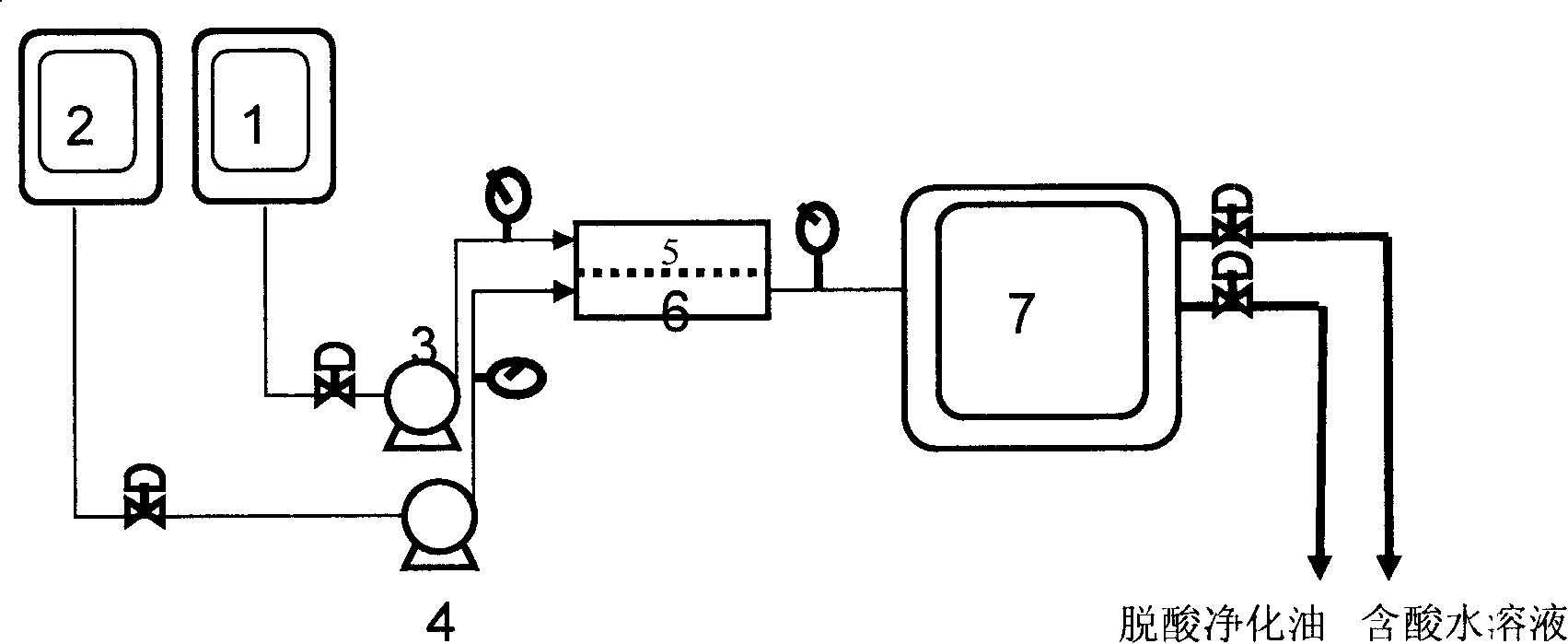

Method for removing petroleum acid in hydrocarbon oil by using membrane dispersion extractor

An extractor and membrane dispersion technology, which is applied in the field of petroleum acid removal from hydrocarbon oil, can solve the problems of complicated process, easy emulsification of oil and water, high energy consumption of solvent recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Composition of deacidification solvent (by weight percentage)

[0020] The composition of table 1 deacidification solvent

[0021] name

Ammonia concentration%

Auxiliary concentration%

water%

Deacidification solvent 1

1

20 (alcohol)

79

Deacidification solvent 2

3

30 (alcohol)

67

Deacidification solvent 3

5

40 (alcohol)

55

Deacidification solvent 4

8

45 (alcohol)

47

Deacidification solvent 5

10

50 (alcohol)

40

Deacidification solvent 6

12

55 (alcohol)

33

Deacidification solvent 7

15

60 (alcohol)

25

Deacidification solvent 8

13

70 (alcohol)

17

Deacidification solvent 9

11

65 (alcohol)

24

Deacidification solvent 10

2

0.02 (sodium petroleum acid)

97.98

Deacidification solvent 11

4

0.2 (sodium petroleum acid)

...

Embodiment 2

[0026] Deacidification solvent 4: 8% ammonia + 45% alcohol + 47% water;

[0027] Ordinary third-line distillate oil: the acid value is 4.6mgKOH / g;

[0028] The constant third-line distillate continuous phase with an acid value of 4.6mgKOH / g and a temperature of 50°C and the above-mentioned deacidification solvent 4 dispersed phase with a temperature of 10°C are passed through the volume ratio of the continuous phase to the dispersed phase at a volume ratio of 50:1. The respective metering pumps are sent into the flat ceramic membrane with a membrane pore size of 0.05 μm, and the flow rate of the dispersed phase is 0.5L / cm 3 h, the pressure difference between the dispersed phase and the continuous phase is 0.06MPa, the mixture of the continuous phase and the dispersed phase stays in the membrane device for 0.5 seconds and then enters the phase separation and clarification tank, and after 1min settling time at room temperature, petroleum acid is removed The purified oil and the...

Embodiment 3

[0030] Deacidification solvent 3: 5% ammonia + 40% alcohol + 55% water;

[0031] Diesel: the acidity is 37mgKOH / 100ml;

[0032] The continuous phase of diesel oil with an acidity of 37mgKOH / 100ml and a temperature of 20°C and the above-mentioned deacidification solvent 3 dispersed phase at a temperature of 15°C are respectively pumped through respective metering pumps according to the volume ratio of the continuous phase to the dispersed phase at a volume ratio of 47:1. The flow rate of the dispersed phase is 0.5L / cm in the flat stainless steel sintered membrane with a pore size of 0.05 μm 2 h, the pressure difference between the dispersed phase and the continuous phase is 0.08MPa, the mixture of the continuous phase and the dispersed phase stays in the membrane device for 0.4 seconds and then enters the phase separation and clarification tank. After 45 seconds of settling time at room temperature, the oil is removed The purified oil of acid and the aqueous solution containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com