Wet type ball mill discharge particle uniformity detection device

A technology of particle uniformity and detection device, which is applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc. It can solve problems such as lack of precision, high moisture content of the material entering the grinding, and unknown change amount, so as to achieve easy on-line detection and realize on-line detection , The effect of smooth detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

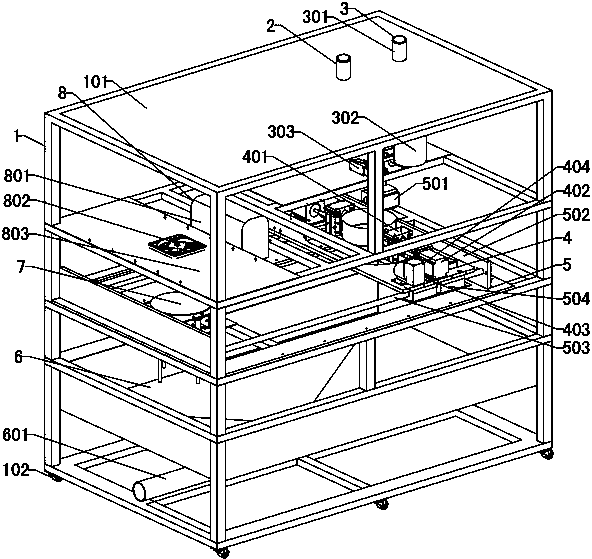

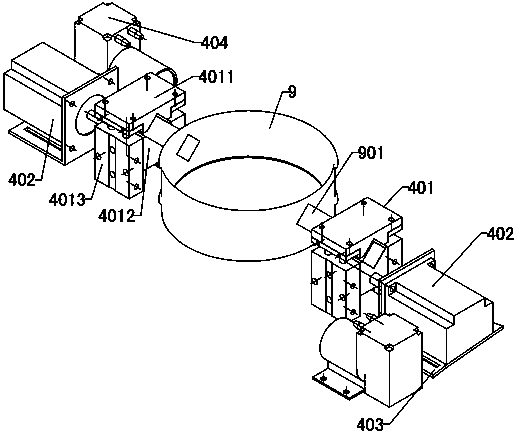

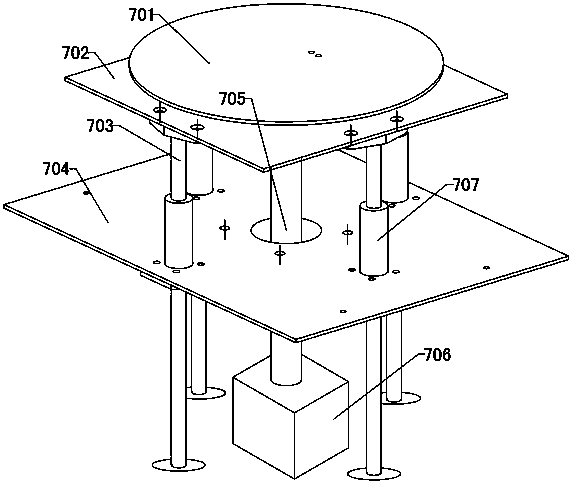

[0028] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~3 The present invention will be further described.

[0029] Refer to attached Figure 1~3: Wet type ball mill discharge particle uniformity detection device, including frame 1 and feeding mechanism 3 installed in frame 1, slide rail mechanism 5, washing mechanism, drying mechanism 8, weighing mechanism 7 and sampling sieve 9. The sampling sieve 9 is slidably installed on the slide rail mechanism 5 in the middle of the frame 1 through the translation and turning mechanism 4. The feeding mechanism 3, the drying mechanism 8 and the washing mechanism are respectively arranged above the sampling sieve 9. The weighing mechanism 7 is arranged below the sample sieve 9, a drying mechanism 8 is arranged above the weighing mechanism 7, and a water tank 6 is arranged at the bottom of the frame 1. The frame 1 can adopt a frame structure, and the rear and top of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com