Fruit tea processing equipment and method

A processing equipment and fruit tea technology, applied in the fruit tea processing equipment and processing field, can solve the problems of inconvenient cleaning, large difference in drying quality, large difference in water evaporation speed of fruit slices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

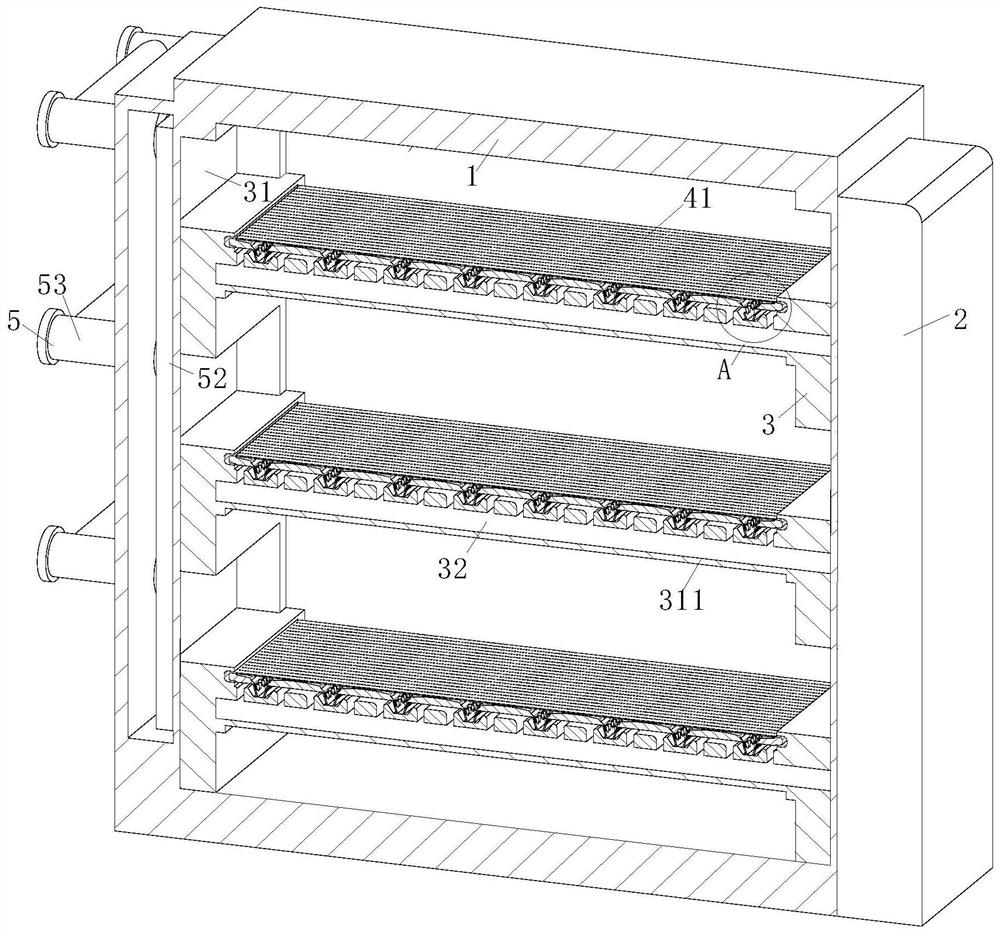

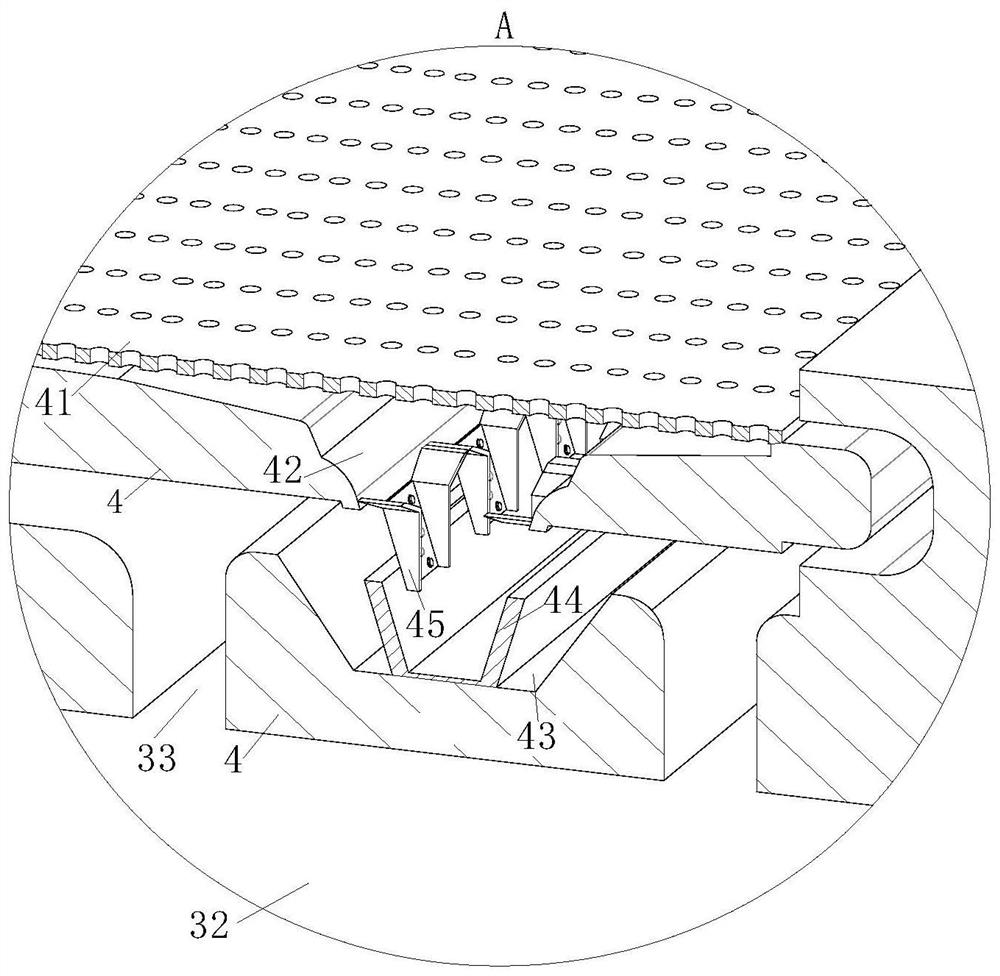

[0057] As an embodiment of the present invention, the drying module includes:

[0058] A long hole 32, the long hole 32 is arranged inside the support frame 311, and the length of the long hole 32 is greater than the length of the leakage plate 41, and the long hole 32 communicates with the inside of the hot air blower 2;

[0059] No. 2 notch 33, the No. 2 notch 33 is uniformly arranged on the top of the long hole 32, and the second notch 33 communicates with the bottom of the drain plate 41 and the inside of the long hole 32;

[0060] During work, in the process of drying the fruit slices, because the elongated hole 32 communicates with the inside of the hot air blower 2, after the hot air blower is started, a part of the dry hot air flows into the inside of the elongated hole 32, and fills the inside of the elongated hole 32 from the long hole 32. No. 2 notch 33 that hole 32 communicates flows out, and dry hot air flows from No. 2 notch 33 to No. 4 notch 42, and flows out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com