Wet ball mill discharge detection device

A detection device, ball mill technology, applied in the direction of measuring device, material weighing, analysis of materials, etc., can solve the problems of lack of precision, "wrapping balls, high moisture content of the grinding material, etc., to achieve online detection, easy online detection, and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

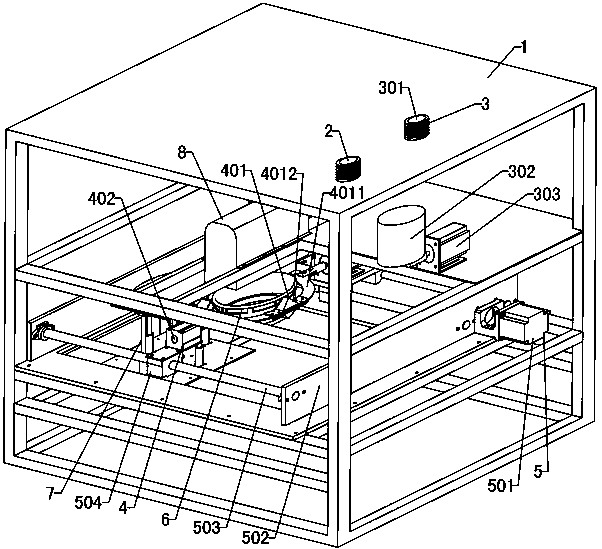

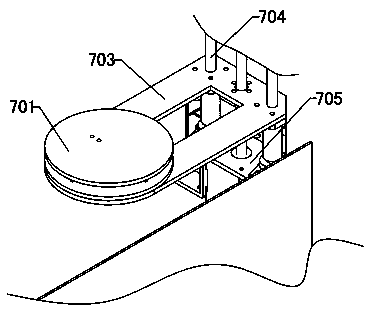

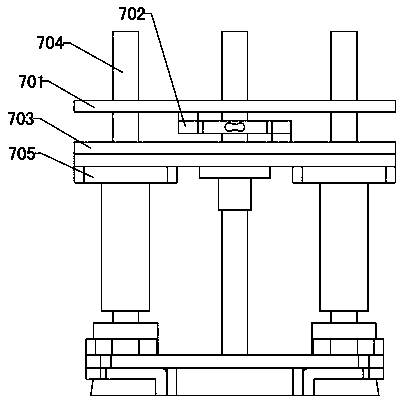

[0031] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0032] Refer to attached Figure 1~5: Wet type ball mill discharge detection device, including frame 1, feeding mechanism 3, washing mechanism, drying mechanism 8, weighing mechanism 7 and a moving conveying mechanism that translates or flips between each mechanism, and the moving conveying mechanism passes through the sliding The rail mechanism 5 is horizontally installed in the middle of the frame 1, the feeding mechanism 3 and the flushing mechanism are respectively arranged above the moving conveying mechanism, the weighing mechanism 7 is arranged below the moving conveying mechanism, and the weighing mechanism 7 and the feeding mechanism 3 are respectively It is arranged on both sides of the frame 1 , and a drying mechanism 8 is arranged between the weighing mechanism 7 and the feeding mechanism 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com