Wet ball mill discharge detection system

A detection system, ball mill technology, applied in measuring devices, analytical materials, weighing equipment for materials with special properties/forms, etc. Smooth, ensure uniformity, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

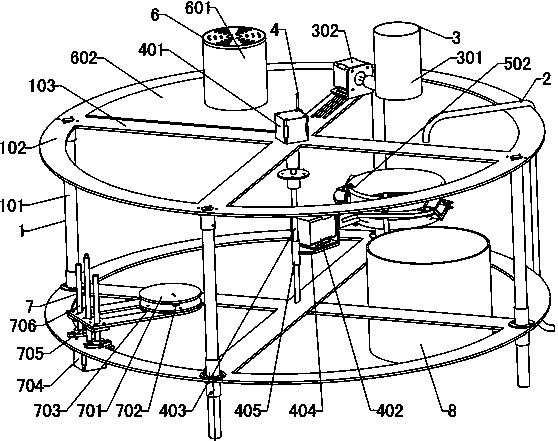

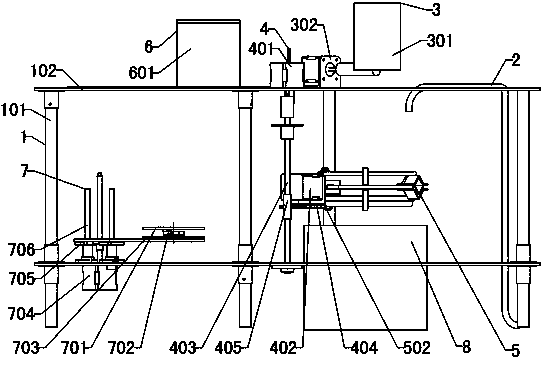

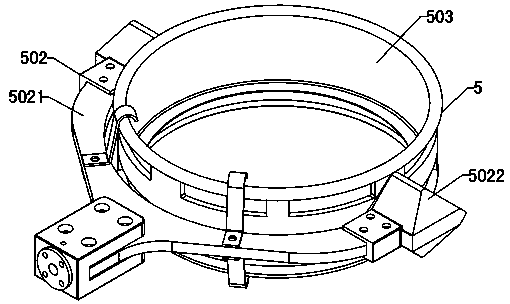

[0029] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0030] Refer to attached Figure 1~4 : Wet type ball mill discharge detection system, including frame 1 and sample sieve 5 installed on frame 1, feeding mechanism 3, washing mechanism, drying mechanism 6 and weighing mechanism 7, sample sieve 5 rotates Turning mechanism 4 is installed in rotation on the central axis in frame 1; Feeding mechanism 3, flushing mechanism, drying mechanism 6 and weighing mechanism 7 are ring-shaped and arranged around sample sieve 5, wherein, feeding mechanism 3, The washing mechanism and the drying mechanism 6 are arranged above the sample sieve 5 respectively, and the weighing mechanism 7 is arranged below the sample sieve 5 in a liftable manner.

[0031] The frame 1 includes support legs 101 and annular mounting plates 102. At least two sets of annular mounting plates 102 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com