A kind of dehydration processing method of down and down anti-caking

A processing method and anti-caking technology, which is applied in the field of down processing, can solve problems such as easy caking and poor dehydration effect of down, achieve good efficiency, avoid mutual transfer interference of water, and improve dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

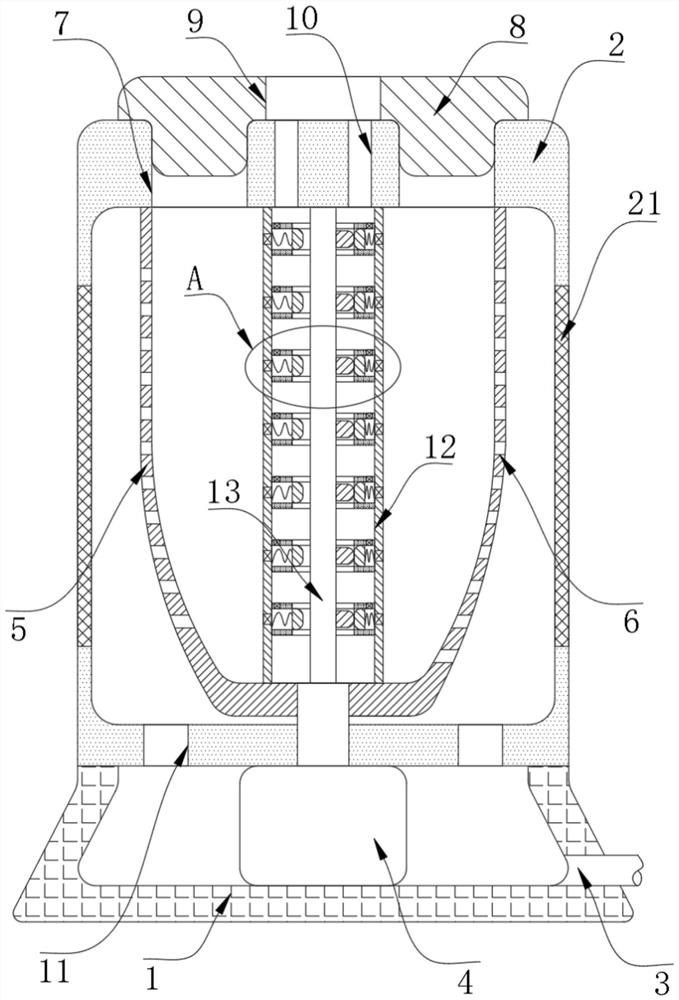

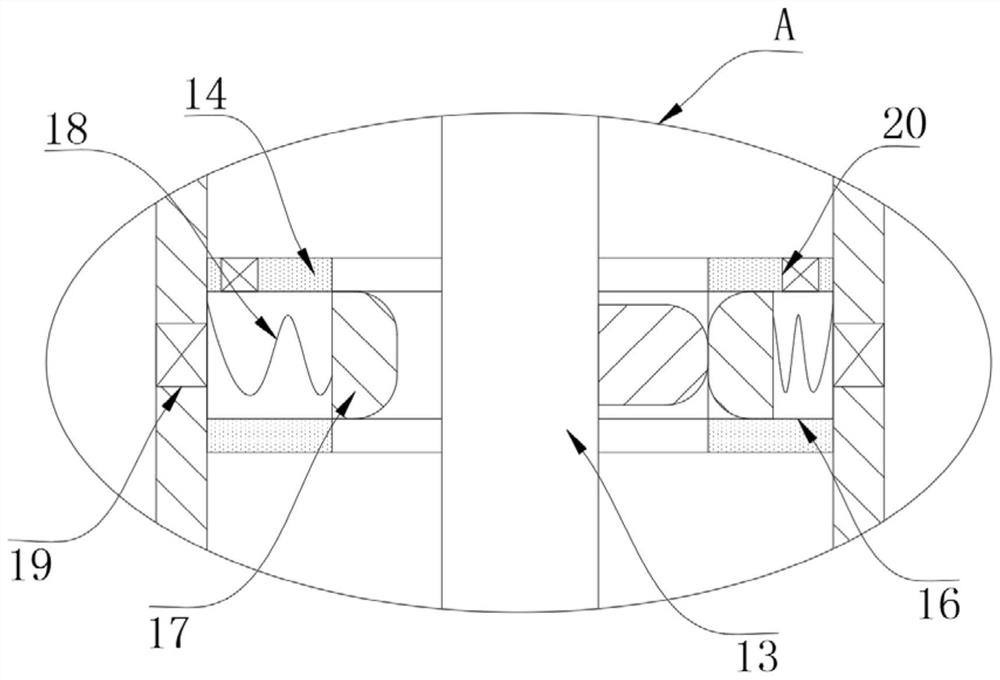

[0024] refer to Figure 1-4 , a dehydration processing method for anti-caking down, comprising the following processing steps:

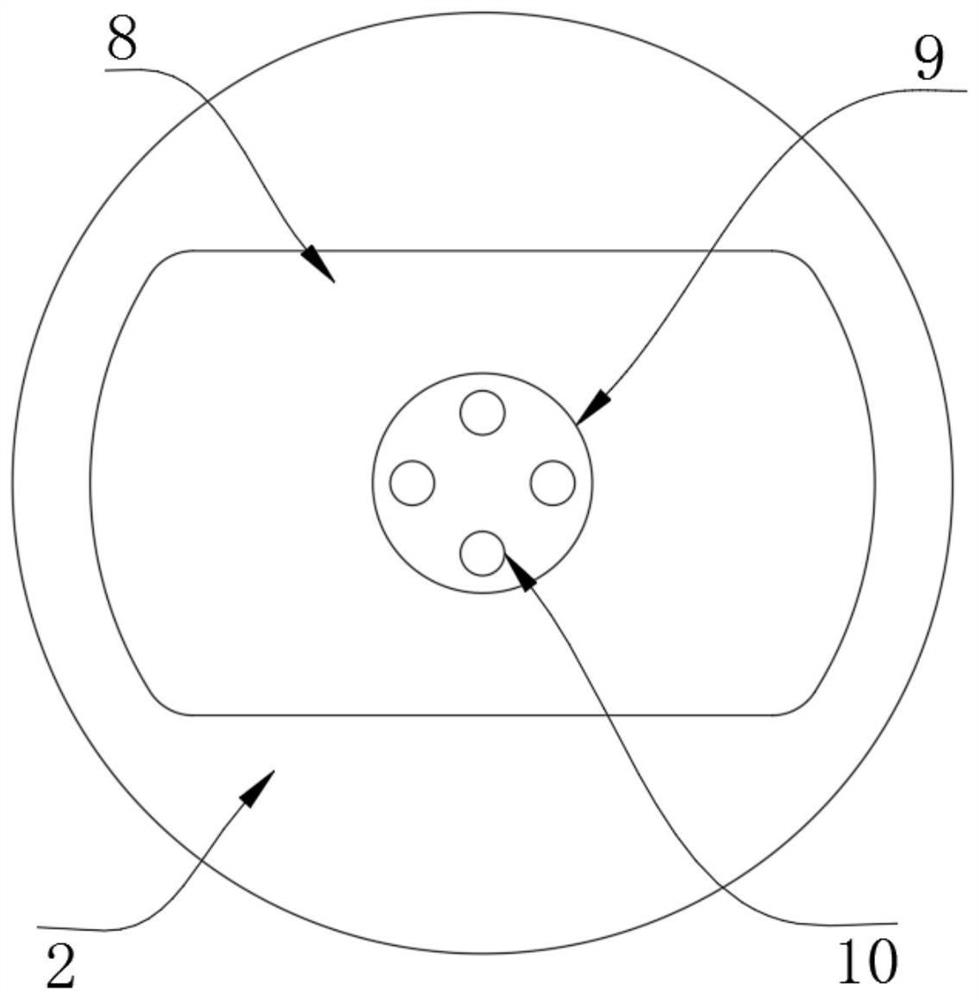

[0025] S1. Discharging: Pour some clean water into the processing box 2, start the motor 4 for self-cleaning of the drum 5 to avoid contamination of the down, and then turn off the motor 4 and then pour the down to be dehydrated into the processing box 2 through the discharging hole 7 inside, and then use the cover plate 8 to close the discharge hole 7;

[0026] S2. Dehydration: Restart the motor 4 to drive the drum 5 to rotate, so that the down moves to the inner wall of the drum 5 under the action of centrifugal force, and is evenly distributed on the inner wall of the drum 5, so that the down and the inside of the drum 5 are continuously Squeeze occurs, so that the water in the down is lost, and the dehydration is completed. The water flow will leave the drum 5 from the water outlet 6, and enter the collection box 1 at the bottom through the drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com