Method for refining mixed oil of microalgae DHA oil

A technology of mixed oil and microalgae, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of unused refining application of mixed oil, achieve the effect of improving product color, improving product quality, and reducing refining consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

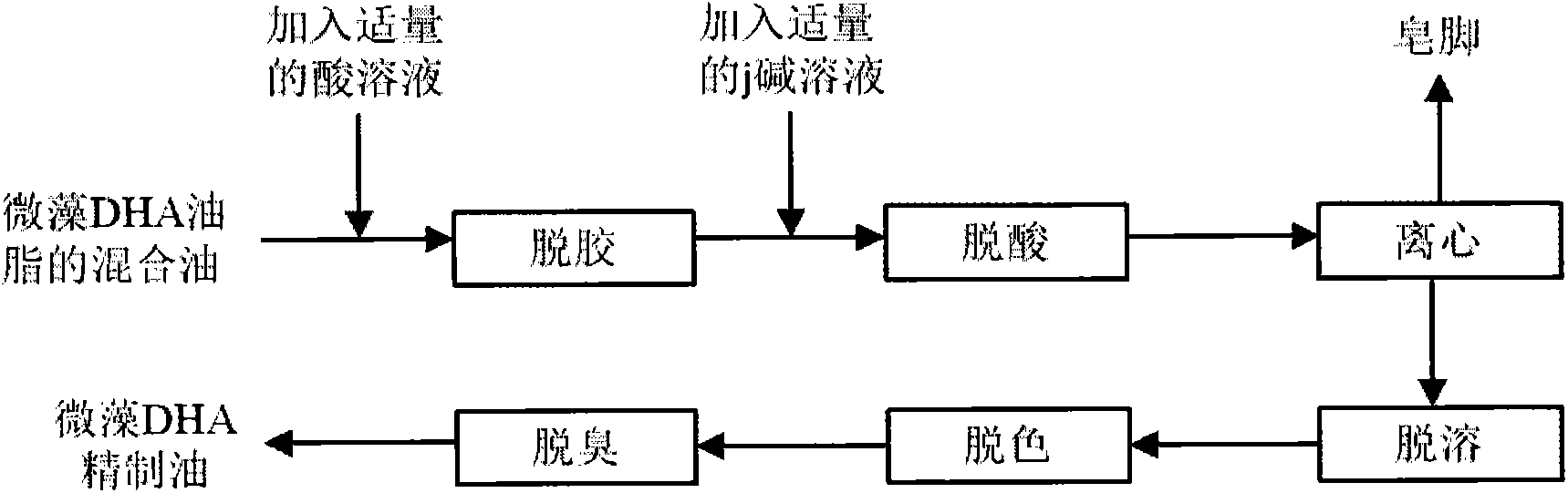

Method used

Image

Examples

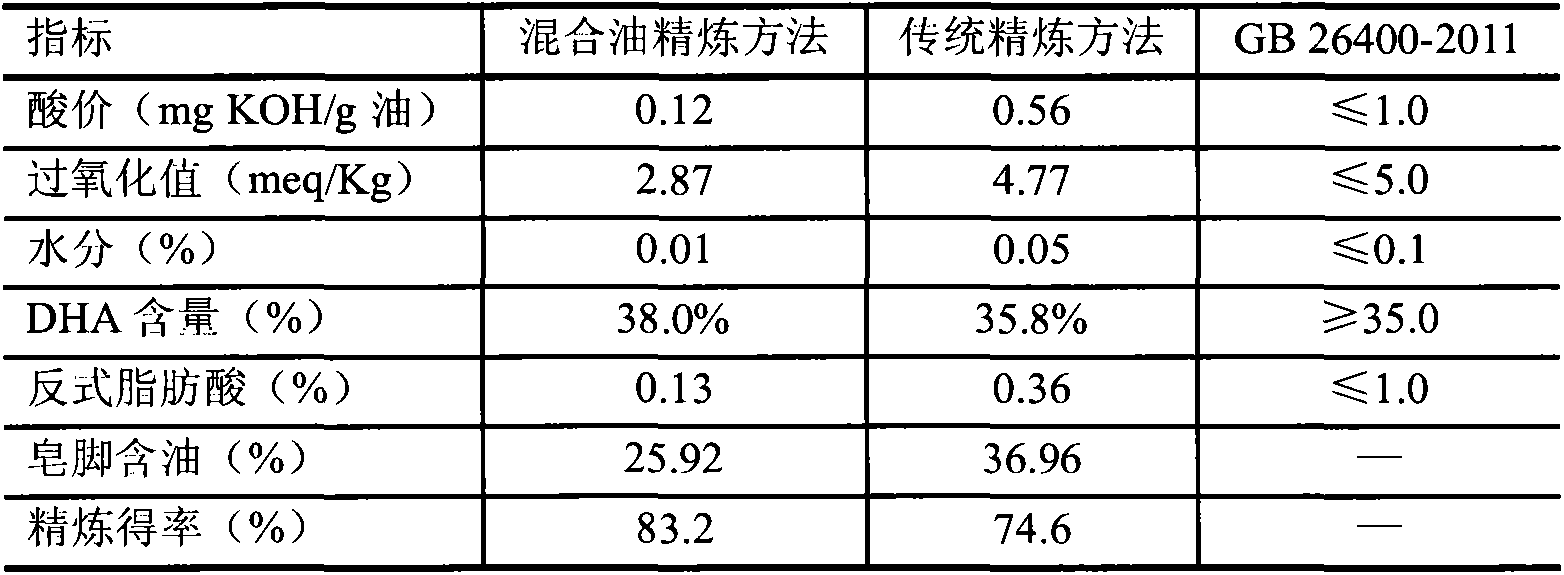

Embodiment 1

[0023] The mixed oil refining method of embodiment 1 microalgae DHA oil refines microalgae DHA oil

[0024] The specific method of refining the mixed oil used in this experiment is as follows:

[0025] (1) Microalgae DHA mixed oil pretreatment: the solid impurities in the mixed oil are controlled below 0.2% by filtration;

[0026] (2) Degumming of microalgae DHA mixed oil: heat the mixed oil to 45° C., add 0.4% food-grade citric acid aqueous solution with a mass concentration of 55% under rapid stirring, and stir evenly and slowly for 30 minutes;

[0027] (3) Deacidification of microalgae DHA mixed oil (alkali refining): the temperature is controlled at 45° C., the concentration of the added lye is 12%, and the excess alkalinity is 0.2% of the oil weight. After fully mixing, stir evenly and slowly for 40 minutes to obtain a mixture of oil and soap;

[0028] (4) Oil and soap separation: control the temperature of the mixture of oil and soap below 50°C, and centrifuge the mixe...

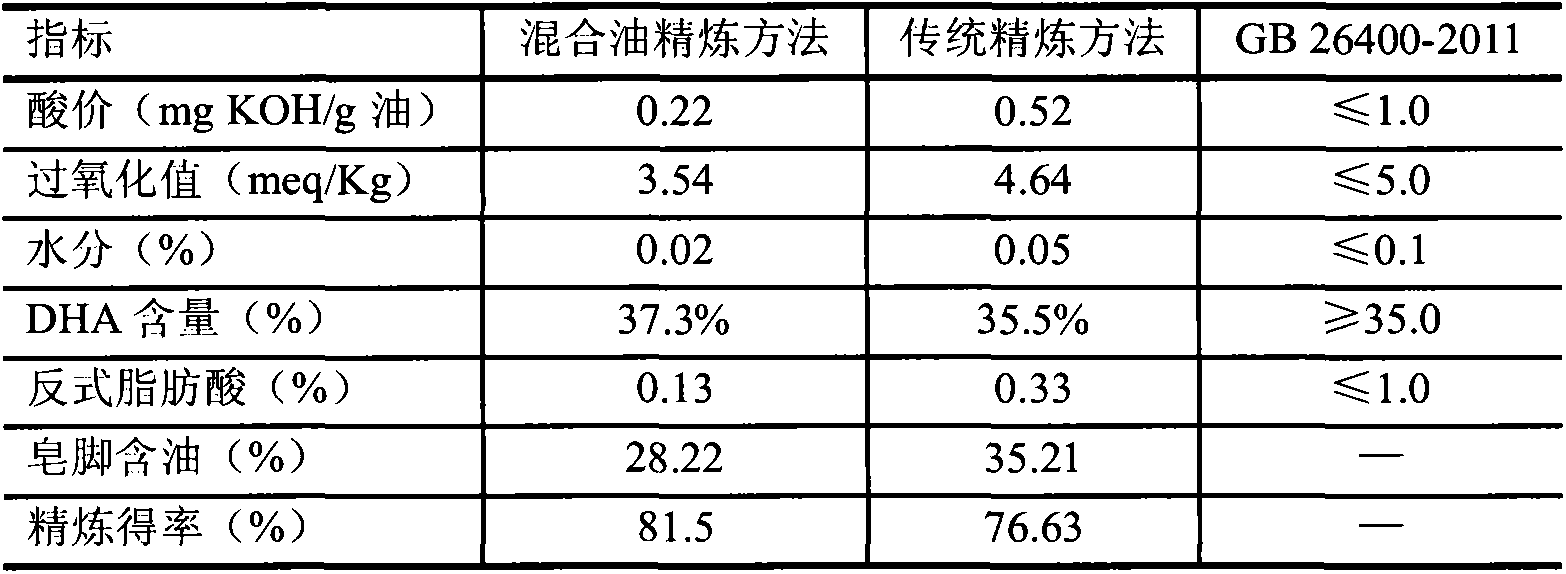

Embodiment 2

[0034] The mixed oil refining method of embodiment 2 microalgae DHA oil refines microalgae DHA oil

[0035] The specific method of refining the mixed oil used in this experiment is as follows:

[0036] (1) Microalgae DHA mixed oil pretreatment: the solid impurities in the mixed oil are controlled below 0.2% by filtration;

[0037] (2) Degumming of microalgae DHA mixed oil: heat the mixed oil to 50°C, add 0.2% of food-grade phosphoric acid aqueous solution with a mass concentration of 75% under rapid stirring, and stir evenly and slowly for 20 minutes;

[0038] (4) Deacidification of microalgae DHA mixed oil (alkali refining): the temperature is controlled at 50° C., the concentration of the added lye is 12%, and the excess alkalinity is 0.2% of the oil weight. After fully mixing, stir evenly and slowly for 30 minutes to obtain a mixture of oil and soap;

[0039] (5) Oil and soap separation: control the temperature of the mixture of oil and soap below 50°C, and centrifuge the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com