A wood drying equipment with an auxiliary adjustment structure for humidity in the air

A technology for adjusting the structure and drying equipment, applied in the direction of wood drying, drying, drying machine, etc., can solve the problems of affecting the efficiency of wood processing and production, long use time, low drying efficiency, etc., and achieve comprehensive improvement. , Improve the effect of moisture absorption, and speed up the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

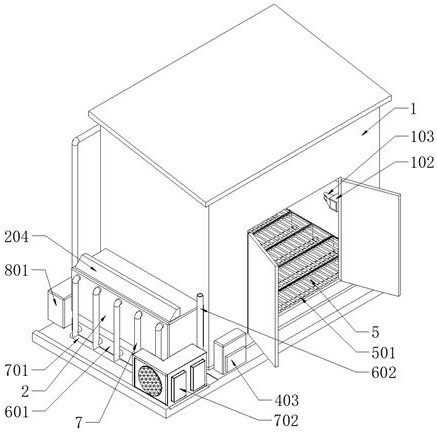

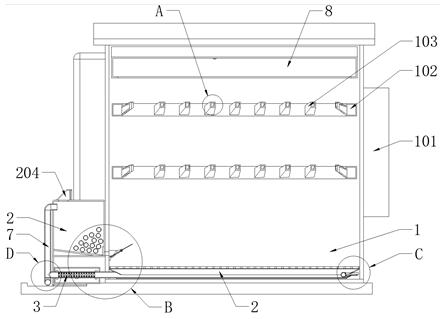

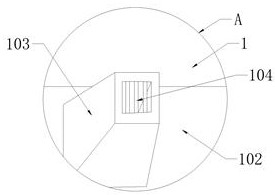

[0052] see Figure 1-2 and Figure 9 , a kind of wood drying equipment with an auxiliary humidity adjustment structure in the air, comprising a drying room 1, a hot air blower 101 is fixedly installed on the outside of the drying room 1, and a ring-shaped hot air blower is fixedly installed inside the drying room 1 pipe 102, and each hot air pipe 102 is evenly fixed with a plurality of spray pipes 103 on the side outer wall close to the middle position of the drying room 1; Inside the drying room 1, after the staff controls the hot air blower 101 to be energized and started, the inside of the hot air pipe 102 is supplied with hot air. 1 The wood stacked inside is continuously heated and dried.

[0053] see Figure 1-2 and Figure 4 A ball storage box 2 is fixedly installed on the left side outer wall of the drying room 1, and the interior of the ball storage box 2 is filled with a plurality of drying balls 3, and the drying balls 3 include a hollow sphere 301 arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com