Low-carbon air compressing integrated machine

An air compressor and air compression technology, applied in the field of air compressors, can solve the problems of not doing any corresponding effective treatment, long process flow, complicated device, etc., to improve working conditions, reduce energy consumption, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

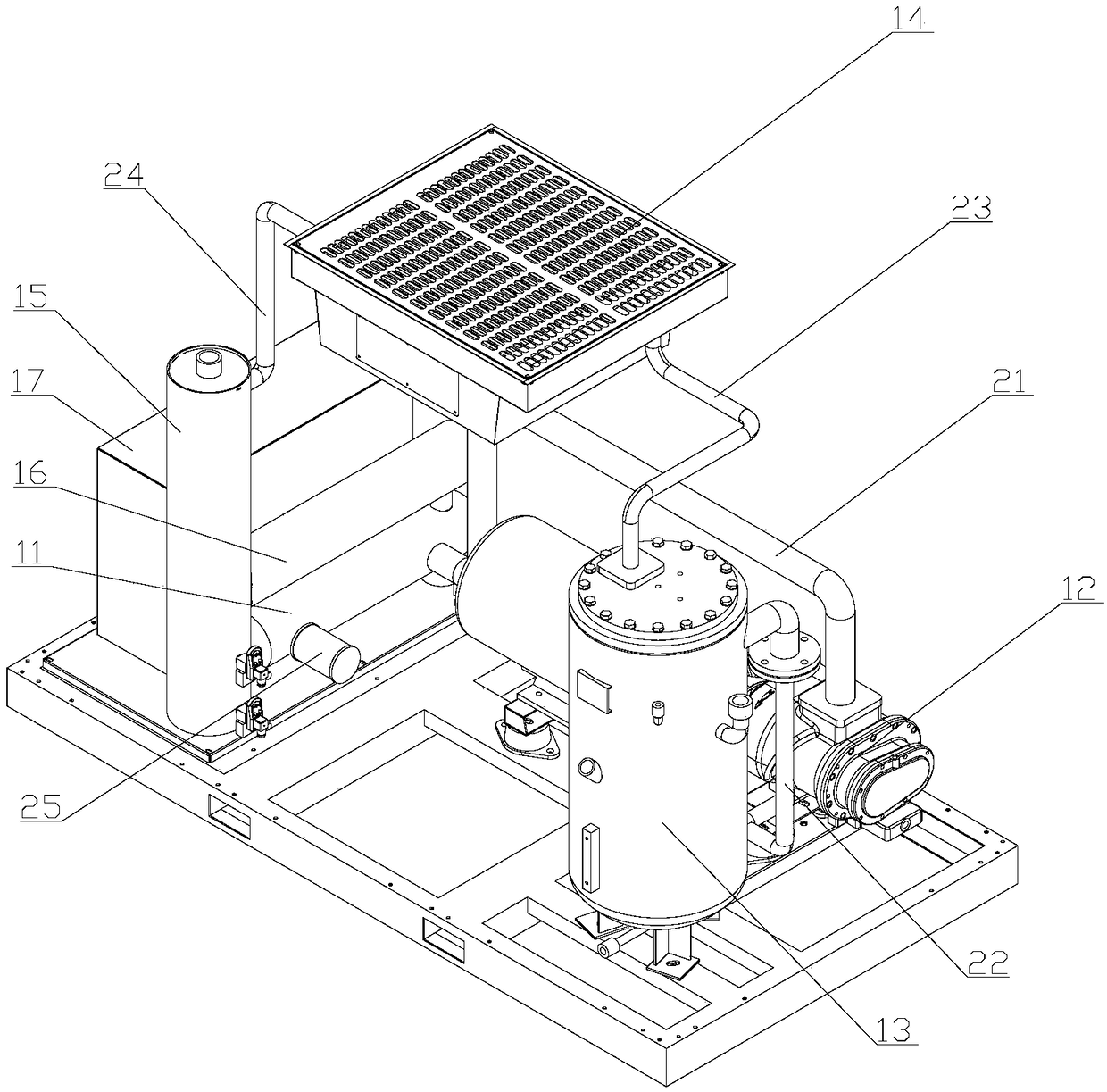

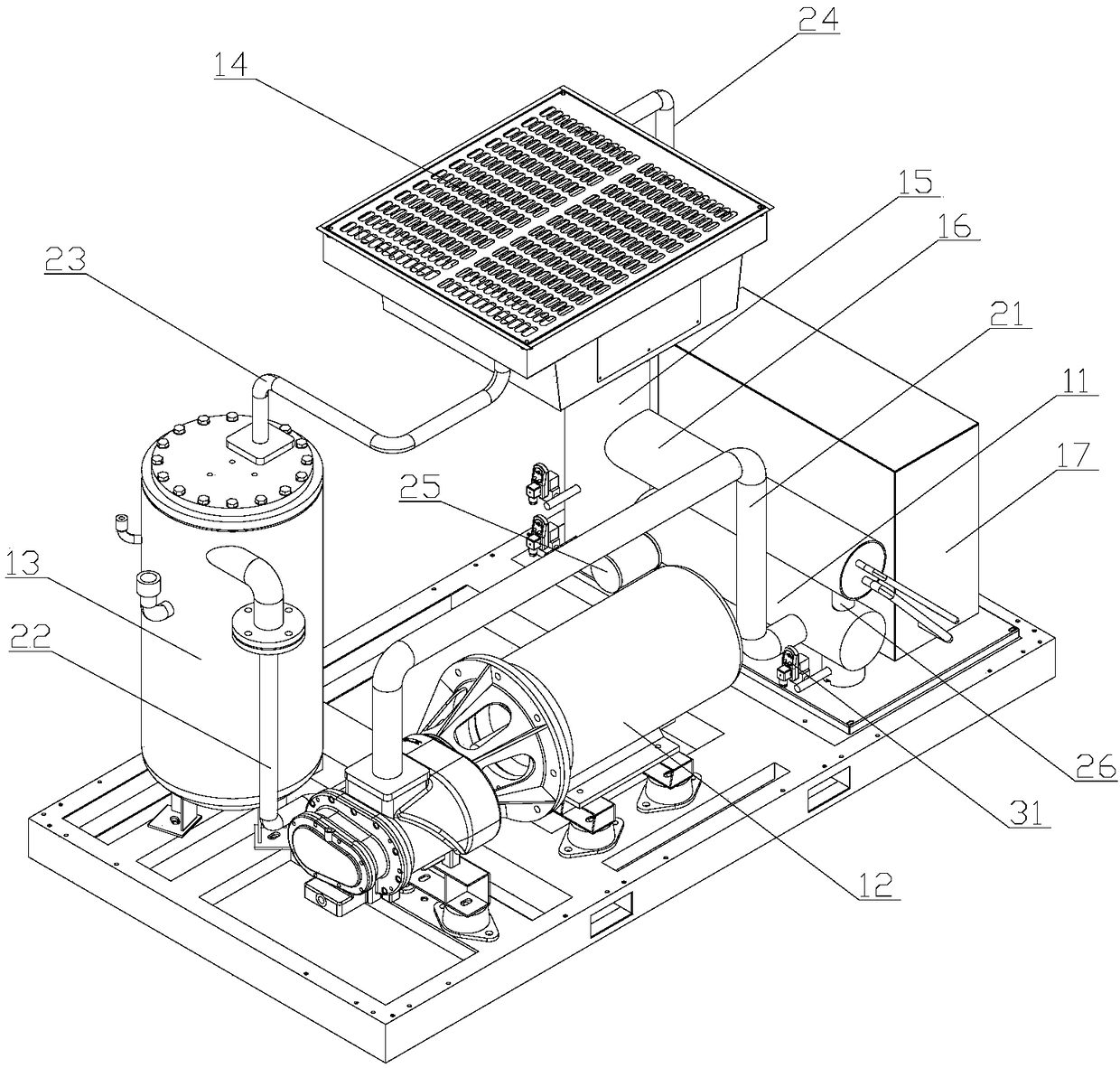

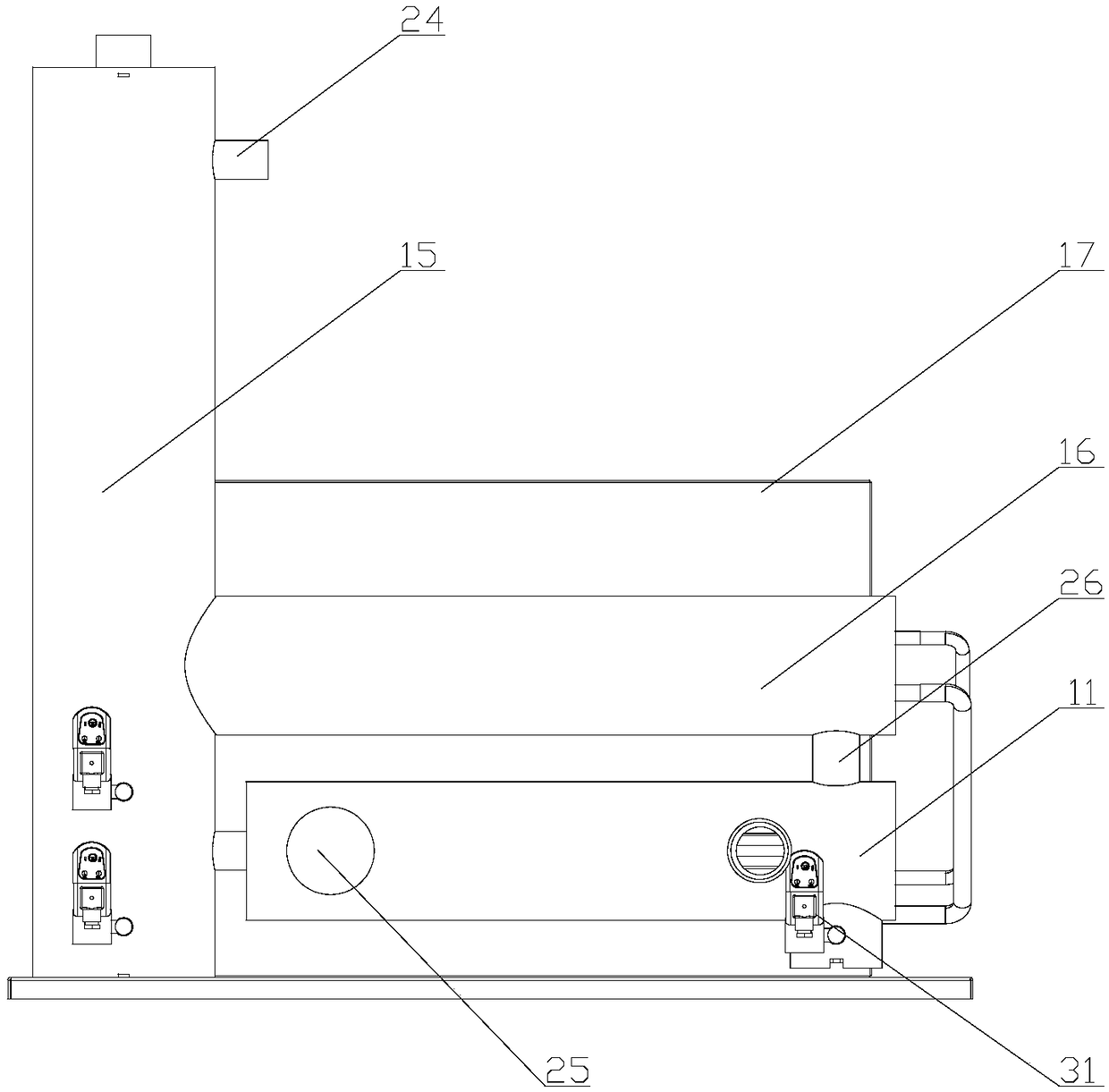

[0027] Such as figure 1 and figure 2 , a low-carbon air compressor integrated machine, including an intake precooler 11, an air suction pipe 21, an air compressor 12, a first exhaust pipe 22, an oil-gas separator 13, a second exhaust pipe 23, and a cooler 14 , the third exhaust pipe 24, the exhaust gas reheater 15, the evaporator 16 and the refrigeration unit 17;

[0028] The intake precooler 11, the evaporator 16 and the exhaust gas regenerator 15 are all heat exchangers; the shell side of the intake precooler 11 is connected with an air inlet 25, and the intake air precooler The shell side of the device 11 is connected to the inlet of the air compressor 12 through the suction pipe 21, and the outlet of the air compressor 12 is connected to the oil-gas separator 13 through the first exhaust pipe 22, and the oil-gas separator The cooler 13 is connected to the inlet of the cooler 14 through the second exhaust pipe 23, and the outlet of the cooler 14 is connected to the shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com