Metal cleaner used for coating production line and preparation method thereof

A technology of metal cleaning agent and coating production line, applied in the field of metal cleaning agent and its preparation, can solve the problems of high price, lower cost performance, etc., and achieve the effects of reducing environmental protection pressure, improving solubility, and good foam suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

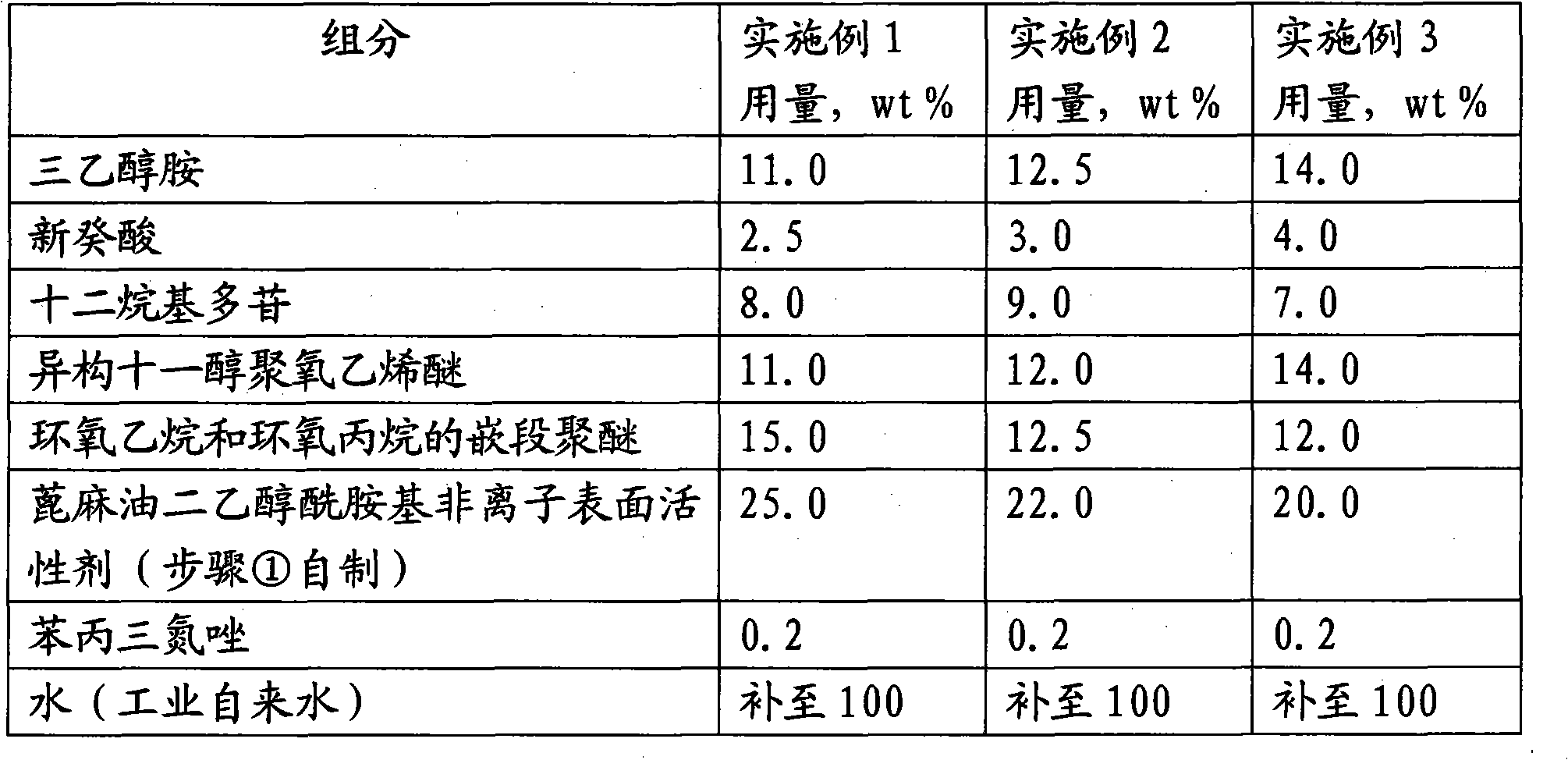

[0027] Embodiment 1~3 preparation is used for the metal cleaning agent 1#~3# of coating production line

[0028] The present invention is used for the metal cleaning agent of coating production line, and the consumption of each component is as follows in weight percentage: triethanolamine 10~14, neodecanoic acid 2~4, dodecyl polyglycoside 6~12, isomerized undecanoic acid Alcohol polyoxyethylene ether 10-15, block polyether of ethylene oxide and propylene oxide 10-15, castor oil diethanolamide-based nonionic surfactant 20-25, phenylacryltriazole 0.1-0.2, The balance is water.

[0029] Concrete preparation steps are:

[0030] ① Preparation of castor oil diethanolamide-based nonionic surfactant

[0031] In 85 grams of castor oil, add 22 grams of maleic anhydride and 1.2 grams of catalyst phosphoric acid, heat together to 175 ° C and keep at this temperature for 5 hours, stop heating, depressurize to a vacuum of 0.1 atmospheres, and evacuate 30 minutes, then add 250 grams of di...

Embodiment 4

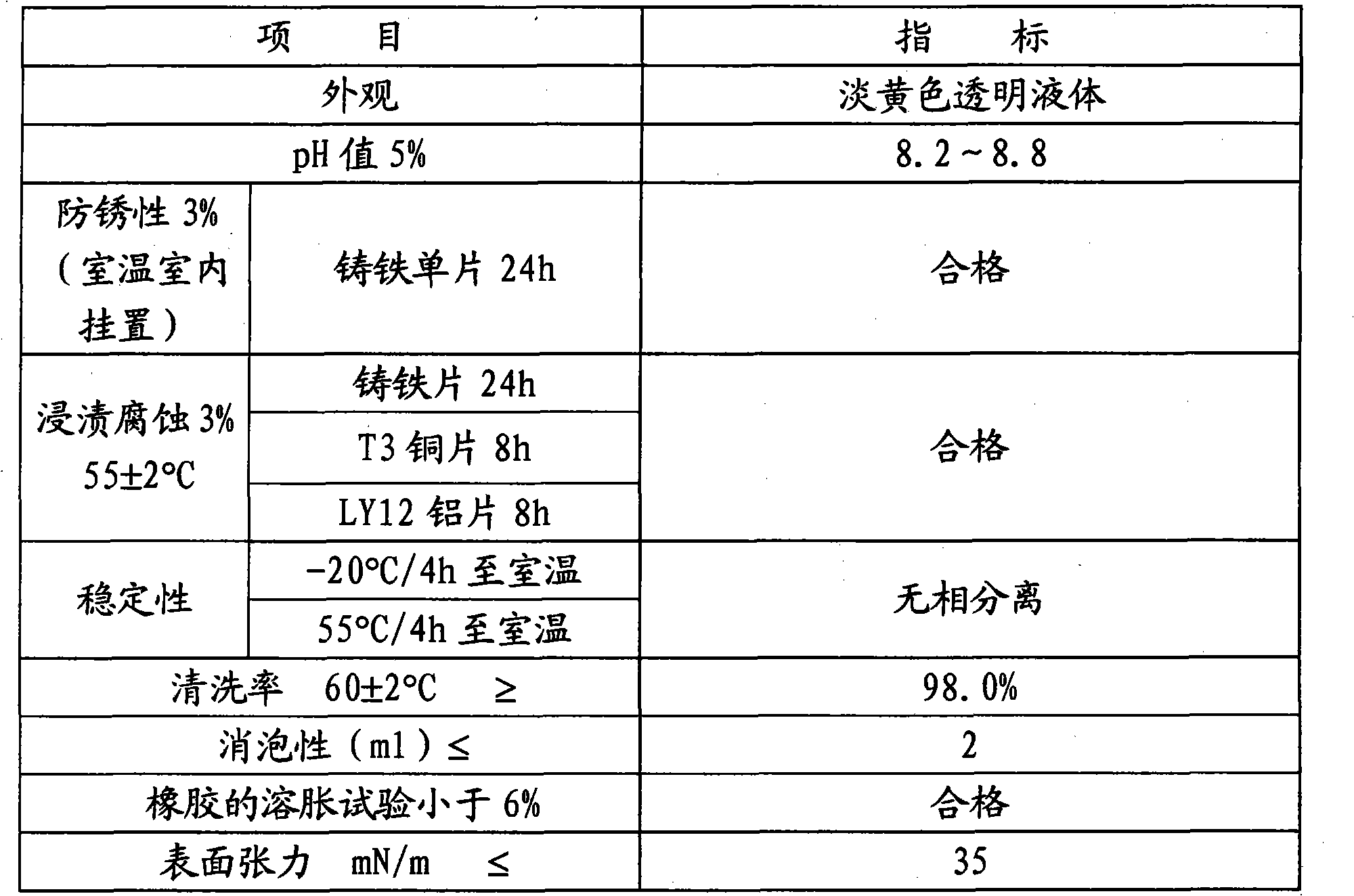

[0041] Embodiment 4 metal cleaning agent performance detection

[0042] ① Compatibility test of metal cleaning agent and anti-rust oil or anti-rust paint

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com