Multi-layer intelligent drying kiln for ceramic tile production

A drying kiln and intelligent technology, which is applied in the drying of ceramic products, drying solid materials, drying chambers/containers, etc., can solve the problem of uneven heating of bricks, lowering the quality of tile production, and ineffective drying of the contact parts between bricks and installation plates etc. to avoid uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

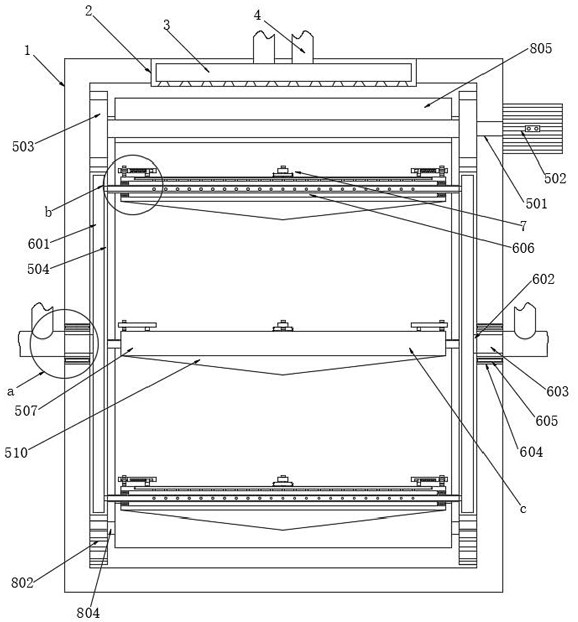

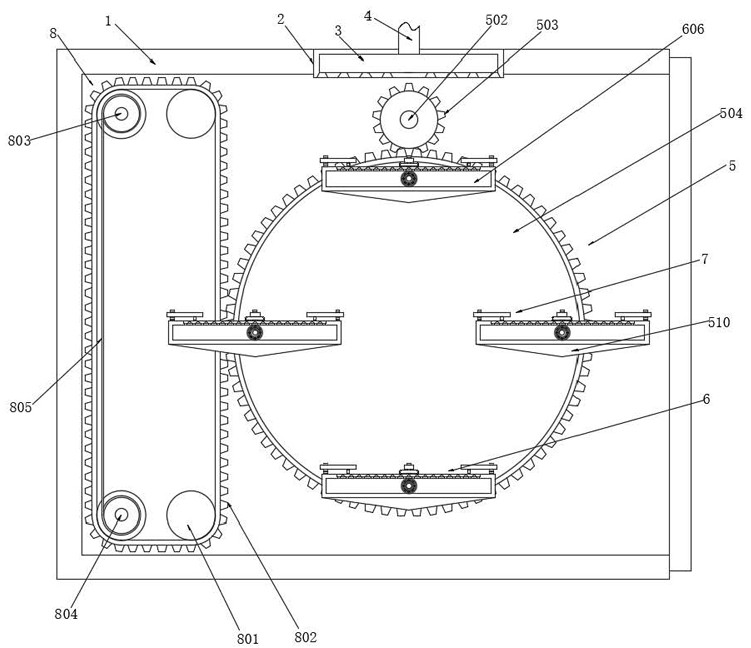

[0039] Example: such as Figure 1-6 As shown, the present invention provides the following technical solutions: a multi-layer intelligent drying kiln for producing ceramic tiles, the multi-layer intelligent drying kiln for producing ceramic tiles includes a kiln 1, an installation hole 2, an exhaust pipe 3, an air intake pipe 4. Uniform drying component 5, drying enhancement component 6;

[0040] The upper end of the kiln 1 is provided with an installation hole 2, and an exhaust pipe 3 is fixedly installed in the installation hole 2, and an inlet pipe 4 is fixedly connected to the input end of the exhaust pipe 3, through which the exhaust pipe 3 can The hot gas conveyed by the air inlet pipe 4 is discharged from the inner upper end of the kiln 1, and the uniform drying assembly 5 is fixedly installed in the kiln 1, and the installation plates 507 of different levels in the kiln 1 can be rotated through the uniform drying assembly 5 , so that the bricks on the mounting plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com