Multistage condensation miniature hot water stove

A technology for condensing and hot water stoves, which is applied in the field of gas stoves, can solve the problems of increasing investment costs and management production costs of enterprises, reducing thermal efficiency of boilers, and being unsuitable, so as to improve heat exchange efficiency, improve thermal efficiency, and avoid safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

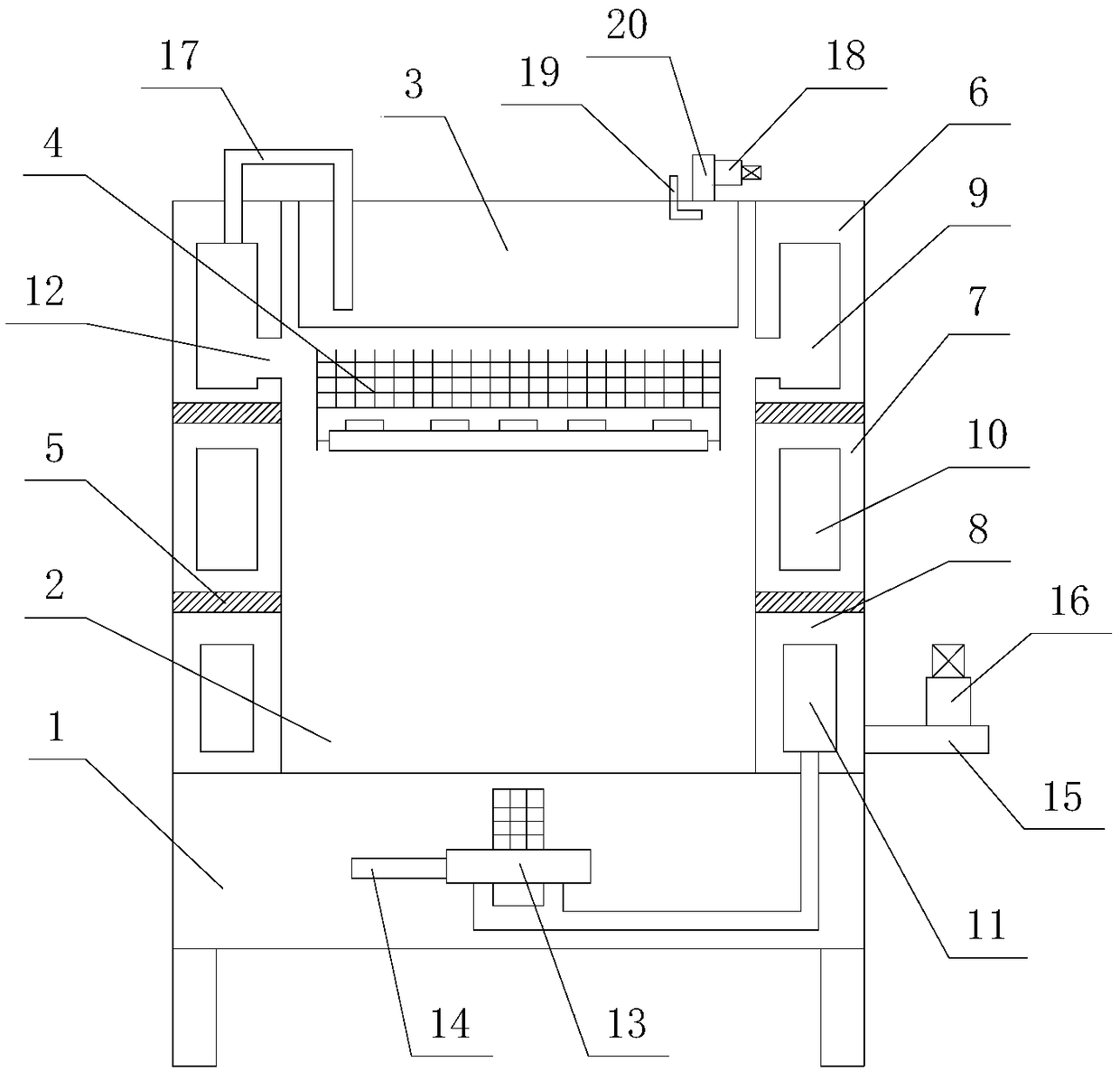

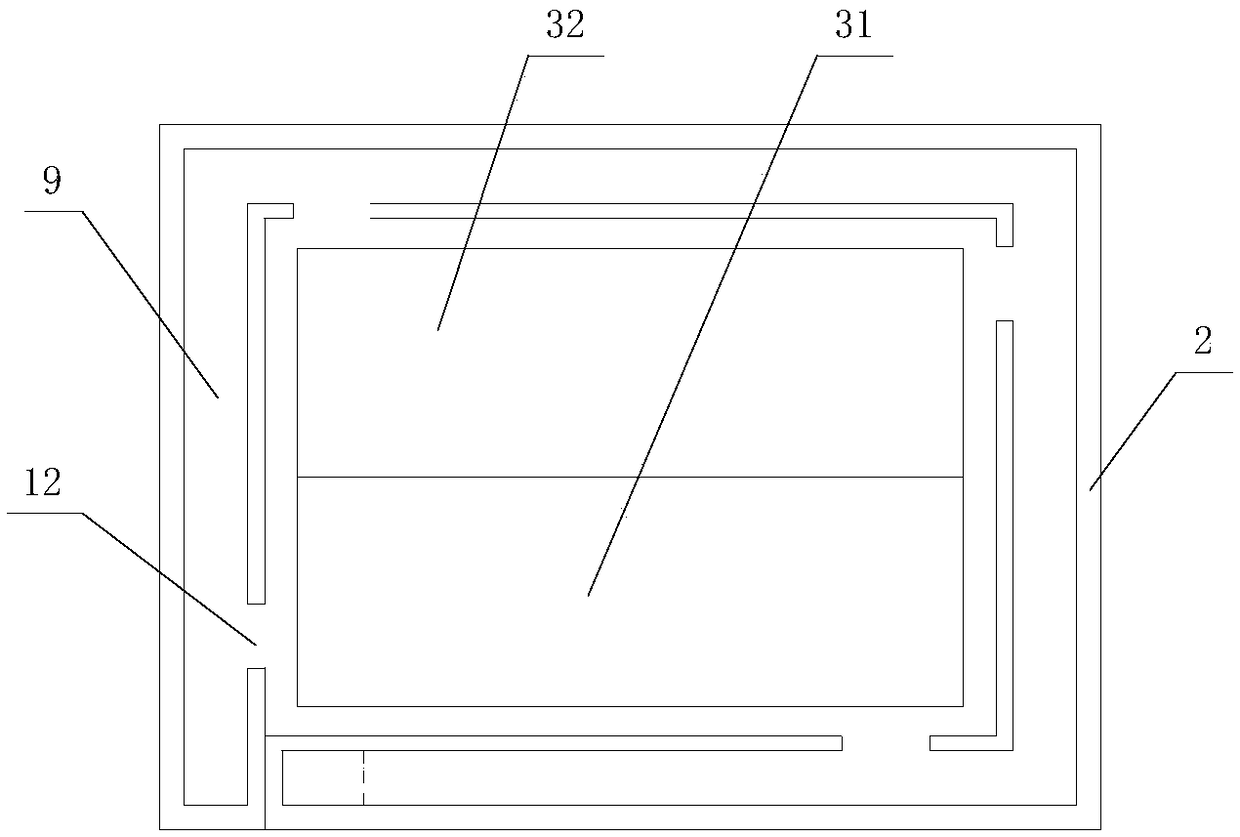

[0027] Such as figure 1 and figure 2 As shown, the multi-stage condensing miniature hot water stove provided in this embodiment includes a stove body 1 and a combustion chamber 2, and a heating water tank 3 is installed on the upper part of the stove body 1, and the heating water tank 3 includes a medium-temperature water tank 31 and a high-temperature water tank 32. The medium-temperature water tank 31 and the high-temperature water tank 32 are identical and arranged side by side. A heating fire row 4 is installed in the combustion chamber 2. The heating fire row 4 is located directly below the medium-temperature water tank 31 and the high-temperature water tank 32. The medium-temperature water The box 31 and the high-temperature water tank 32 are subjected to different combustion heat by the heated fire row 4. There is a cavity around the outer wall of the combustion chamber 2 in the said stove body 1, and two annular horizontal partitions are arranged in the cavity from to...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, except that the high-temperature tail gas heat exchange channel 9, the medium-temperature tail gas heat-exchange channel 10 and the low-temperature tail gas heat-exchange channel 11 have been changed. The cross-sections of the channel 10 and the low-temperature exhaust gas heat exchange channel 11 are rectangular; the cross-sectional areas of the high-temperature exhaust gas heat exchange channel 9, the medium-temperature exhaust gas heat exchange channel 10, and the low-temperature exhaust gas heat exchange channel 11 decrease successively, and their wall thickness Also decrease in turn; the high temperature tail gas heat exchange channel 9 is made of stainless steel, the medium temperature tail gas heat exchange channel 10 and the low temperature tail gas heat exchange channel 11 are made of copper or aluminum.

[0031]Working principle: when the hot water stove starts to work, the heating fire row 4 is started, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com