Patents

Literature

75results about How to "Not easy to emulsify" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fountain solution and preparation method thereof

InactiveCN101870213AEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentGermabenPropylene glycol

The invention discloses a fountain solution, which is characterized in that: the fountain solution comprises the following raw materials in percentage by weight: 1 to 15 percent of glycerin, 0.1 to 10 percent of ammonium citrate, 0.1 to 10 percent of malic acid, 0.1 to 5 percent of defoaming agent, 0.1 to 10 percent of wetting agent, 0.1 to 5 percent of bactericide, 1 to 15 percent of L-PCA-Na, 1 to 15 percent of propylene glycol and 1 to 15 percent of sorbierite; and the preparation method comprises the following steps: adding the ammonium citrate, the malic acid, the wetting agent, the L-PCA-Na in a weight percentage ratio, then adding 50 to 80 percent of water, uniformly mixing the materials and the water; and adding the propylene glycol, the sorbierite, the glycerin, the defoaming agent and the bactericide into the obtained mixture and then uniformly stirring the mixture so as to obtain the fountain solution. The fountain solution has the advantages of environmental protection, strong fountain capability, wet non-verbal-visual part, sufficient pH-value buffering, difficult ink emulsification, large electric conductivity, large surface-tension buffering range and easy operating control.

Owner:杜广清

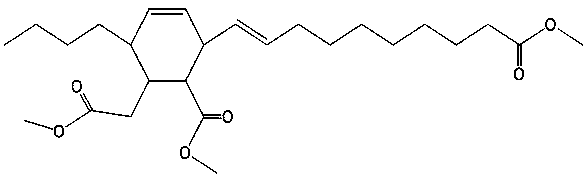

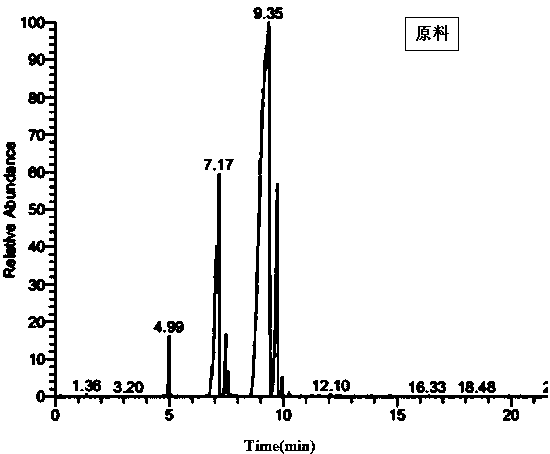

Improver for improving lubricity of low sulfur diesel oil and preparation method thereof

ActiveCN109576021AImprove the lubrication effectNot easy to emulsifyLiquid carbonaceous fuelsFuel additivesBiodieselDistillation

The invention relates to an improver for improving lubricity of low sulfur diesel oil and a preparation method thereof. According to the method, unsaturated dicarboxylic acid ester and a polymerization inhibitor are mixed together at 150-180 DEG C, tung oil biodiesel is gradually added, after the addition, a reaction continues producing at 200-240 DEG C for a certain period of time, and after thereaction, an improver product is obtained by distillation under reduced pressure. The improver prepared by the preparation method of the invention can improve the lubricity of the low sulfur diesel oil, and the improver product is low in condensation point and acid value, and is low in blending ratio with the low sulfur diesel, and can make the low sulfur diesel meet national V lubricity standardsand condensation point requirements after blending.

Owner:CHINA PETROLEUM & CHEM CORP +1

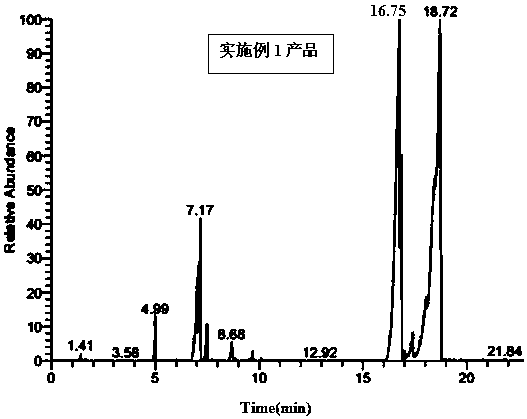

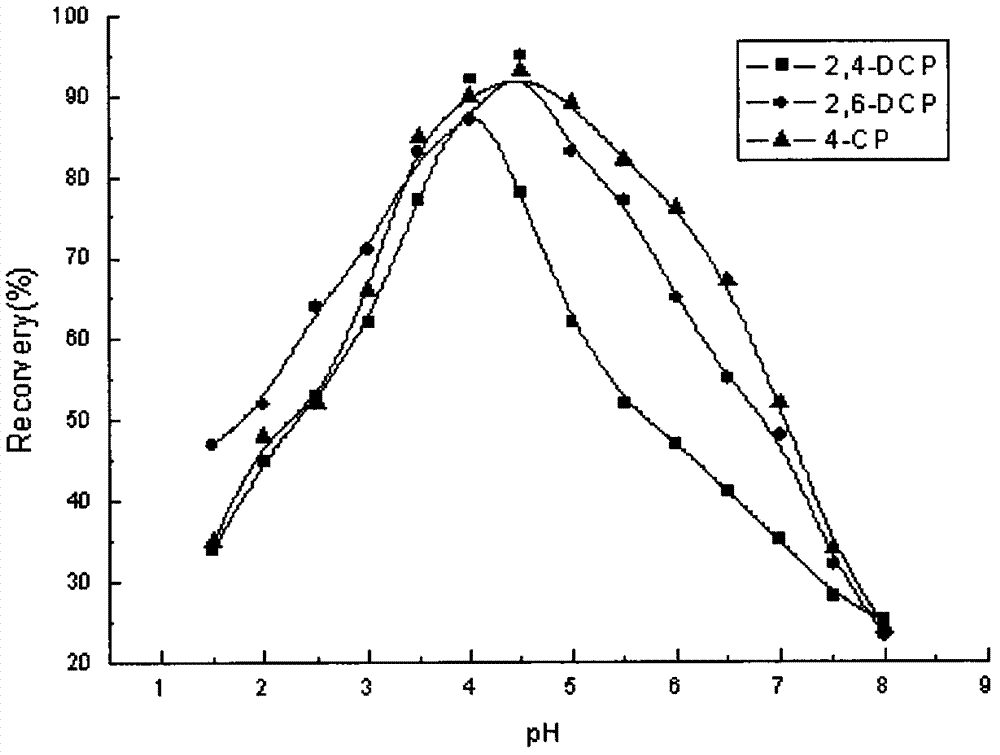

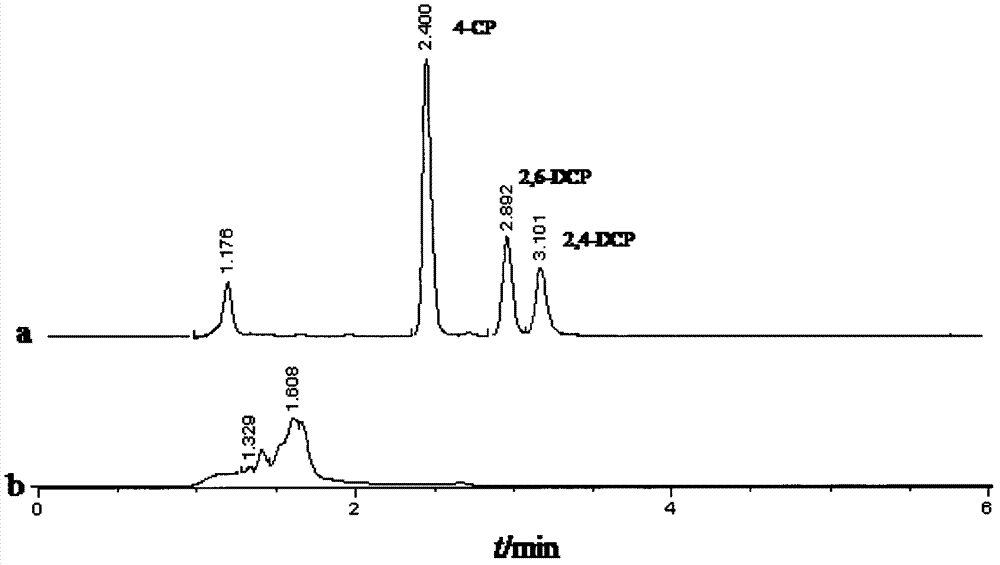

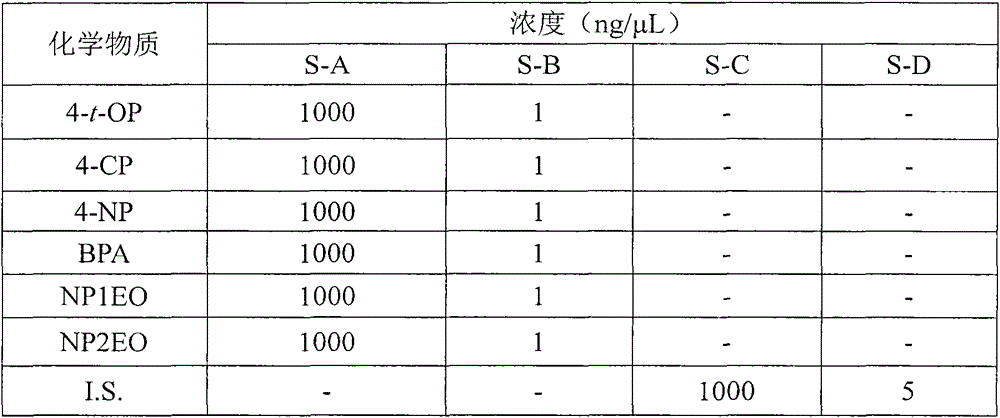

Method for determining trace chlorophenol endocrine disruptor in water

InactiveCN102768245AImprove accuracyShort split timeComponent separationPerturbateurs endocriniensIonic liquid

The invention relates to a chlorophenol compound measuring method, specifically to a method for determining a trace chlorophenol endocrine disruptor in water. The method comprises the following steps of: adding NaH2PO4 phase separation salt, adding a Na2HPO4-H3PO4 buffer solution to adjust pH value of the solution, adding a [Bmim]BF4 hydrophilic ionic liquid for extraction separation, separating by a centrifuge, taking an ionic liquid phase, and finally determining the content of the chlorophenol endocrine disruptor through HPLC. According to the invention, the ionic liquid is used as an extractant, NaH2PO4 is used as the phase separation salt, and the trace chlorophenol endocrine disruptor in water is determined by the utilization of the ionic liquid aqueous biphasic extraction-high performance liquid chromatography (HPLC) method, which has advantages of short phase separation time, no easy emulsification during the extraction process, nontoxicity, no pollution and the like in comparison with polymer aqueous biphasic extraction. The method provided by the invention has high accuracy and good precision.

Owner:JILIN NORMAL UNIV

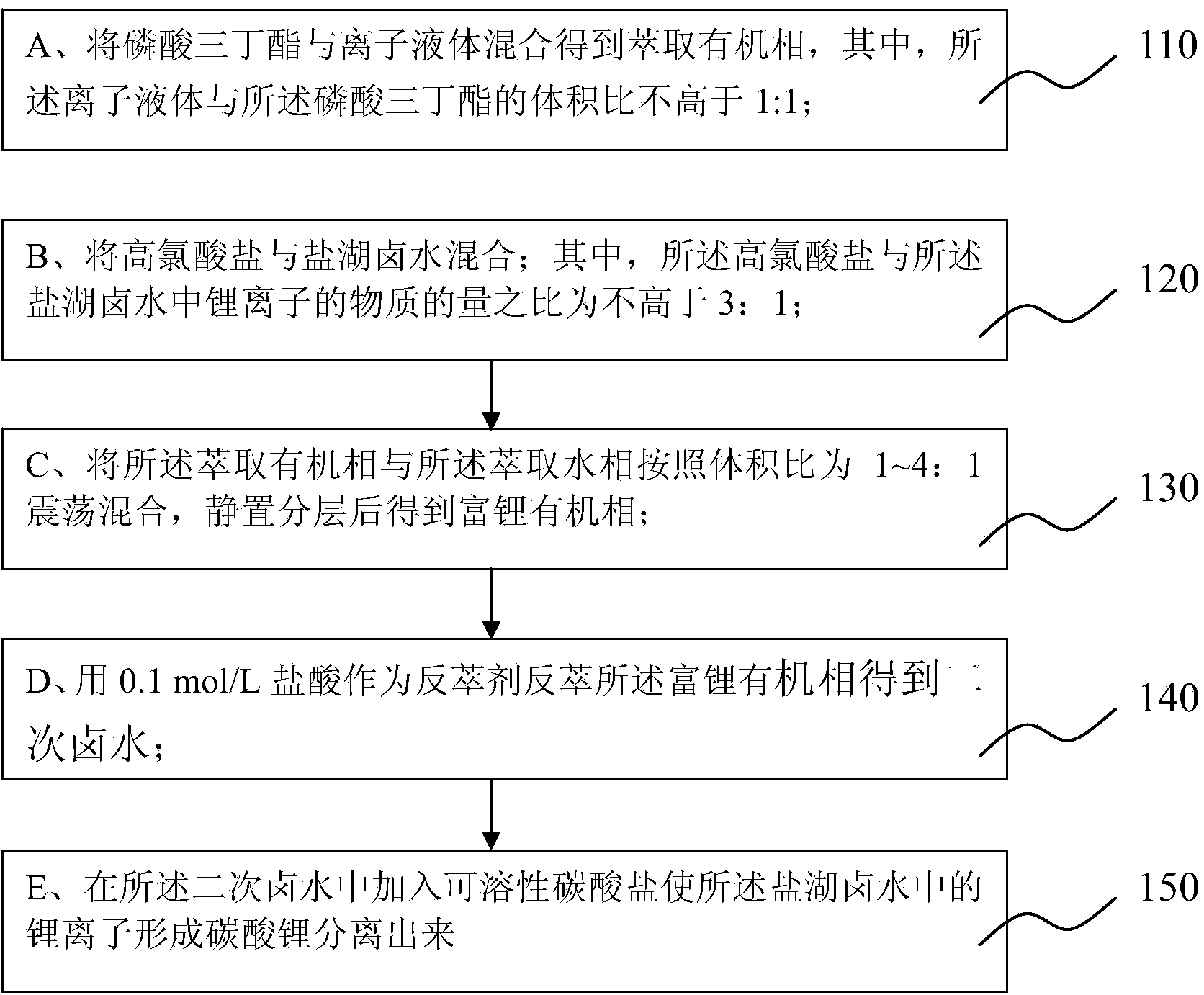

Method for separating lithium from salt lake brine

InactiveCN104232896ANo pollution in the processAvoid pollutionProcess efficiency improvementPhase splittingSalt lake

The invention discloses a method for separating lithium from salt lake brine. The method comprises the steps as follows: tributyl phosphate and an ionic liquid are mixed to obtain an extracted organic phase, wherein the volume ratio of the ionic liquid to tributyl phosphate is not higher than 1:1; perchlorate and the salt lake brine are mixed, wherein the ratio of lithium ions in the perchlorate to those in the salt lake brine is (0.5-3):1, and the extracted organic phase and an aqueous phase are oscillated and mixed for 8-12 min at room temperature at the volume ratio of (1-4):1 and is left to stand for 20 min to obtain a lithium-rich organic phase. According to the method for separating lithium from the salt lake brine, lithium is separated from the salt lake brine with high ratio of magnesium to lithium, the separating efficiency is high, and the problems of pollution caused by solvent volatilization and phase-splitting difficulty due to system emulsification are solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

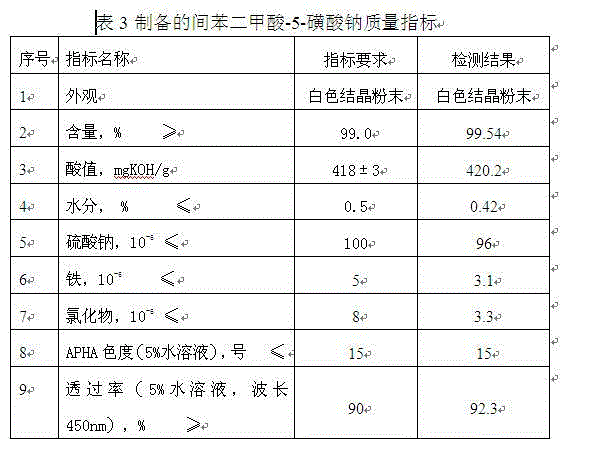

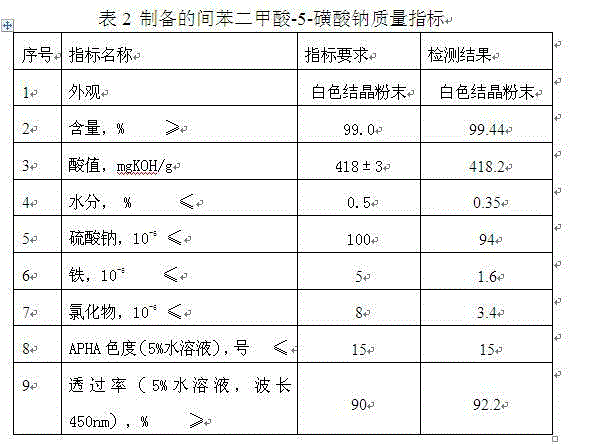

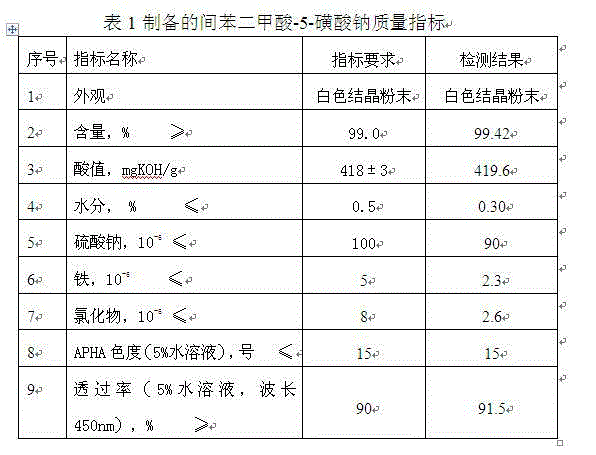

Method for extracting m-phthalic acid-5-sodium sulfonate from trimonomer production wastewater

ActiveCN104086462AHigh extraction rateLarge extraction capacityOrganic chemistryOrganic compound preparationPhthalic acidAlkylbenzenes

The invention discloses a method of extracting m-phthalic acid-5-sodium sulfonate from trimonomer production wastewater. The method sequentially comprises the following steps: preparing an extraction agent; adjusting the pH value; extracting; re-extracting; concentrating re-extracting liquid; acidifying; concentrating and crystallizing; and drying. In the extraction agent, double components (trioctylamine and ditertiary amine 2, 4-di(N, N-dihexyl) amino dodecylbenzene) are used as complexing agents, 2-heptyl undecyl alcohol is used as a cosolvent and double components (sulfonated kerosene and n-octyl alcohol) are used as diluents. According to the method provided by the invention, a complexing and extracting process is adopted for extracting m-phthalic acid-5-sodium sulfonate from liquid waste at the bottom of a tower after methanol is recovered from trimonomer and the best extraction system and reasonable extraction conditions are selected, so that the extraction rate of m-phthalic acid-5-sodium sulfonate is over 99%, the economic benefit of the trimonomer product is greatly improved, and comprehensive utilization of resources is realized.

Owner:WEIFANG WORLD CHEM

Oxidized polyethylene wax emulsion water-repellent agent and preparation method thereof

ActiveCN102720093AImprove stabilitySmall particlesWater-repelling agents additionCardboardSilicon dioxide

The invention relates to an oxidized polyethylene wax emulsion water-repellent agent which is prepared from the following raw materials by weight: 35-40% of oxidized polyethylene wax, 3-5% of compound mixed emulsifying agent of Tween-60, Span-80 and disproportionated rosin, 0.2-0.4% of silicon dioxide nano powder and the balance of water. The water-repellent agent has pH of 7-8 and viscosity of 150-450 mP*s. The emulsion is modified by nano silicon dioxide, so that the blend-modified emulsion stably exists in the form of adsorbing gas atom on nano-sized concave surface, and is equivalent to a layer of stable gas film on macroscopic surface, and oil or water cannot directly contact the surface of the material, therefore, the material surface presents hydrophobicity and oleophobicity, and obtains super-hydrophobic super-oleophobic effects. The product also has certain fire retardancy, and can meet waterproof and moistureproof functions as well as combustion-supporting performance of carton and pasteboard high-grade paper products.

Owner:连云港三友包装制品有限公司

Synergic reagent for separating glycolic acid from water solution containing inorganic salt and uses thereof

InactiveCN101264394AConstant sourceWide variety of sourcesLiquid solutions solvent extractionChemical recyclingInorganic saltsKerosene

The invention discloses a synergistic extract for separating glycollic acid from water solution with inorganic salt and the application, the components and the volume percentage are as follows: trioctylamine 30 to 70%, tributyl phosphate 5 to 30%, coal oil 5 to 40%, and octanol 5 to 40%. The synergistic extract has the advantages of excellent extraction and stripping separation performance for glycollic acid, good effect, less liability to emulsification, and low extractant loss.

Owner:EAST CHINA UNIV OF SCI & TECH

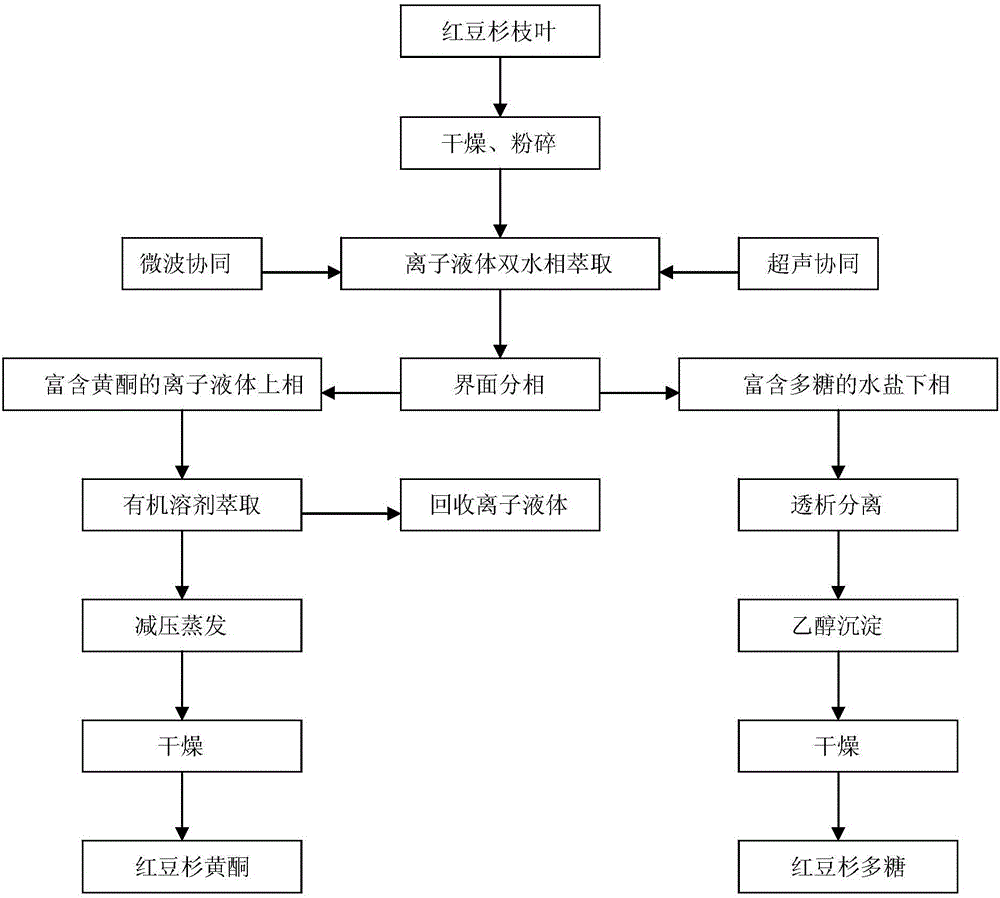

Extraction liquid for synchronously extracting flavone and polysaccharide of taxus chinensis and method thereof

InactiveCN106176835AReduce volatilityLow steam pressureConiferophyta medical ingredientsBulk chemical productionSolventBULK ACTIVE INGREDIENT

The invention belongs to the technical field of extraction and separation of flavone and polysaccharide active ingredients in plants, and particularly relates to an extraction liquid for synchronously extracting flavone and polysaccharide of taxus chinensis and a method thereof. The method comprises the following steps of using crushed branches and leaves of taxus chinensis as raw material; under the synergetic action of ultrasonic wave and microwave, extracting and separating flavone and polysaccharide by a novel double-water phase system which is built by ionic liquid, inorganic salt and water; extracting and separating a flavone compound from an upper ionic liquid phase by an organic solvent, and recycling the ionic liquid and the organic solvent; obtaining a polysaccharide compound from a lower inorganic salt water phase by dialysis, and alcohol precipitation. The method has the advantages that the extraction efficiency is high, the separation condition is moderate, the green and environment-friendly effects of extracting solvent are realized, the recycling degree is high, and the like; the method is suitable for industrialized synchronous separation of flavone and polysaccharide compounds.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

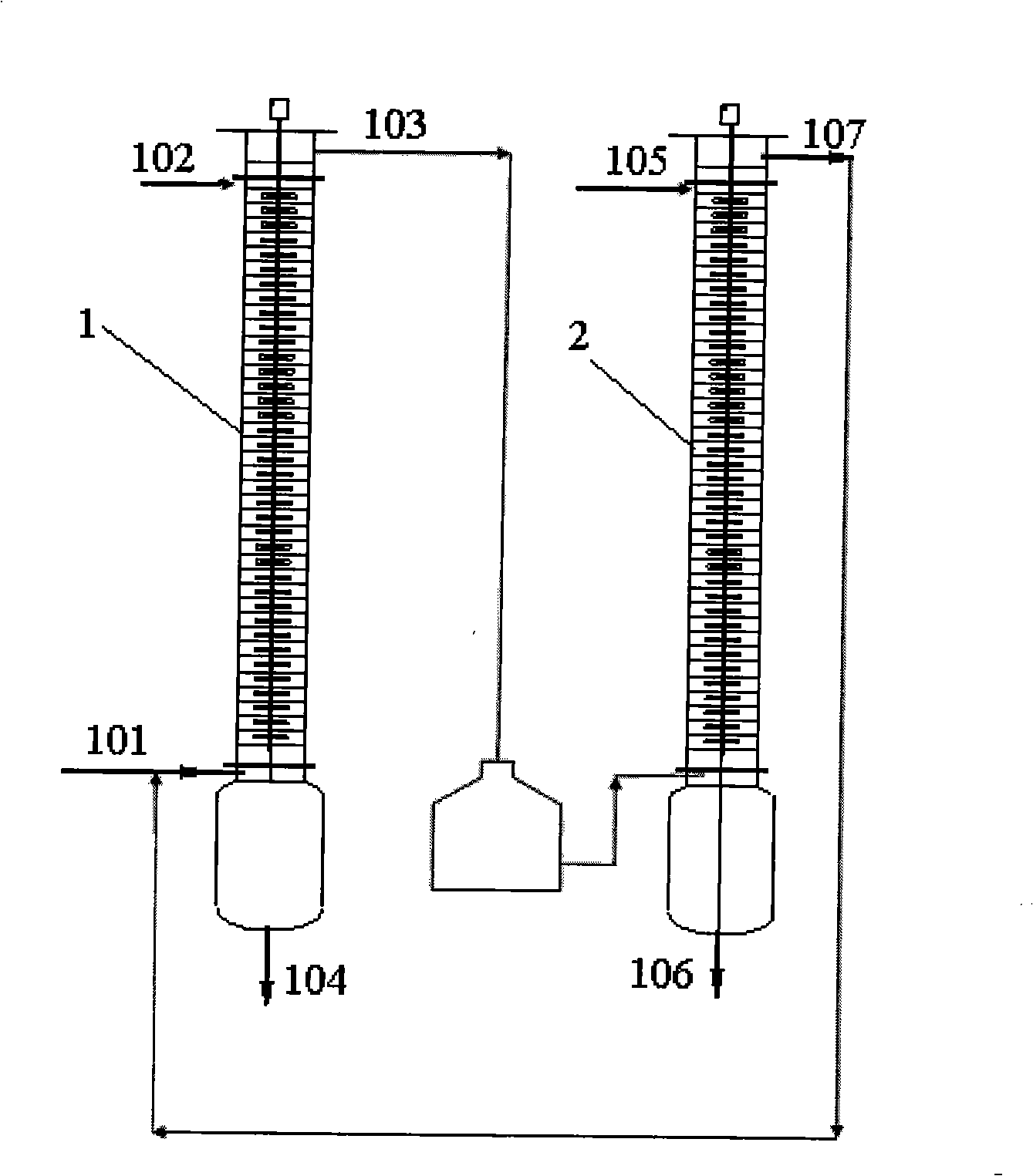

Method for extracting hydroxyacetic acid from water solution mixture containing hydroxyacetic acid

InactiveCN101265174APromote regenerationEasy to prepareCarboxylic compound separation/purificationAcetic acidGlycollic acid

The invention discloses a method of extracting glycolic acid from water solution mixture containing the glycolic acid. The method has the following steps: synergistic extraction agent is delivered into an extraction column from the bottom, the water solution mixture containing the glycolic acid is delivered into the extraction column from the top, extraction phase after extraction flows out of the upper part of the extraction column, and raffinate phase after extraction flows out of the lower part of the extraction column; the extraction phase flowing out of the upper part of the extraction column is delivered into a back-extraction column from the bottom; back-extraction water is delivered into the back-extraction column from the top of the back-extraction column; back-extraction water phase which flows out of the lower part of the back-extraction column is concentrated to obtain the glycolic acid; back-extraction organic phase flows out of the upper part of the back-extraction column. The method has the advantages that the technological process is simpler, the capacity of the organic phase is large, the production capacity of equipment is high, the extractant regeneration is convenient, the energy consumption during the process is small, and the manufacturing cost is low; the volatility of the extractant is small without toxicity, the emulsification is hard, the misphasing speed is high, and the separative efficiency is high; the operation is convenient and stable, and the product quality is high.

Owner:EAST CHINA UNIV OF SCI & TECH

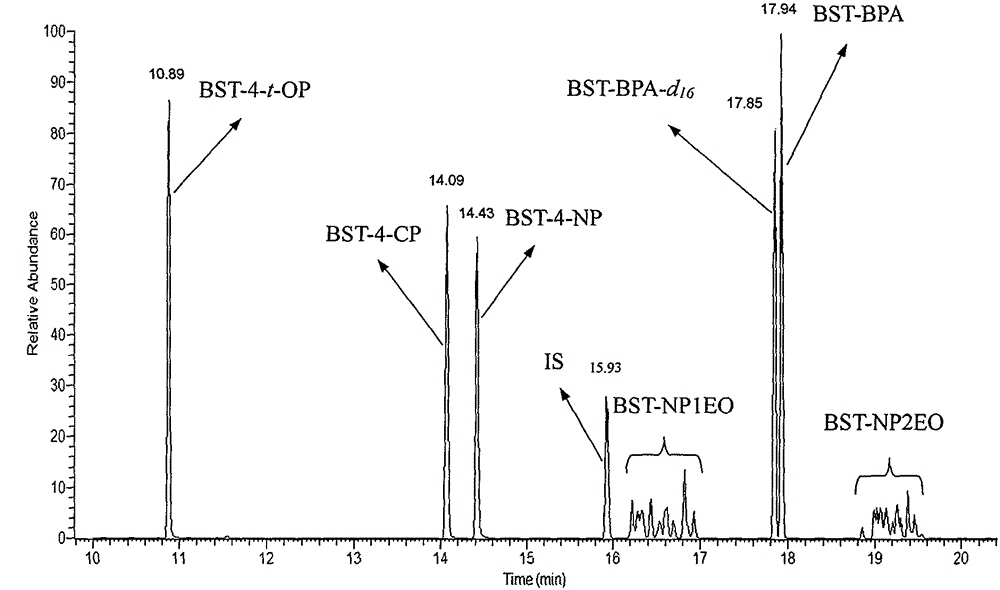

Analysis method for simultaneous determination of 6 kinds of trace phenol environmental endocrine disrupting chemicals in solid environmental sample

InactiveCN105092727AImprove accuracyHigh sensitivityComponent separationRotary evaporatorSolid phase extraction

The invention discloses an analysis method for simultaneous determination of 6 kinds of trace phenol environmental endocrine disrupting chemicals (EDCs) in a solid environmental sample. The method comprises the steps: carrying out microwave-assisted extraction and gel permeation chromatography purification and the like, after solid-phase extraction, concentrating with a rotary evaporimeter, then blowing to dry with moderate nitrogen, adding BSTFA and pyridine, carrying out trimethyl silylation treatment on hydroxyls of the phenol EDCs, and finally analyzing by using GC-MS. Through sample concentration, purification, derivatization and other processes, a chromatographic peak pattern is improved, the detection limit and the impurity interference are reduced, the purification effect is improved, and the instrument analysis accuracy and sensitivity are increased. The method simplifies the operations, has the advantages of high efficiency, energy saving, short phase separation time, not easy emulsification in the extraction process, no pollution, simple operations and the like, and can well suitable for analysis determination of 6 kinds of typical trace phenol EDCs in the solid environmental sample.

Owner:SOUTHWEAT UNIV OF SCI & TECH

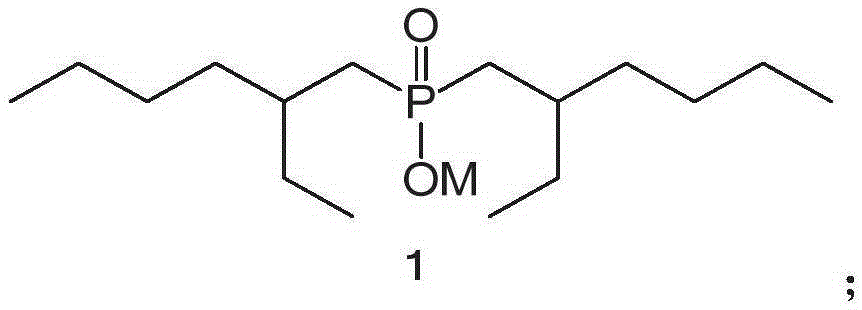

Method for removing iron through solvent extraction

The invention discloses a method for removing iron through solvent extraction. The method for removing iron through solvent extraction, which is disclosed by the invention, contains the following step: contacting an organic phase with a water phase containing Fe<3+> to obtain an organic phase loaded with Fe<3+>, wherein the organic phase contains a compound shown in formula 1 and a diluent; and in the water phase, the concentration of the Fe<3+> is greater than or equal to 1.0g / L; and M is one or more of hydrogen, alkali metal ion and NH4<+>. The method is simple in process, good in the effect of removing iron through extraction, and not liable to emulsify; and moreover, the generated organic phase loaded with Fe<3+> can be reversely extracted under a low acidity, so as to be cyclically utilized. The method is high in efficiency, low in cost, convenient to use, and environment-friendly, and has potential to realize industrialized application.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

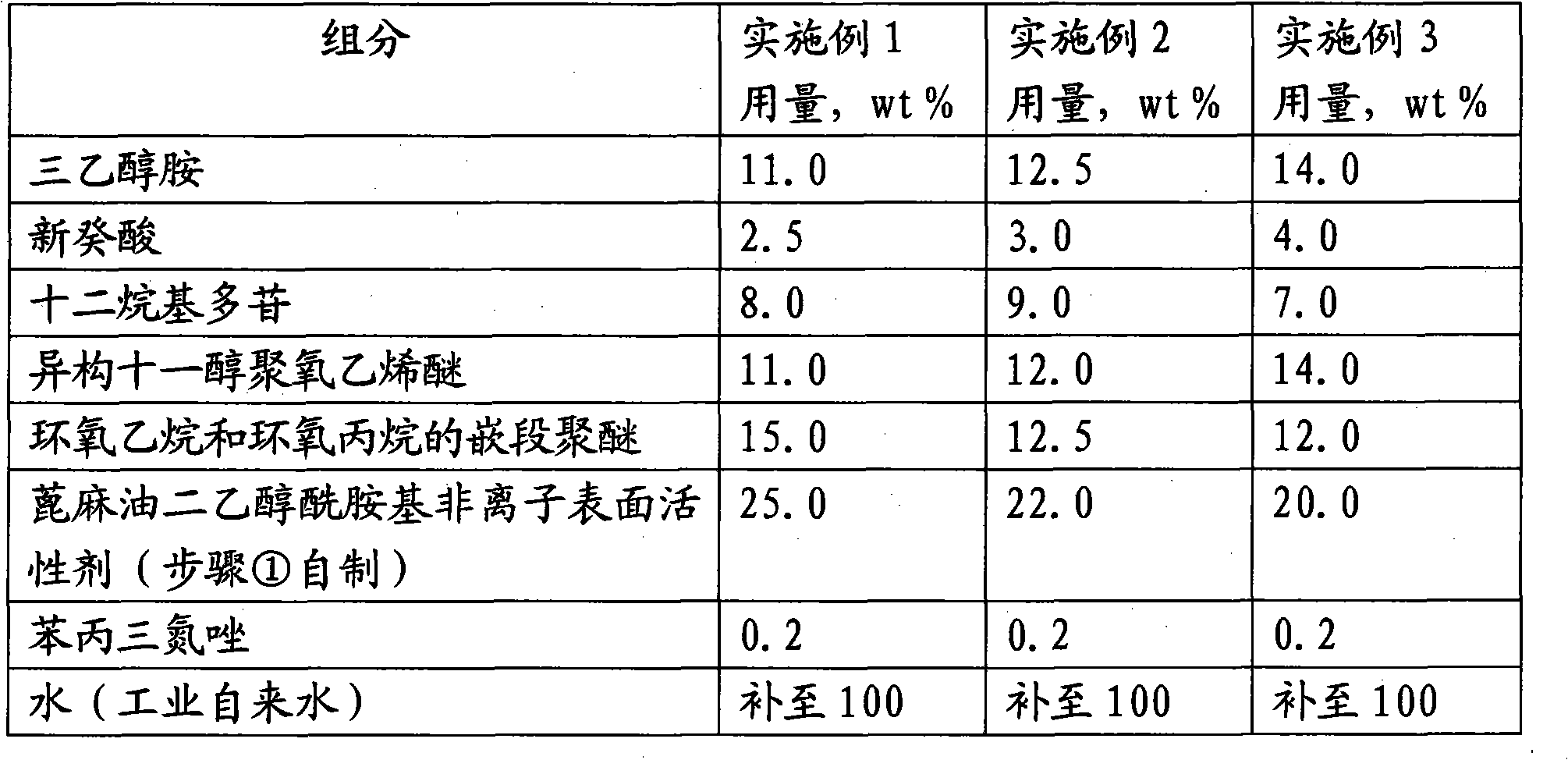

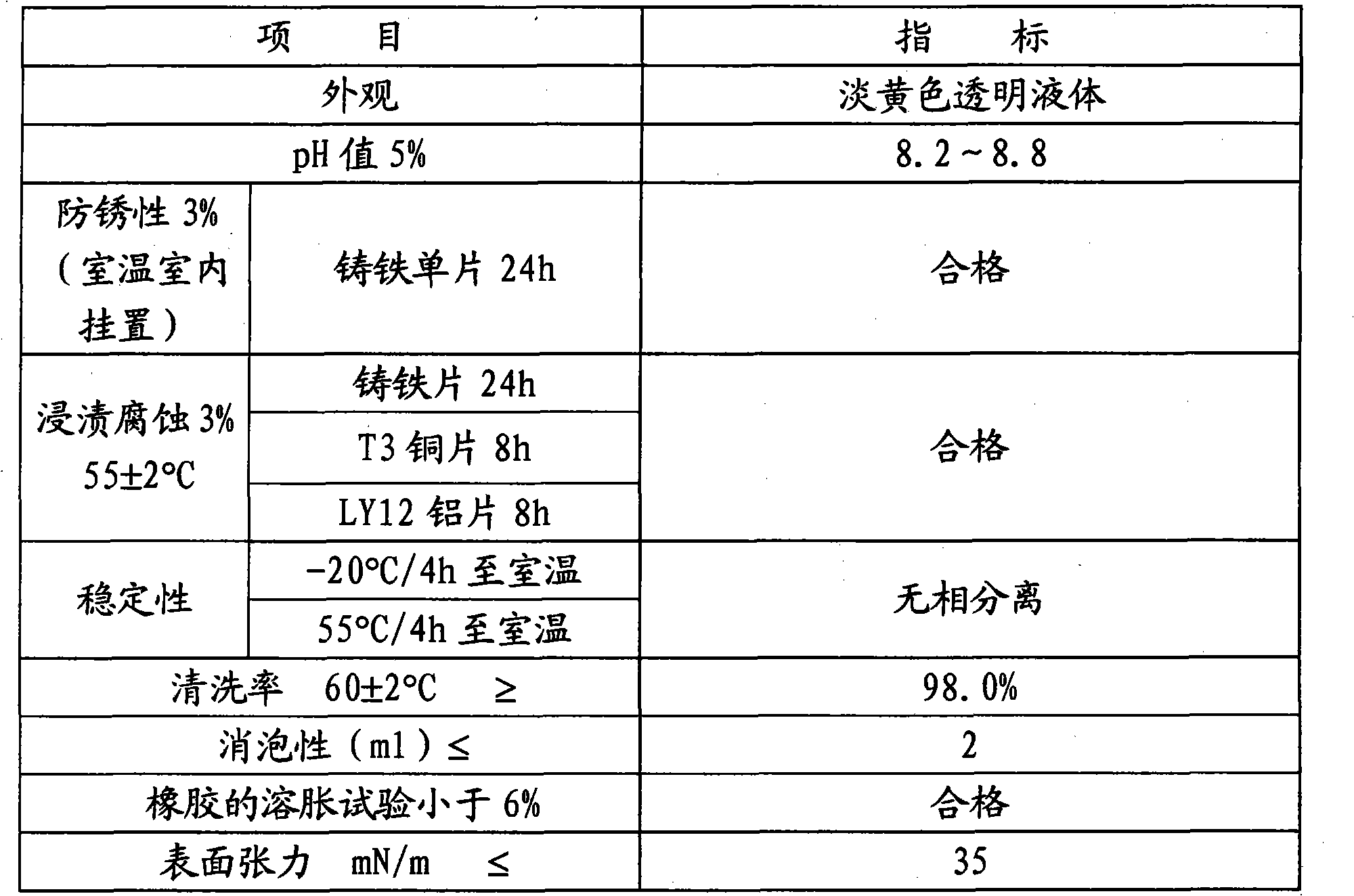

Metal cleaner used for coating production line and preparation method thereof

The invention relates to a metal cleaner used for a coating production line and a preparation method thereof. The metal cleaner consists of the following components in percentage by weight: 10 to 14 percent of triethanolamine, 2 to 4 percent of neodecanoic acid, 6 to 12 percent of dodecyl polyglycoside, 10 to 15 percent of heterogeneous XI alcohol ethoxylate, 10 to 15 percent of block polyether of ethylene oxide and propylene epoxide, 20 to 25 percent of caster oil diethanolamide-based non-ionic surfactant, 0.1 to 0.2 percent of styrene triazole and the balance of water. The appearance of the metal cleaner is transparent light yellow liquid; and when the metal cleaner is diluted at the concentration of 5 percent with water, the pH value is between 8.2 and 8.8. The metal cleaner is particularly suitable to be used for cleaning a metal workpiece on a coating production line before coating, meets the requirement on environmental protection, and has the characteristics of high cleaning performance, long service life, low foam, high compatibility with anti-rust oil and anti-rust paint, low influence on rubber plastic parts, high cost performance and capacity of replacing similar imported cleaner products.

Owner:常州市永丰油脂厂

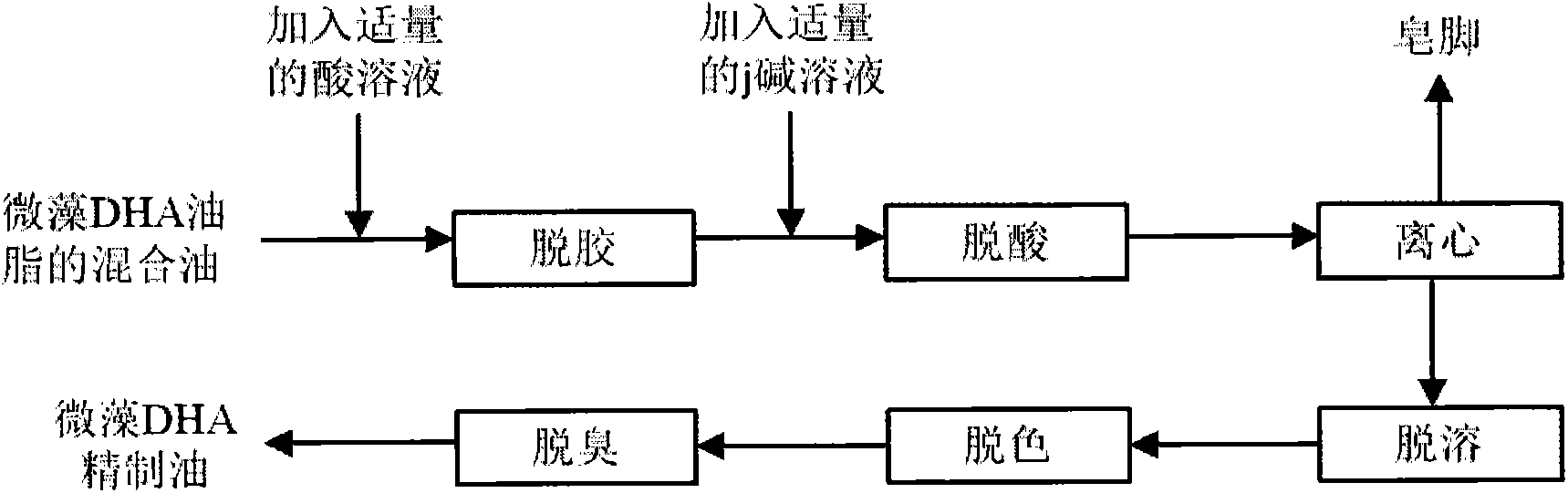

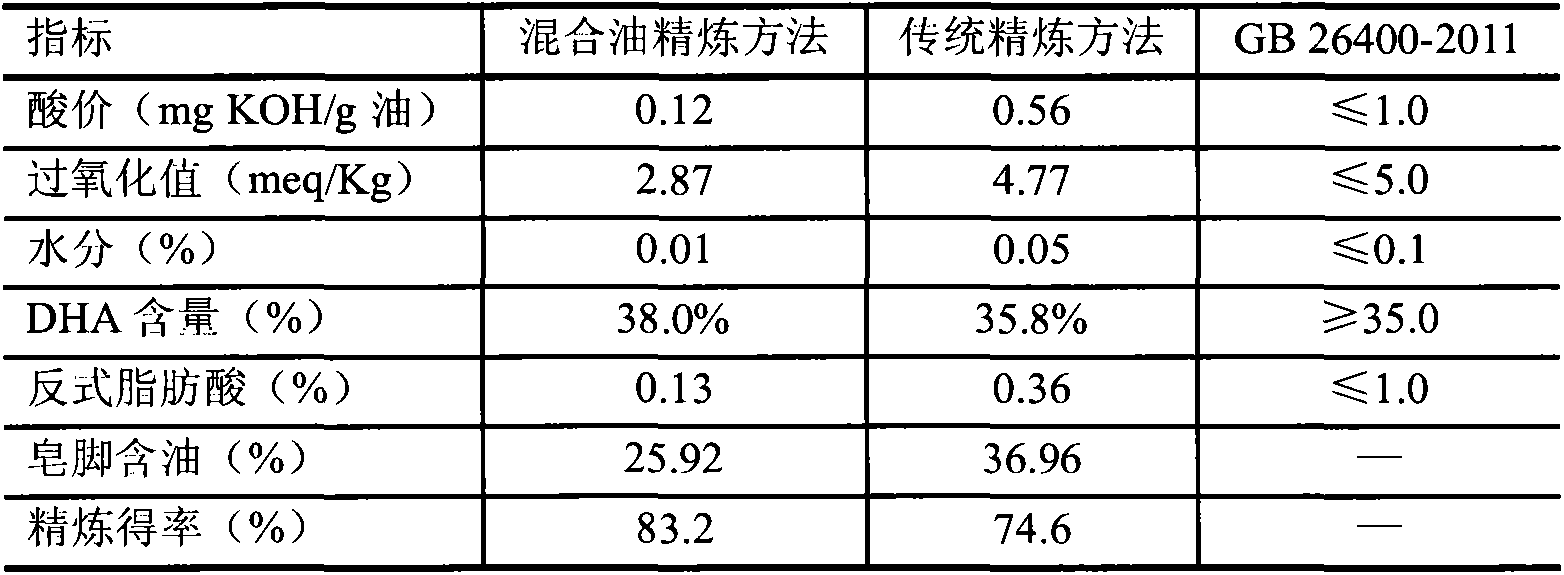

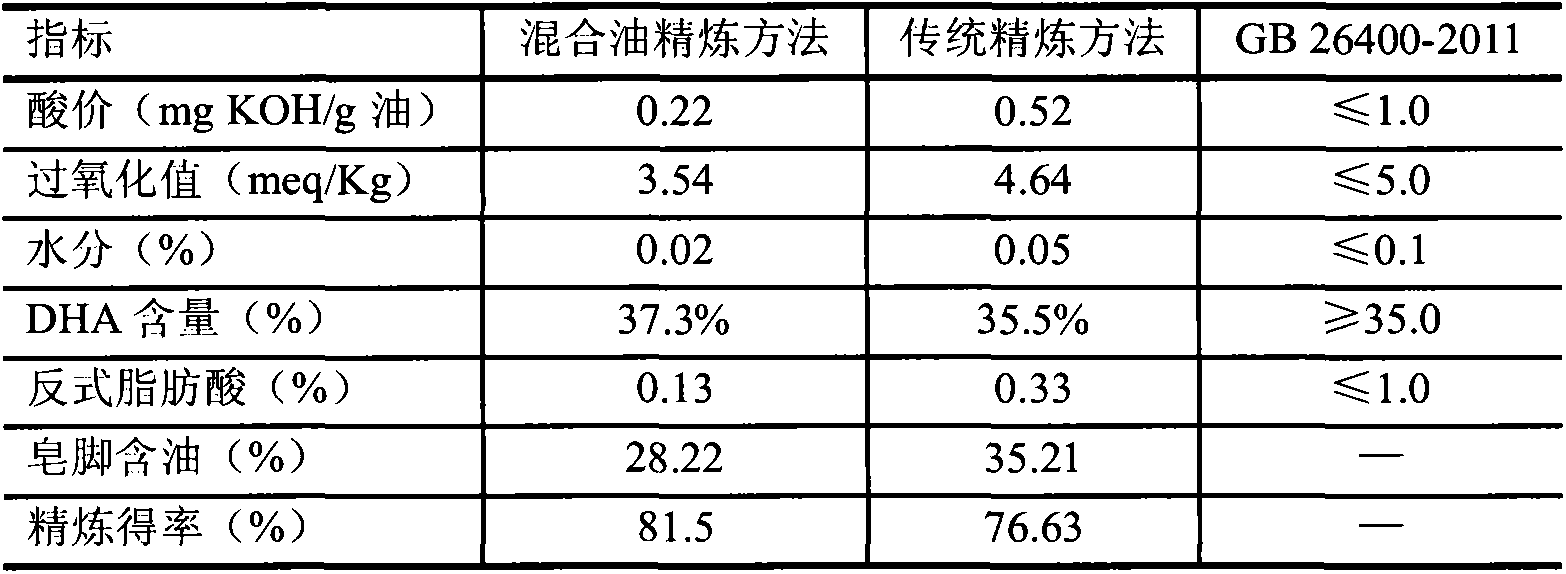

Method for refining mixed oil of microalgae DHA oil

The invention relates to a technology for refining microbial oil, and particularly relates to a method for refining mixed oil of microalgae DHA oil. Leached microalgae DHA crude oil is taken as a raw material; before complete desolvation is carried out, firstly, degumming and deacidification are carried out; then desolvation is carried out; and finally decolorization and deodorization are carried out on oil according to the conventional method, thus obtaining refined microalgae DHA oil. The indexes of the microalgae DHA oil prepared by the method for refining the mixed oil of the microalgae DHA oil completely reach the index requirements of the national standard GB-26400. According to the method disclosed by the invention, the product quality and the refining yield (higher than 80%) of the microalgae DHA oil are improved, meanwhile, the oil content of nigre is reduced, the washing process is omitted, energy consumption is reduced, and industrial application of the mixed oil refining technology in the microbial oil is facilitated.

Owner:青岛海智源生命科技有限公司

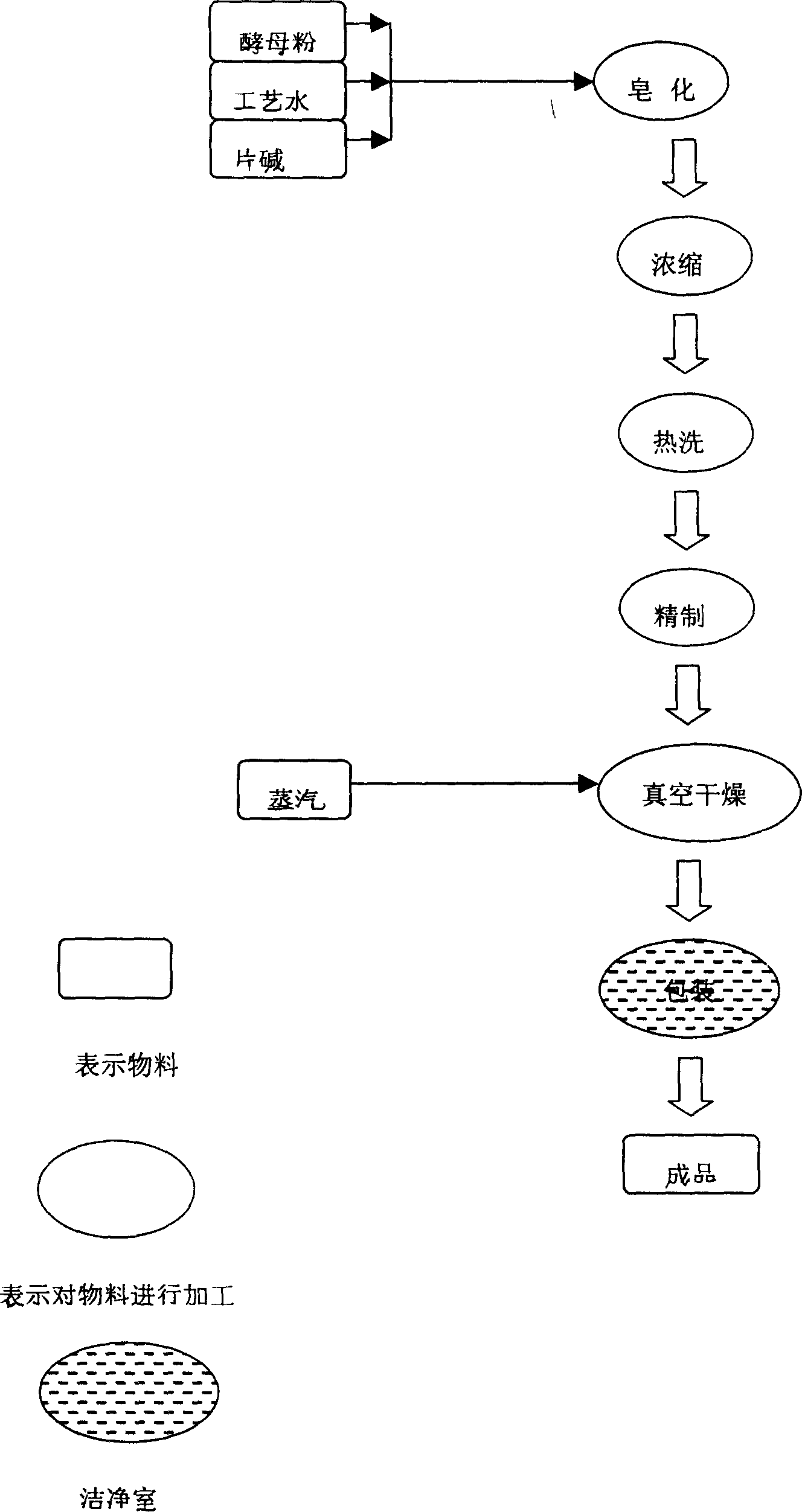

Ergosterol preparation method

The invention relates to a process for preparing ergosterol, which comprises the steps of (1) saponification, (2) charging toluene for extraction, (3) extracting toluene ergosterol solution, (4) a first concentration, (5) a second concentration, (6) hot cleaning, (7) refining.

Owner:MENGYONG MEDICINE IND

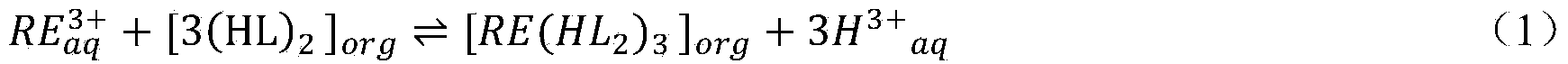

Extraction system, extraction method and reextraction method

The invention discloses an extraction system, an extraction method and a reextraction method. The extraction system disclosed in the invention comprises an organic phase and an aqueous phase, wherein the organic phase comprises a diluent and an extraction agent shown as a formula I; the aqueous phase comprises rare earth ions; the pH value in the aqueous phase is 2.5-4.5; M is hydrogen, alkali metal ions or positive ammonium ions. The extraction method disclosed in the invention comprises the following steps: oscillating and balancing the extraction system. The reextraction method disclosed in the invention comprises the following steps: (1) saponifying the organic phase of the extraction system, mixing with the aqueous phase containing the rare earth ions, and obtaining an organic phase loaded with the rare earth ions; and (2) mixing the organic phase loaded with the rare earth ions with an aqueous solution of acid. According to the extraction system, the rare earth ions can be efficiently separated under low acidity, the extraction system is high in saturation capacity and difficult in emulsification, realizes reextraction of the rare earth ions under low acidity and is suitable for actual production.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

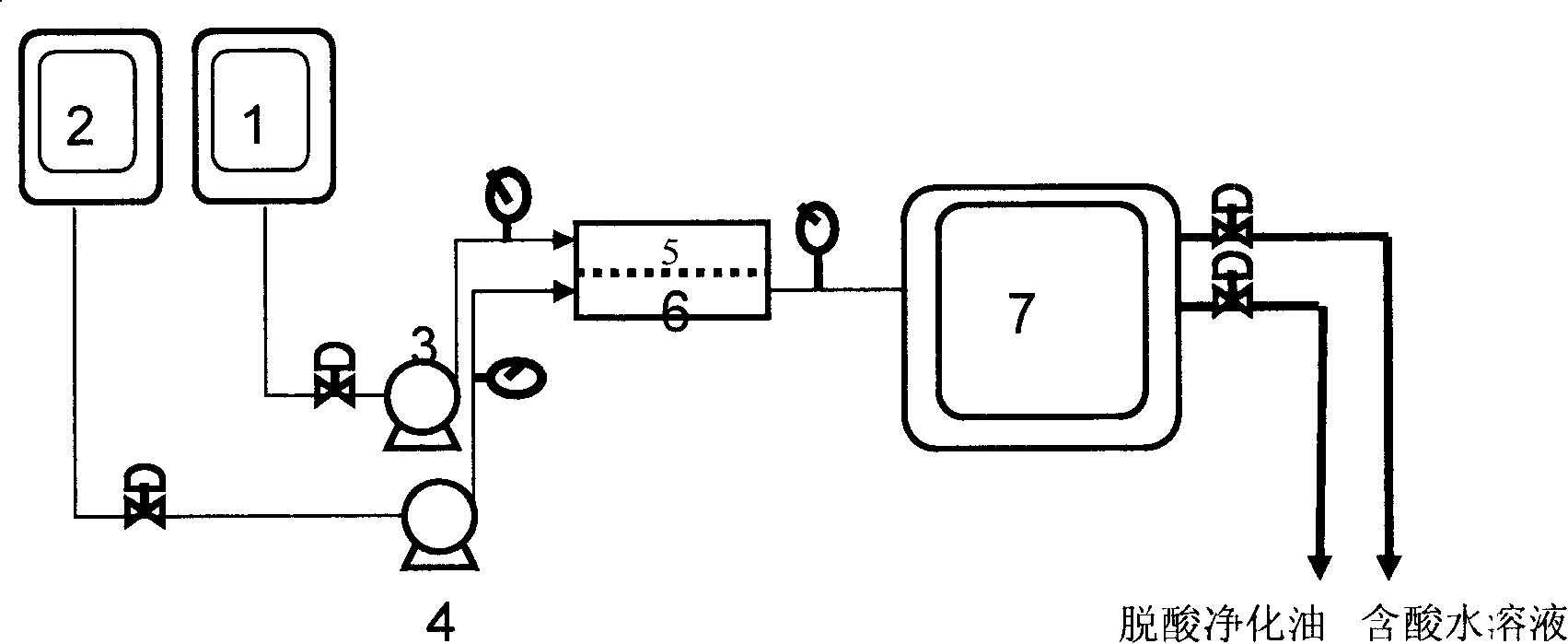

Method for removing petroleum acid in hydrocarbon oil by using membrane dispersion extractor

InactiveCN101200653ASmall amount of lye entrainmentLow lye entrainmentRefining by dialysisSolventChemistry

The present invention relates to a method of removing petroleum acid from hydrocarbon oil by a membrane dispersion extraction device. A continuous phase of the hydrocarbon oil is heated up to 10 DEG C to 150 DEG C; deacidification solvent dispersed phase is heated up to 10 DEG C to 90 DEG C; the cubage ratio of the continuous phase and the dispersed phase is 50 to 2 ®U 1; the pressure difference of the dispersed phase and the continuous phase is 0.05MPa to 0.4MPa; the flow velocity of the dispersed phase deacidification solvent is 0.5 to 5L / <2> per hour; membrane aperture is 0.01 to 60 microns; the dispersed phase deacidification solvent is dispersed into continuous phase oil through membrane micropores; clean oil after the deacidification is obtained after sedimentation and separation. The deacidification solvent is 1 percent to 15 percent of ammonia, 20 percent to 70 percent of alcohol or 0.02 percent to 5 percent of petroleum acid or 0.004 percent to 1 percent of demulsifier and the water with the rest quantity. The contacting time of the oil and the solvent is short; mass transfer efficiency is high; the disposal capability is large; the extraction course is not emulsified easily; the hydrocarbon oil contains little alkali liquid; the device operation is convenient.

Owner:PETROCHINA CO LTD +1

Metal water-based rust removal antirust solution and preparing method thereof

InactiveCN108018567AWide temperature rangeEmulsifyingMetallic material coating processesWater basedMesoporous silica

The invention provides a metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution comprises raw materials including, by weight part, 2 to 6 parts of citric acid, 2 to 8 parts of lauryl sodium sulfate, 2 to 4 parts of tartaric acid, 1 to 5 parts of sodium citrate, 2 to 6 parts of polyaspartic acid, 0.4 to 1.2 parts of oxidized starch, 5 to 10 parts of cetyl-trimethyl ammonium bromide, 10 to 15 parts of polyoxyethylene fatty alcohol sodium sulfate, 1 to 2 parts of OP-10, 1 to 3 parts of chitosan, 2 to 8 parts of mesoporous silica, 10 to 20 parts of PEG200, 15 to 20 parts of propanediol butyl ether and 60 to 90 parts of water. The invention further provides a preparing method of the metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution has multiple functions of rust removal, dirt removal, phosphatization, passivation and the like, a reaction is carried out at the normal temperature, the rust removal time is short, the antirust time is long, and corrosion to the metal is avoided.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Modified titanium dioxide/sulfonated hydrogenated castor oil succinate composite material and preparation method thereof

InactiveCN104480235AStrong UV Absorbing PropertiesImprove lipophilicityLeather impregnationAnhydrous ethanolSodium bisulfate

The invention relates to a preparation method for a modified titanium dioxide / sulfonated hydrogenated castor oil succinate composite material. Application of nanometer TiO2 to leather fatliquors is not reported at present. The preparation method for the composite material comprises: mixing anhydrous ethanol, water and nanometer TiO2 and performing ultrasonic processing, heating, adding a modifier, adjusting the pH for reaction, washing and drying to prepare modified TiO2; and then reacting hydrogenated castor oil with maleic anhydride, adding the modified TiO2 prepared at the early stage, cooling to 65 DEG C, adding a sodium bisulfite solution for reaction, and adjusting the solid content, so as to obtain the composite material. The prepared composite material is not layered and does not have floating oil after being stored at room temperature for 3 months, is easy for water emulsification, strong in stability and friendly to environment, and after fat liquoring is performed, the crust leather is fine in particle surface, obvious in thickness increase, good in flexibility and fullness, and also good in yellowing resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Mixed cotton seed oil refining process

The mixed cotton seed oil refining process treats leached mixed cotton seed oil directly with the evaporating unit in the leaching plant. Leached mixed cotton seed oil is refined based on its special physical and chemical properties through treatment in vacuum condition and pressurized condition successively. The technological process is simple, low in power consumption, convenient in niger and high product quality.

Owner:白长军

Preparation method of environment-friendly non-alcoholic fountain solution

The invention discloses a preparation method of an environment-friendly non-alcoholic fountain solution, relating to the technical field of fountain solutions. The method comprises following steps: firstly, extracting fish oil from fatty Chinese herring; making saponification reactions with alkali to obtain saponification resultants by supplementing with tea saponin, gums and acid electrolytes such that the fountain solution is prepared. The preparation method of the environment-friendly non-alcoholic fountain solution has following beneficial effects: by replacing isopropanol with saponated substance of fish oil, surface tension of water is reduced and viscosity of the fountain solution is improved such that water can dampen a form roller more uniformly; therefore, a thick water film is formed on a water roller such that performance of printing ink, paper and a printing plate; water and ink balance can be better achieved so that the problem that a conventional fountain solution may easily pollute the environment, be harmful to people's health and have poor wettability and stability is solved; and the preparation method has a broad application prospect.

Owner:温州豪正实业有限公司

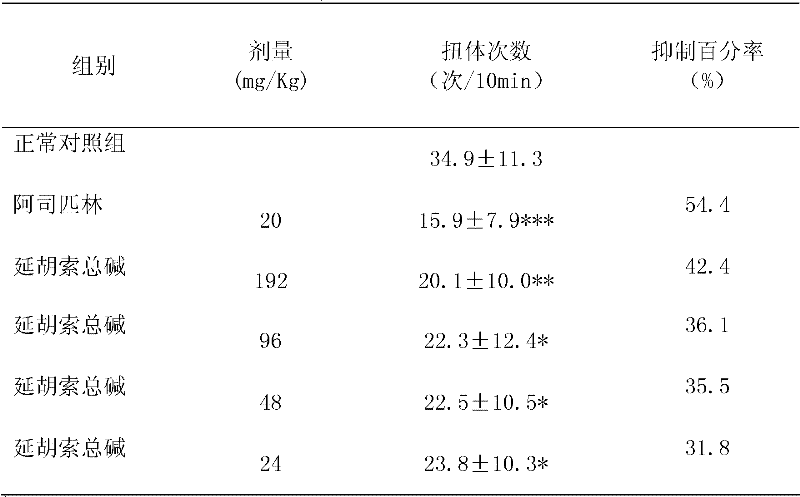

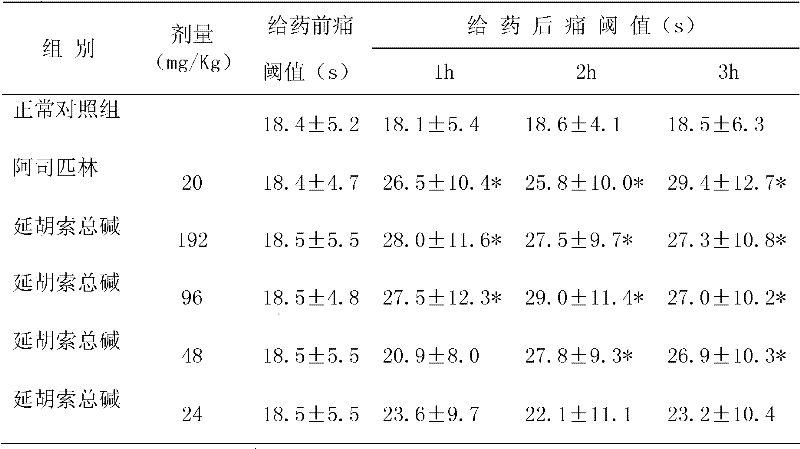

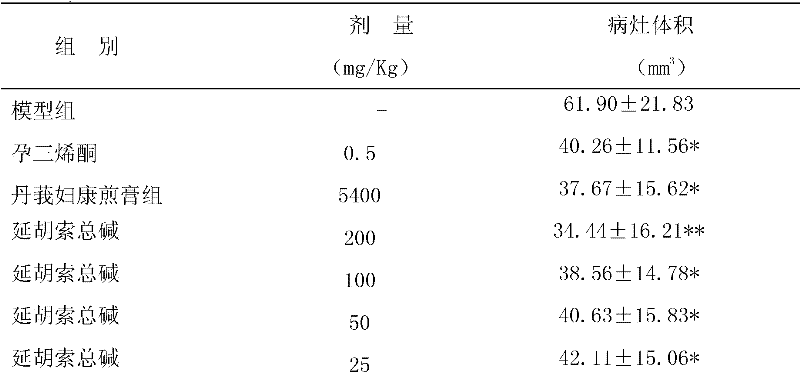

Preparation method of total alkali of corydalis tuber, and corydalis tuber preparation and use thereof

ActiveCN102188497AIncrease relative volatilityLow recovery rateSexual disorderPlant ingredientsSolventEthyl acetate

The invention relates to a preparation method of total alkali of corydalis tuber, and a corydalis tuber preparation and use thereof. The preparation method of the total alkali of corydalis tuber, which is prepared by the invention, comprises: grinding, extracting and post-treatment, wherein the post-treatment comprises extracting ethyl acetate, concentrating, freezing and drying. In the invention, an ethyl acetate extracting method is adopted, so the recovery is easy, the recovery rate is high, the toxicity is low, the environment pollution is avoided, and ethyl acetate is an ideal solvent for industrial production; and the drawbacks of high volatility, low recovery rate, high production cost, and high toxicity to human beings and the environment of the conventional biological alkali extraction solvents which mainly are chloroform are overcome, and the production cost is reduced. The ethyl acetate extraction purity reaches over 80 percent. The invention also provides a corydalis tubertotal alkali preparation and the use of the corydalis tuber total alkali preparation in the preparation of medicines for treating gynecological diseases, in particular the use of the corydalis tuber total alkali preparation in the preparation of medicines for treating dysmenorrheal, abnormal menstruation or endometriosis.

Owner:傅宏征 +2

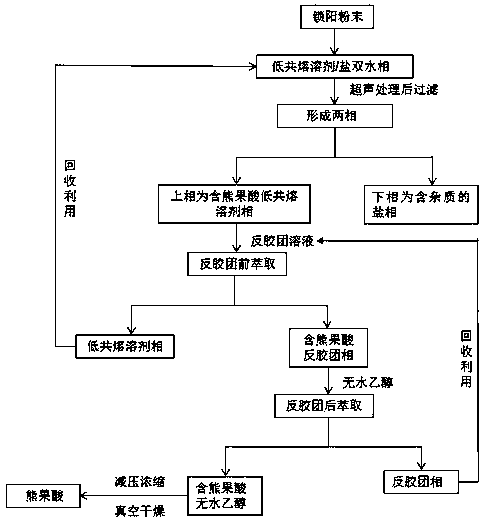

Method for extracting ursolic acid from Cynomorium songaricum by using eutectic solvent/salt aqueous two-phase system

The invention provides a method for extracting ursolic acid from Cynomorium songaricum by using a eutectic solvent / salt aqueous two-phase system. The method comprises the following steps: with the eutectic solvent / salt aqueous two-phase system as an extraction solvent, subjecting the powder of Cynomorium songaricum to ultrasonic extraction at first so as to obtain a eutectic solvent phase containing ursolic acid, then carrying out pre-extraction by using a reversed micelle solution, and carrying out standing for layering, wherein an upper phase is a reversed micelle phase containing ursolic acid; and adding absolute ethyl alcohol into the reversed micelle phase containing ursolic acid for extraction, then carrying out standing and layering, wherein a lower phase is an absolute ethyl alcohol phase containing ursolic acid, and subjecting the absolute ethyl alcohol phase containing ursolic acid to pressure-reduced concentration and vacuum drying so as to obtain ursolic acid powder. According to the invention, the eutectic solvent / salt aqueous two-phase system is employed for extraction of the powder of Cynomorium songaricum, and reversed micelle extraction is employed for separation of ursolic acid in the eutectic solvent, so the method has the characteristics of short phase-splitting time, low viscosity, small possibility of emulsification and the like; the eutectic solvent and the reversed micelle solvent can be cyclically utilized; and the method is low in extraction cost, high in the purity and yield of a ursolic acid product and is a green, highly-efficient and simple separation method.

Owner:NORTHWEST NORMAL UNIVERSITY

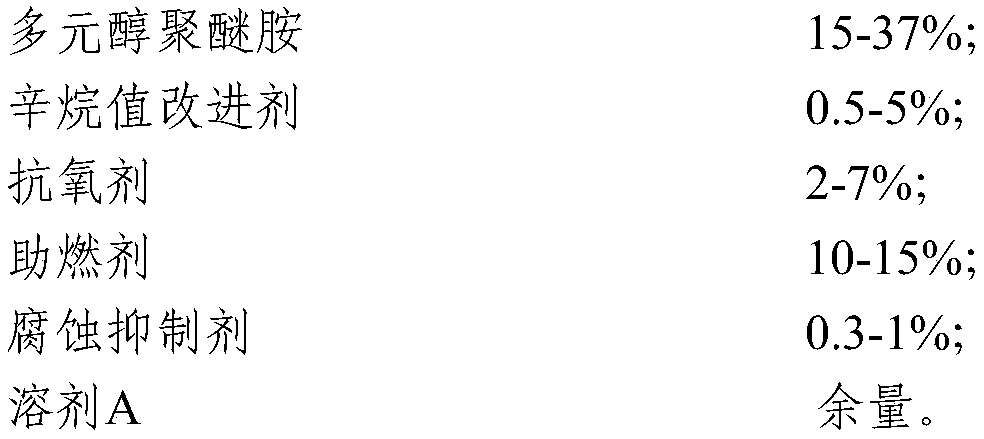

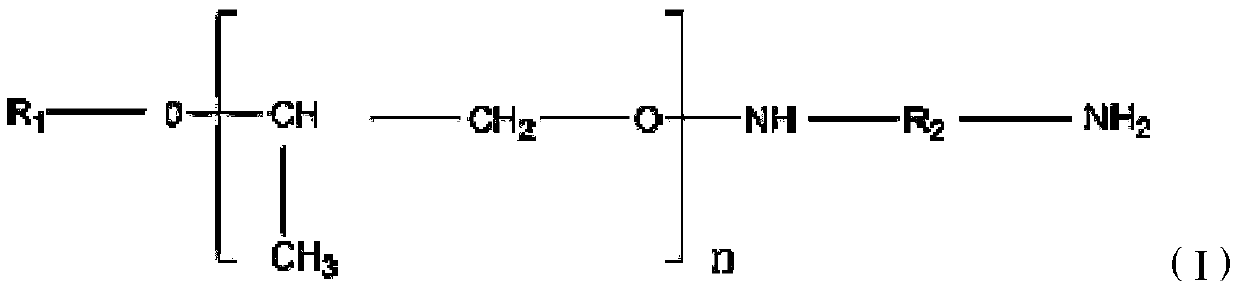

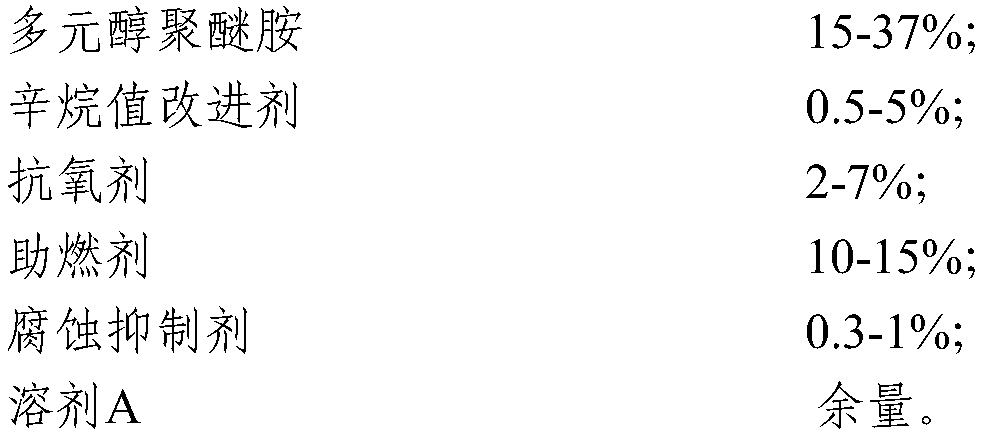

Polyether amine type detergent

ActiveCN110484314AAvoid formingAvoid generatingLiquid carbonaceous fuelsFuel additivesCombustion chamberPetrochemical

The invention belongs to the field of petrochemical engineering, and particularly relates to a polyether amine type detergent. The detergent comprises, by mass, 15-37% of polyol polyether amine, 0.5-5% of an octane number improver, 2-7% of an antioxidant, 10-15% of a combustion improver and 0.3-1% of a corrosion inhibitor, with the balance being a solvent A. According to the polyether amine type detergent, the polyol polyether amine is used as a detergent; Mannich base and polyisobutene amine detergents do not need to be added any more, and the polyether amine type detergent is excellent in detergency, can clean sediments formed by an engine, can prevent production of sediments, cannot emulsify agent-added oil products, can obviously reduce oil consumption, reduces tail gas emission and cannot cause secondary pollution to an engine combustion chamber.

Owner:山东京博众诚清洁能源有限公司

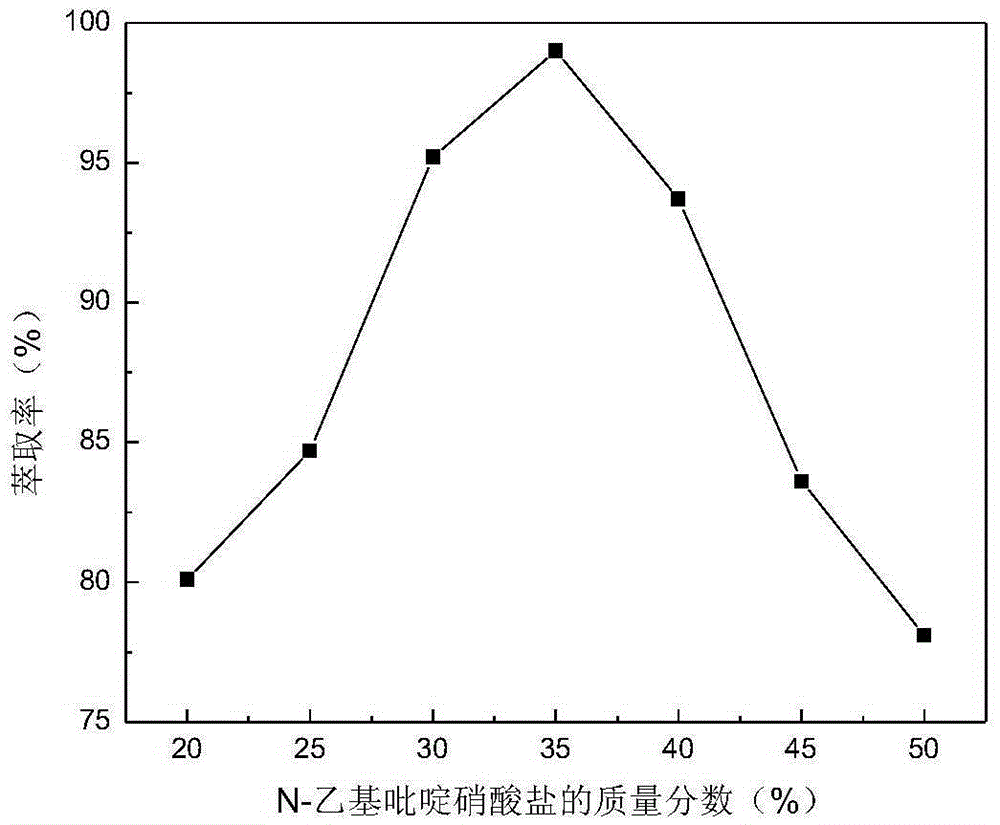

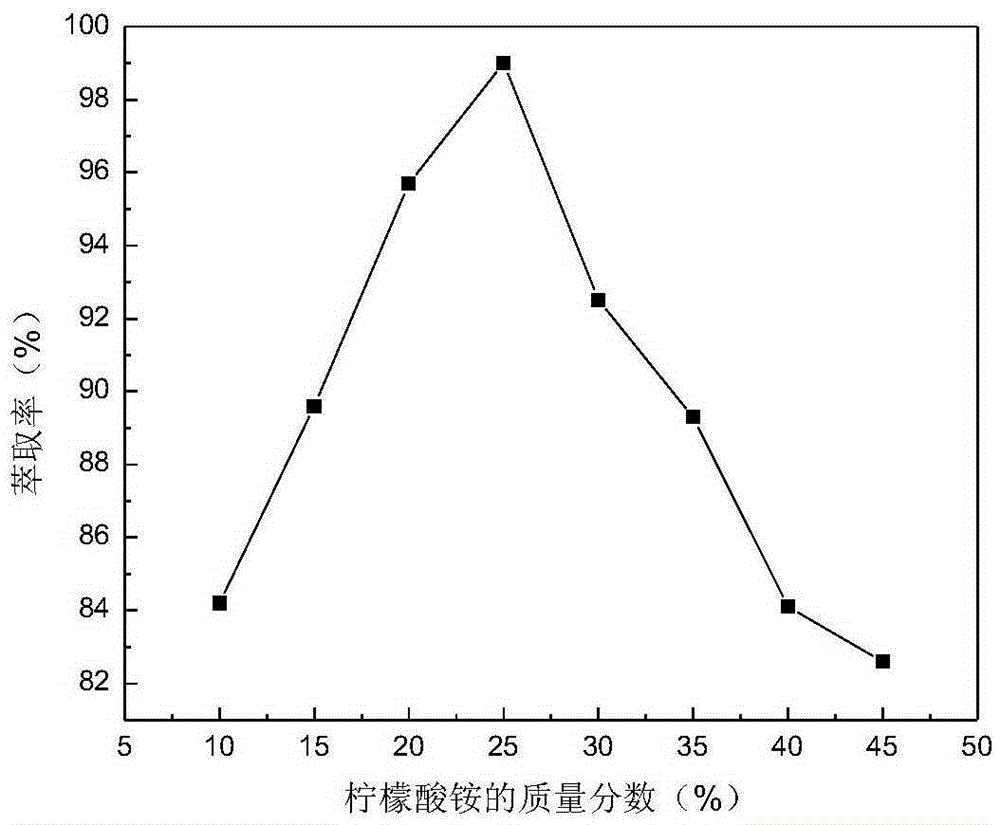

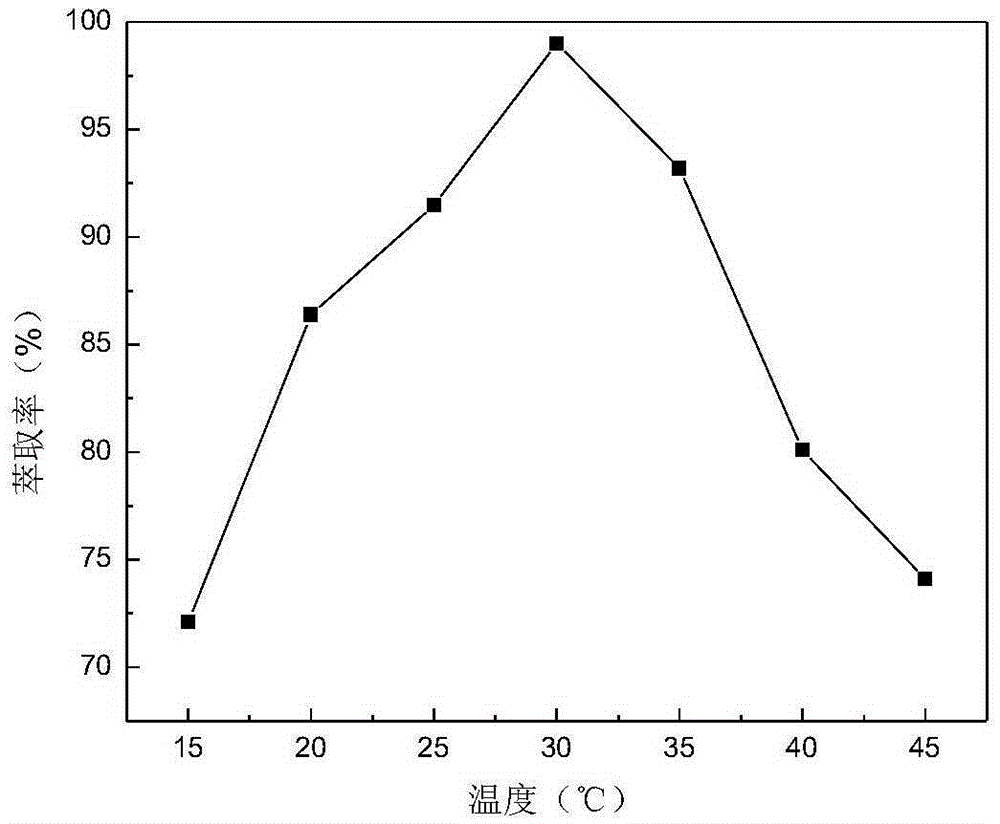

Aqueous two-phase system and application of same to separation of vitamin B6 in sunflower seeds

InactiveCN105424455AShort split timeReduce viscosityPreparing sample for investigationAqueous two-phase systemVitamin B6 synthesis

The invention discloses an aqueous two-phase system and application of same to separation of vitamin B6 in sunflower seeds of same. The aqueous two-phase system is prepared from, by mass, 30-40% of N-ethyl pyridine nitrate ion liquid, 20-30% of ammonium citrate and the balance water, wherein the sum of the mass ratio of the N-ethyl pyridine nitrate ion liquid, the ammonium citrate and the water is 100%. The aqueous two-phase system has the advantages of being wide in linearity range, low in checkout limit, small in relative deviation and high in detection recovery rate of samples; the checkout requirement for residual vitamin B6 of the nation can be met, meanwhile, operation is simple, and the aqueous two-phase system is applicable to quantitative analysis of vitamin B6 in sunflower seeds.

Owner:CHANGAN UNIV

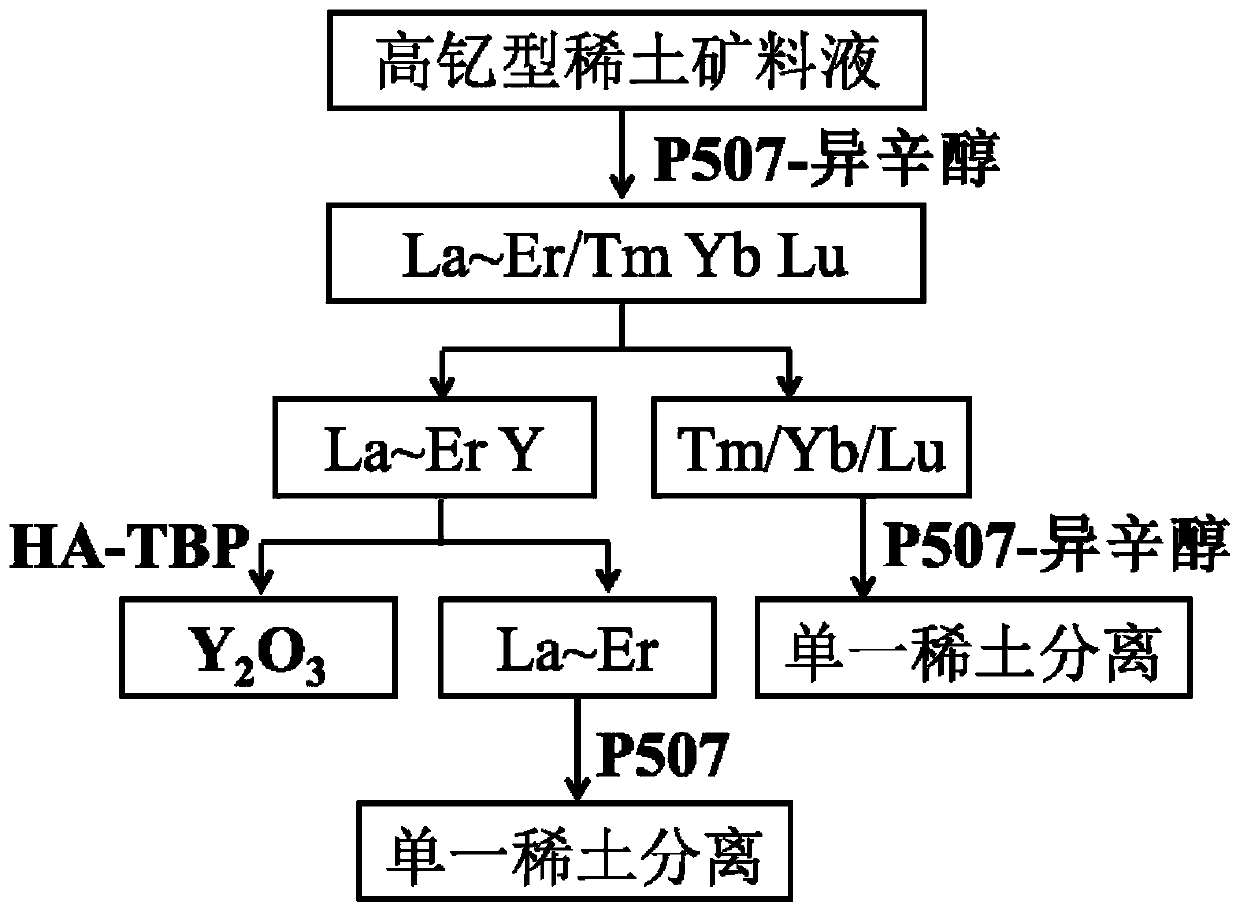

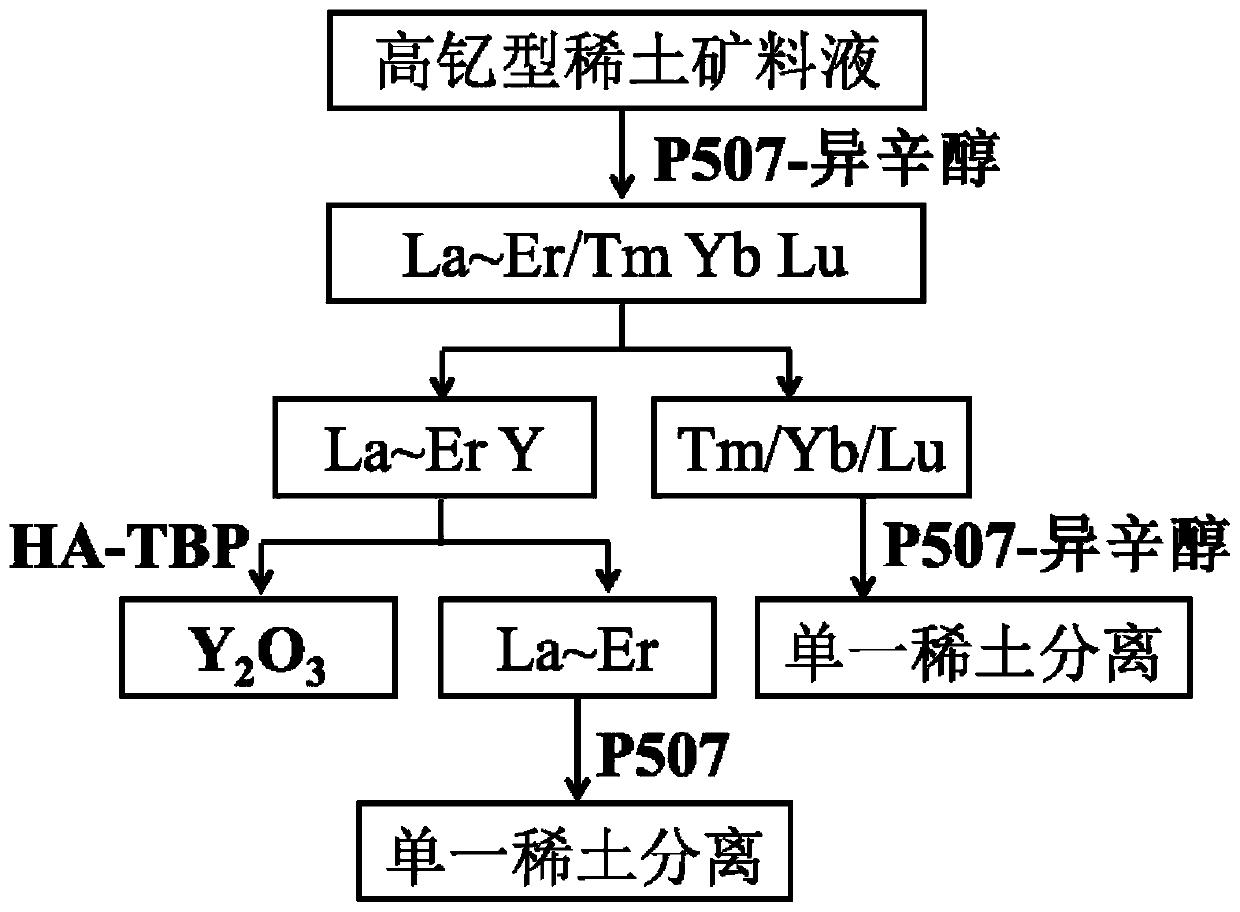

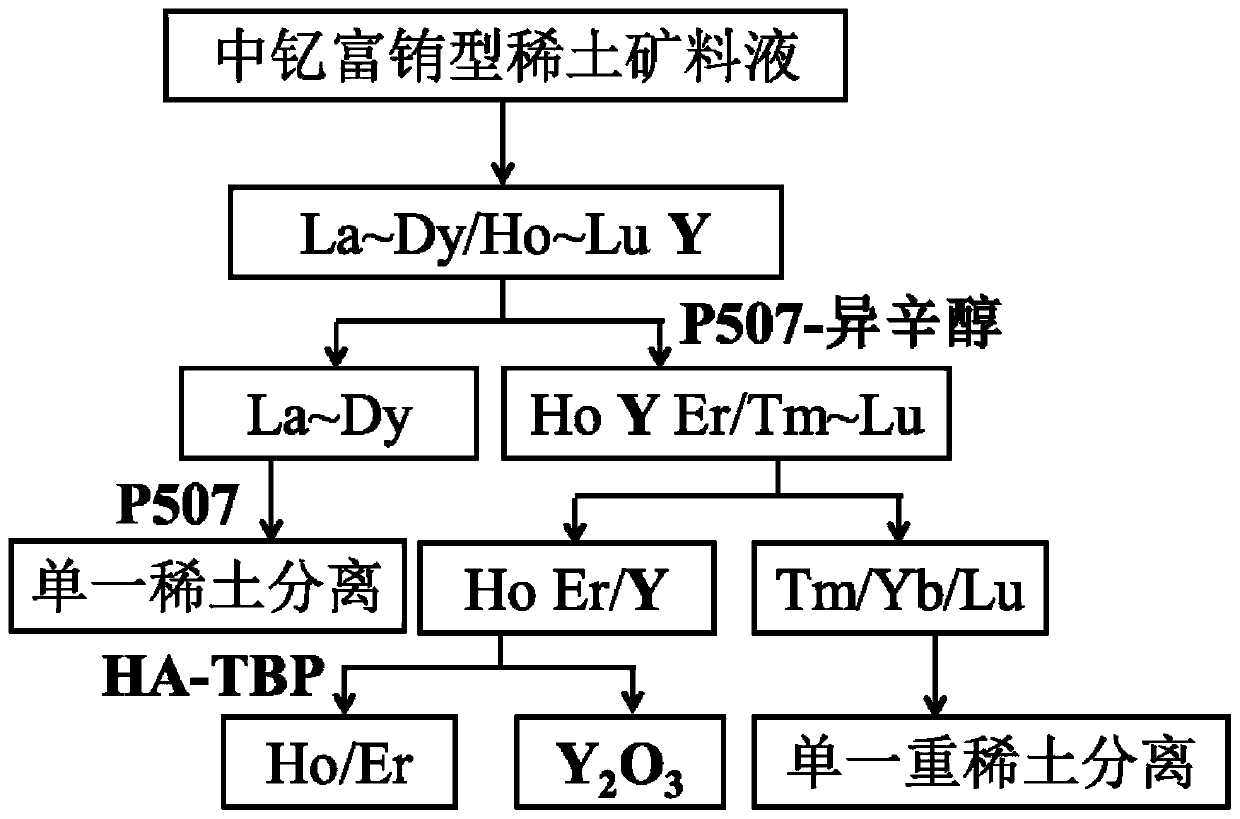

Method for grouping high-yttrium rare earth ore and separating yttrium oxide

ActiveCN110002487AAvoid problems with low separation factorsAvoid problems such as difficult to quickly analyzeRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentRare-earth elementIsooctyl alcohol

The invention relates to a method for grouping high-yttrium rare earth ore and separating yttrium oxide, and belongs to the technical field of rare earth extraction separation. The problem of restriction of industrial application by naphthenic acid replacement needed in the long-term process flow of separation of yttrium oxide from an existing naphthenic acid system and HAB mixed system and the problem of difficulty in rapid onsite analysis of the change of the concentrations of two extractants in the HAB system is solved. The system comprises the following steps: grouping erbium and thulium by a P507-isooctyl alcohol mixed system to obtain a high-yttrium concentrate and a thulium-ytterbium-lutetium concentrate, separating the high-yttrium concentrate and the thulium-ytterbium-lutetium concentrate to prepare lutetium oxide and other heavy rare earths, separating the high-yttrium concentrate by a carboxylic acid extractant HA-TBP mixed system to prepare yttrium oxide, and grouping the La to Er concentrate by adopting a P507 system to separate other single rare earth elements. The grouping and separating method has the advantages of advanced and reasonable process, short process flow, low production cost, strong adaptability, and easiness in operation control, has better comprehensive, technological and economic indicators than the naphthenic acid technology, and has practical application values.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

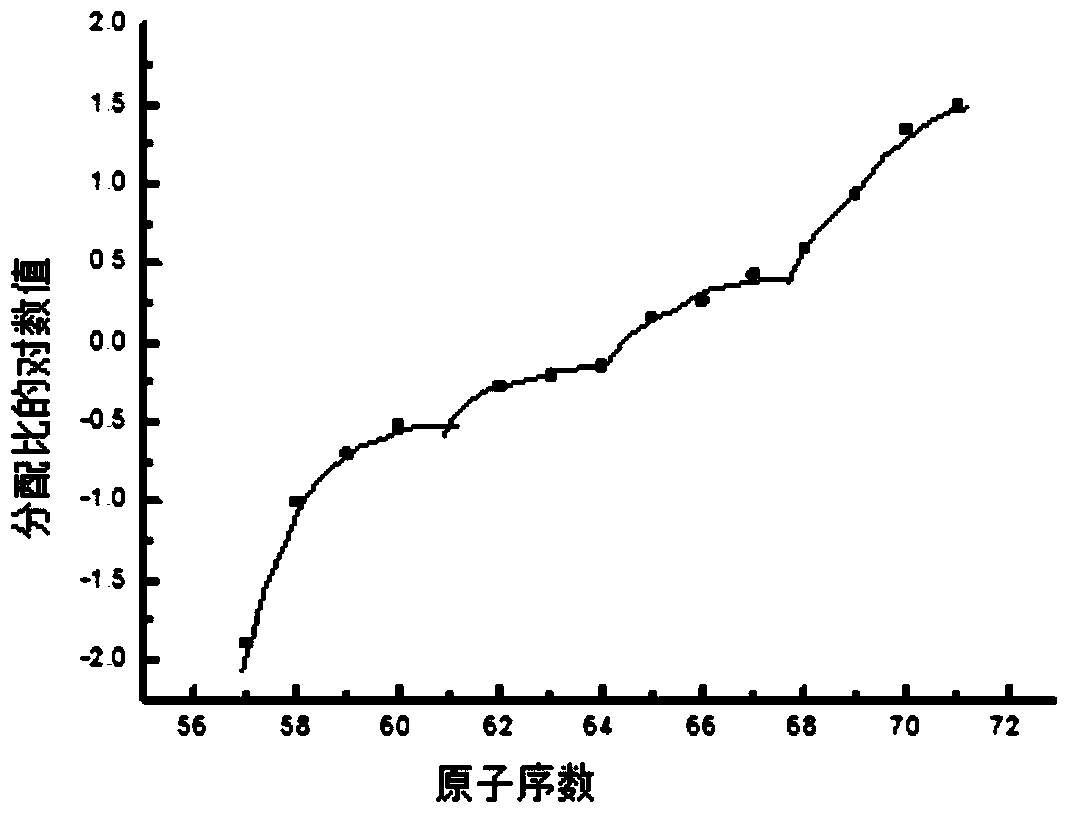

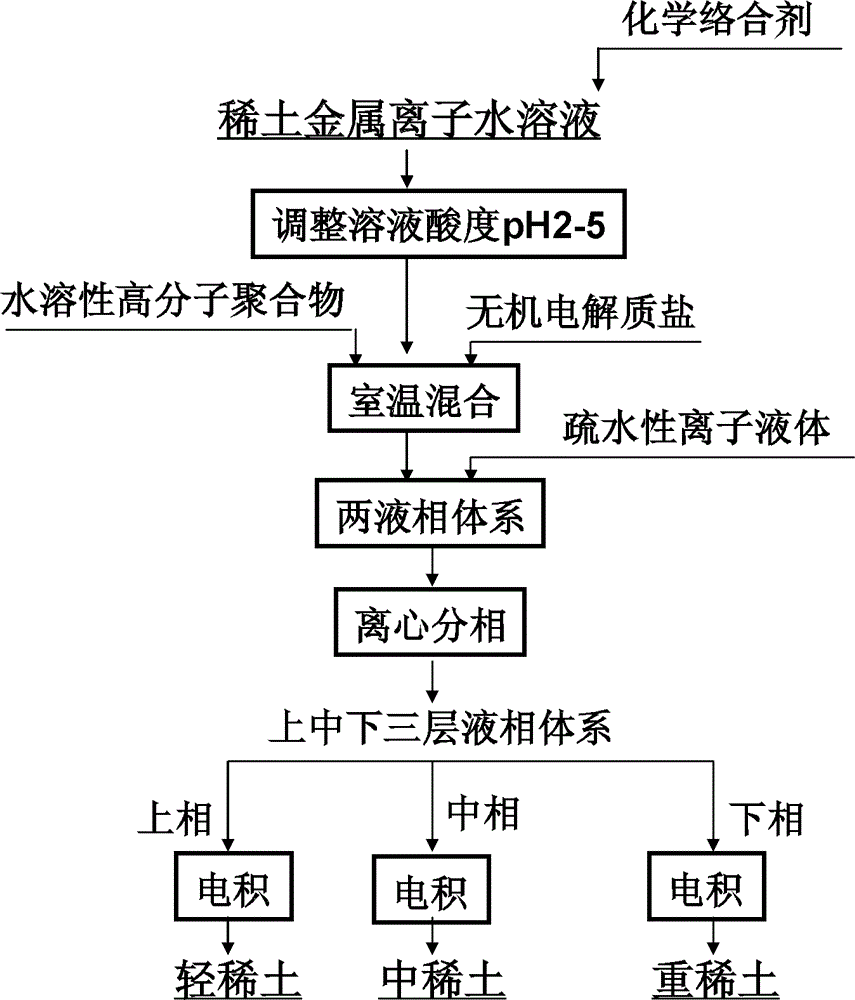

Method for separating rare earth ions by extraction of liquid-liquid-liquid three-phase system

InactiveCN102382982BSpeed up clarification and phase separationReduce usageProcess efficiency improvementInorganic electrolyteIonic liquid

The invention relates to a method for separating rare earth ions by extraction of a liquid-liquid-liquid three-phase system, and belongs to the technical field of rare earth extraction and separation. The method comprises the following steps of: adding a chemical complexing agent into an aqueous solution containing the rare earth ions, regulating the acidity of the solution, adding a water-soluble high polymer and an inorganic electrolyte salt, oscillating and mixing at room temperature, and obtaining a liquid phase system of upper and lower layers; adding a hydrophobic ionic liquid, fully mixing the solution at room temperature, and obtaining an insoluble three-liquid phase coexistence system of upper, middle and lower layers; and respectively taking the upper, middle and lower phases of the three-liquid phase system, and reclaiming the rare earth ions by using an electro-deposition method. According to the method, a volatile organic solvent is not used, so that the phase forming behavior and the phase separation process of the three-phase system are easily artificially controlled; and light, medium and heavy rare earth ions are selectively enriched or grouped and separated in three different liquid phases respectively. Compared with conventional oil-water two-phase separation, the method has the advantages that: the process flow is greatly simplified, the method is quick in phase separation and avoids emulsifying, and the hydrophilic and hydrophobic properties of the ionic liquid three-phase system are easily controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

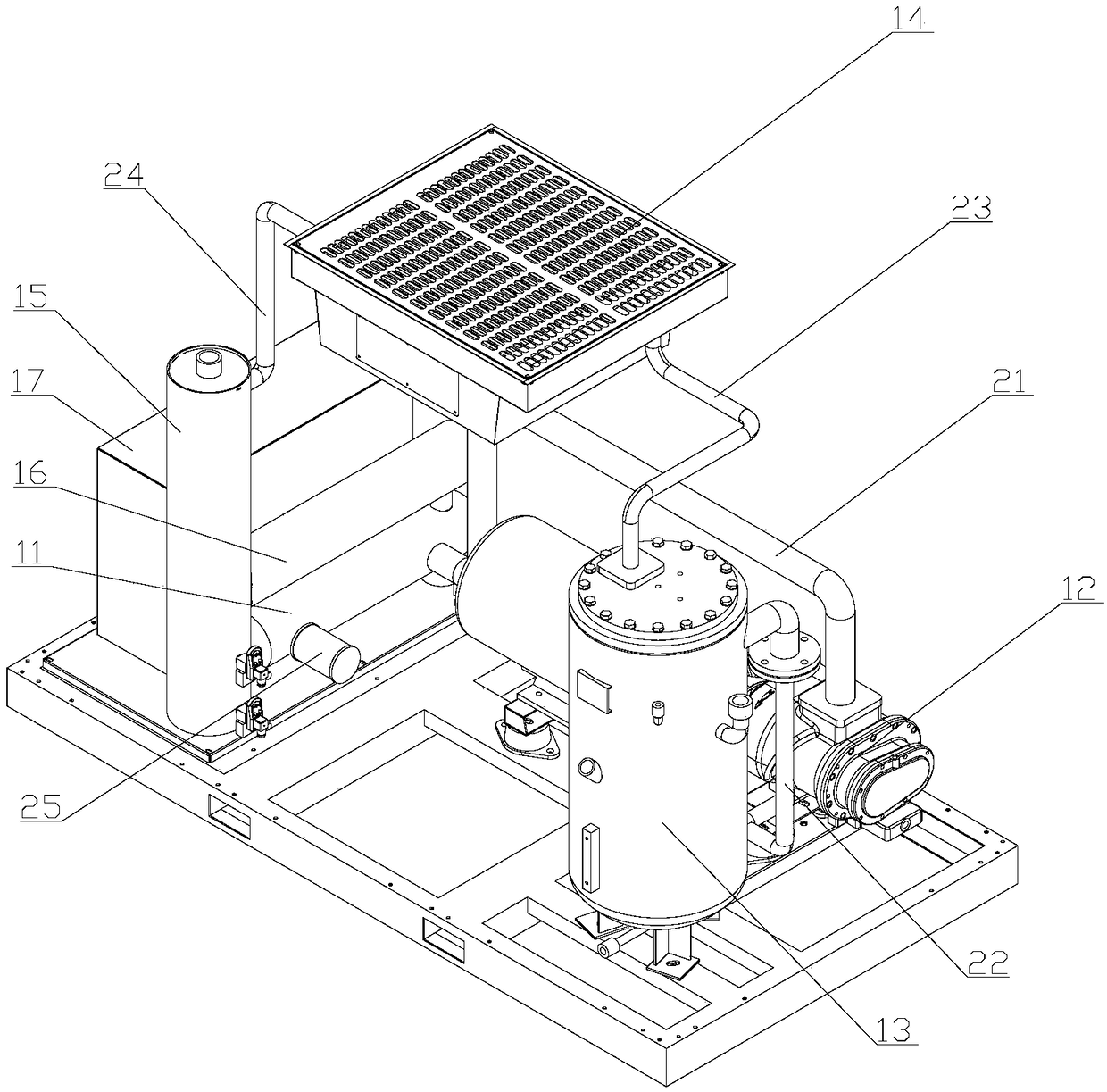

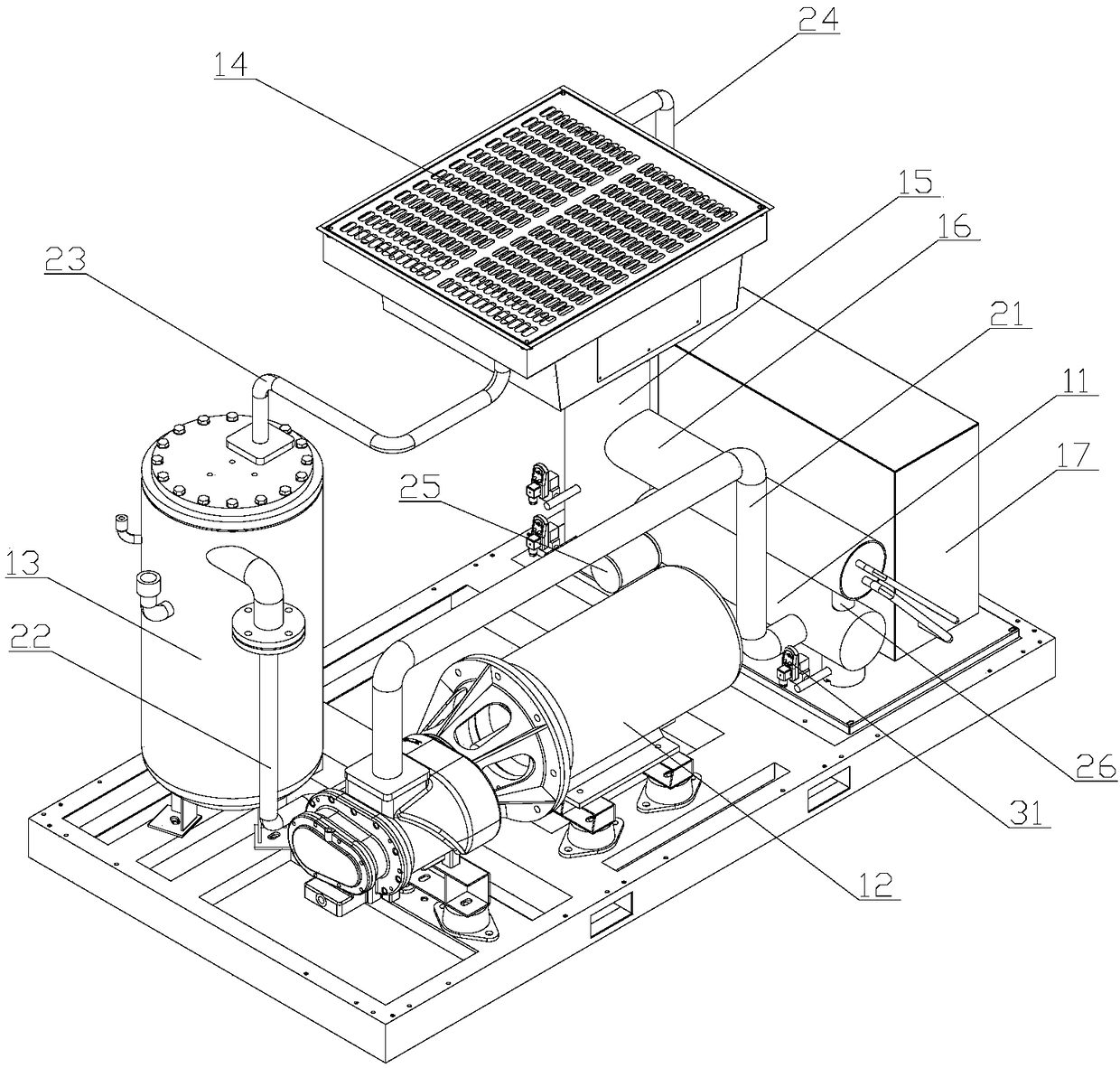

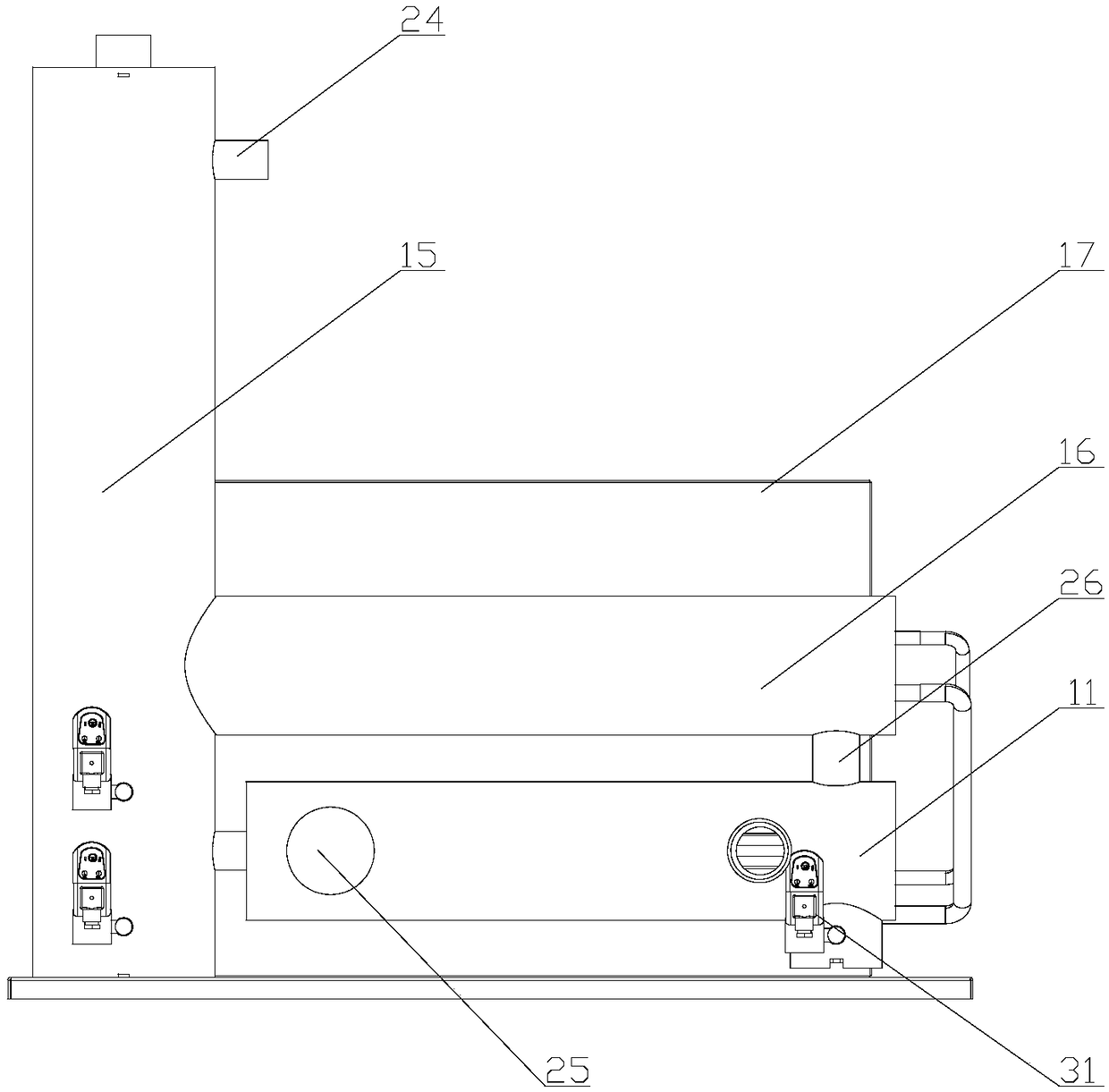

Low-carbon air compressing integrated machine

InactiveCN108488062AImprove compression efficiencyImprove efficiencyPositive displacement pump componentsPump controlExhaust gasWater content

The invention relates to a low-carbon air compressing integrated machine. The machine comprises an air inlet pre-cooler, an air suction pipe, an air compressor, a first exhaust pipe, an oil-gas separator, a second exhaust pipe, a cooler, a third exhaust pipe, an exhaust regenerator, an evaporator, a refrigerating unit and a controller, wherein the inner path of the air inlet pre-cooler is communicated with the inner path of the exhaust regenerator; and the controller is electrically connected with the air compressor, the oil-gas separator, the cooler and the refrigerating unit. The machine disclosed by the invention has the advantages that the compression efficiency of the air compressing main machine is greatly improved; the water content of exhaust gas of the air compressor is reduced; the requirements of the water content of the compressed air in most occasions can be met; the problem of complex pipeline configuration of rear-end post-treatment equipment of the air compressor is solved; and the cost is controllable.

Owner:广州嘉美制造有限公司

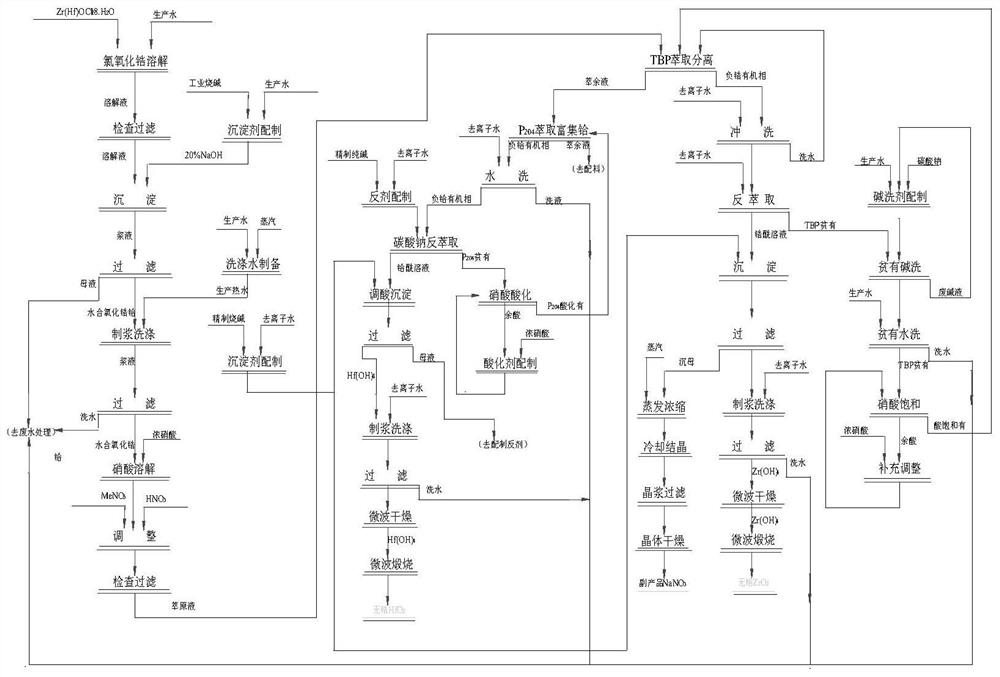

Production method of nuclear-grade zirconium dioxide

PendingCN112723413AEasy to separateSimple processAlkali metal nitratesZirconium compounds preparationExhaust fumesWastewater

The invention belongs to the technical field of nuclear material production and manufacturing, and particularly relates to a production method of nuclear-grade zirconium dioxide, which comprises the following steps: step 1, preparing an extraction stock solution, step 2, conducting fractionating and extracting for separating zirconium and hafnium, step 3, producing zirconium dioxide, and step 4, treating and recycling process waste liquid. According to the method, qualified nuclear-grade zirconium and hafnium products are obtained through one-time extraction separation; and no toxic reagent is adopted in the production process, and waste water and waste gas generated in the production process are treated and then returned for use or harmlessly discharged.

Owner:中核二七二铀业有限责任公司

Method for separating total alkaloids from Melaleuca extract

ActiveCN112402466BTo rationalizeIncrease contentOrganic chemistryPteridophyta/filicophyta medical ingredientsAcid waterActive agent

The present invention relates to a method for separating total alkaloids from Melaleuca extract, comprising the following steps: (1) dissolving; (2) stripping; (3) decolorizing, filtering, and concentrating; (4) extracting; (5) ) silica gel chromatography. In the stripping of step (2), the extract obtained in step (1) is stripped with acidic water containing a surfactant. The present invention optimizes and screens the conditions and operations of each step, and finally uses a comparative The method is simple, and the alkaloids from the Melaleuca tower are prepared with a high yield, and the high-purity 6β-hydroxyhuperzine A, huperzine A and huperzine B are further separated. The method of the invention has small raw material processing capacity, less solvent consumption, less emulsification in the extraction process, short production cycle, coherent and simple process, strong operability, low production cost, safety and environmental protection, and is suitable for industrial production.

Owner:HUNAN HUACHENG BIOTECH

Method for separating yttrium oxide from middle-yttrium europium-rich rare earth ore by grouping

ActiveCN109881005AAvoid problems with low separation factorsLow costRare earth metal compoundsProcess efficiency improvementLutetiumHolmium

The invention relates to a method for separating yttrium oxide from middle-yttrium europium-rich rare earth ore by grouping, and belongs to the field of rare earth extraction separation. The problem that the industrial application is limited due to the fact that the problems that naphthenic acid needs to be replaced in the long using process of the technological process of separating the yttrium oxide by an existing naphthenic acid system and an HAB mixed system and the difficulty of rapid analysis of the concentration changes of two extraction agents of the HAB system on the site is solved. The method comprises the steps that firstly, dysprosium and holmium grouping is carried out by adopting a P507 mixed system to obtain a yttrium-rich material 1 and light-medium rare earth enrichment, and single rare earth is separated from the light-medium rare earth enrichment by the P507 system; then the yttrium-rich material 1 is subjected to erbium and thulium grouping by adopting P507-isooctylalcohol and other mixed systems, a yttrium-rich material 2 and thulium-ytterbium-lutetium enrichment are obtained, and single heavy rare earth is separated from the thulium-ytterbium-lutetium enrichment; and finally, the yttrium oxide is separated and prepared by the yttrium-rich material 2 by adopting an HA-TBP mixed system. The grouping separating method has the advantages of advancement and reasonability, short technological process, low production cost, high adaptability, easy operation and control, and comprehensive technical and economic index performance is better than a naphthenic acid process, and practical application value is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com