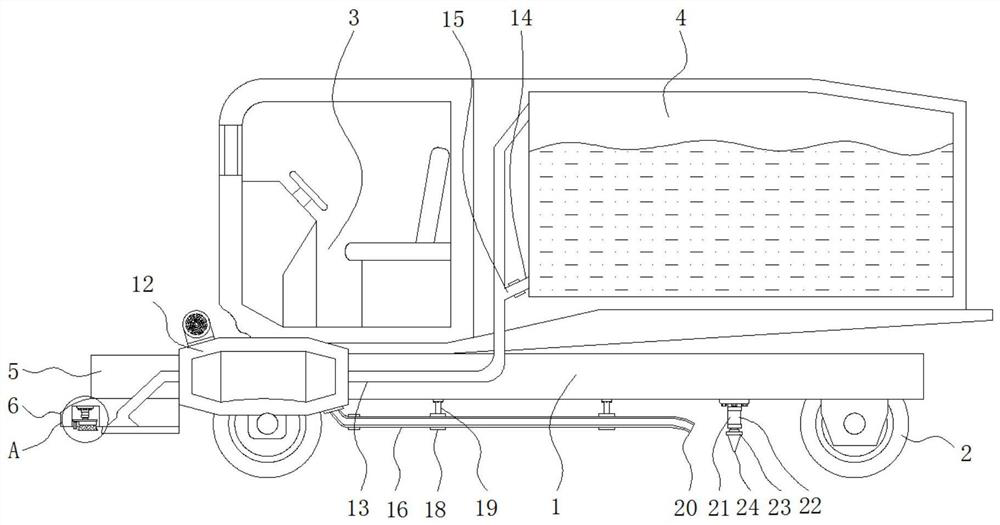

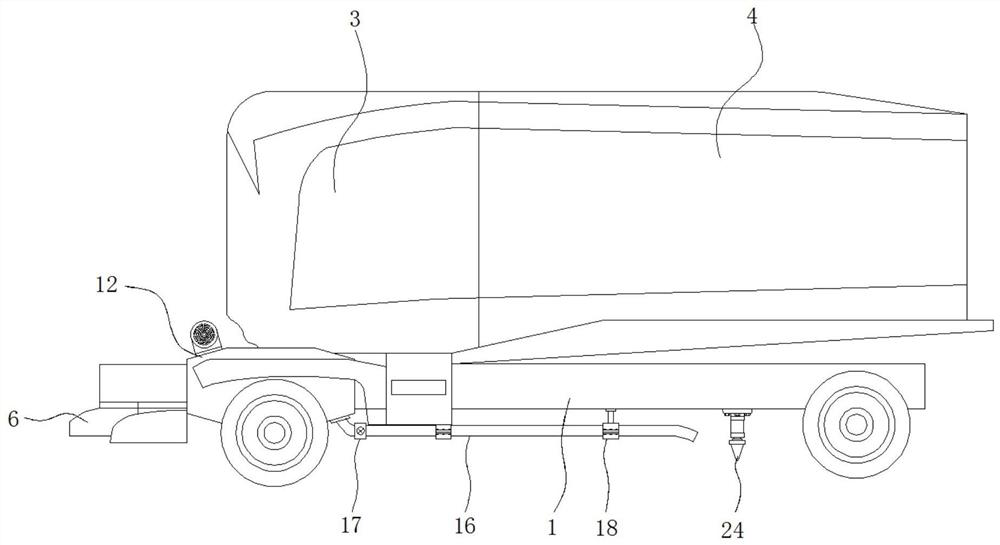

Agricultural vehicle assisting in grain airing

InactiveCN113005959AImprove cleanlinessAffect cleanlinessConveyorsSeed preservation by dryingAgricultural scienceVehicle frame

The invention discloses an agricultural vehicle assisting in grain airing, and relates to the technical field of agricultural vehicles, the agricultural vehicle comprises a vehicle frame and a storage cabin, transmission hubs are mounted at the left end and the right end of the lower portion of the vehicle frame, a cab is arranged at the left end of the upper portion of the vehicle frame, the storage cabin is located at the right end of the upper portion of the vehicle frame, and a fixing seat is arranged at the left end of the vehicle frame; a protective shell is installed on the outer side of the lower portion of the fixing base, a first hydraulic rod is installed at the front end of the lower portion of the fixing base, a cleaning mechanism is arranged at the lower end of the first hydraulic rod, a suction motor is arranged above the right end of the fixing base, a pipeline is arranged at the right end of the suction motor, and the suction motor is connected with a storage cabin through the pipeline. A discharging mechanism is arranged below the left end of the storage cabin, and a paving mechanism is arranged at the right end of the lower portion of the vehicle frame. According to the agricultural vehicle, grain aired on the ground can be automatically collected and aired, meanwhile, the aired grain can be evenly spread, manpower can be saved, and the grain airing efficiency can be improved.

Owner:ZHONGKAI UNIV OF AGRI & ENG

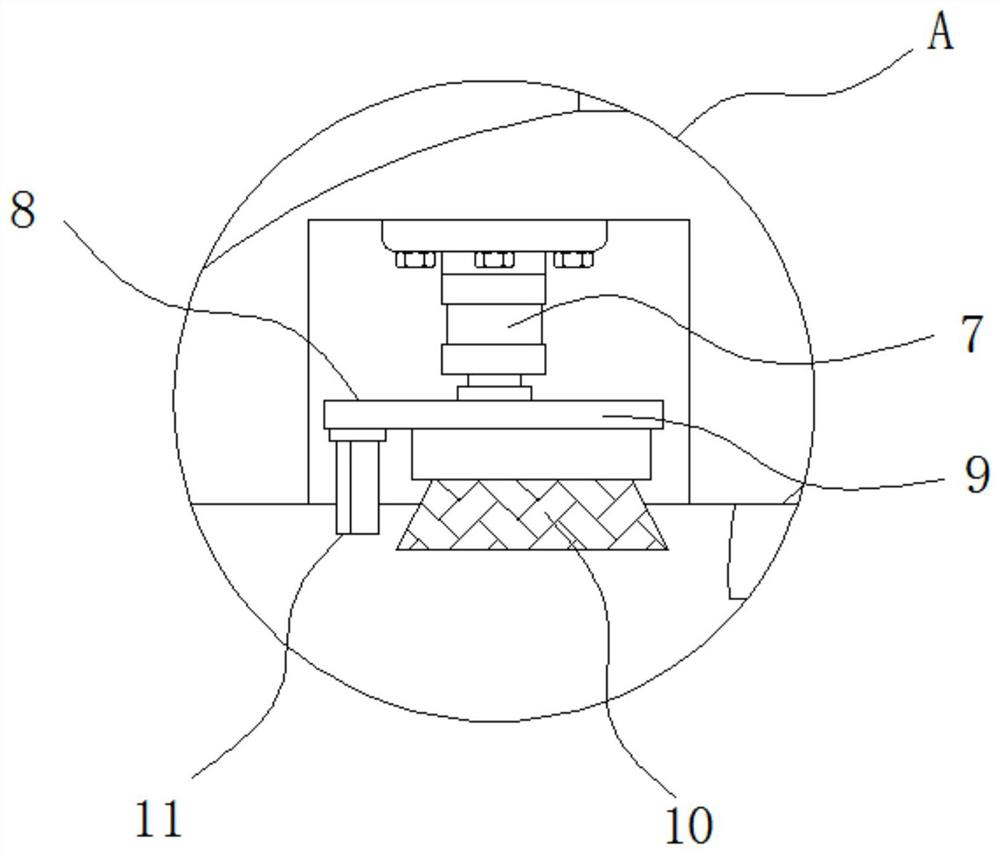

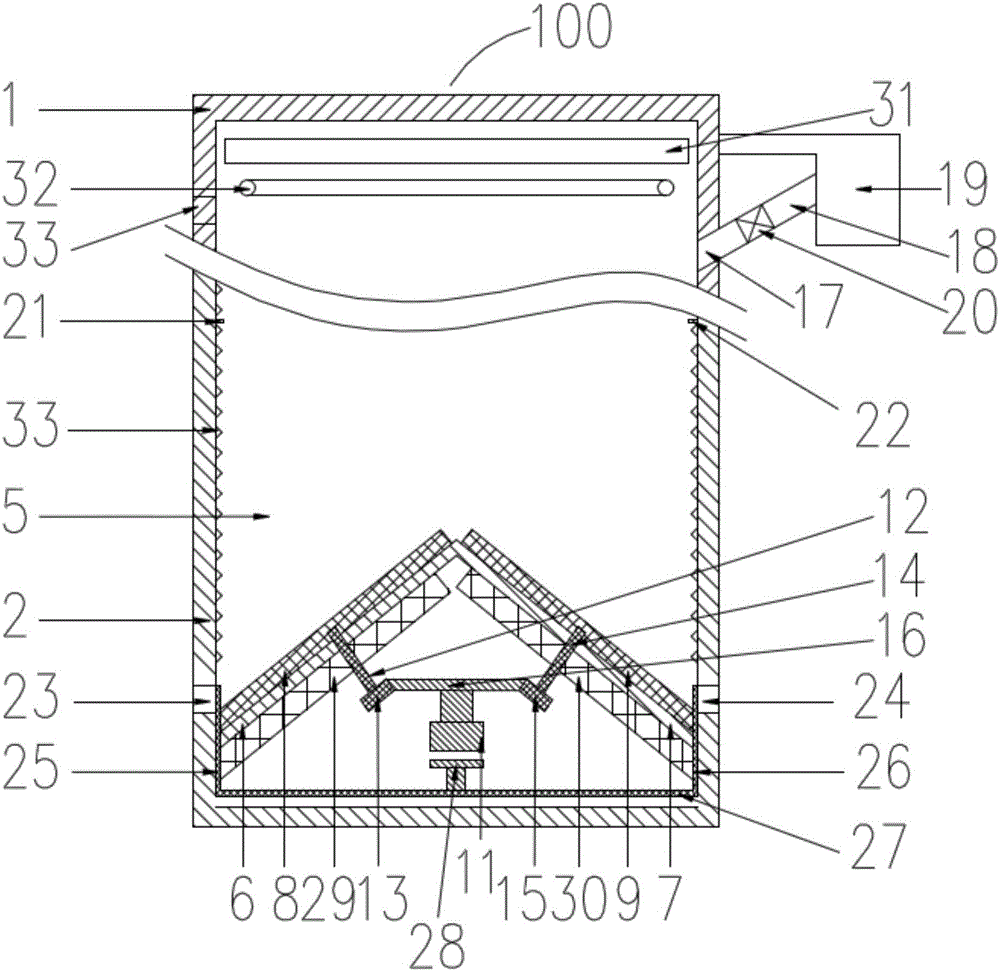

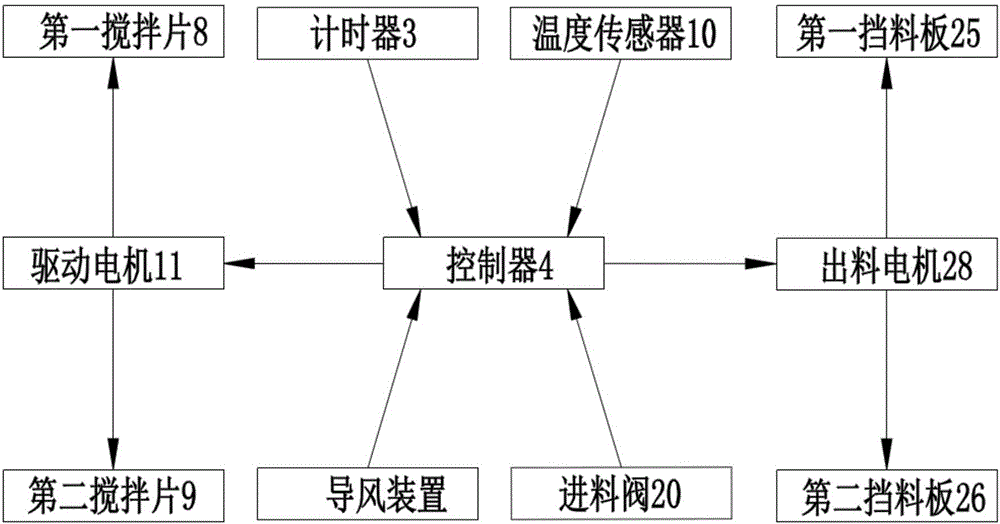

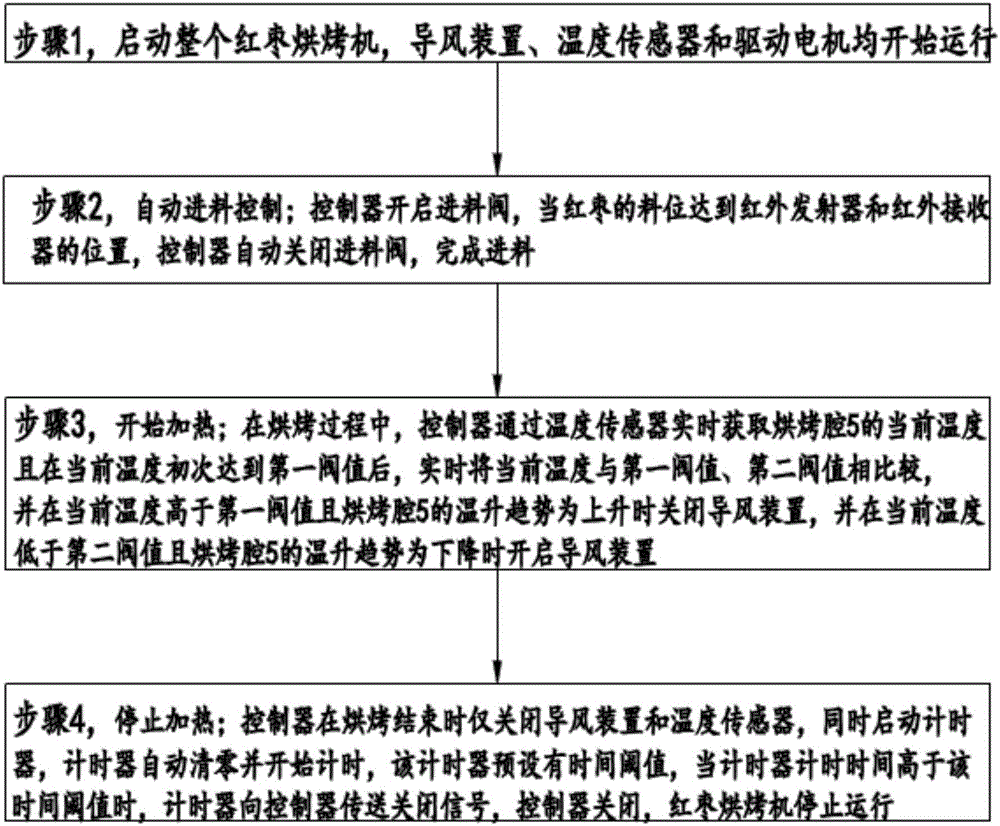

Red date baking method without producing cancerogenic substances

ActiveCN106720222AImprove baking efficiencyAvoid concentrated accumulationFood treatmentFruits/vegetable preservation by dehydrationDrive motorEngineering

The invention discloses a red date baking method without producing cancerogenic substances. The method comprises the following steps: 1, starting a whole red date baking machine; 2, performing automatic feeding control, namely opening a feeding valve by a controller, and automatically closing the feeding valve to complete feeding by the controller when the material level of red dates reaches an infrared transmitter and an infrared receiver; 3, starting heating, namely acquiring a current temperature of a baking chamber in real time by the controller by virtue of a temperature sensor in the baking process, comparing the current temperature with a first threshold value and a second threshold value in real time when the current temperature preliminarily reaches the first threshold value, closing an air ducting device when the current temperature is higher than the first threshold value and the temperature of the baking chamber is rising, and opening the air ducting device when the current temperature is lower than the second threshold value and the temperature of the baking chamber is dropping; and 4, stopping heating, namely only closing the air ducting device and the temperature sensor by the controller when baking is ended, starting a timer, and enabling the timer to automatically perform zero clearing and start timing, wherein a time threshold value is preset on the timing module, the timer transfers a closure signal to the controller when the time of the timer is higher than the time threshold value, the controller is closed, a driving motor and the timer are simultaneously closed, and the red date baking machine stops working.

Owner:山东鑫义食品科技股份有限公司

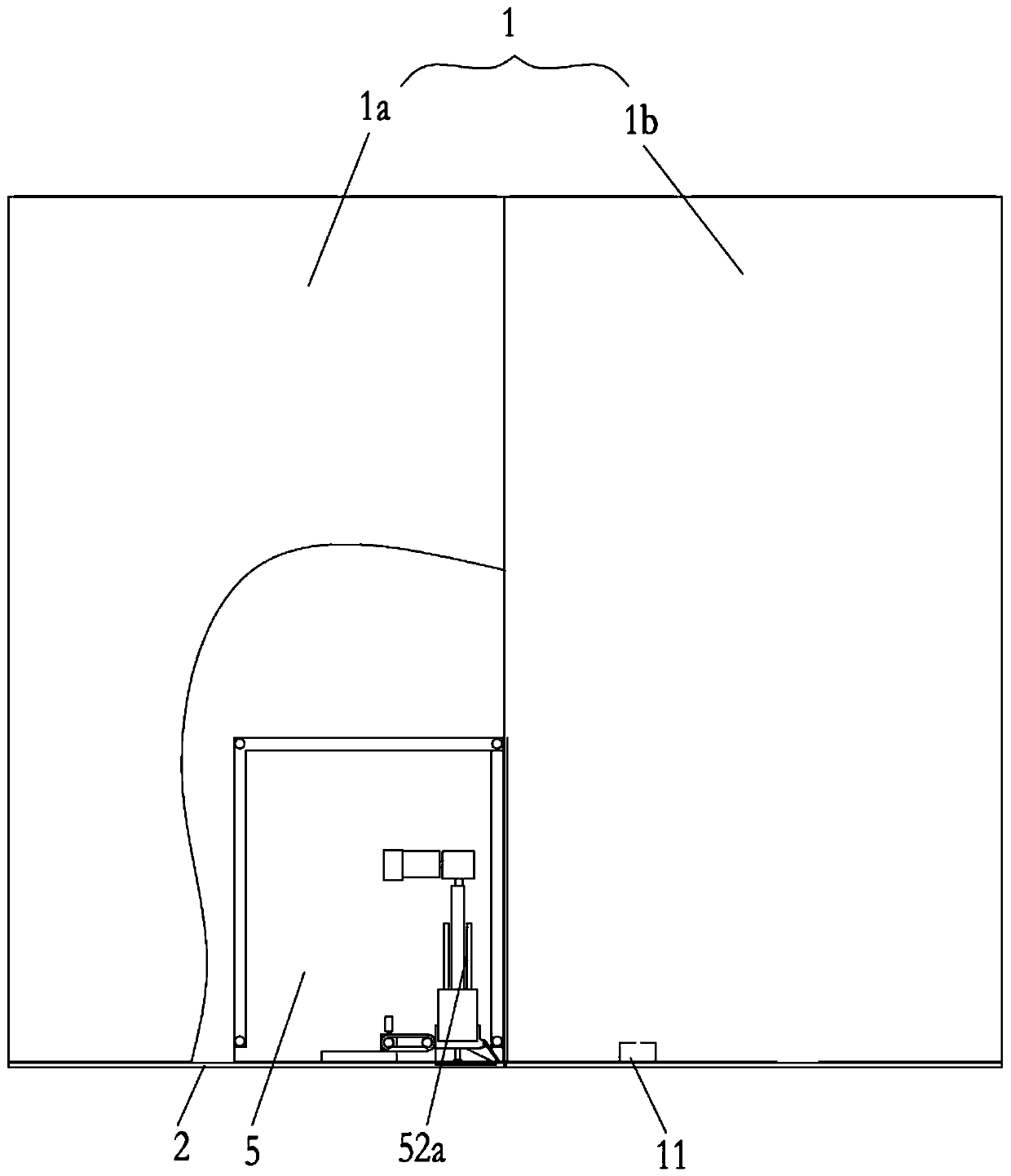

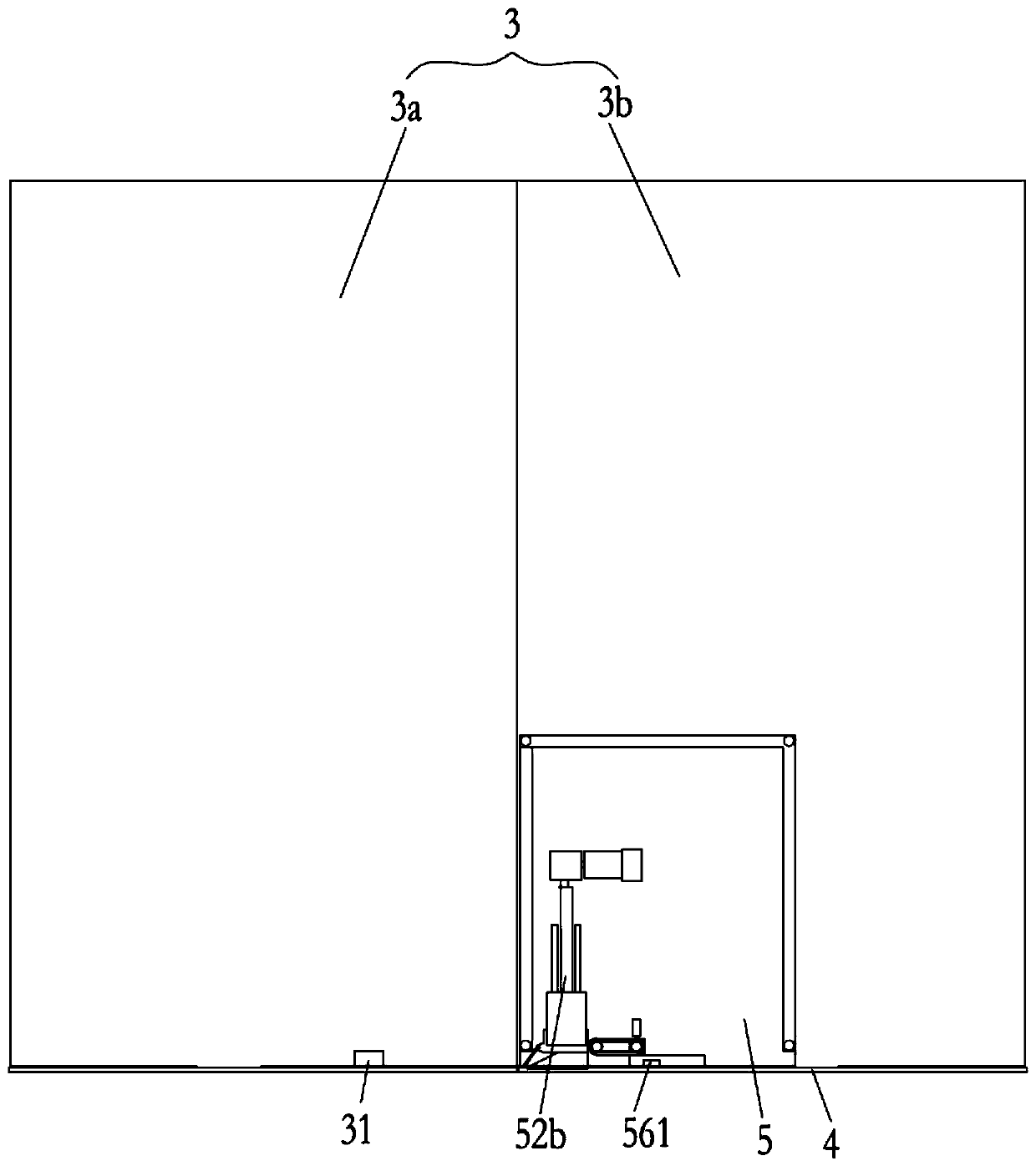

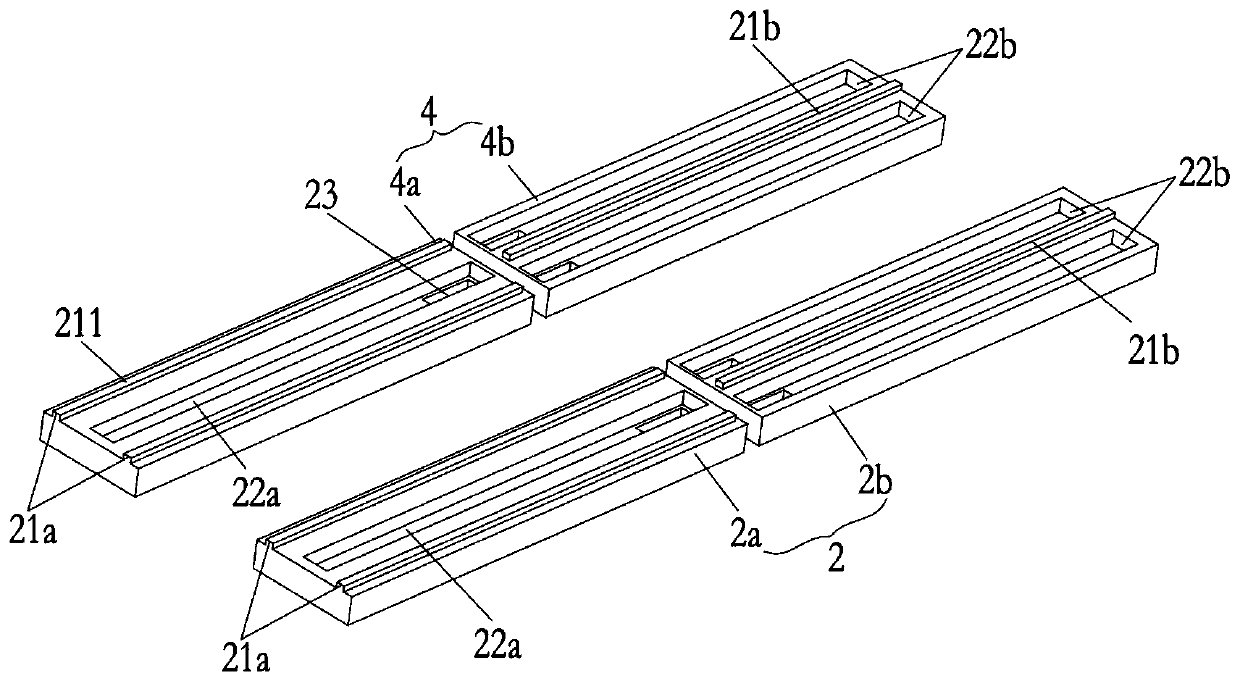

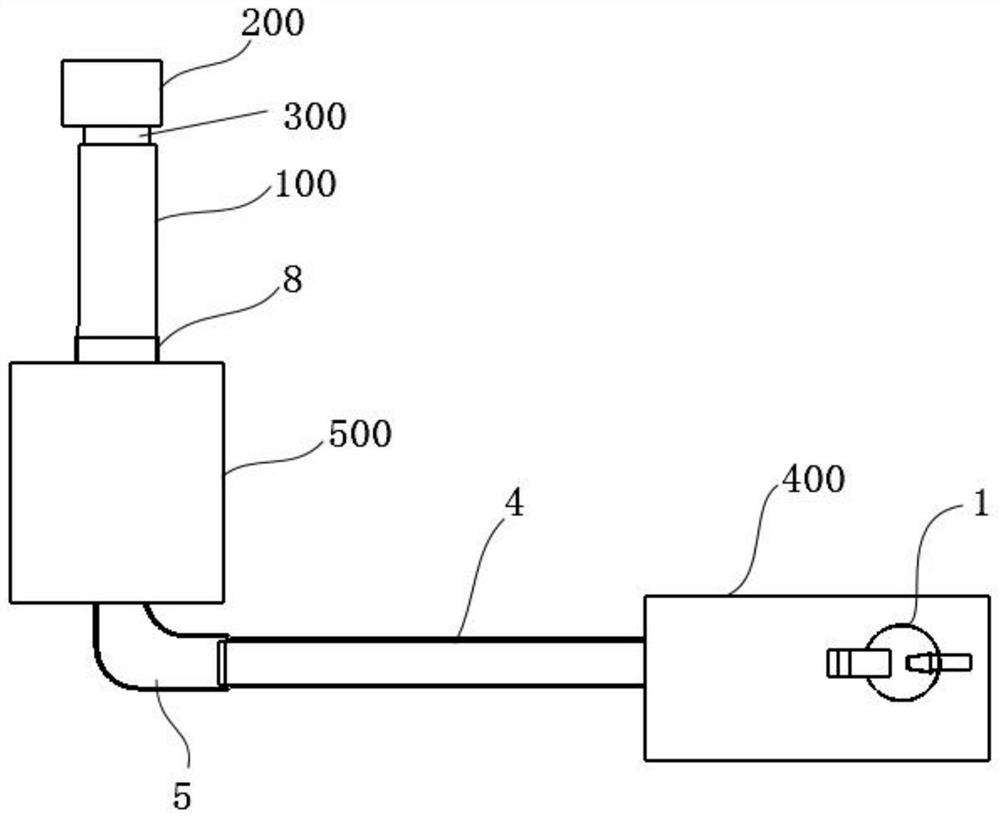

Elevator capable of automatically cleaning landing doors and car doors

The invention discloses an elevator capable of automatically cleaning landing doors and car doors. The elevator capable of automatically cleaning the landing doors and the car doors comprises the landing doors, landing sills, the car doors, car sills and a cleaning part connected with the landing doors and the car doors; the cleaning part comprises a connecting part, a lifting assembly and a cleaning slider; the cleaning slider is arranged in the landing doors and the car doors and comprises a fitting seat, an angling blade and a guide assembly installed on the fitting seat, a baffle is arranged above the angling blade, an inclined guide matched with the angling blade is arranged on the fitting seat, and a belt assembly is arranged at the tail end of the inclined guide; the belt assembly is driven to rotate by a driving assembly; and a dust collecting hopper is arranged at the tail end of the belt assembly, a window is arranged at the bottom of the dust collecting hopper, the landing doors and the car doors are provided with dust removal ports, and the window communicates with the dust removal ports. According to the elevator capable of automatically cleaning the landing doors andthe car doors, sand stones inside the landing sills and the car sills can be effectively removed, so that the running reliability of the elevator is improved.

Owner:佛山市高明区安承升降装备研究院

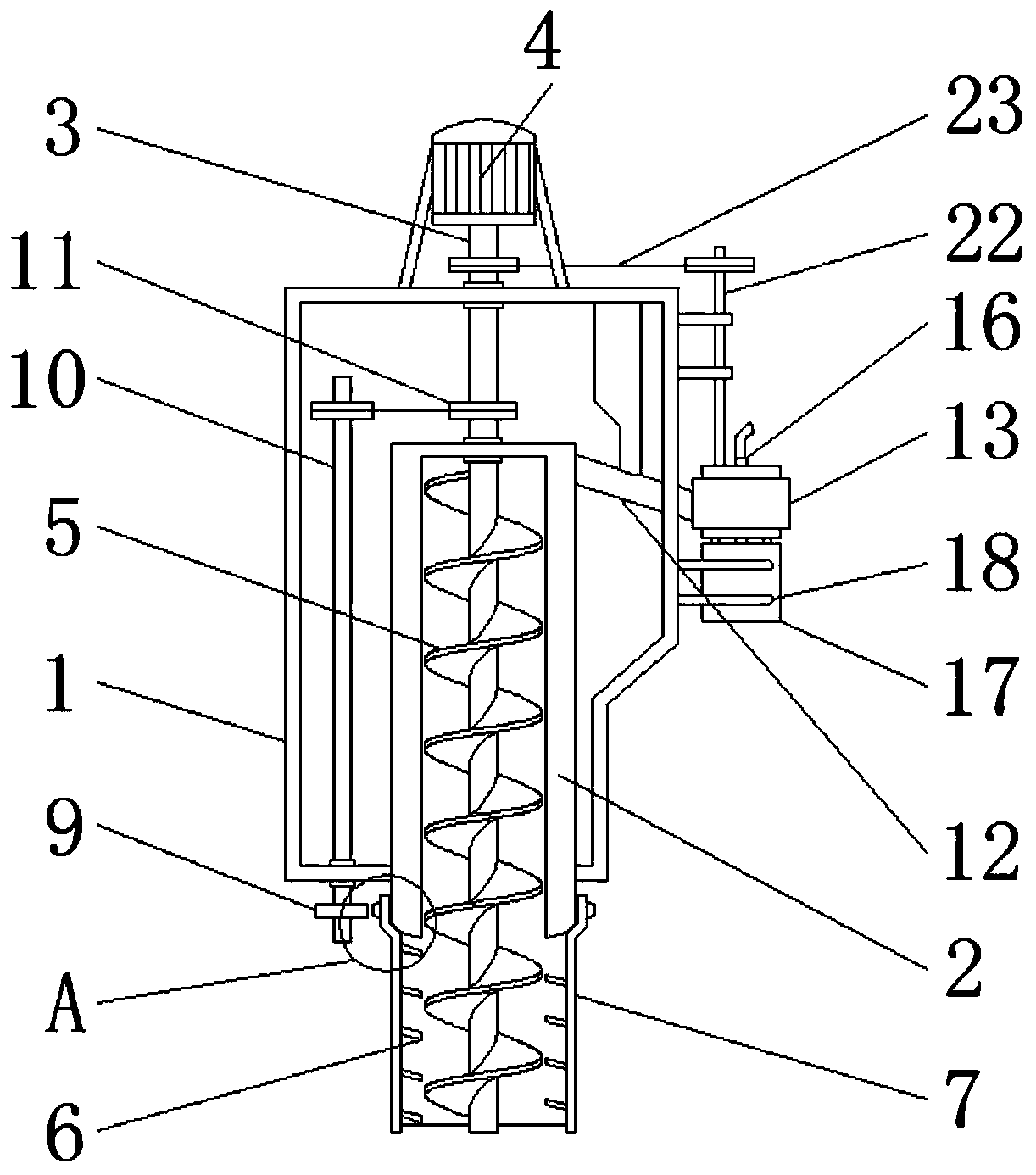

Material stirring and conveying device for cultivating agaricus bisporus

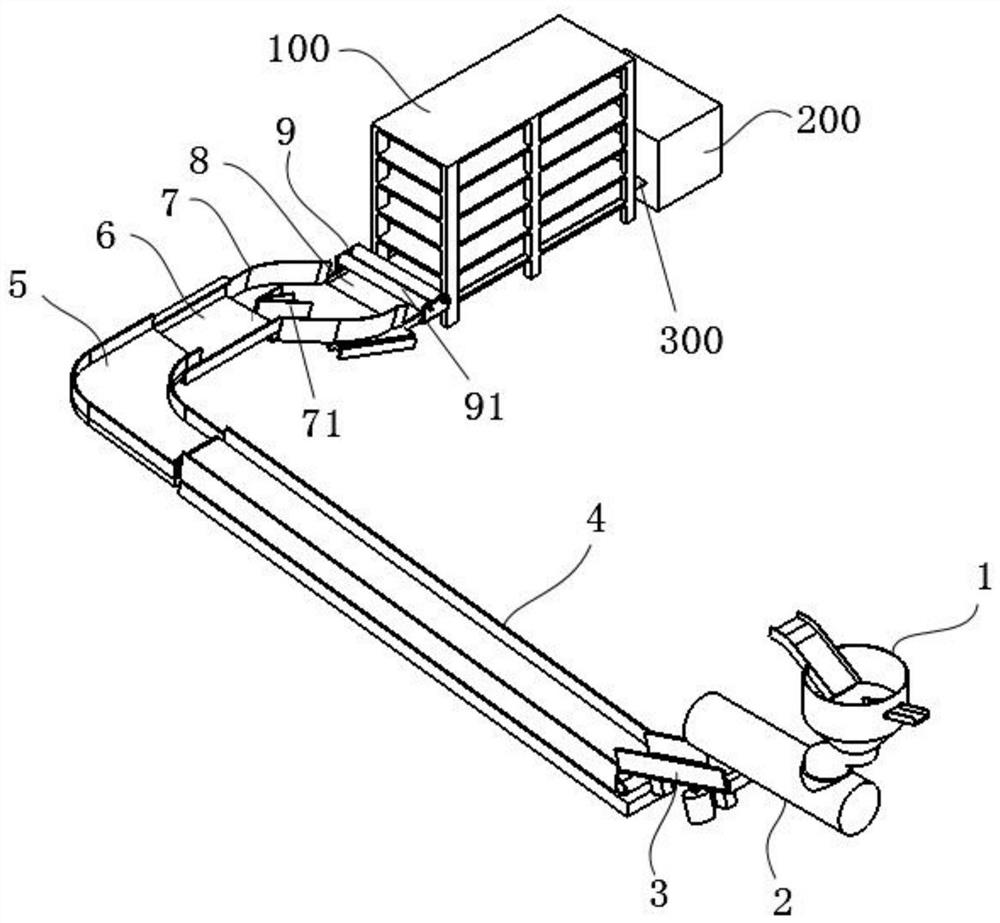

PendingCN114097533AAvoid concentrated accumulationHas a slight compaction effectCultivating equipmentsMushroom cultivationAgaricusAgricultural engineering

The invention provides a material stirring and conveying device for cultivating agaricus bisporus, and adopts the scheme that the material stirring and conveying device comprises a material mixing hopper, an auger, a uniform mixing and discharging device, a long-distance conveying device, a conveying reversing device, a short-distance conveying device, an oscillation transition device, a connection conveying device, a cultivation frame and a net pulling machine which are sequentially arranged in the feeding direction; a fertilizer conveying table for conveying a fertilizer into the mixing hopper and a strain conveying table for conveying strains into the mixing hopper are mounted on the mixing hopper. Fertilizer and strains are placed in the packing auger together through the mixing hopper, preliminary stirring and mixing of the fertilizer and the strains are achieved in the packing auger, and the output end of the long-distance transmission device is heightened through inclined arrangement of the long-distance transmission device so that the following material conveying face can be widened to provide conditions for adapting to the width of a cultivation frame. The conveying direction of the mixture is changed through the conveying reversing device so as to adapt to long-distance reversing conveying, and the conveying width is changed through the oscillation transition device.

Owner:临沂瑞泽生物科技股份有限公司 +1

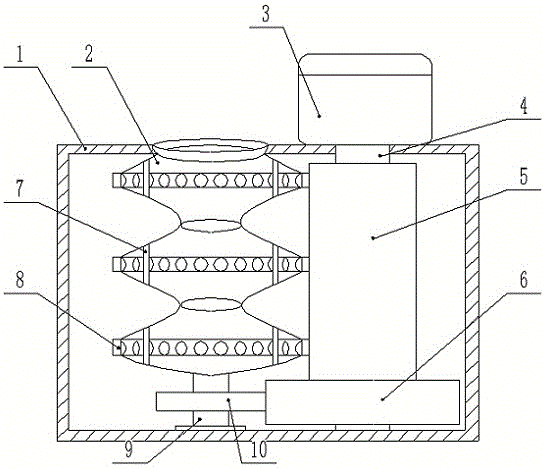

Automobile part cleaning device

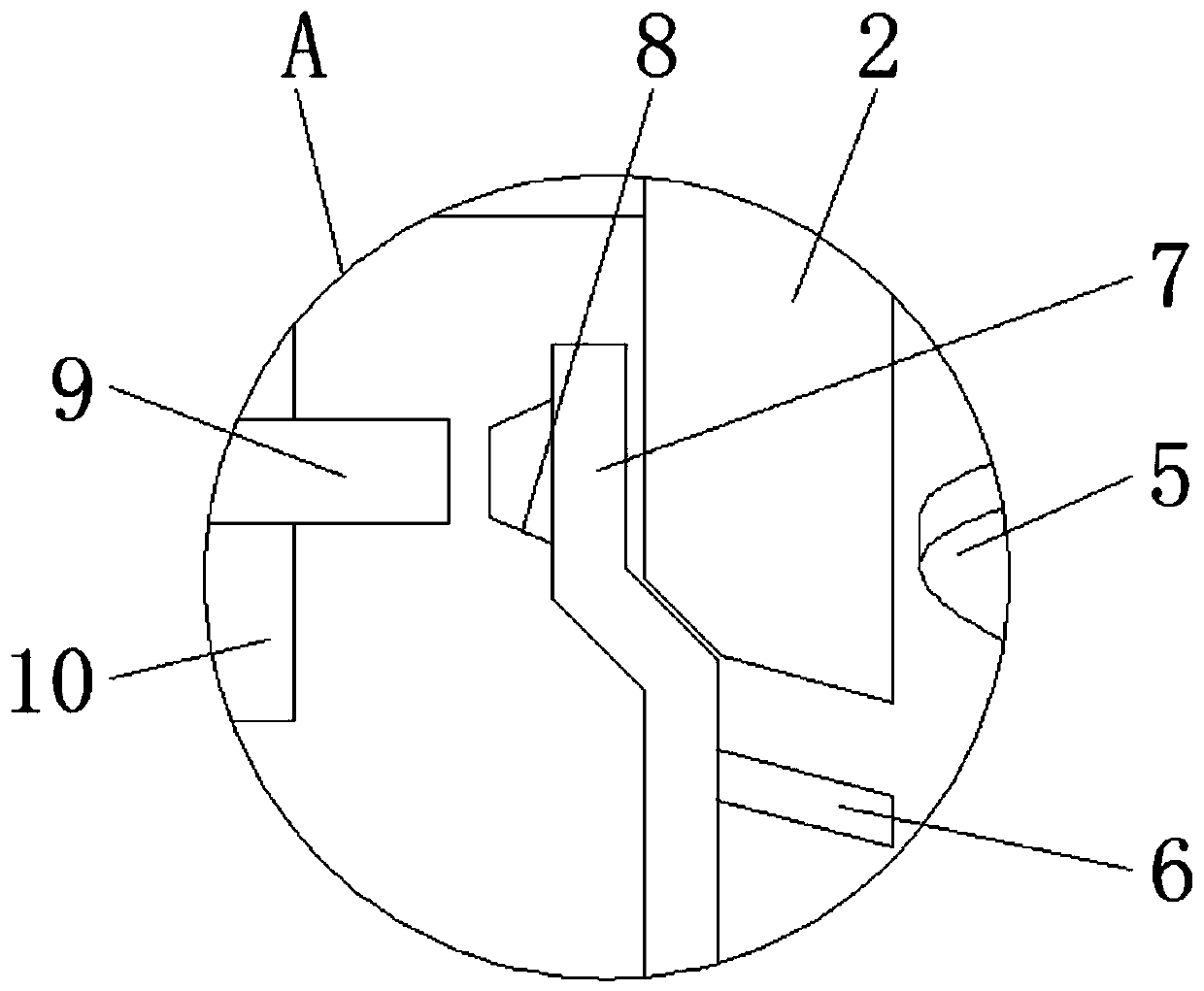

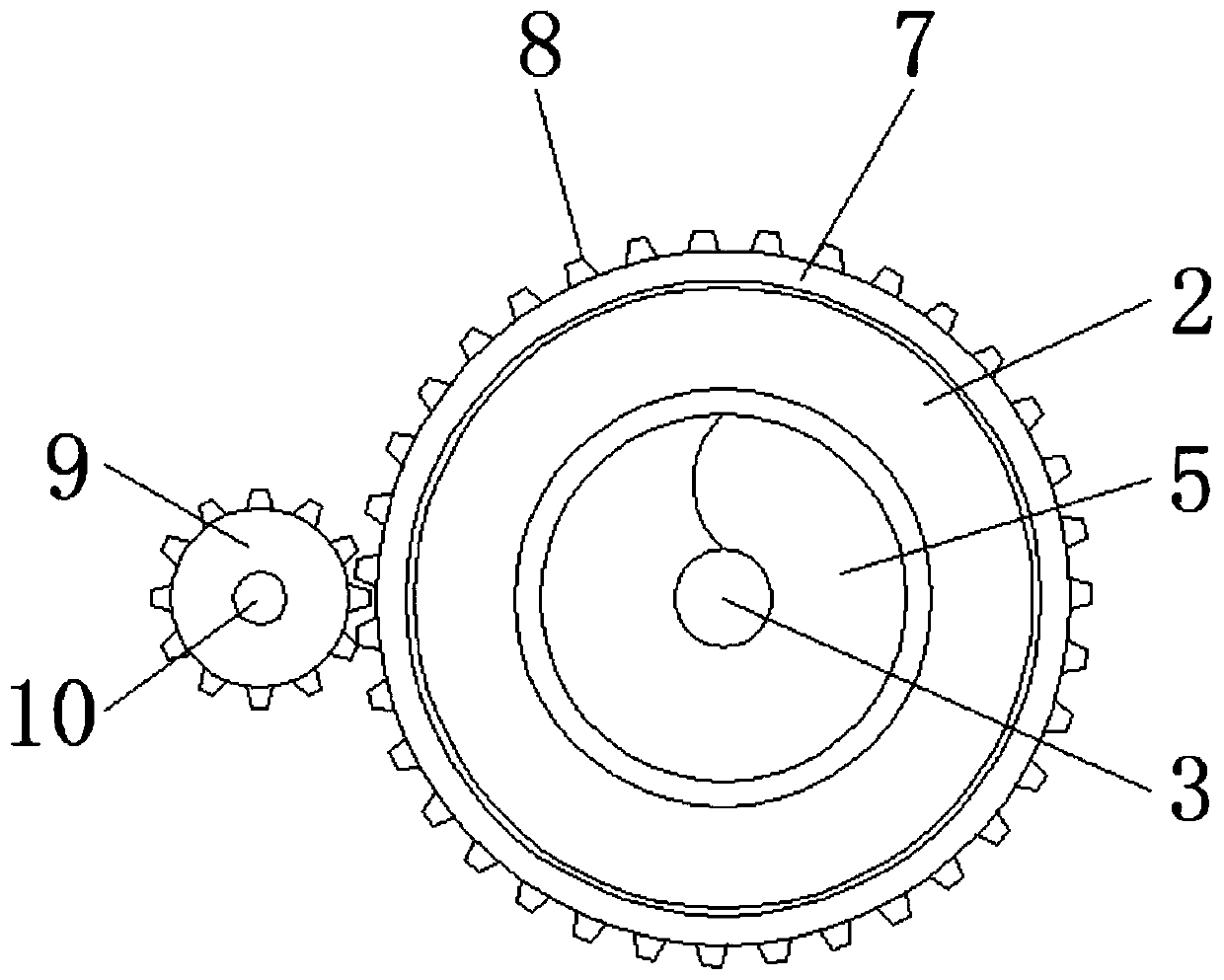

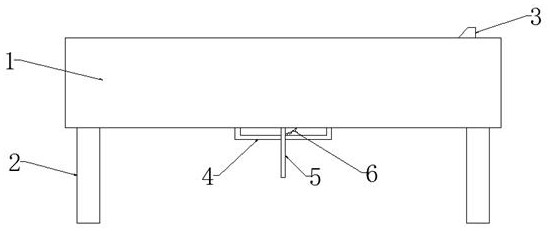

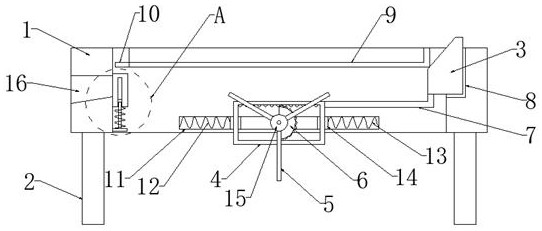

ActiveCN106623211AEasy to crushAvoid concentrated accumulationCleaning using liquidsGear wheelDrive shaft

The invention relates to the field of part cleaning, and in particular relates to an automobile part cleaning device. The automobile part cleaning device comprises a cleaning bucket, a chassis and a motor, wherein a transmission mechanism is arranged inside the chassis, and the transmission mechanism is driven to rotate by the motor; the cleaning bucket is arranged in the chassis and comprises multiple vertically arranged cleaning units, the middle part of each cleaning unit contracts inwards, multiple connecting columns are fixedly connected between upper and lower cleaning units, a stirring ring is rotationally connected between two adjacent cleaning units, multiple stirring teeth are arranged at the inner side of the stirring ring, and the transmission teeth meshed with a second gear on the transmission mechanism is arranged outside the stirring ring; a driving shaft is arranged on the cleaning bucket, a driving gear is arranged on the driving shaft, and is meshed with a first gear on the transmission mechanism. The automobile part cleaning device provided by the invention utilizes rotation of the cleaning bucket in a cleaning process, so that parts are separated and layered in the cleaning bucket due to centrifugal action, the parts are prevented from being extruded and accumulated in the cleaning bucket, and therefore, the cleaning is facilitated.

Owner:CHONGQING SUTENG MACHINERY MFG

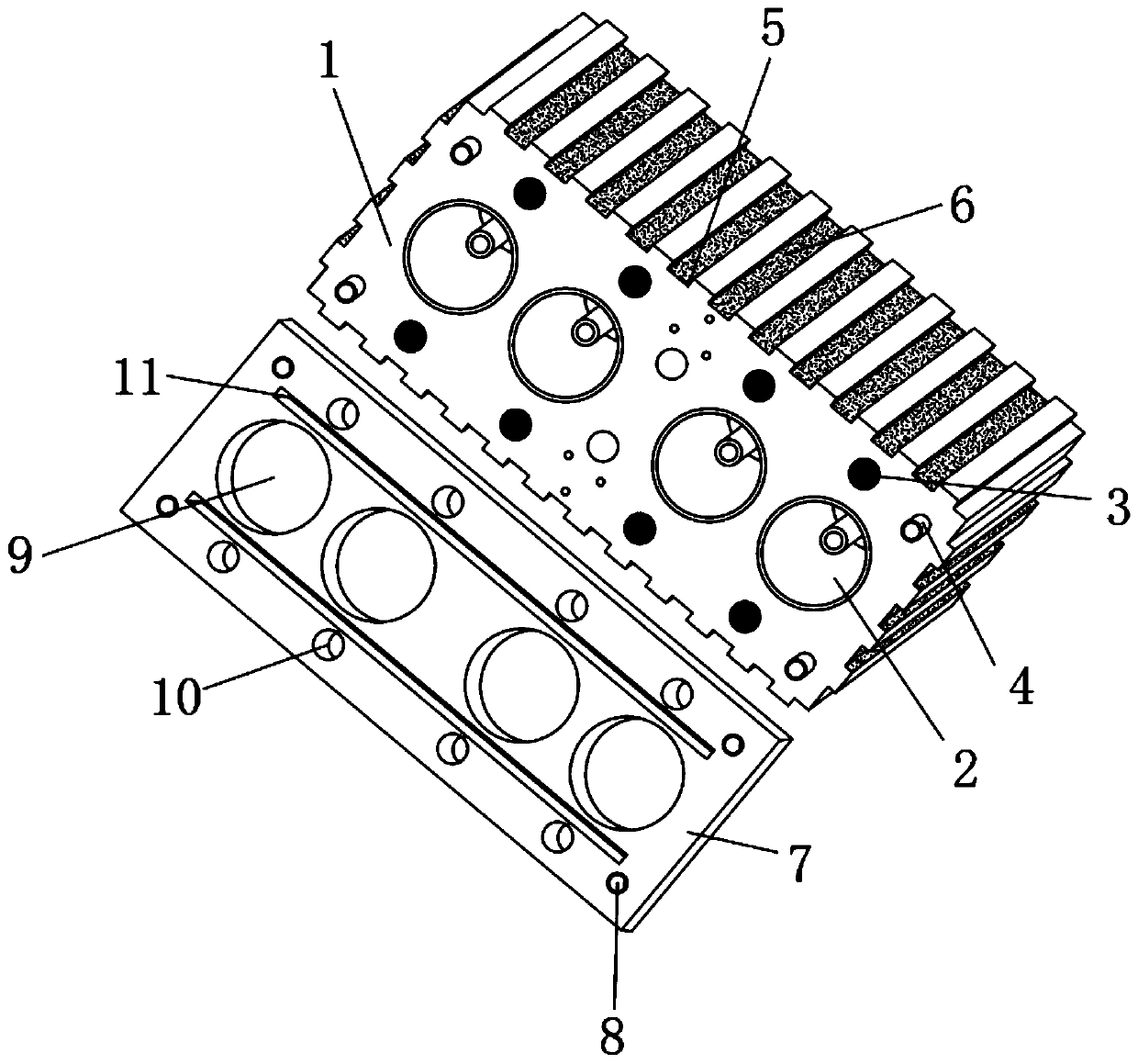

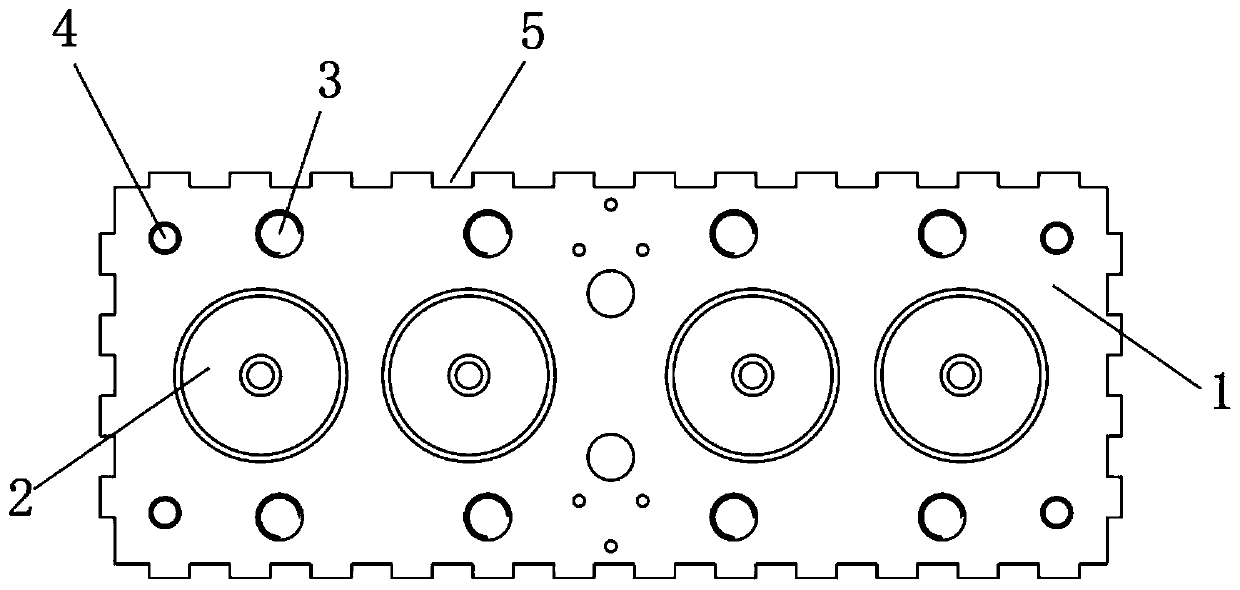

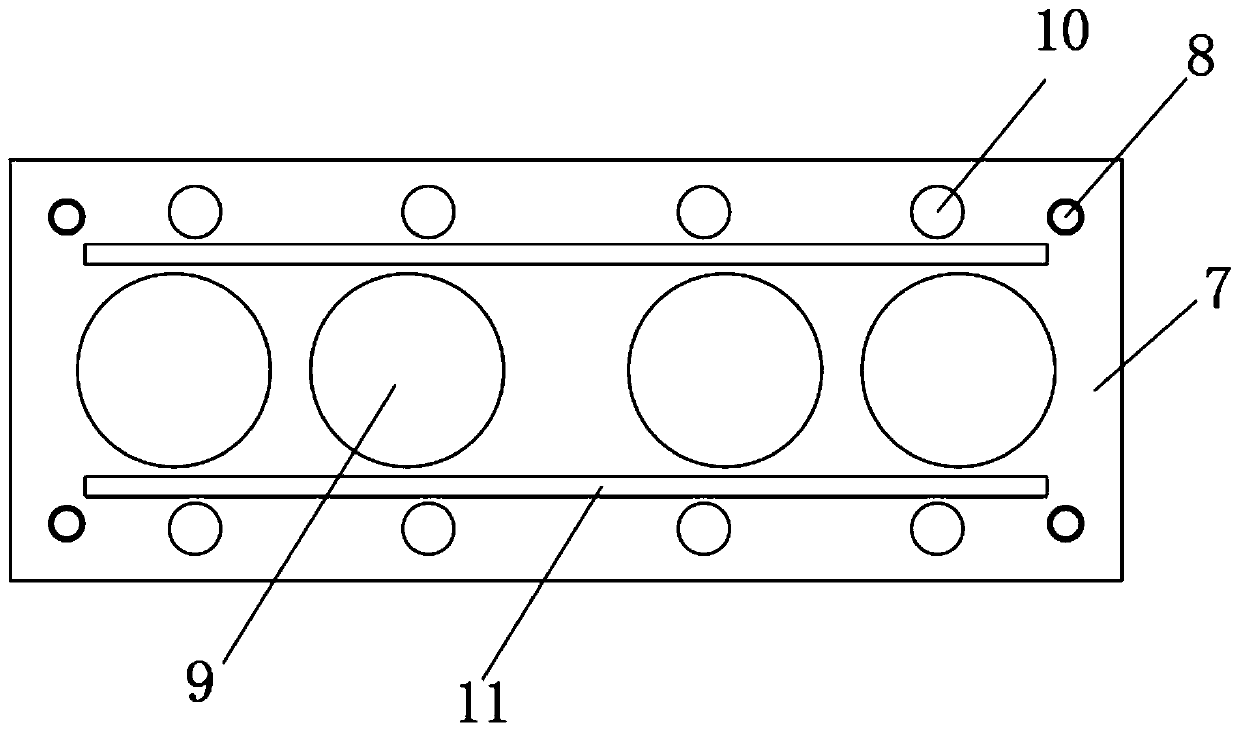

Engine air cylinder cover

ActiveCN110242436AIncrease surface areaImprove heat transfer efficiencyCasingsElectrical controlCushionSilica gel

The invention discloses an engine air cylinder cover. The engine air cylinder cover comprises an air cylinder cover and a sealing cushion plate. Heat dissipation grooves are formed in the front side, back side, left side and right side of the air cylinder cover at equal intervals. Four air cylinder seats are transversely and uniformly arranged in the center of the bottom of the air cylinder cover in the horizontal direction. A plurality of fixing screw holes are formed in the bottom of the air cylinder cover. A plurality of limiting columns are fixedly connected to the bottom of the air cylinder cover. Limiting holes are formed in positions, corresponding to the limiting columns, of the surface of the sealing cushion plate. The limiting columns are fixedly inserted into the limiting holes. First through holes are formed in positions, corresponding to the air cylinder seats, of the bottom of the sealing cushion plate. Second through holes are formed in positions, corresponding to the fixing screw holes, of the bottom of the sealing cushion plate. The shape and structure of the second through holes are the same as that of the fixing screw holes. By means of the engine air cylinder cover, heat in the air cylinder cover is prevented from being accumulated in a centralized manner and can be quickly guided outwards through a heat conduction silica gel sheet.

Owner:YANCHENG JIANGDONG GASOLINE ENGINE MFG +1

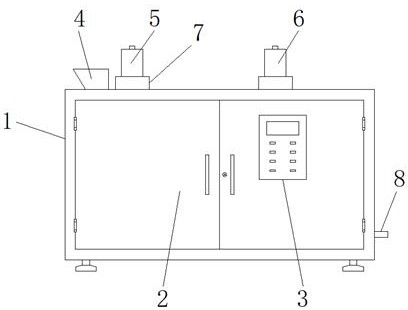

Handheld heavy metal detection device for flour food detection

InactiveCN111122891ASave human effortThe test result is accurateWithdrawing sample devicesHand heldStructural engineering

The invention discloses a handheld heavy metal detection device for flour food detection. The device comprises a shell, a detection rod, a solution cup, a mounting ring and a fan, wherein conveying cylinders which are vertically distributed are arranged in the shell; a rotating shaft is rotationally mounted in the top wall of the conveying cylinder; a first auger plate is mounted on the surface ofthe rotating shaft; and a second tooth block and a stirring rod are fixed to the upper portion and the lower portion of the inner wall of the first circular ring correspondingly, a second vertical shaft is rotatably installed on the side of the shell, the top end of the second vertical shaft is connected with a rotating shaft through a second belt wheel mechanism, an auxiliary pipe is arranged inthe shell, and a draught fan is installed in the auxiliary pipe. According to the handheld heavy metal detection device for flour food detection, through redesign of an internal transmission structure of the detection device, the device can perform automatic sampling and subsequent stirring, so that the manpower is greatly saved, the detection result is more accurate, and the use is more convenient.

Owner:张惠文

Concrete raw material screening device for water conservancy project

PendingCN113399254AAvoid cloggingNormal screening efficiencySievingScreeningElectric machineArchitectural engineering

The invention discloses a concrete raw material screening device for a water conservancy project, relates to the field of water conservancy projects, and provides the following scheme aiming at the problem that the service life of a water conservancy project building body is shortened due to the fact that the concrete strength cannot reach the standard due to low concrete raw material screening efficiency in the prior art. The concrete raw material screening device for the water conservancy project comprises a frame, wherein supporting legs are fixedly installed at the four corners of the bottom end of the frame, a screening frame is rotatably installed in the frame, a driving motor is fixedly installed at one side of the frame, and the end part of an output shaft of the driving motor penetrates through the side wall of the frame and extends into the frame to be fixedly connected with a rotating plate; and a moving frame is horizontally and slidably installed at the side, close to the driving motor, of the inner wall of the frame. According to the invention, effective screening treatment can be carried out on concrete raw materials, the phenomenon that screening holes of the screening frame are blocked can be prevented, meanwhile, the phenomenon that sand grains are intensively accumulated at the same position can be avoided, and the normal strength standard of the concrete raw materials is guaranteed.

Owner:潘涛 +4

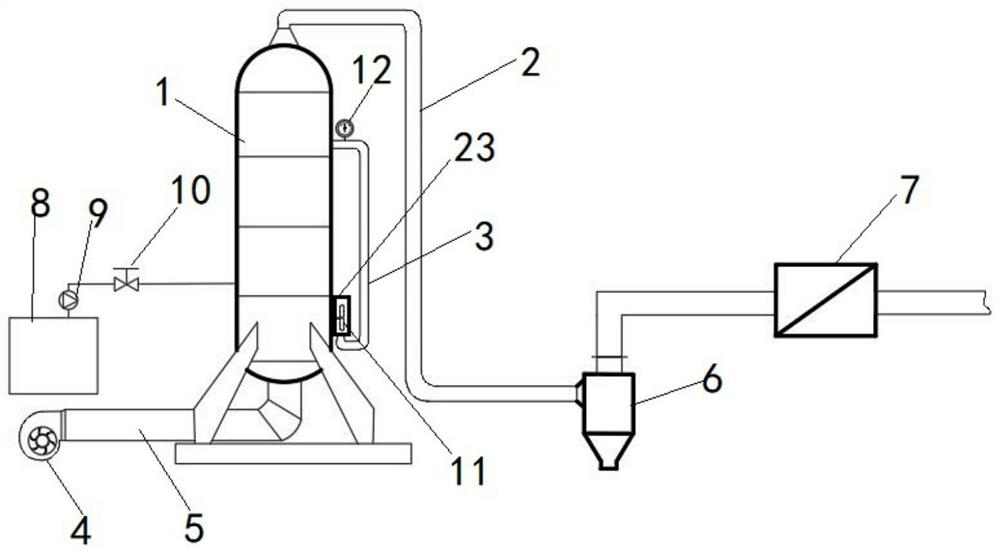

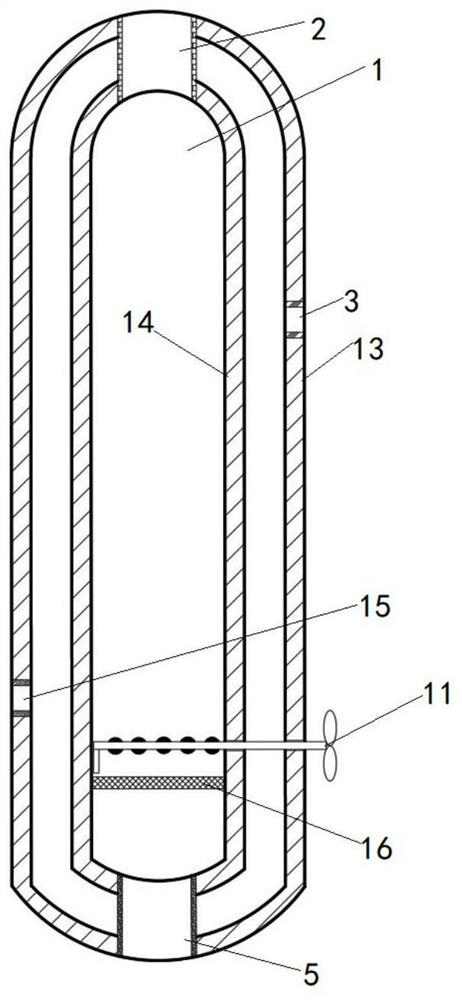

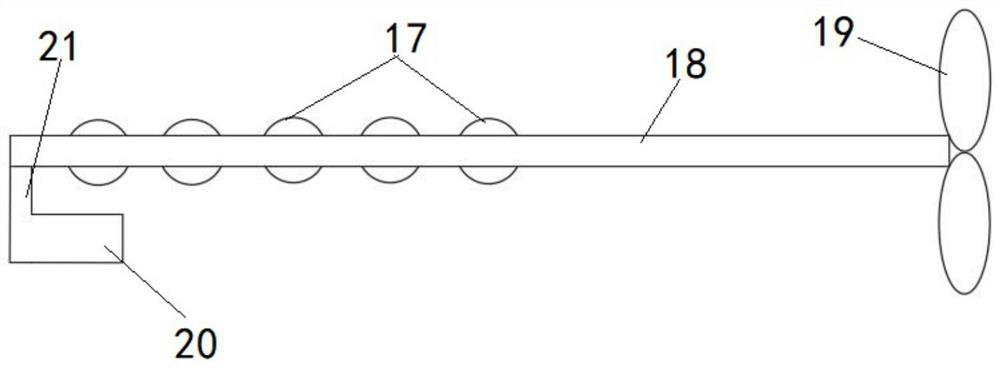

Thermodynamic cycle accumulation-free efficient incineration boiler

PendingCN112113227AAvoid concentrated accumulationSave drive energyRotary stirring mixersTransportation and packagingProcess engineeringIncineration

The invention discloses a thermodynamic cycle accumulation-free efficient incineration boiler. The efficient incineration boiler comprises an incineration cavity, an air blowing pipe, a fan and a stirring device, wherein an air outlet of the air blowing pipe is connected to the bottom of the incineration cavity, the fan is connected with the air blowing pipe and blows air into the air blowing pipe, and the stirring device is arranged at the lower end inside the incineration cavity and used for stirring garbage in the incineration cavity; and the incineration cavity comprises a double-layer wall, wherein the side face of the double-layer wall is connected with an air collecting pipe, and the air collecting pipe collects flowing gas between the double-layer wall of the incineration cavity todrive the stirring device to rotate. According to the thermodynamic cycle accumulation-free efficient incineration boiler, incinerated garbage in the incineration boiler can be fully dispersed, accumulation is avoided during incineration, combustion is sufficient, and meanwhile hot gas outside the incineration cavity can be collected and utilized, so that the incinerated garbage is further fullydispersed.

Owner:江阴市锦绣江南环境发展有限公司

A screening dust removal device for ecological rice processing

ActiveCN111842113BAvoid concentrated accumulationImprove screening effectSievingGas current separationDust controlEnvironmental engineering

The invention relates to the technical field of ecological rice screening and dedusting, and discloses a screening and dedusting device for ecological rice processing, including a working box, the top of the working box is connected with a feeding hopper, and the top of the working box is symmetrically opened with Dust removal port, the top of the working box is symmetrically fixedly connected with two first dust suction hoods, and the input ends of the two first dust suction hoods are symmetrically connected with two sets of first dust suction pipes, each of the first The number of suction pipes is several, and the front and rear inner walls of the working box are symmetrically rotatably connected with two first rotating shafts, and a lifting plate is fixedly connected between the adjacent ends of the two first rotating shafts. The invention solves the problem that the existing ecological rice screening and dedusting equipment has poor screening effect and quality, and cannot effectively and thoroughly remove the dust in the rice, resulting in low dedusting quality.

Owner:ANHUI WANSHAN FOODS

Turning transition device of conveyor

InactiveCN113173412AAvoid damageAvoid jamming and damage to conveyed goodsConveyor partsPhysicsTransmission belt

The invention belongs to conveyor belt devices, and particularly relates to a turning transition device of a conveyor. The turning transition device comprises an installation box body, a front conveying roller and a rear conveying roller, wherein the front conveying roller and the rear conveying roller are installed in the installation box body, the rear conveying roller is perpendicular to one side of the rear end of the front conveying roller in the conveying direction, a push rod is arranged on the other side of the rear end of the front conveying roller in the conveying direction and driven by a driving mechanism, a lifting mechanism is arranged at the rear end of the conveying direction of the front conveying roller and below the rear conveying roller, the bottom of the lifting mechanism is arranged in the installation box body, and the lifting mechanism is used for lifting a conveyed object. The lifting mechanism is arranged, so that the conveyed objects are transferred in the state of being separated from the conveying rollers, and the conveyed objects are prevented from being damaged; and meanwhile, a plurality of conveyed objects can be prevented from being concentrated at the turning position of a conveying device, and blockage and damage to the conveyed objects caused by incorrect turning of the conveyed objects are avoided.

Owner:无锡百擎智能机器人科技有限公司

Low-vibration epoxy floor paint stirring device for indoor construction

ActiveCN112808114AAvoid accumulationWell mixedShaking/oscillating/vibrating mixersTransportation and packagingElectric machineStructural engineering

The invention discloses a low-vibration epoxy floor paint stirring device for indoor construction. The low-vibration epoxy floor paint stirring device for indoor construction comprises a device body, a support, a forward or reverse motor, a feed port, a main shaft, a stirring blade mechanism, a scraping mechanism and a discharge port, wherein the device body is fixedly connected with the upper end of the support; the bottom end of the support is in contact with the ground; the forward or reverse motor is arranged at the top end of the device body; the feed port is located in one side of the forward or reverse motor; the main shaft penetrates through the interior of the device body in a vertical direction; one end of the main shaft penetrates through the side wall of the device body and is connected with the acting end of the forward or reverse motor; the main shaft and the device body are connected in a sealed mode through a bearing; the scraping mechanism and the stirring blade mechanism sequentially penetrate through and are arranged on the main shaft; the scraping mechanism is located above the stirring blade mechanism; one end of the scraping mechanism is movably connected with the main shaft, and the other end of the scraping mechanism is fixedly connected with the stirring blade mechanism; the scraping mechanism is transversely attached to the inner side wall of the device body; and the discharge port is formed in one side of the device body.

Owner:乐清市路航电气有限公司

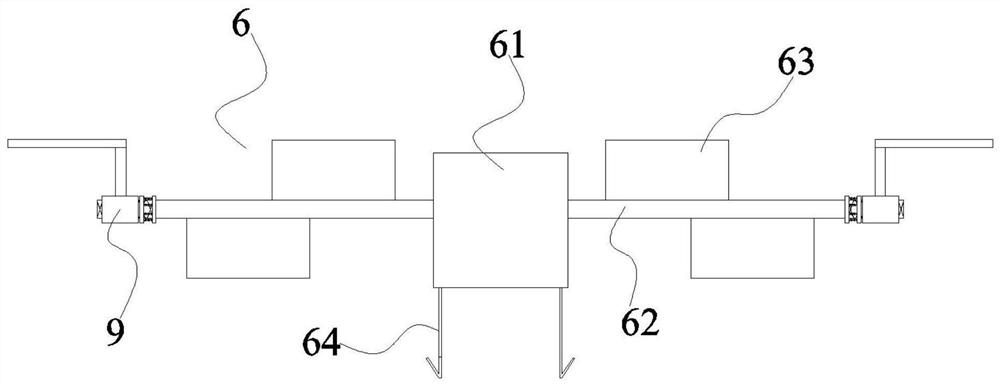

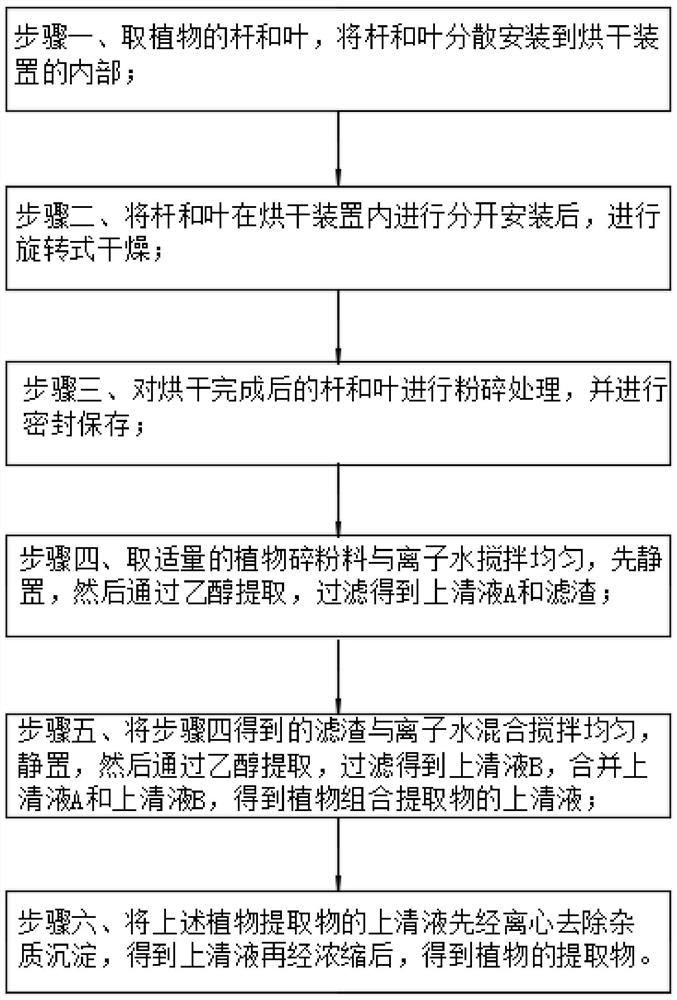

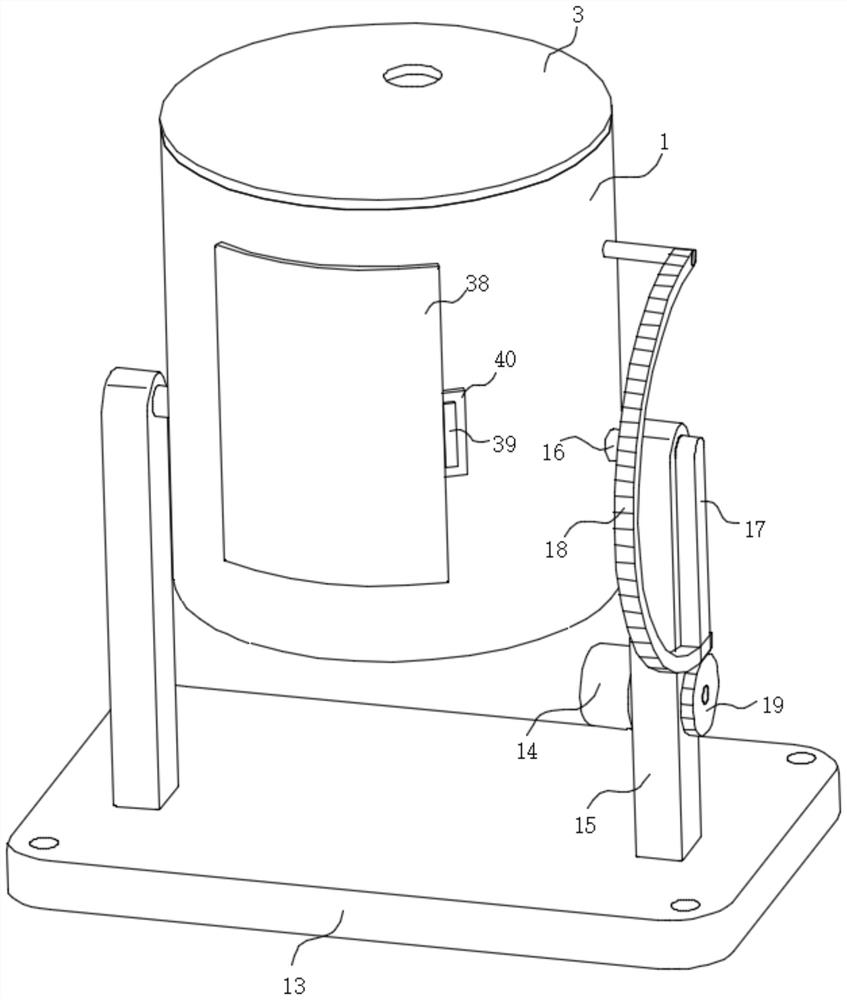

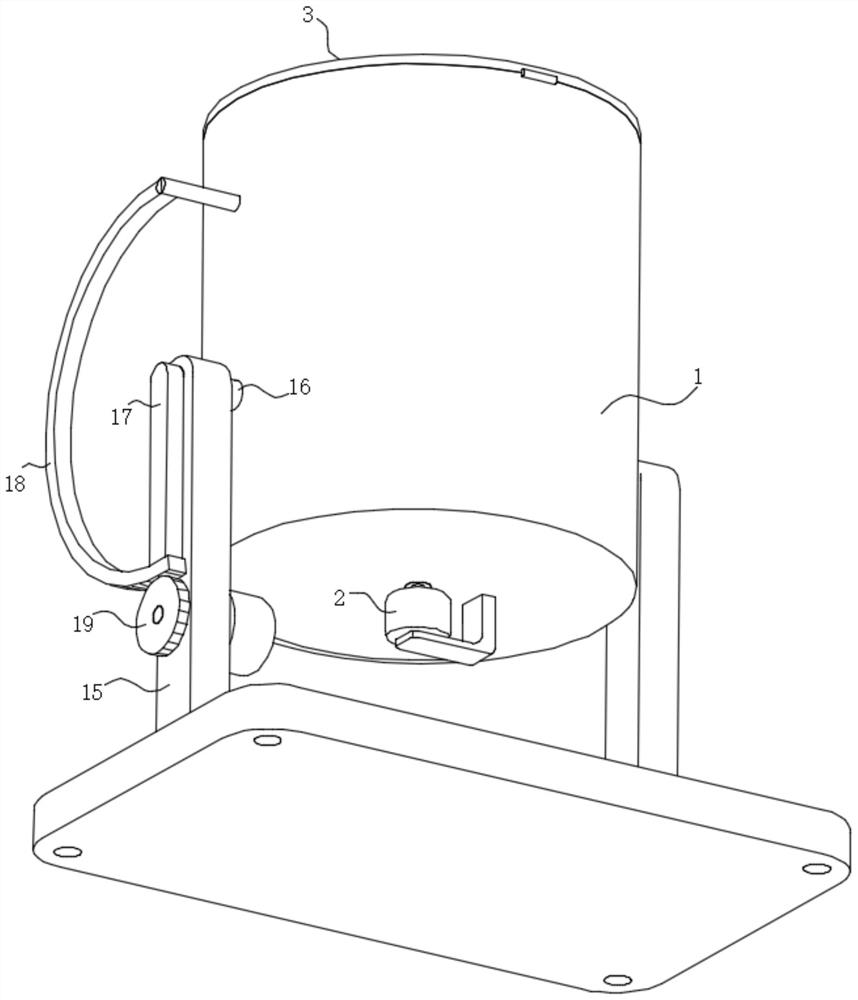

Method for extracting active ingredients of natural plants

ActiveCN114543463AEasy accessAvoid concentrated accumulationDrying gas arrangementsDrying chambers/containersAgricultural engineeringMechanical engineering

The invention relates to the technical field of natural plant active ingredient extraction methods, in particular to a natural plant active ingredient extraction method which comprises the following steps: step 1, taking stems and leaves of a plant, and dispersedly mounting the stems and the leaves in a drying device; 2, the stems and the leaves are separately installed in a drying device, and then rotary drying is conducted; thirdly, the dried stems and leaves are smashed and stored in a sealed mode; in the moving process of the connecting base, the linkage mechanism can be in linkage with the connecting base to rotate, the connecting base can rotate while moving, the connecting base drives the connecting rod and the drying net barrel to rotate together, then branches and leaves in the whole drying net barrel can get close to a heating plate with the same opportunity, and therefore it is guaranteed that heating and drying are uniform; the situation that branches and leaves are dried unevenly due to concentrated accumulation is avoided, and thorough and even drying of the branches and leaves is facilitated.

Owner:山东聚胜生物科技有限公司

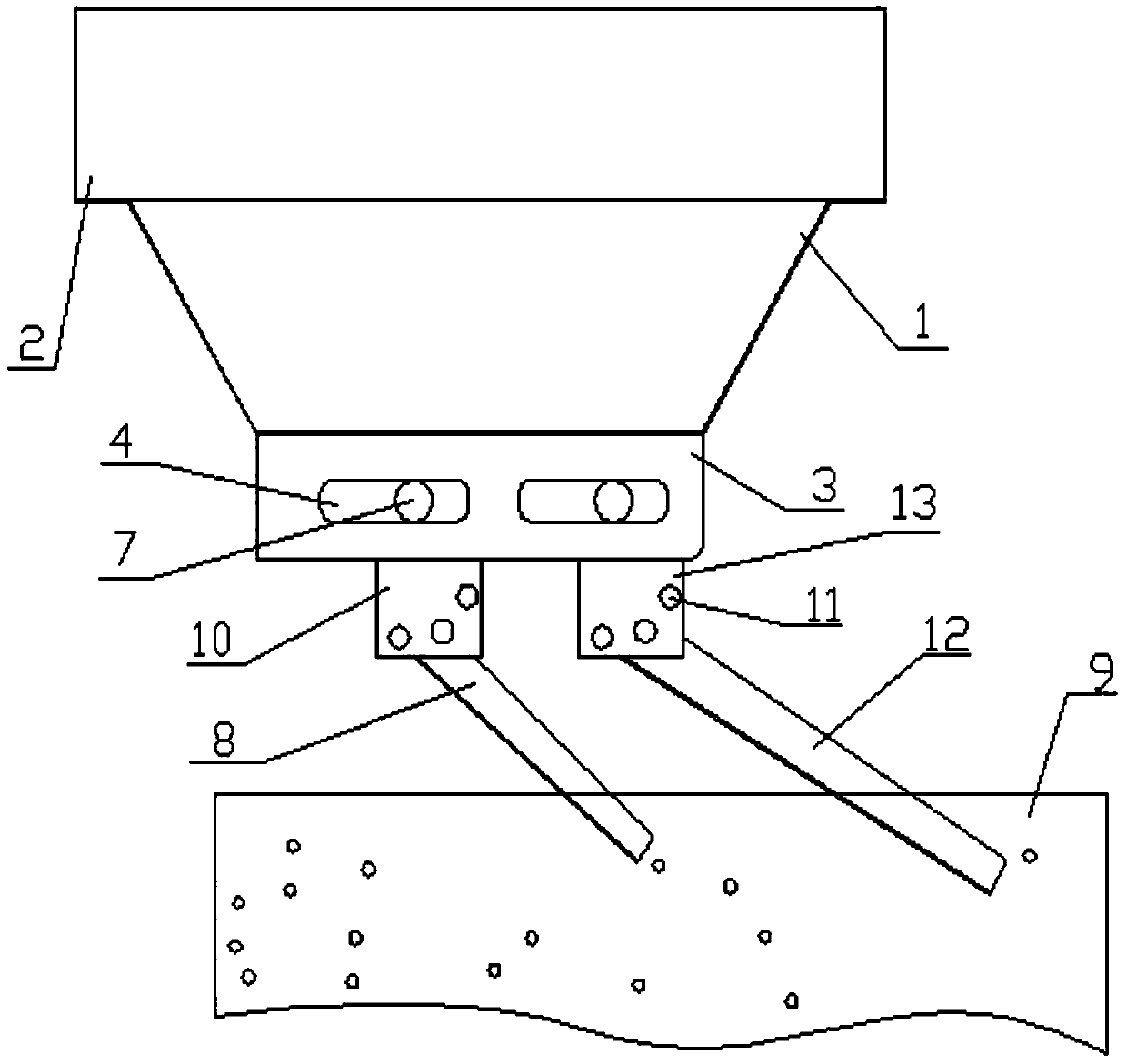

A uniform material distribution mechanism on an induced hoist

ActiveCN105540295BAvoid concentrated accumulationChange whereaboutsLoading/unloadingMechanical engineering

The invention discloses a uniform material distributing mechanism on an induced type elevator. The uniform material distributing mechanism comprises a discharging hopper. The upper end of the discharging hopper is connected with a rack of the elevator, and the lower end of the discharging hopper is connected with a discharging channel. Guide grooves are formed in the side wall of the discharging channel. A first partition plate and a second partition plate are arranged in the discharging channel. Guide rods are arranged on the two sides of each of the first partition plate and the second partition plate. The guide rods are arranged in the guide grooves. The first partition plate is connected with a first sliding groove, and the second partition plate is connected with a second sliding groove. The lower end of the first sliding groove and the lower end of the second sliding groove stretch in a bin. In the uniform material distributing mechanism, the first partition plate and the second partition plate are arranged in the discharging channel so that three material falling channels can be formed, materials evenly fall into the bin through the first sliding groove and the second sliding groove, and therefore the materials are effectively prevented from being stacked at a certain position of the bin.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

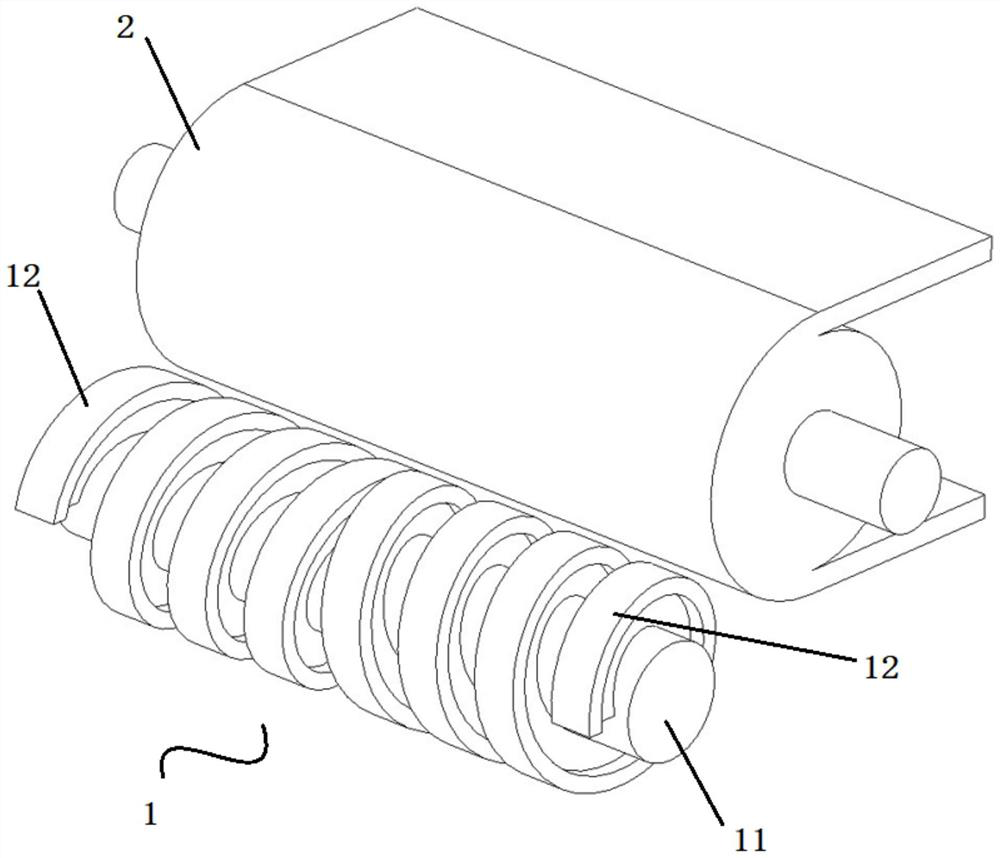

Cut tobacco bulker feeding and homogenizing device

PendingCN113734832AEvenly arrangedAvoid concentrated accumulationTobacco preparationConveyorsAnimal scienceEngineering

The invention discloses a cut tobacco bulker feeding and homogenizing device which is arranged in the discharging direction of a longitudinal spreading trolley and located above a cut tobacco bulker. The cut tobacco bulker feeding and homogenizing device comprises a round roller located in the center and a homogenizing brush located on the surface of the round roller, and the homogenizing brush is fixedly connected with the surface of the round roller and synchronously rotates along with the round roller; and the homogenizing brush comprises a left spiral material homogenizing brush body and a right spiral material homogenizing brush body which are symmetrically arranged relative to the center line of the round roller, the cross section of the homogenizing brush is of a T-shaped structure, the top face of the T-shaped structure is located on the outer circumferential face, the bottom face of the T-shaped structure is fixedly connected with the surface of the round roller, and a groove for containing tobacco shreds is formed between the bottom face of the T-shaped structure and the top face of the T-shaped structure. By means of the device, it is guaranteed that the tobacco shreds are evenly arranged in the belt direction, and concentrated accumulation and poor quality consequences are avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Molding sand dispersing and screening device for mechanical casting

The invention relates to the technical field of mechanical casting tool devices, and particularly relates to a molding sand dispersing and screening device for mechanical casting. According to the molding sand dispersing and screening device for mechanical casting, the electric push rod stretches out and draws back to drive the hopper to move, and the discharging position of the discharging pipe is changed; meanwhile, a discharging assembly is arranged, a first gear moves along with a hopper and is meshed with a fixed rack so that a connecting shaft is driven to drive a rotating disc to rotate, therefore, along with rotation of the rotating disc, a through hole and an outlet in the bottom end of a discharging pipe intermittently coincide, discharging is achieved, and therefore molding sand falls on a screen in a dispersed mode and is prevented from being accumulated at a certain position of the screen in a concentrated mode; in addition, based on transmission, through movement of the hopper and cooperation of a pull rope, a rack, a gear and the like, a cam below the screen rotates and acts on the screen, the screen vibrates up and down, and therefore screening is accelerated.

Owner:含山县天宇机械铸造厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com