Method for extracting m-phthalic acid-5-sodium sulfonate from trimonomer production wastewater

A technology for the production of isophthalic acid and wastewater, which is applied in chemical instruments and methods, organic chemistry, and the preparation of organic compounds, and can solve problems such as increasing the production cost of three monomers, refractory biodegradable wastewater, and endangering human health. To achieve the effect of changing the performance of extraction operation, reducing the amount of extracted water, and making it difficult to emulsify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

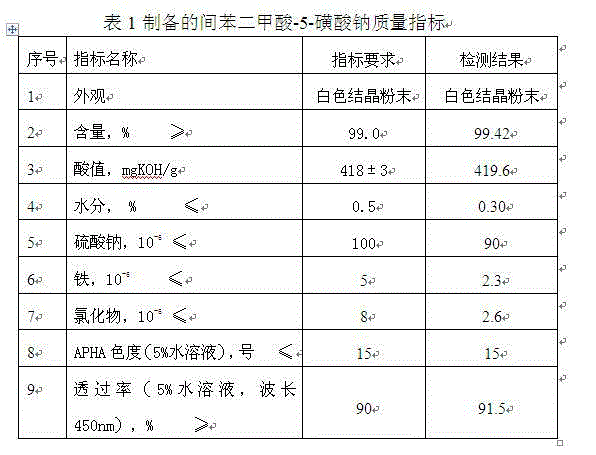

Embodiment 1

[0025] An analysis of the selection of the three monomers to extract the method of extracting the phenyl acid -5-sodium sodium sodium sodium sodium acid-5-sodium sulfonate:

[0026] Listing theory:

[0027] As an important separation method, extraction has high processing capacity, high separation efficiency, high recovery rate, wide application range, strong adaptability, good economy, and easy to achieve continuous operation and automatic control.For the occasion that is not suitable for separation and crystallization, there is a certain technical advantage in the extraction process: (1) The melting point or boiling point of each component is very close or forms a co -boiling material, which is difficult to or cannot be separated by the fine distillation method; (2 2) A small amount of high boiling point components, inorganic objects, and metal material recycling of the high boiling point of the volatile objects; (3) the thermal component, the funeral swimsuit causes decompositi...

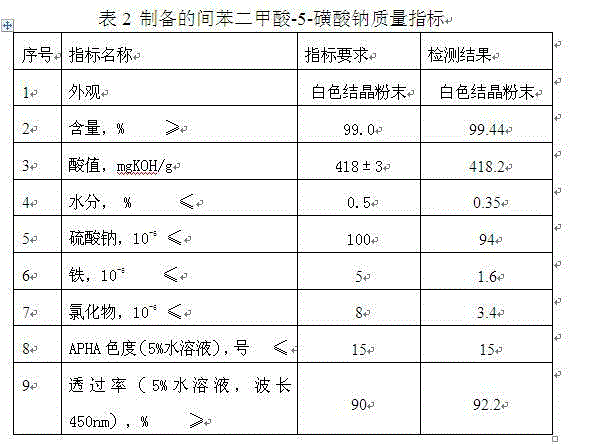

Embodiment 2

[0060] A three-monomer production wastewater extract the method of sodium-5-sodium-5-sulfate, including the following steps: prepare extraction agents, pH value, extraction, anti-extraction, anti-extraction solution concentration, acidification, concentrated crystal, dryness, drynessEssence

[0061] 1. Prepare the extraction agent:

[0062] The quality ratio of each material in the extraction agent is performed according to the following three schemes:

[0063] Option One:

[0064] Weigh 700kg of triomamine, bisoprobinamine 2,4-two (N, N-two-based) amino duoline benzene 210kg, 2-Gee eleven alcohol 70kg, sulfide kerosene 420kg, Zhengxinol 280kg 280kg, Add the extraction kettle, stir for 40-60 minutes, and need to be used.

[0065] Option II:

[0066] Weigh 700kg of triomine, 2,4-two (n, n-dihal) amino duoline benzene 300kg of 2,4-two (N, N-two-based), 2-Gee elevenol 100kg, sulfide kerosene 585kg, orthopedic alcohol 325kg 325kg, Add the extraction kettle, stir for 40-60 minutes, and...

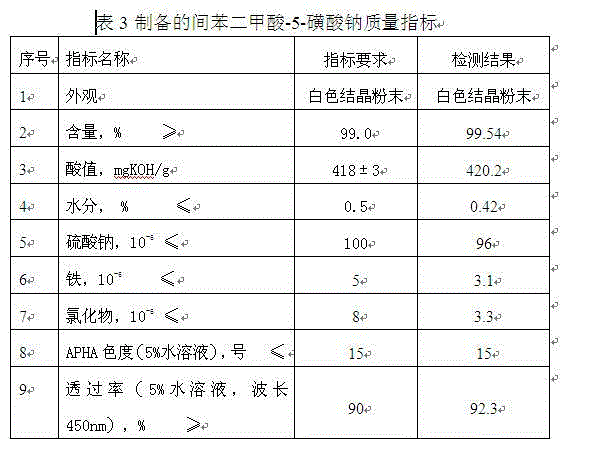

Embodiment 3

[0092] 1. Prepare the extraction agent

[0093] Weigh 700kg of triomine, 2,4-two (n, n-dihal) amino duoline benzene 300kg of 2,4-two (N, N-two-based), 325kg of orthopedly, 100kg of 2-Gee eleven alcohol, sulfide kerosene 585kg, Add the extraction kettle, stir for 40-60 minutes, and need to be used.

[0094] 2. Adjust the pH value

[0095] At 12.5m 3 In the pH adjustment kettle, measure the three monomer wastewater after the alcohol, add 10.5m 3 The concentration of 93%sulfuric acid is 200kg, and the pH value of the water phase is adjusted to 2.3.

[0096] 3. Extract

[0097] Add 2000kg to the wastewater with the pH value to the extraction kettle, turn on the stir, open the fixture steam valve, heat the material temperature in the kettle to 35 ° C within 20 minutes, and then continue to stir for 15 minutes.release.The organic phase is placed in the extraction kettle for use.

[0098] 4. Anti -extraction

[0099] Add the concentration of 14%NAOH solution 310kg to the extraction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com