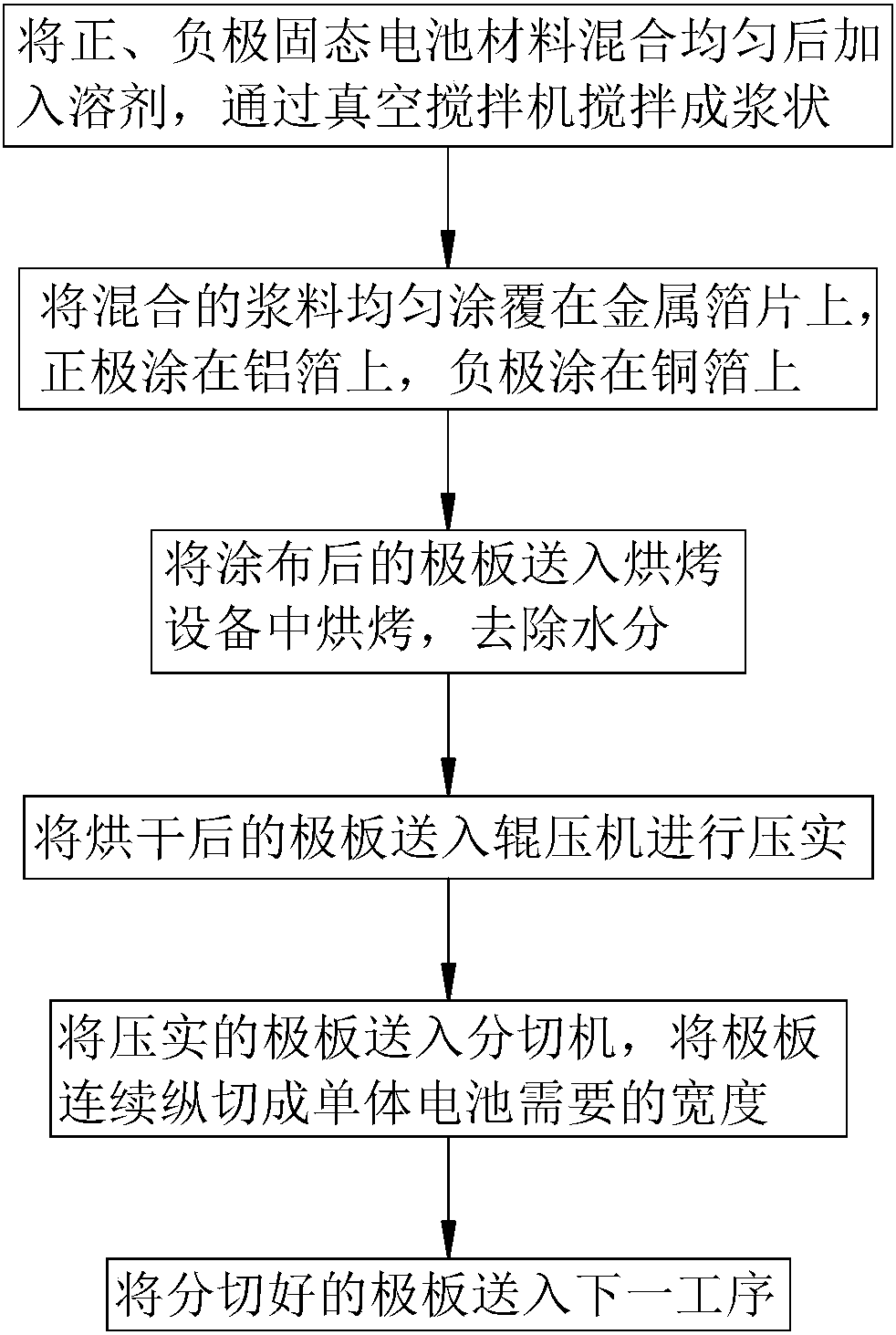

Lithium battery production process

A production process and technology for lithium batteries, which are applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, and final product manufacturing, etc., can solve the problems of deformation at the cut-off point of the pole piece, and the application of shearing process is not suitable, so as to improve quality and reduce shearing. The amount of deformation and the effect of avoiding winding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

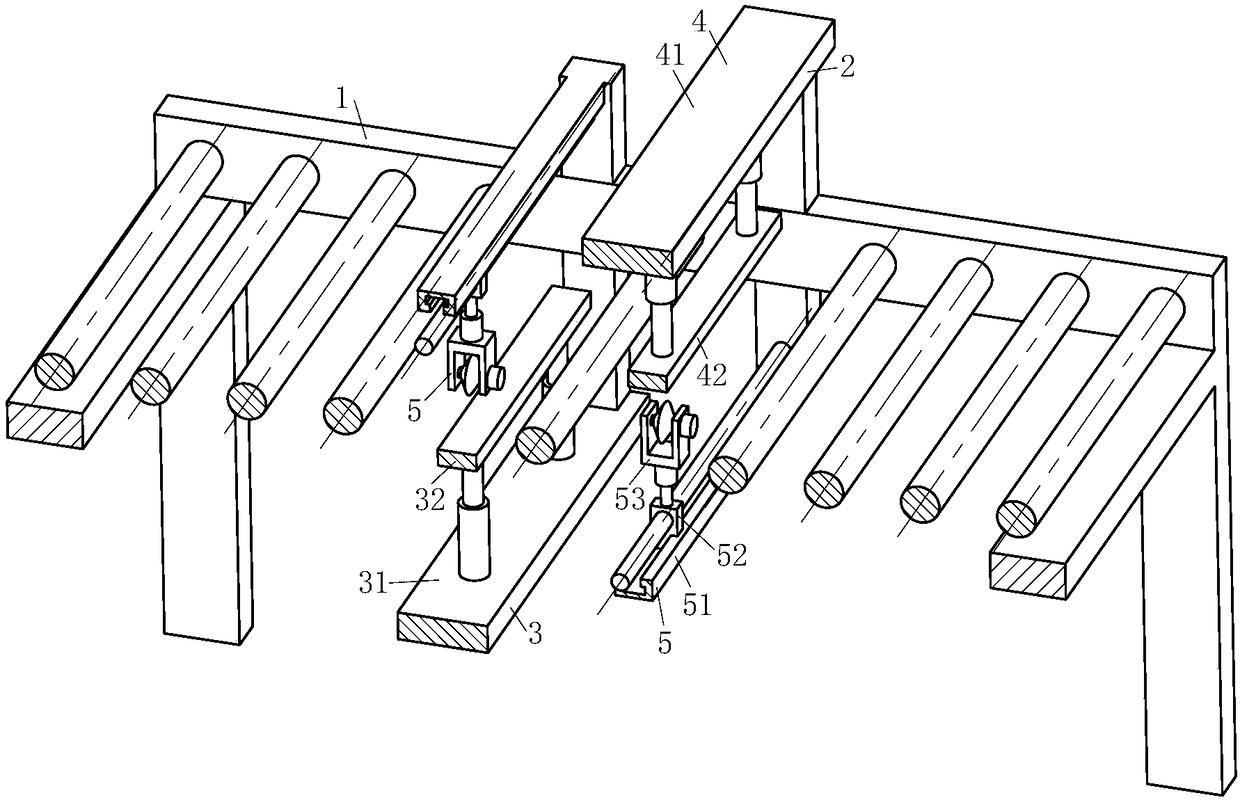

[0049] As an embodiment of the present invention, a motor is provided on one side of the mounting base 53, and a first blade 54 and a second blade 55 are symmetrically arranged on the outer ring of the motor shaft; the first blade 54 passes through a guide post Installed on the outer ring of the rotating shaft, the second blade 55 is installed on the outer ring of the rotating shaft through another guide post, and the first blade 54 and the second blade 55 can move along the normal direction of the outer ring of the rotating shaft. When the motor rotates, the first blade 54 and the second blade 55 move outwards along the normal direction of the outer ring of the rotating shaft under the action of centrifugal force. By controlling the motor speed, the displacement of the first blade 54 and the second blade 55 can be controlled, thereby Control the cutting depth of the polar plate to achieve the purpose of scoring on one side and cutting off the other side, reducing the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com