Patents

Literature

59results about How to "Conducive to follow-up process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

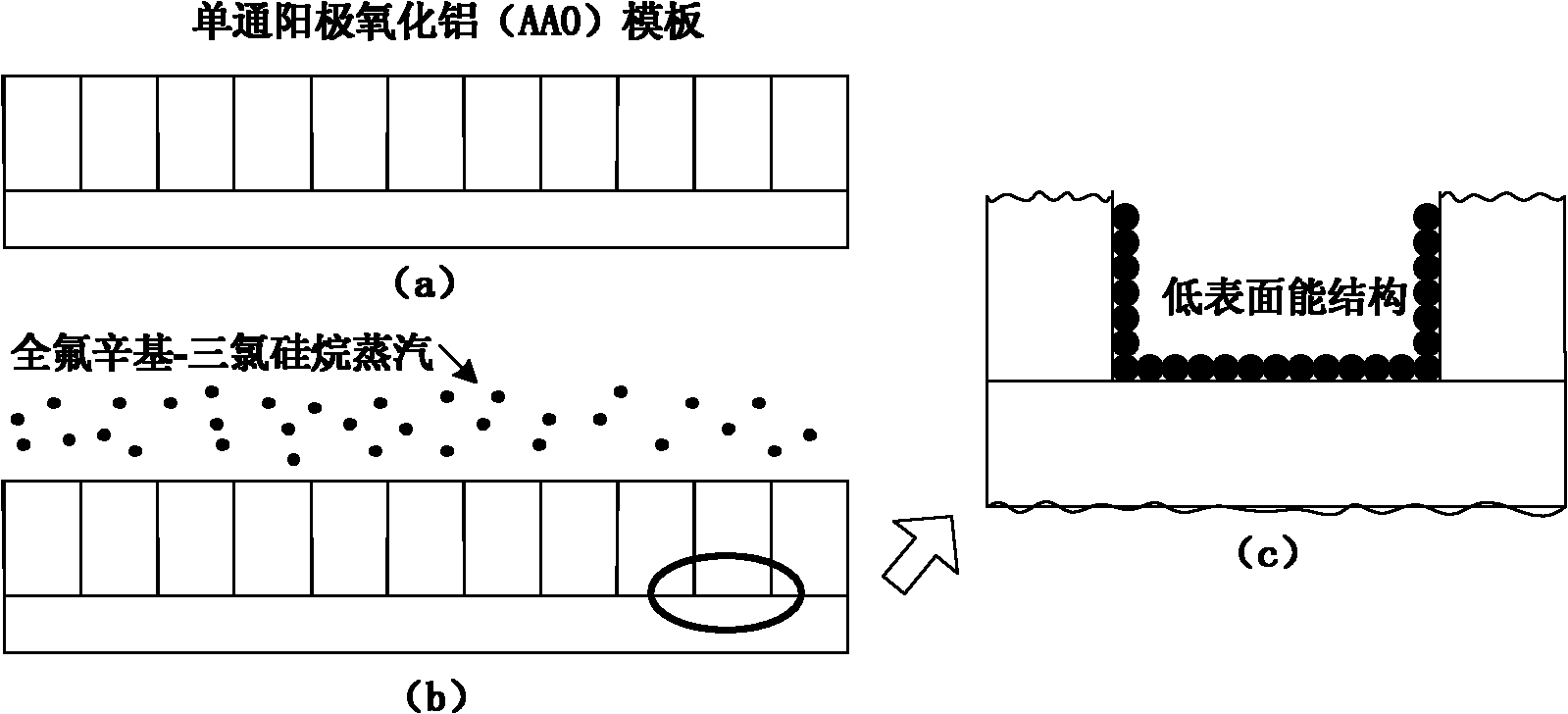

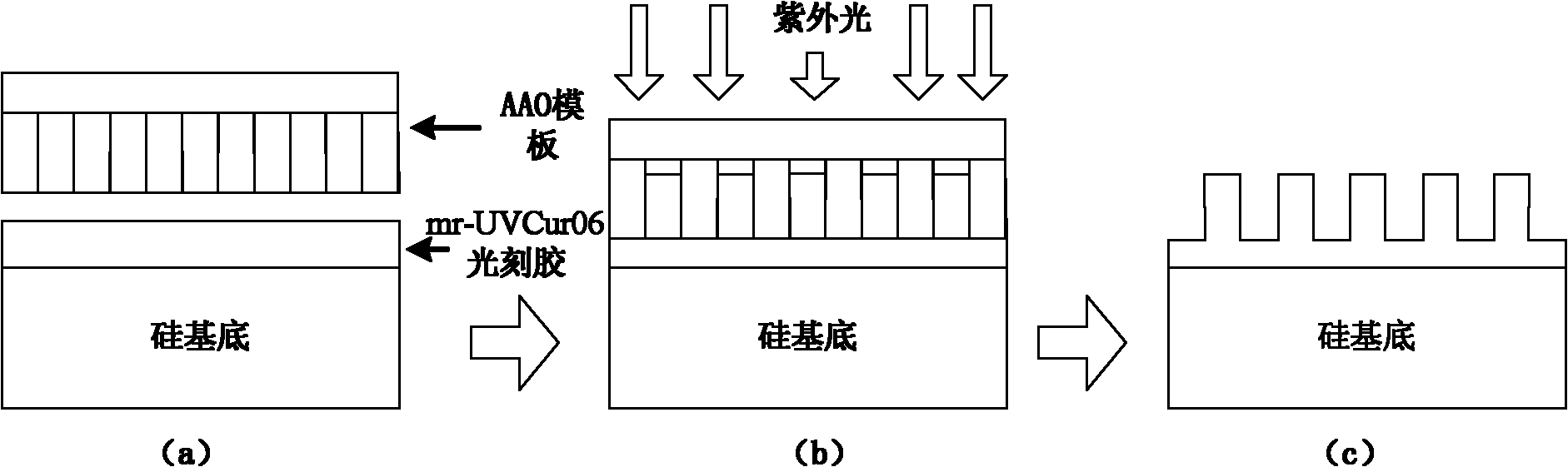

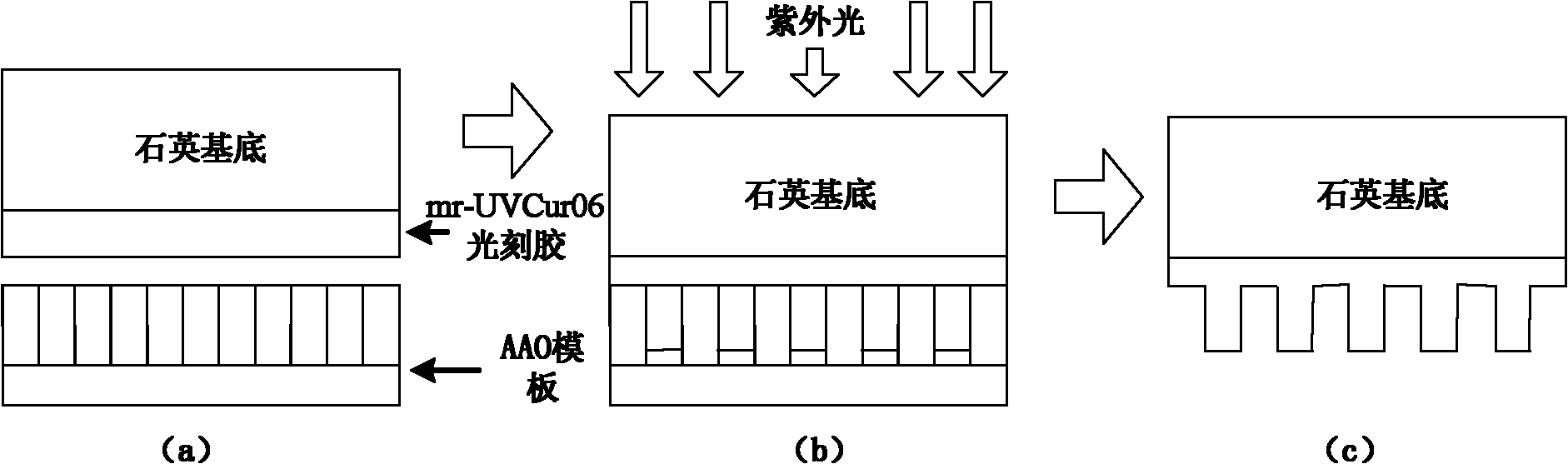

Preparation method of nanoimprint hard templates

InactiveCN101806996AEasily damagedAvoid damagePhotomechanical apparatusOriginals for photomechanical treatmentPerfluoro-octaneChlorosilane

The invention provides a preparation method for preparing hard templates with low price, high reusability and adjustable micro-nano dimension used for nanoimprint in a large scale. The method comprises the following steps: firstly, adopting an electrochemical method for preparing regular anodized aluminum oxide (AAO) templates in oxalic acid electrolyte; then, forming a layer of perfluorooctane 1, 3-chlorosilane (CF3(CF2)5(CH2)2SiCl3) demolding agents through vapor deposition on the surface of AAO; spin coating a layer of ultraviolet curable or thermally curable photoresist on a silicon or quartz substrate; copying micro-nano structures of the anodized aluminum oxide templates to the surface of the photoresist by utilizing an ultraviolet nanoimprint or thermal nanoimprint technology; and finally, using reaction ion beams for etching (RIE). Thereby, the silicon or quartz templates which can be prepared in a large scale, have the advantages of low price, high reusability and adjustable micro-nano dimension and can be used for nanoimprint can be obtained on the silicon or quartz substrate.

Owner:HUAZHONG UNIV OF SCI & TECH

Rayon and polyester filament blended spinning technology

InactiveCN103526418AGuaranteed tensionAvoid breakingAuxillary apparatusWoven fabricsNatural stateEngineering

The invention relates to rayon and polyester filament blended spinning technology. The technology is characterized by including the following steps: 1) placing polyester filaments in a water steaming box for steaming at the water temperature of 85-100 DEG C for 80 minutes; 2) disposing the polyester filaments treated in the step 1) under the natural state for presetting for 10-20 hours; 3) measuring high limit in stretchability of rayon, namely a value of the maximum appliable pressure to the rayon; 4) adopting a water-jet loom for performing blended spinning on the rayon and the polyester filaments with the maximum pressure value. The high limit in stretchability of the rayon, namely the value of the maximum appliable pressure to the rayon, is measured firstly, and stretching resistance capability of the rayon is lower than that of the polyester filaments, so that tension of the rayon and the polyester filaments can be guaranteed within a bearable range by blending with the value of the maximum appliable pressure to the rayon, and both the rayon and the polyester filaments are less prone to breakage.

Owner:HUZHOU JINTADI TEXTILE MILL

Mixed weaving process

InactiveCN102367619AAvoid breakingReduce the number of stoppersLoomsWoven fabricsEngineeringMaximum pressure

The invention discloses a mixed weaving process. In the mixed weaving process, before artificial silk and dacron filaments are used for mixed weaving, firstly, the maximum tensioning limit of the artificial silk, i.e. the maximum pressure value capable of being exerted on the artificial silk is measured, and the tensioning resistance of the artificial silk is weaker than that of the dacron filaments, so the maximum pressure value capable of being exerted onto the artificial silk is adopted for mixed weaving, the tension of the artificial silk and the tension of the dacron filaments can be ensured to be both in the bearable range, and both the artificial silk and the dacron filaments can not easily fracture; and further, before the mixed weaving, the dacron filaments are pretreated so that the characteristics of the artificial silk more conform to the characteristics of the dacron filaments, and the proceeding of the subsequent process can be more favorably realized. In addition, in the process, when a waterjet loom is used for tracking the dacron filaments, a spray nozzle with the specification being 75 to 40 is adopted, a spray nozzle with the specification being 45 to 20 is adopted during the traction of the artificial silk, different characteristics of the artificial silk and the dacron filaments are considered, and the number of blocking elements required by the weaving of one hundred meters of plus materials can be obviously reduced.

Owner:SUZHOU DONGMAO TEXTILE IND

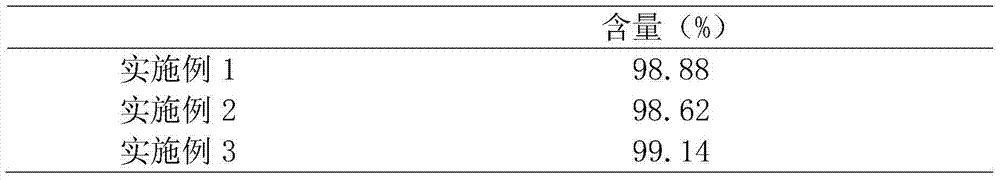

Method for extracting magnolol from officinal magnolia barks

InactiveCN104230673AHigh yieldEasy to handleOrganic chemistryOrganic compound preparationHonokiolMagnolol

The invention discloses a method for extracting magnolol from officinal magnolia barks. The method comprises the following steps of raw material processing, high-pressure microjet superfine smashing processing, supersonic extraction, extraction, crystallization and drying to obtain the magnolol, and has the advantages of being high in content, high in extraction rate, simple in process, suitable for production, low in production cost and the like.

Owner:GUILIN SANBAO PHARMA

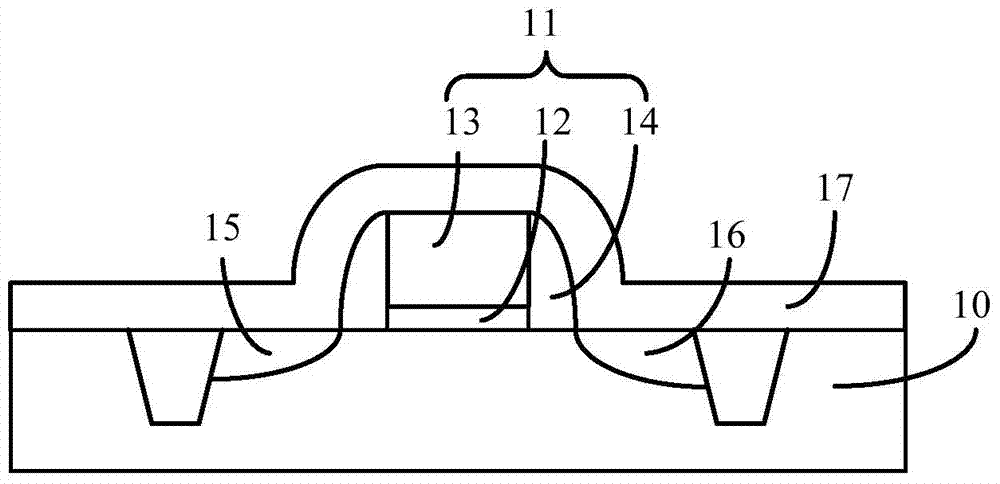

Forming method of diffusion zone

InactiveCN102013392AAvoid damageEvenly distributedSemiconductor/solid-state device manufacturingIon bombardmentIon implantation

The invention relates to a forming method of a diffusion zone, comprising the following steps of: forming a pre-doping layer on the surface of a semiconductor substrate, wherein doping ions are contained in the pre-doping layer; forming a protecting layer on the pre-doping layer; annealing the semiconductor substrate; and diffusing the doping ions in the pre-doping layer into the semiconductor substrate. In the invention, by replacing the traditional mode of injecting ions to dope the diffusion zone with a furnace tube thermal diffusion technology, the damage to the surface of the semiconductor substrate by ionic bombardment is avoided, foreign ions are ensured to be more evenly distributed in the diffusion zone, a surface lattice structure is improved and a subsequent technology is benefited. In the process, the technological flow is slightly regulated, the complexity is not obviously increased, the production cost is not obviously increased, and the productivity is increased to a certain extent.

Owner:SEMICON MFG INT (SHANGHAI) CORP

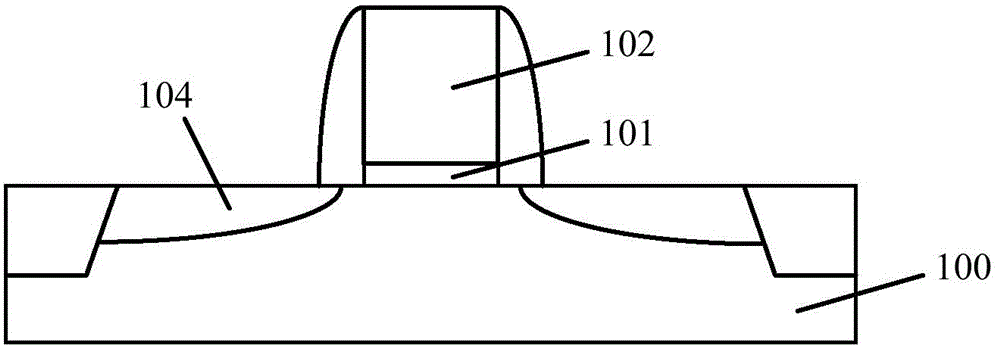

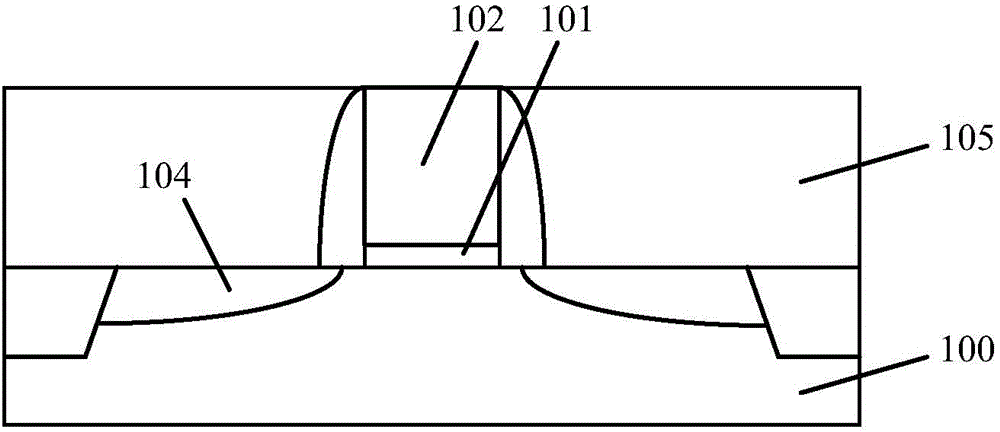

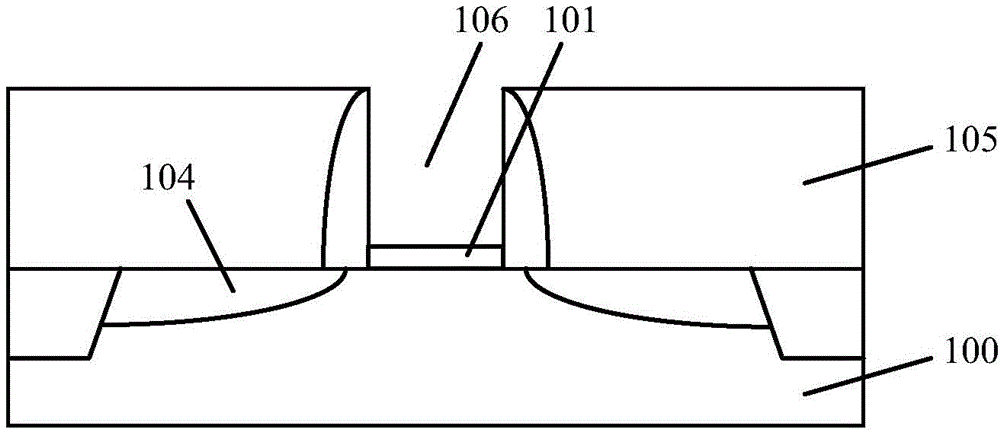

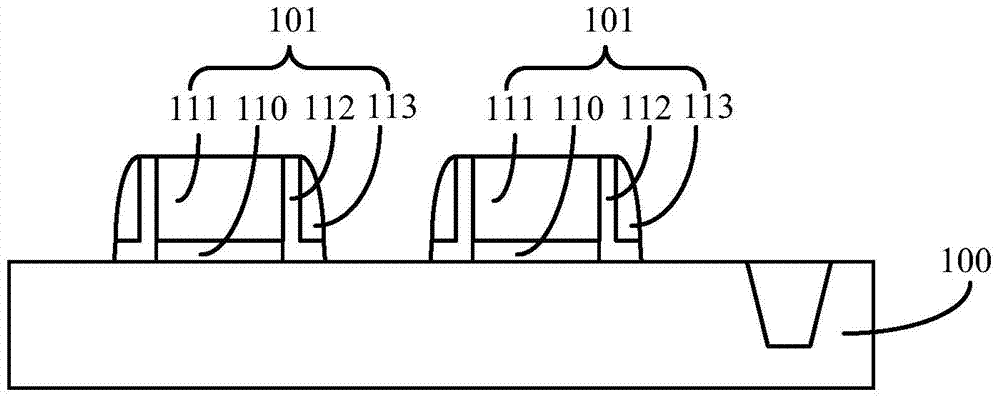

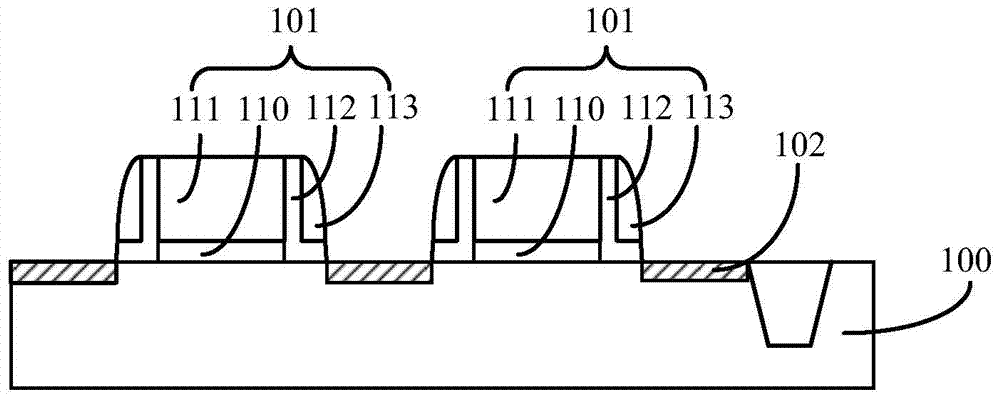

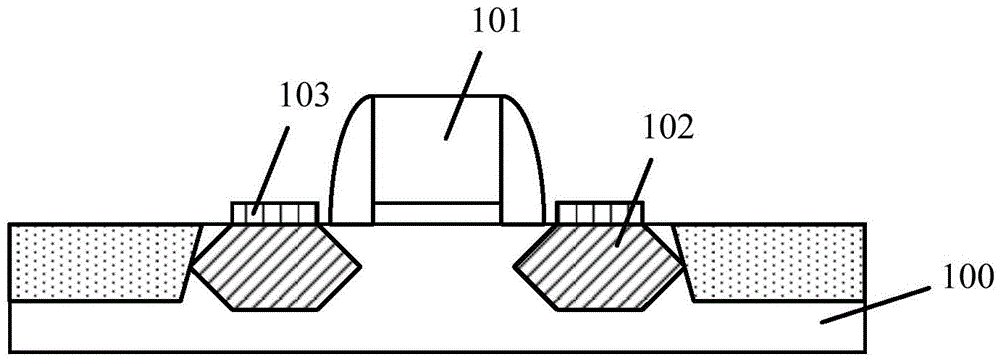

Semiconductor device structure and fabrication method thereof

ActiveCN102881634AAvoid difficultiesImprove performanceTransistorSemiconductor/solid-state device manufacturingUnit deviceEngineering

The invention discloses a semiconductor device structure and a fabrication method thereof. The fabrication method comprises the steps of forming at least one continuous gate line on a semiconductor substrate, forming gate sidewalls around the gate line, forming source or drain regions on both sides of the gate line in the semiconductor substrate, forming conducting sidewalls around the outer sides of the gate sidewalls, realizing electrical isolation among devices in a scheduled region, forming gates of corresponding unit devices at an isolated part of the gate line, and forming contacting parts of the corresponding unit devices at isolated parts of the conducting sidewalls. The fabrication method is particularly suitable for fabricating the contacting parts in an integrated circuit.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

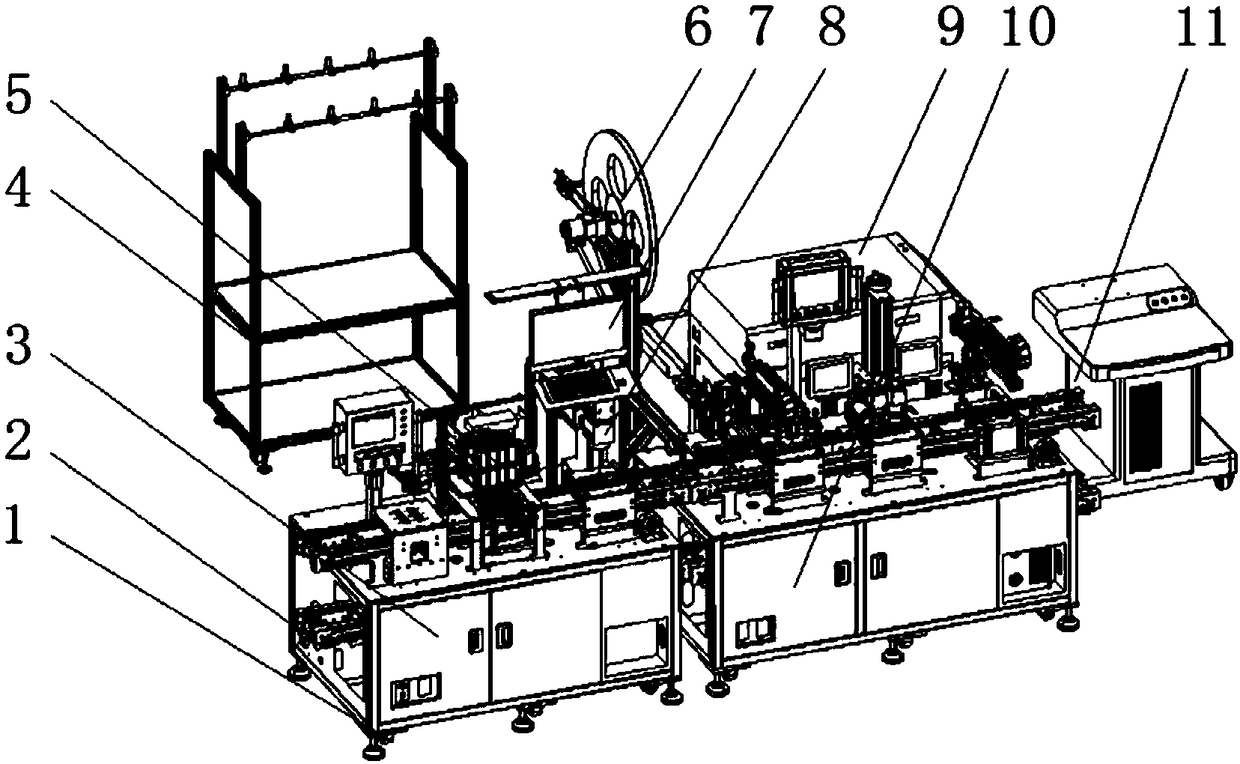

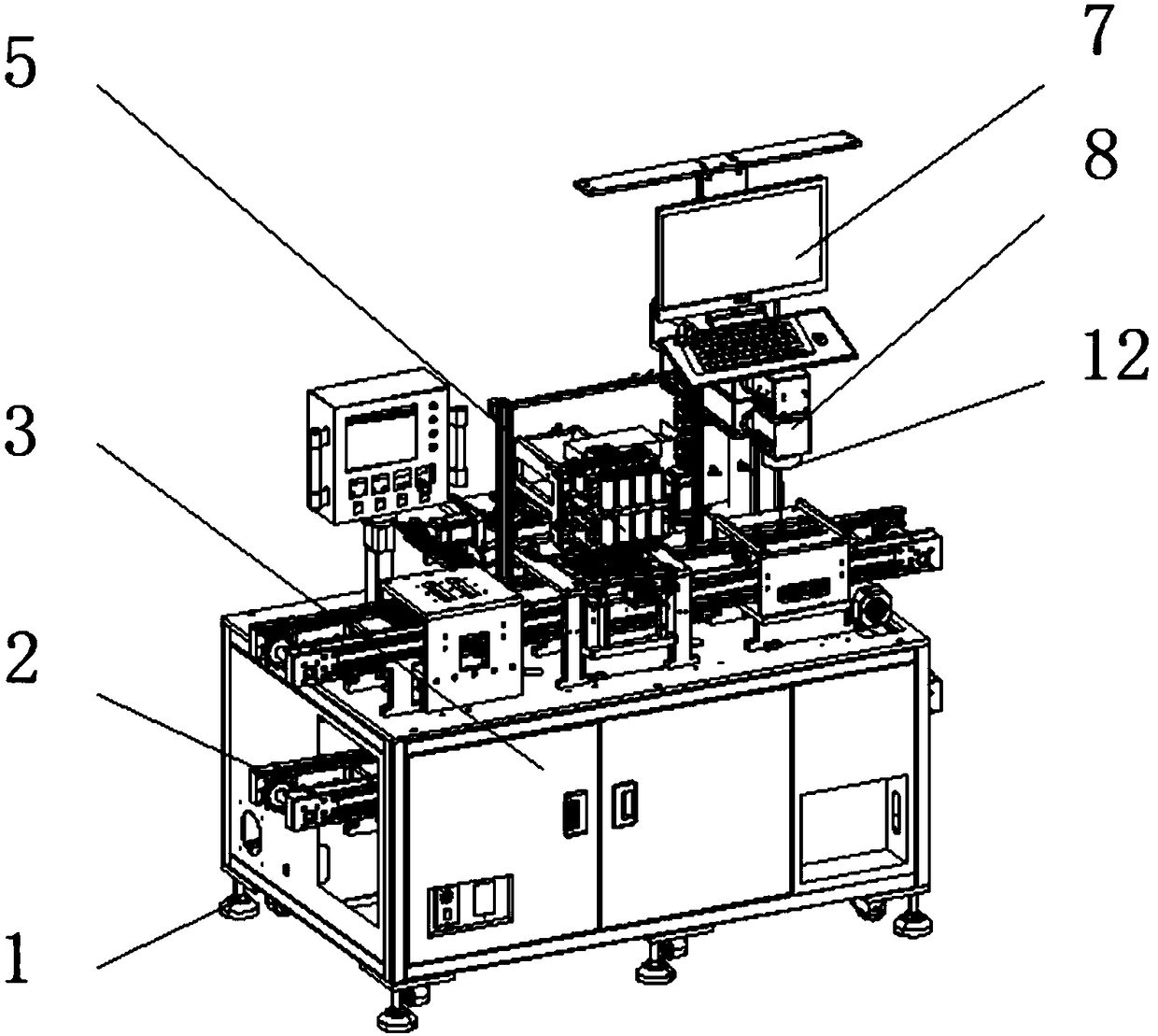

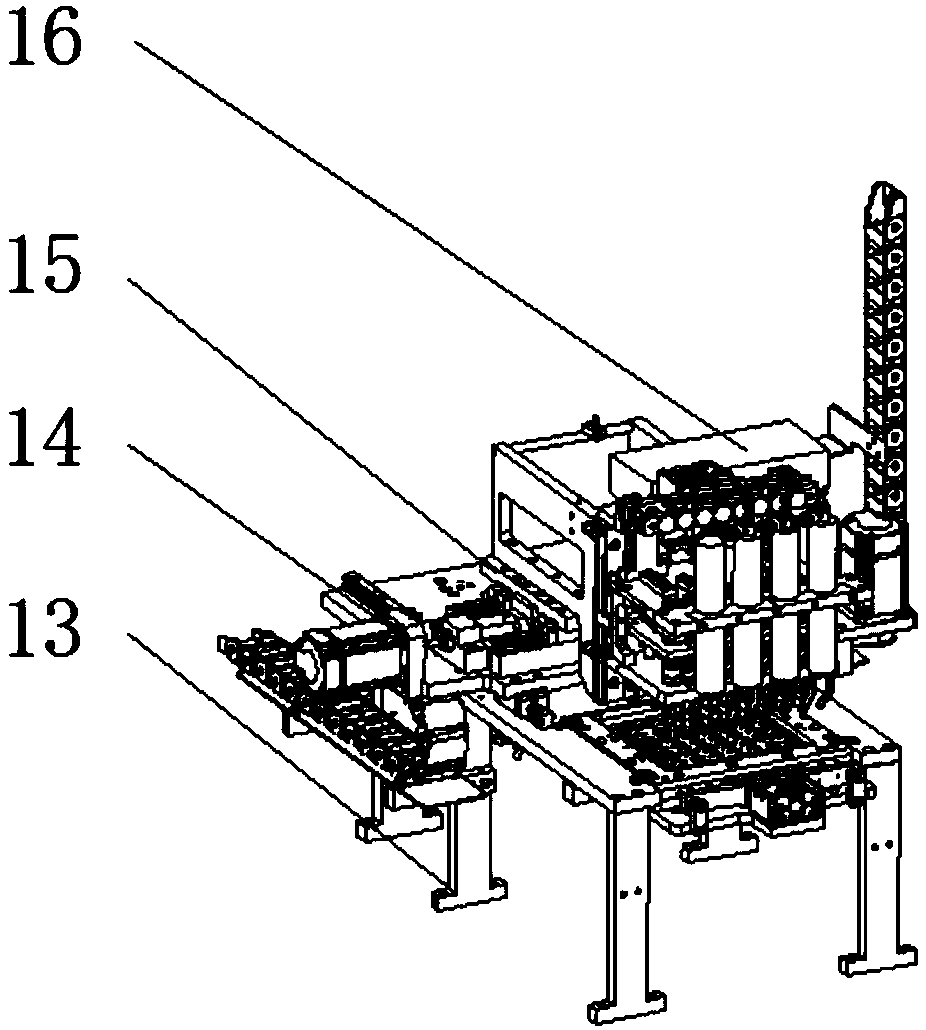

Automatic winding welding device

ActiveCN108074735AAffect the welding effectEasy to peel paint at restCoils manufactureWinding machineEngineering

The invention discloses an automatic winding welding device comprising a winding machine table, a welding machine table, an eight-axis synchronous winding and an up-and-down needle drawing mechanism.A wire discharging frame is mounted on one side of the winding machine table. An loading water circulation device is mounted in the winding machine table, a winding device is mounted at one end of thetop of the winding machine table through a support, a winding machine head left-right mechanism is mounted on the support on one side of the winding device, the welding machine table is mounted at one end of the winding machine table, and universal wheels are mounted at four corners at the bottom of each of the welding machine table and the winding machine table, a laser welding host is mounted at the top of the welding machine table, and a computer host is mounted at one end of the welding machine table far away from the winding machine table. According to the automatic winding welding device, by installation of a damping gasket, the stability of the whole device is improved, to achieve the effect of vibration reduction, and the influence on work progress and winding welding effects caused by vibration in work is avoided.

Owner:东莞市高东电子科技有限公司

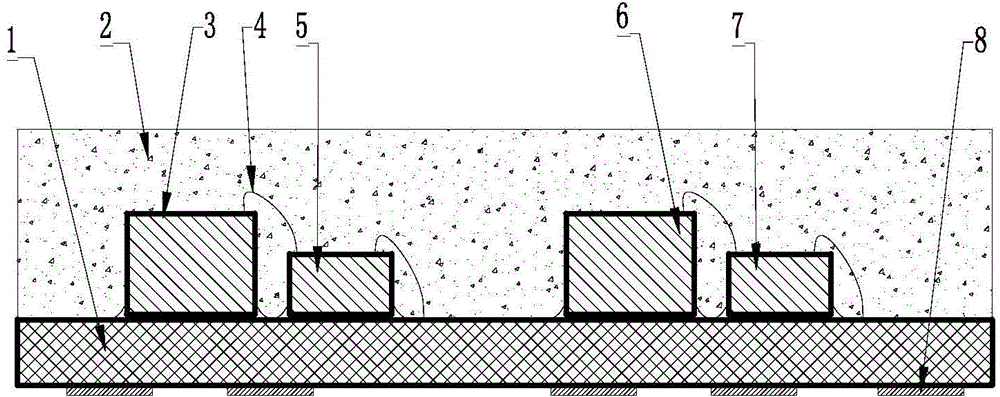

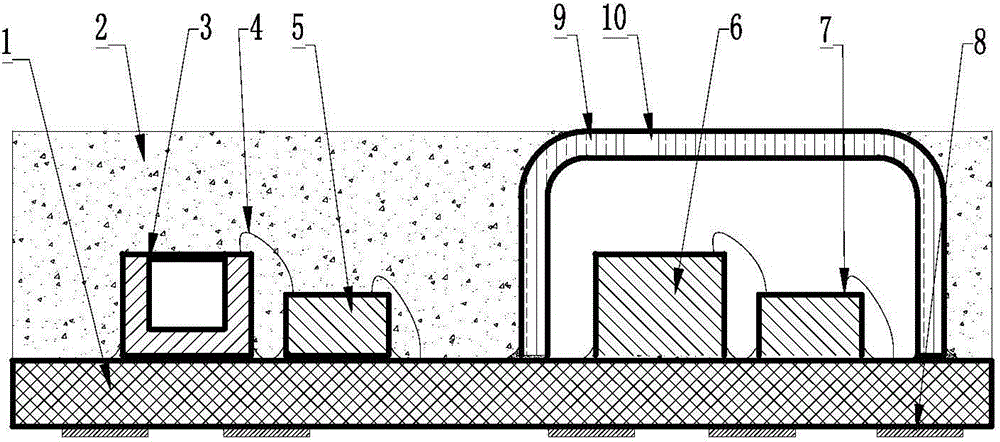

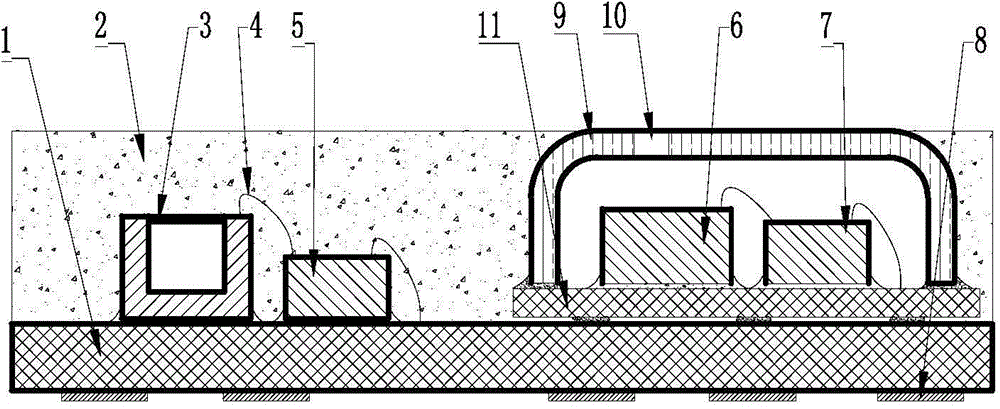

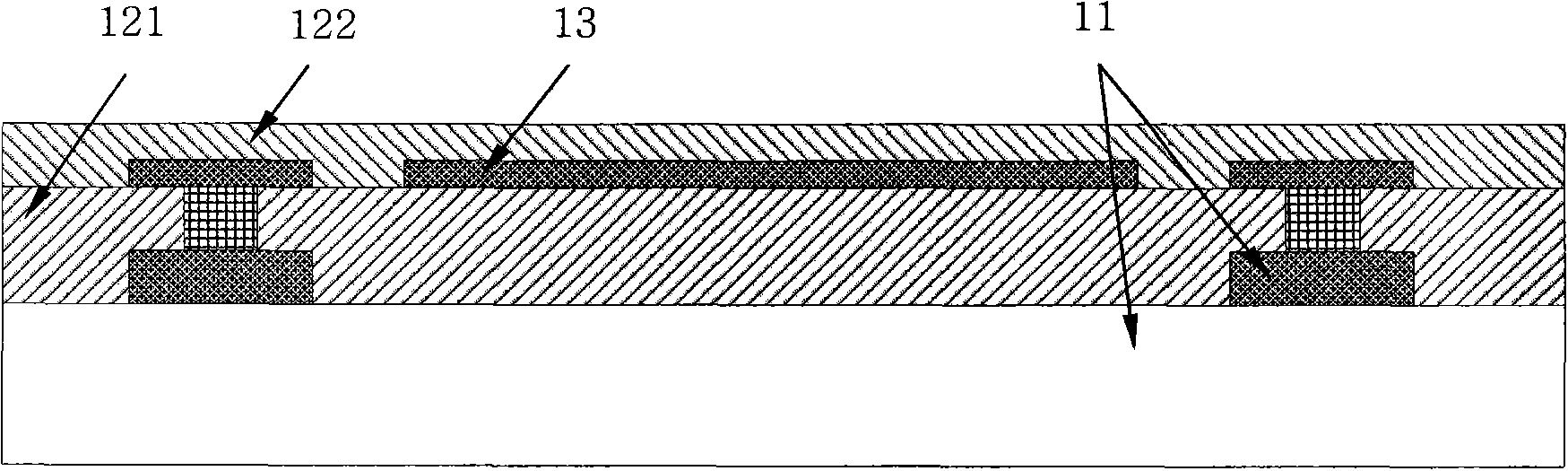

Packaging structure and method of integrated sensor

InactiveCN104900599AThe integrated sensor is solidImprove reliabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStress effectsWork performance

The invention discloses a packaging structure and method of an integrated sensor. The packaging structure comprises a first substrate, multiple sensors, at least one first packaging cavity and a plastic injection molding packaging structure, the sensors are arranged on the first substrate, each sensor comprises an MEMS sensor chip and an ASIC chip electrically connected with the MEMS sensor chip, a casing and the first substrate are enclosed to form the first packaging cavity, each of the internal and the external of the first packaging cavity is provided with at least one sensor, and the plastic injection molding packaging structure packages all the sensors and all the first packaging cavities. The casing packages and protects a relatively sensitive sensor at first, and then all the sensors are packaged on the first substrate via injection molding plastics in an integrated manner; the problems that injection molding plastics have a stress effect on the sensitive sensor and other sensors interfere the sensitive sensor are solved; and the working performance of the integrated sensor is improved.

Owner:GOERTEK INC

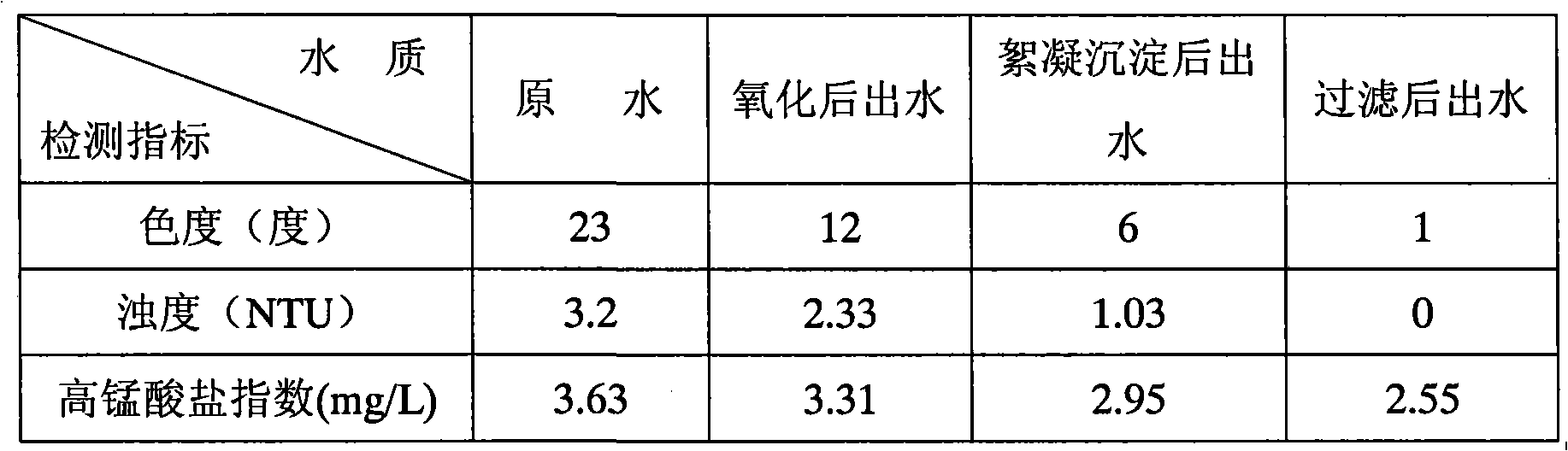

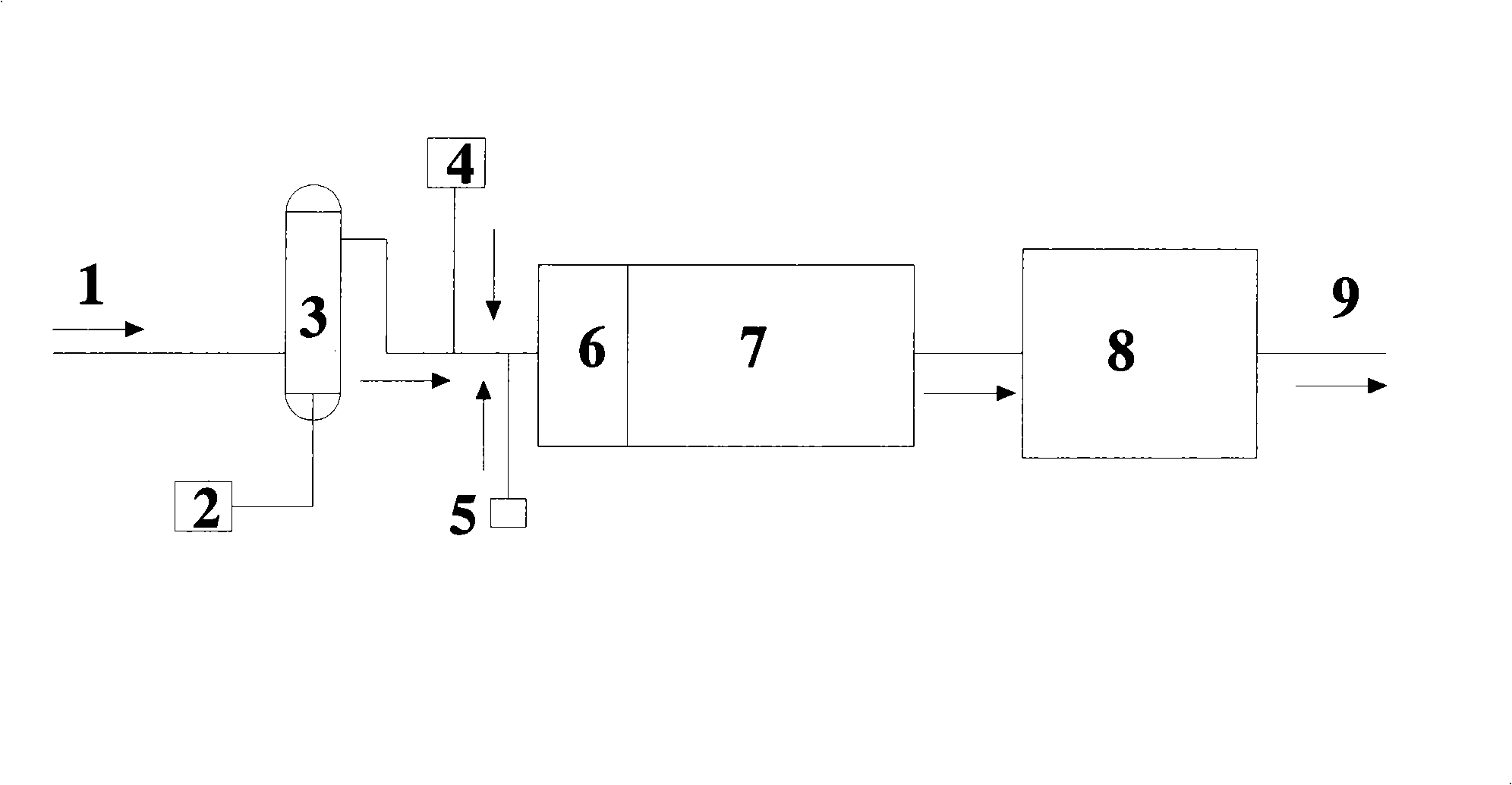

Process for chemically treating pollution of drinking water

InactiveCN101306890AAccelerated settlementStrong oxidation abilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationChemical treatmentOzone generator

The invention discloses a method for chemically treating drinking water pollution, relating to a water treatment technology which uses an ozone generator, an ozone contact oxidation pond, a flocculating agent adder, a coagulant aid adder, a mechanical stirring chamber, a sedimentation tank and a filtering basin. The treatment process is as follows: organic pollutants in source water are oxidized by fully mixing ozone produced by the ozone generator (2) with the source water in the ozone contact oxidation pond (3); then the pre-oxidized water is added with flocculating agent and coagulant aid and enters flocculating settling and filtration of a water plant to be treated. By improving the prior water treatment process, the method with simple operation process, low cost, convenient equipment installation, and micro-pollution removal is provided.

Owner:SHENYANG JIANZHU UNIVERSITY

Rayon and dacron mixed spinning process

InactiveCN105970417ANot easy to breakFeatures matchWoven fabricsLiquid/gas/vapor yarns/filaments treatmentWater temperaturePolymer science

The invention discloses a rayon and dacron mixed spinning process which includes the following steps that 1, dacron is placed into a water steaming box, the water temperature is 90-110 DEG C, and the water steaming time is 80-90 hours; 2, the Dacron obtained after water steaming is placed in a natural state for pre-sizing for 15-25 hours; 3, the largest extension fracture pressure value of the rayon is tested; 4, a hydraulic loom is adopted, and under the largest extension fracture pressure value, the rayon and the dacron are subjected to mixed spinning. The rayon and dacron mixed spinning process has the advantages that the largest stretchable pressure value of the rayon is tested, due to the fact that tension resistance of the rayon is weaker than that of the dacron, by the adoption of the largest pressure value exerted on the rayon for mixed spinning, it can be guaranteed that tension of the rayon and tension of the dacron are in a bearable range, and the rayon and the dacron are not prone to breakage. Meanwhile, before mixed spinning is conducted, the dacron is preprocessed, characteristics of the rayon can better conform to characteristics of the dacron, and thus it is beneficial to subsequent processes.

Owner:JIANGSU YAOZHANG SPORTING GOODS

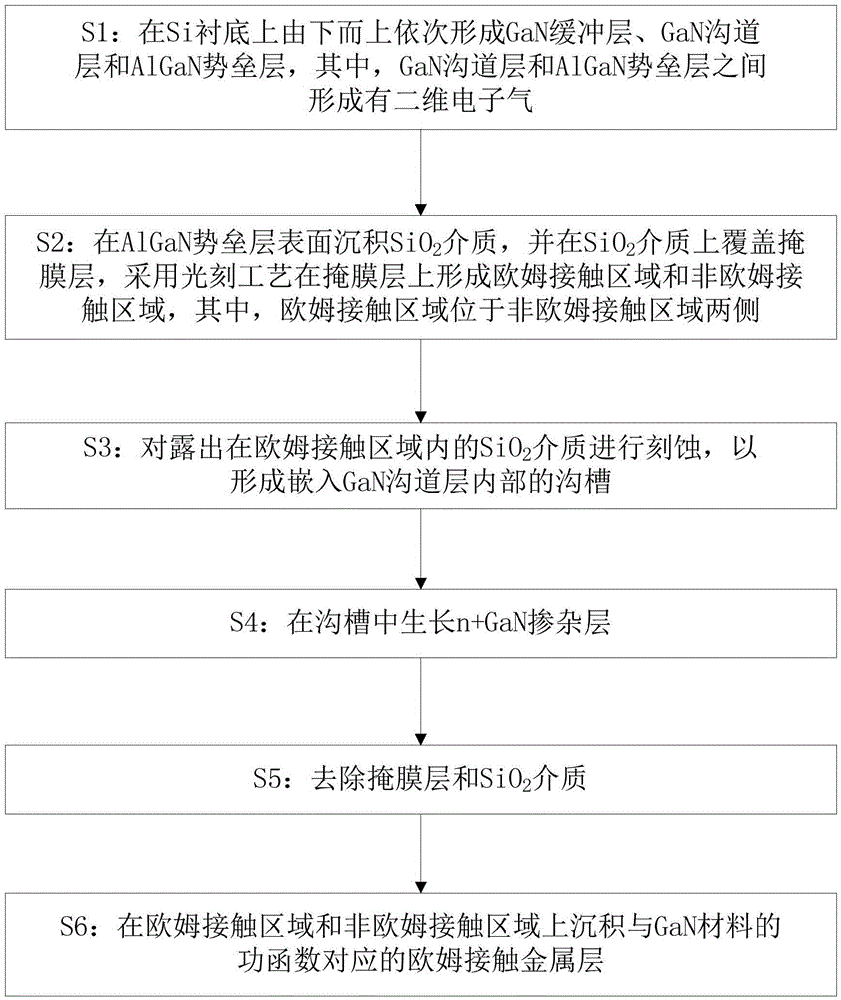

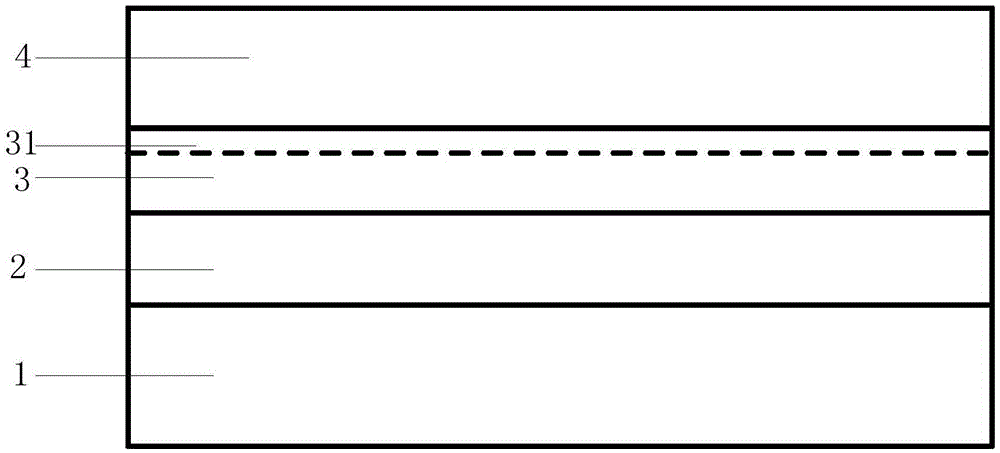

Forming method of non-alloy ohmic contact of GaN HEMT device

InactiveCN105552108AImprove reliabilityReduce roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactOptoelectronics

The invention provides a forming method of non-alloy ohmic contact of a GaN HEMT device. The method comprises the steps of: forming a GaN buffer layer, a GaN channel layer and an AlGaN barrier layer successively on a Si substrate; deposing a SiO2 medium on the surface of the AlGaN barrier layer, covering the SiO2 medium with a mask layer, and using a photoetching process to form ohmic contact areas and a non-ohmic-contact area on the mask layer, wherein the ohmic contact areas are arranged at two sides of the non-ohmic-contact area; carrying out etching on the SiO2 medium exposed in the ohmic contact areas so as to form a channel embedded in the GaN channel layer; growing a n+GaN doped layer in the channel; removing the mask layer and the SiO2 medium; and deposing an ohmic contact metal layer corresponding to a GaN material on the ohmic contact areas and the non-ohmic-contact area. By adopting the method provided by the invention, damages of high-temperature annealing to GaN crystal lattices are avoided.

Owner:CHENGDU HIWAFER SEMICON CO LTD

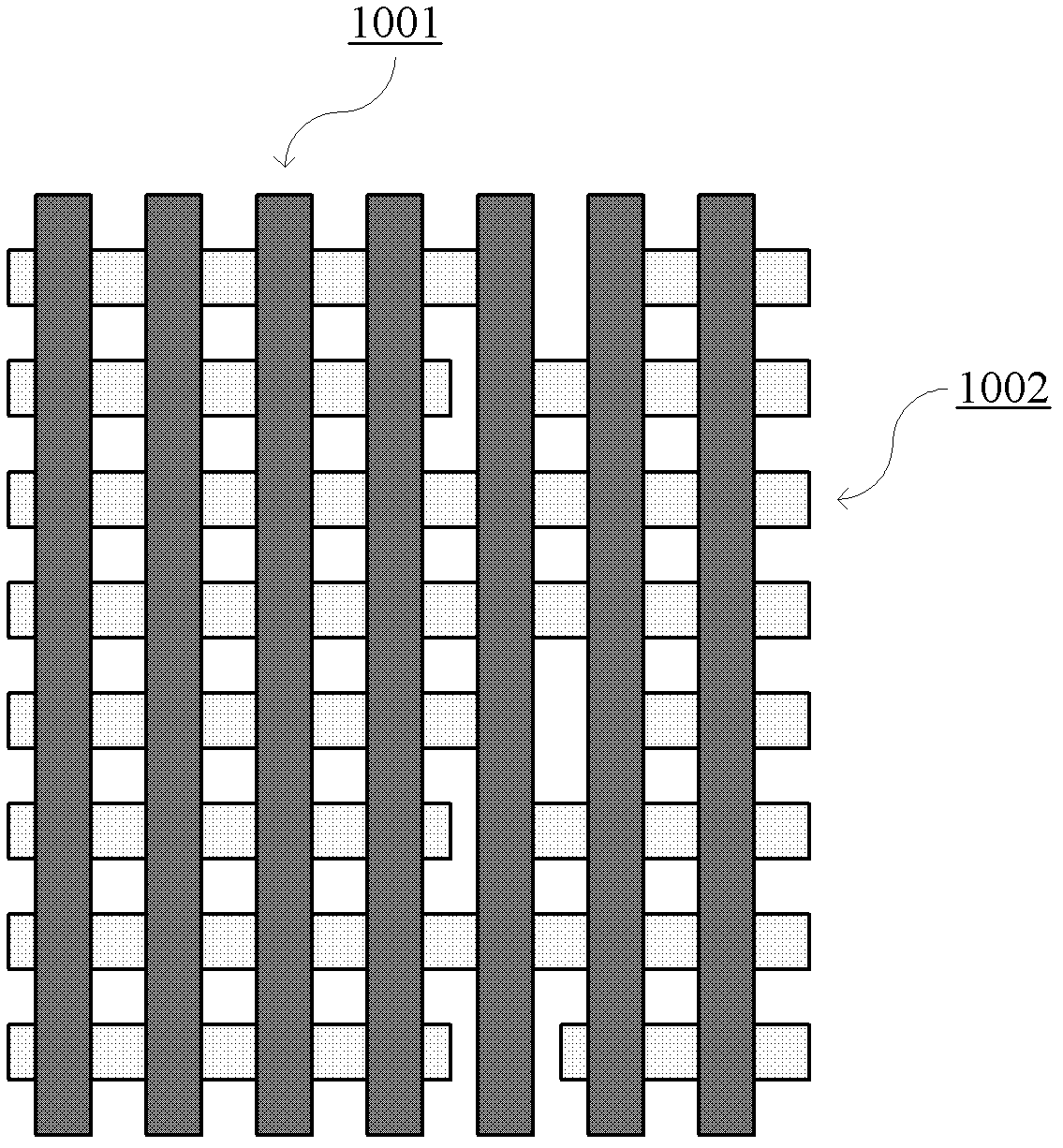

Graphene electrode, patterning preparation method of graphene electrode and array substrate

InactiveCN107104078AEasy to prepareLess difficult to patternSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistGraphene electrode

The invention discloses a graphene electrode, a patterning preparation method of the graphene electrode and an array substrate. In the patterning preparation method of the graphene electrode, firstly, oxidized graphene and photoresist are sequentially formed on a substrate; secondly, development is carried out on the photoresist by ultraviolet light through a mask; thirdly, exposed photoresist is developed by utilizing developing solution; then the corresponding exposed oxidized graphene is reduced; and finally, the residual photoresist is stripped off to obtain the patterned graphene electrode. The graphene electrode is a graphene electrode prepared by utilizing the graphene electrode patterning preparation method. The array substrate is prepared by using the graphene electrode prepared by the method as an electrode material. The method disclosed by the invention is simple in technical process, low in difficulty in patterning preparation and low in cost, and meanwhile, reduction of quality of the graphene electrode in the preparing process can also be avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

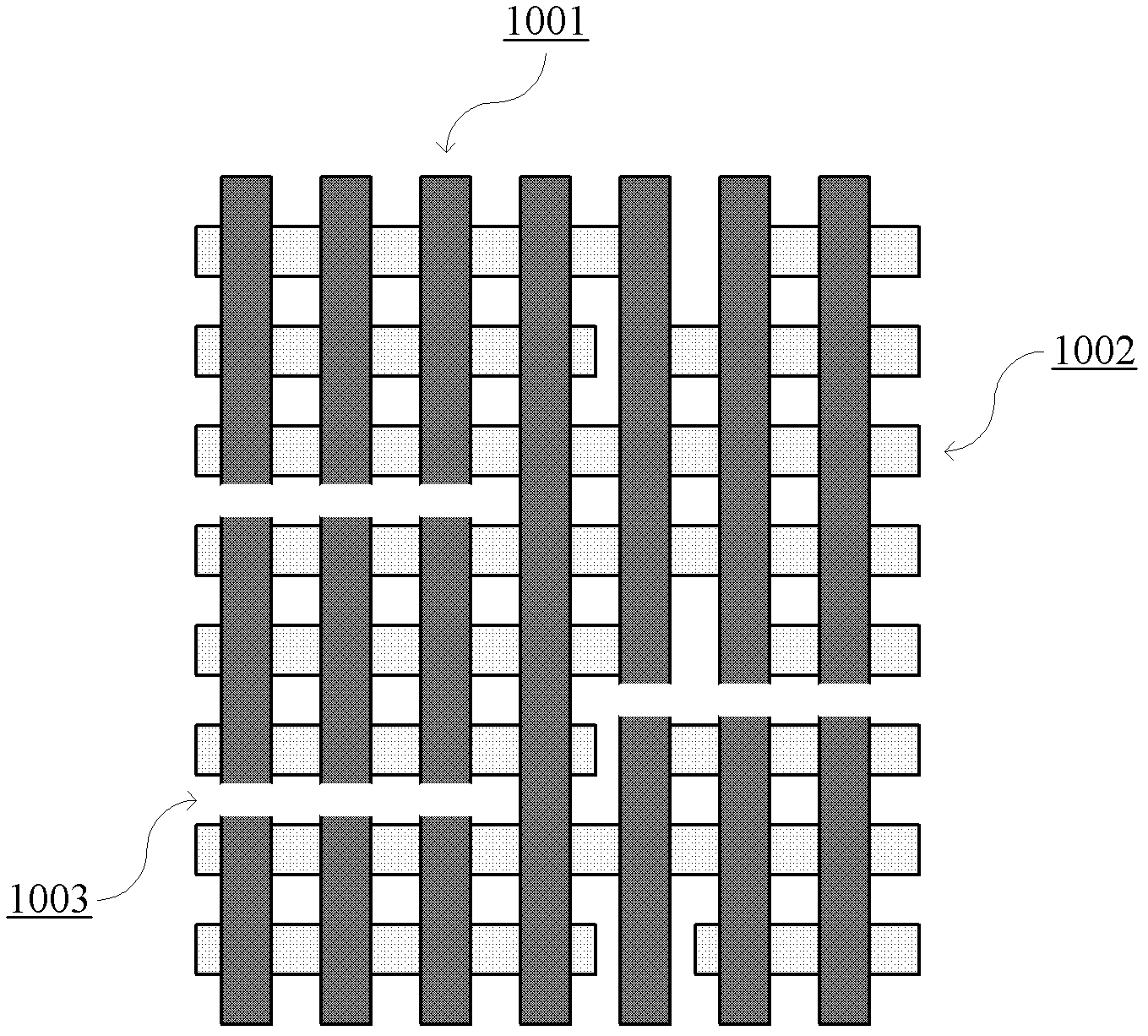

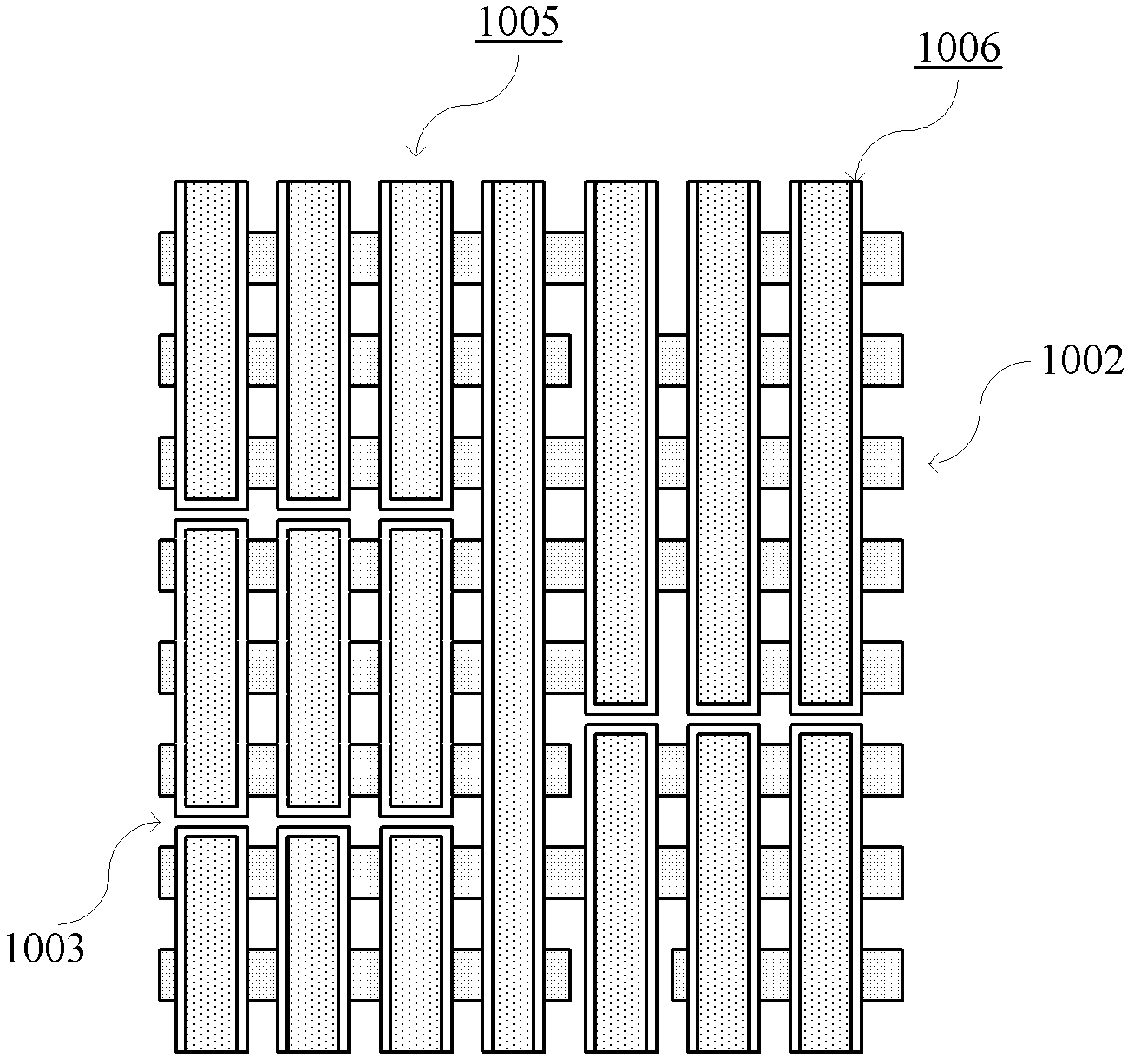

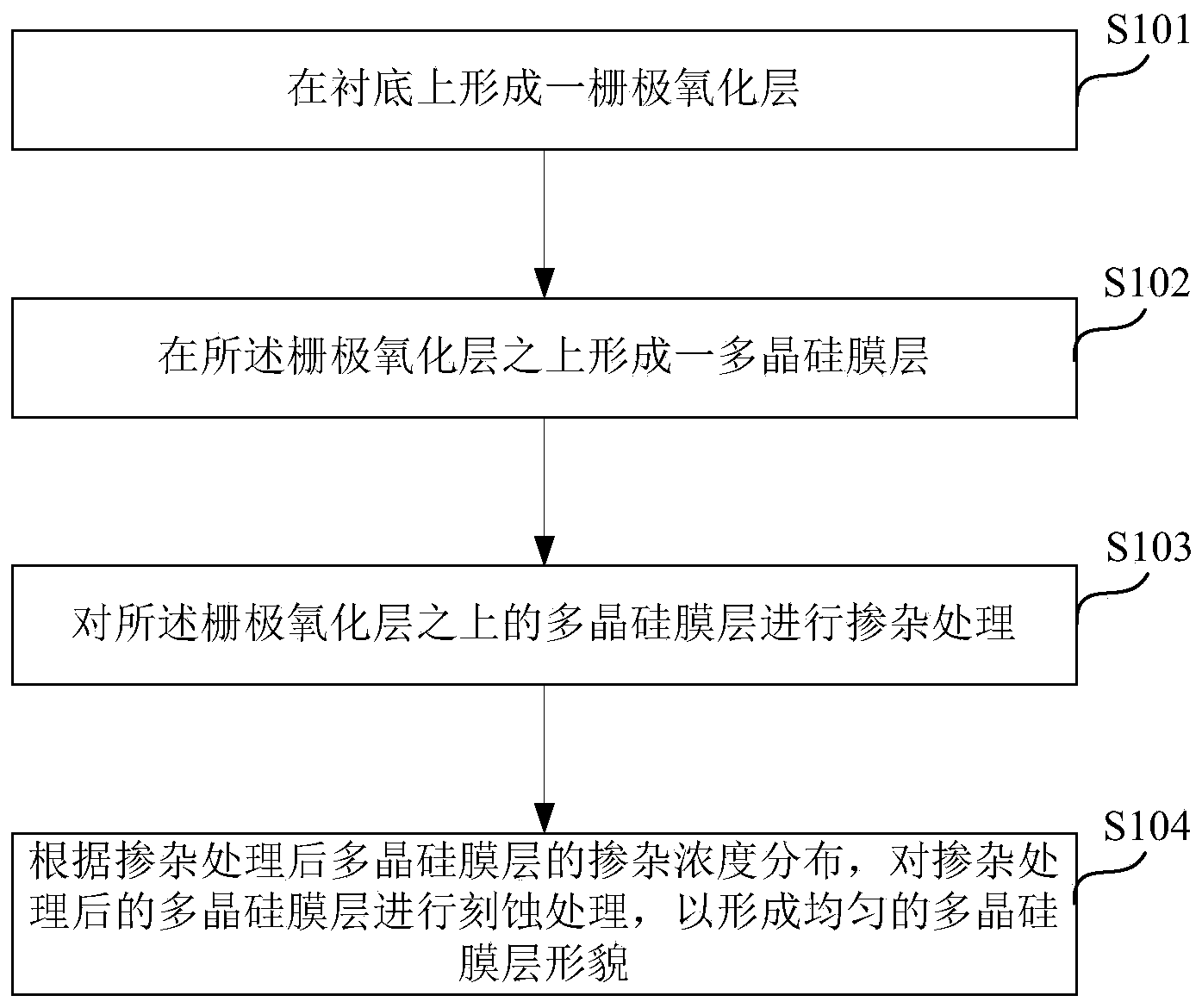

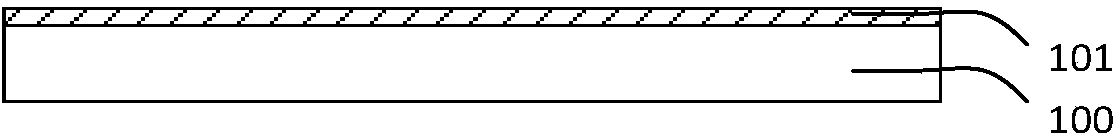

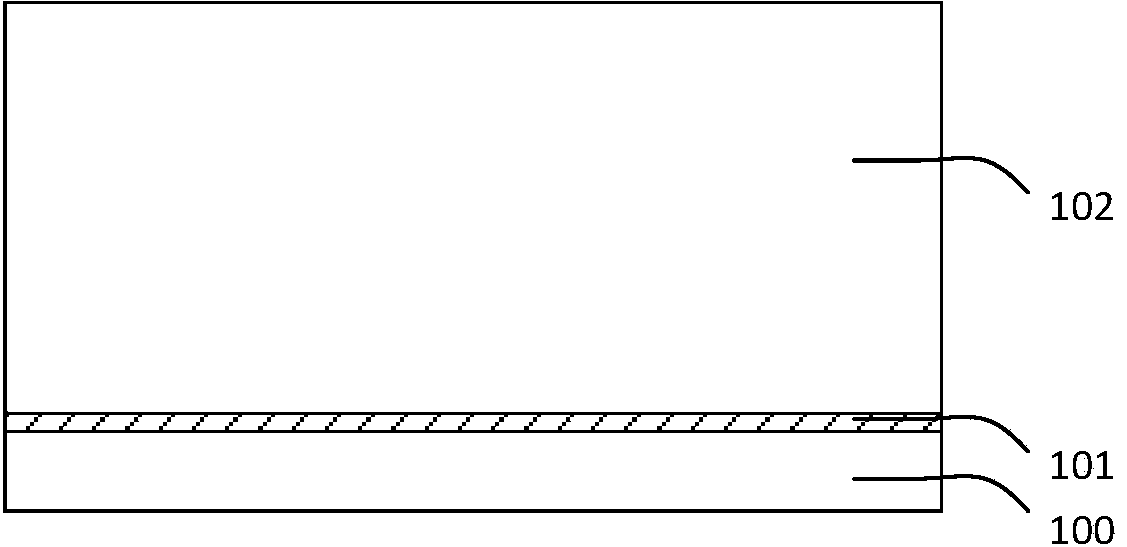

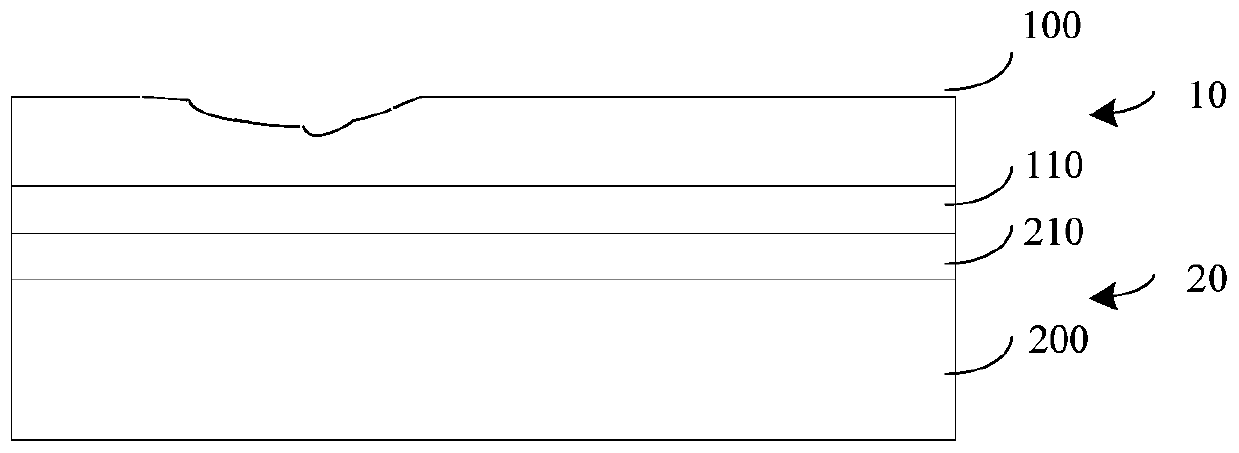

Polycrystalline silicon film morphology forming method

ActiveCN103943486AReduce or eliminate narrow edge casesLongitudinal width is uniformSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingFlow ratio

The invention discloses a polycrystalline silicon film morphology forming method and belongs to the technical field of semiconductors. The polycrystalline silicon film morphology forming method comprises the steps of forming a grid electrode oxidation layer on a substrate and forming a polycrystalline silicon film layer on the grid electrode oxidation layer; performing doping treatment on the polycrystalline silicon film layer on the grid electrode oxidation layer; performing etching treatment on the polycrystalline silicon film layer subjected to the doping treatment according to the doping concentration distribution of the polycrystalline silicon film layer subjected to the doping treatment so as to form even polycrystalline silicon film morphology. In the polycrystalline silicon film morphology forming method, the transverse etching degree is influenced by adjusting the etching gas flow ratio or step-by-step etching according to the doping concentration distribution of the polycrystalline silicon film layer subjected to the doping treatment, accordingly the polycrystalline strip narrow edge situation is relieved or eliminated, even polycrystalline strips identical in longitudinal width are obtained, and follow-up process implementation is facilitated.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

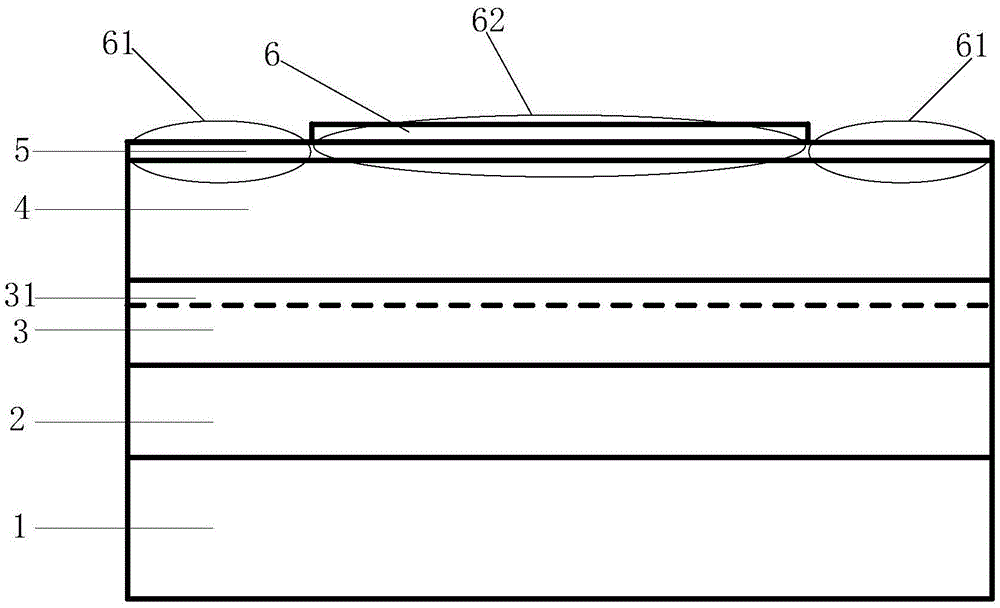

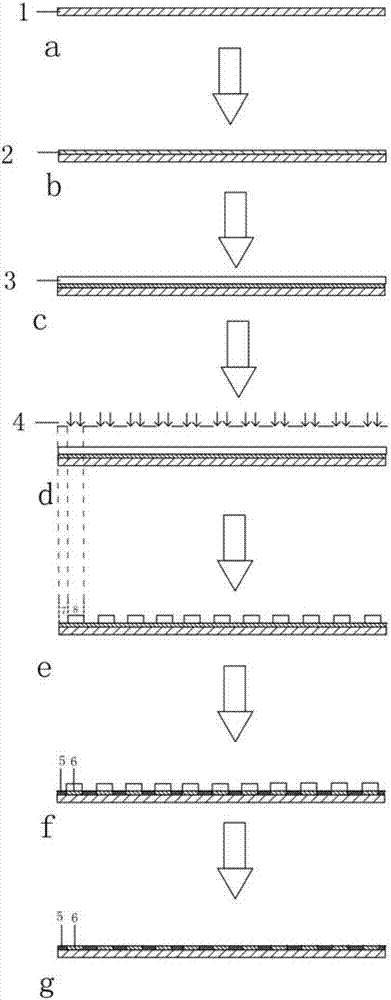

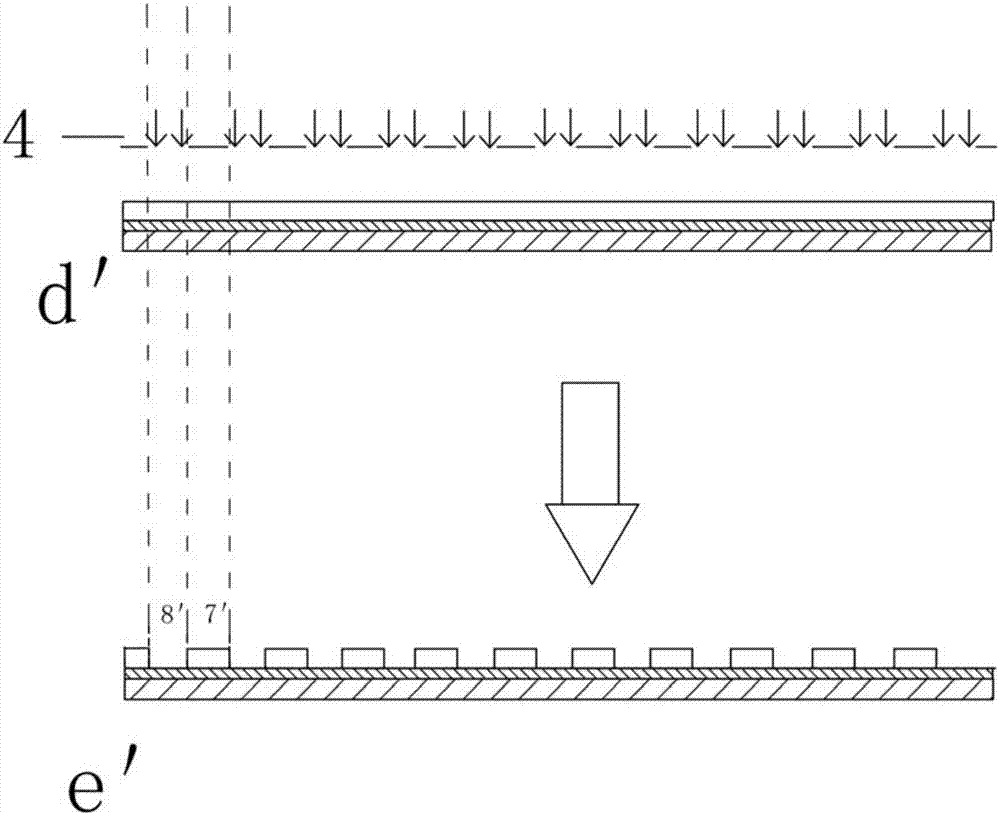

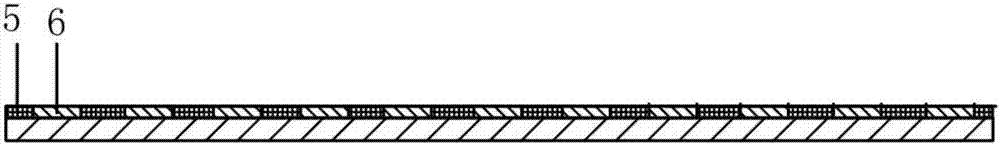

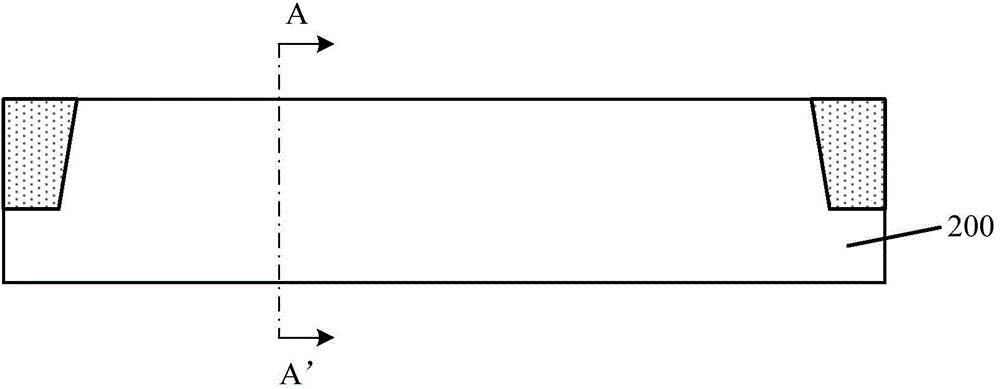

Semiconductor device and manufacturing method thereof

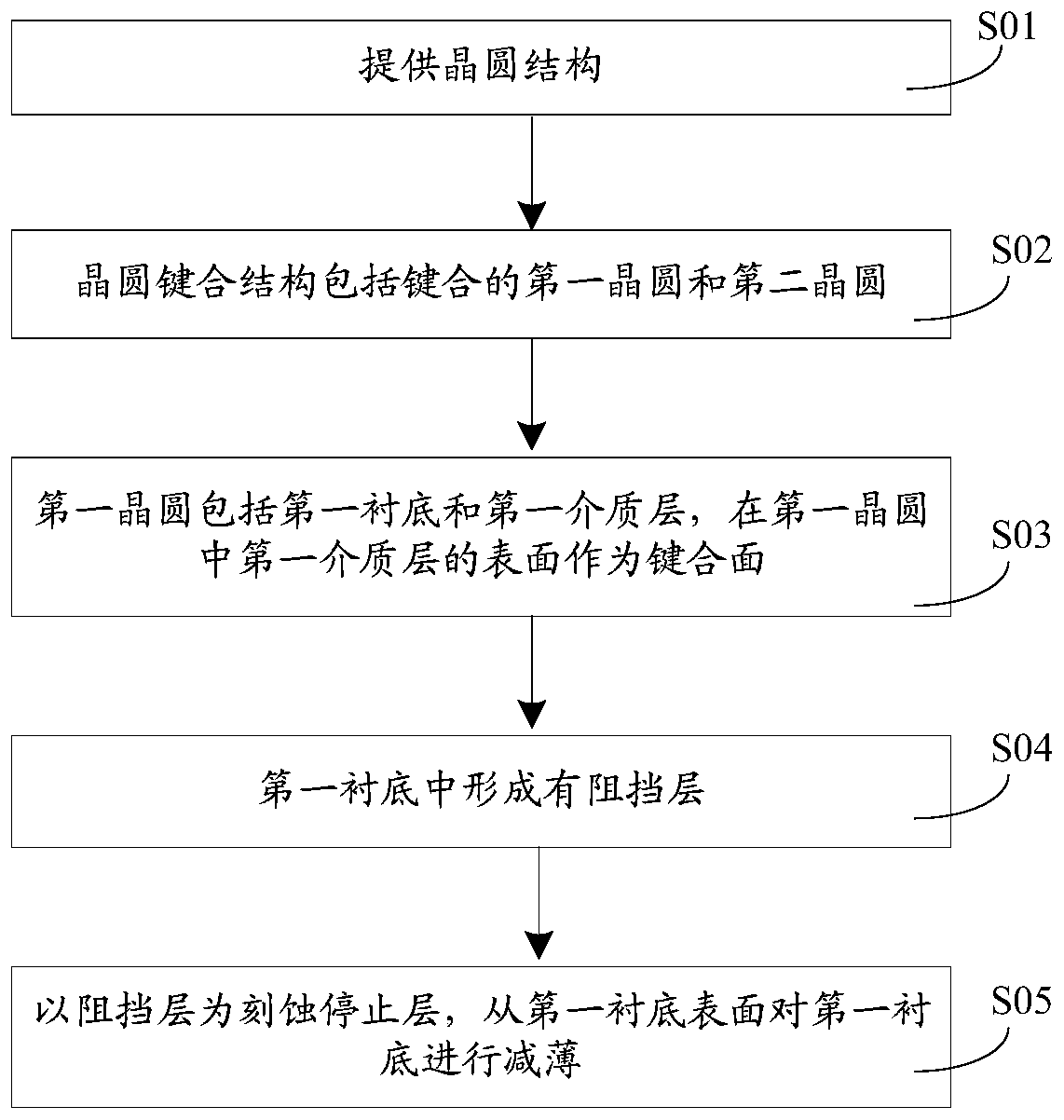

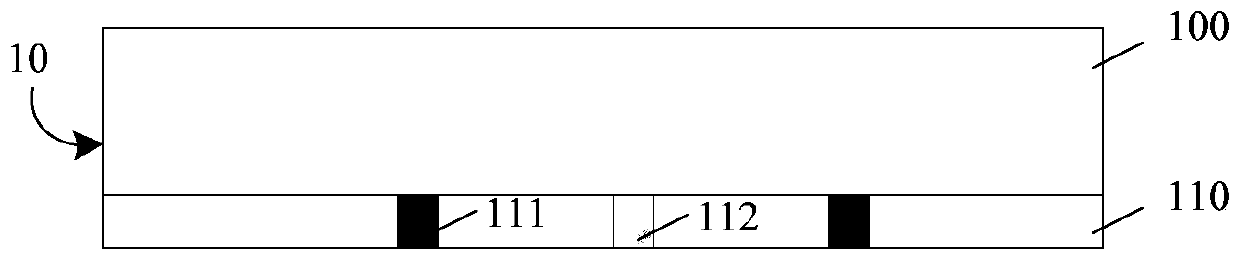

InactiveCN111564368AImprove reliabilityCause damageSemiconductor/solid-state device manufacturingDevice materialWafer bonding

The invention provides a semiconductor device and a manufacturing method thereof, and provides a wafer bonding structure, which comprises a first wafer and a second wafer which are bonded, wherein thefirst wafer comprises a first substrate and a first dielectric layer, the surface of the first dielectric layer is used as a bonding surface of the first wafer and the second wafer, a barrier layer is formed in the first substrate, and by using the barrier layer as an etching stop layer, the first substrate is thinned from the surface of the first substrate so as to remove the first substrate material above the barrier layer in the process of thinning the first wafer without damaging the barrier layer, so that the uniformity of the surface of the thinned first substrate is improved, and the subsequent process is facilitated so as to further improve the reliability of the device.

Owner:YANGTZE MEMORY TECH CO LTD

Infrared detector with micro-bridge structure and manufacturing method thereof

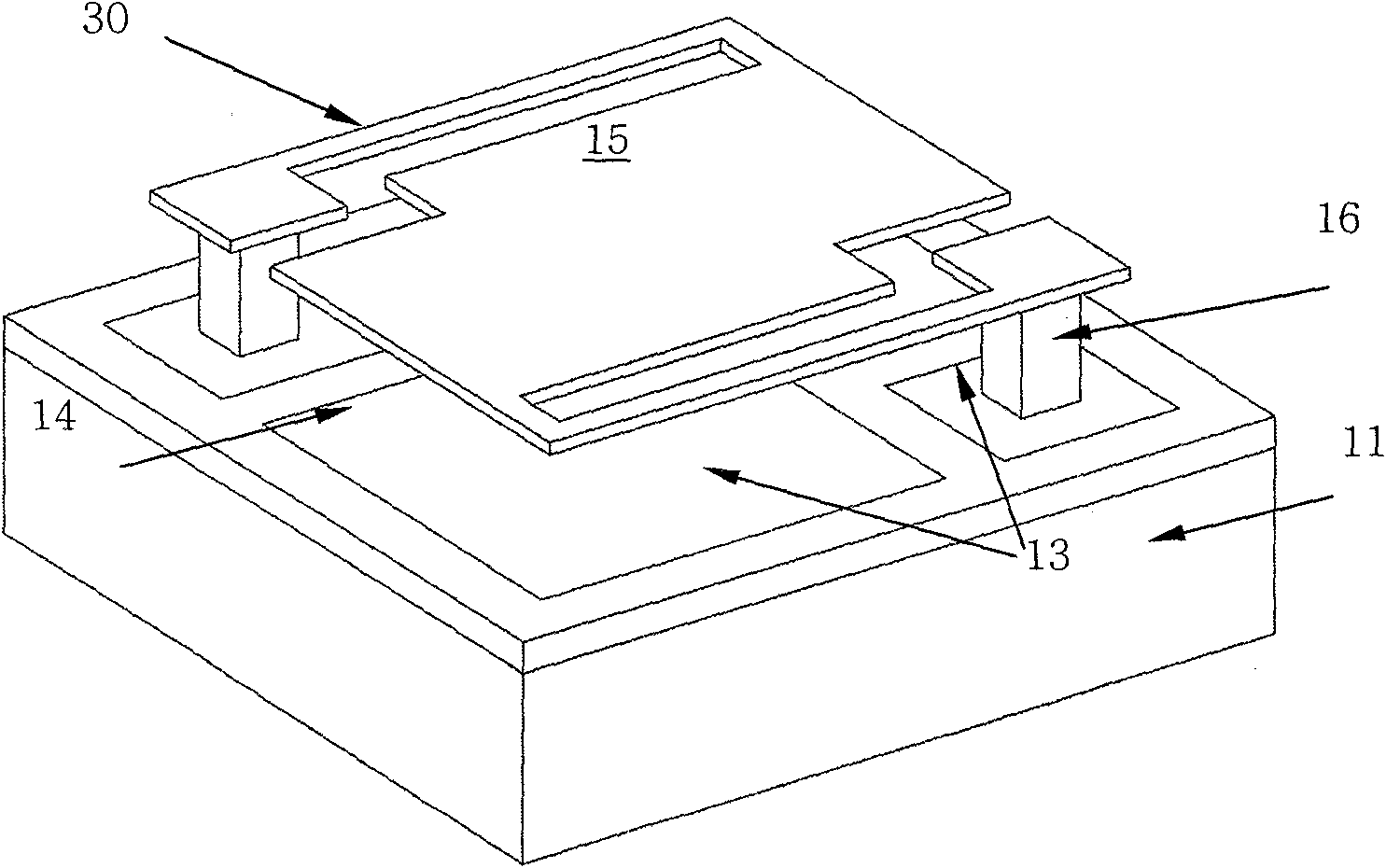

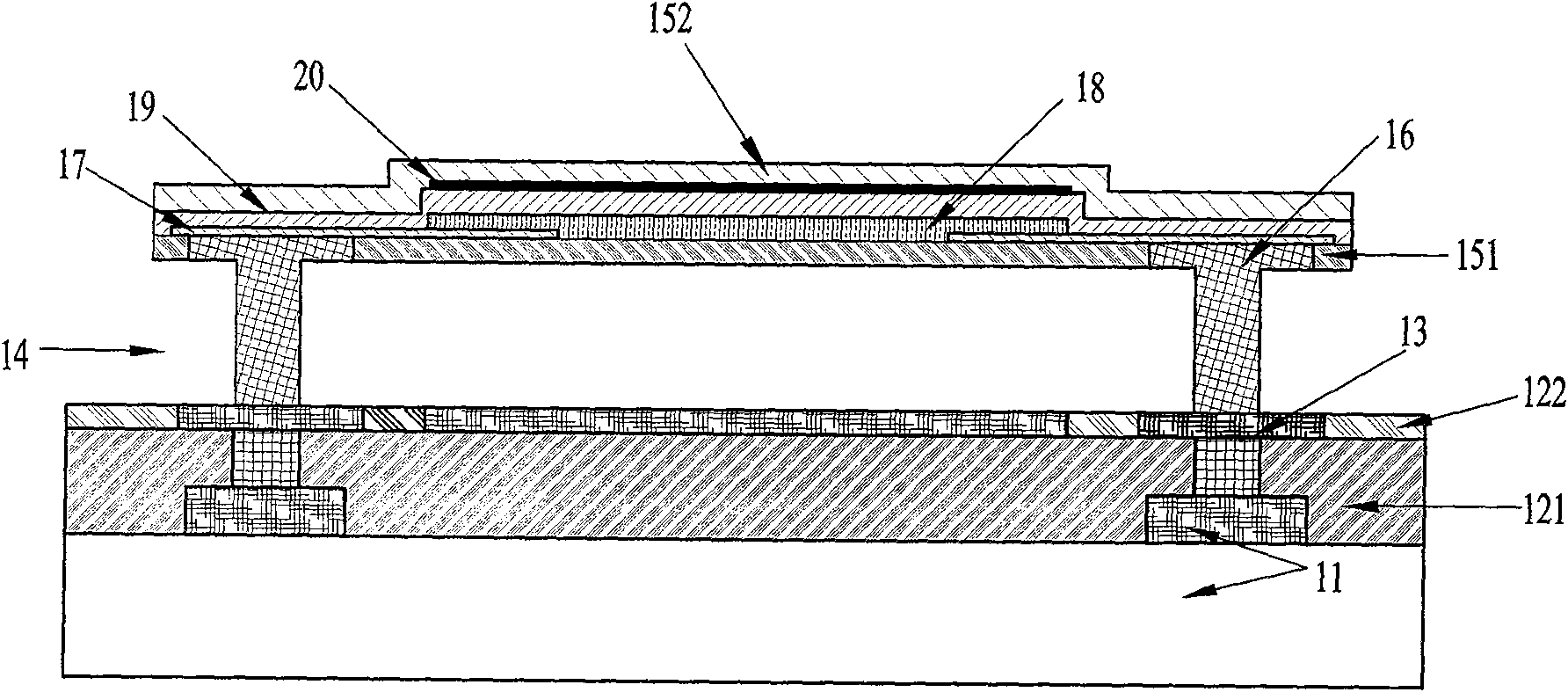

ActiveCN101927976BEasy to processGood process compatibilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectromechanicsLithographic artist

The invention relates to an infrared detector with a micro-bridge structure, which belongs to the technical field of micro-electromechanics, and comprises a silicon substrate as a read-out circuit of the infrared detector; a metal reflecting layer deposited on the silicon substrate; a dielectric layer which is deposited in a groove of the metal reflecting layer and has the height being consistent with that of the metal reflecting layer; a sacrifice layer and a first release protection layer used as protection of release of the sacrifice layer which are deposited on the dielectric layer and the metal reflecting layer and form through holes by lithography and etching; a copper or tungsten pier which is deposited in the through hole of the sacrifice layer; a metal electrode deposited on the copper or tungsten pier and the first release protection layer; and a sensitive material detecting layer which is deposited on the metal electrode and the first release protection layer. A Cu-column micro-bridge structure is manufactured by using the damascene process, and a flat micro-bridge plane is manufactured by introducing the chemical mechanical polishing process (CMP), thereby being conductive to the follow-up process and improving the performances.

Owner:ZHEJIANG DALI TECH +1

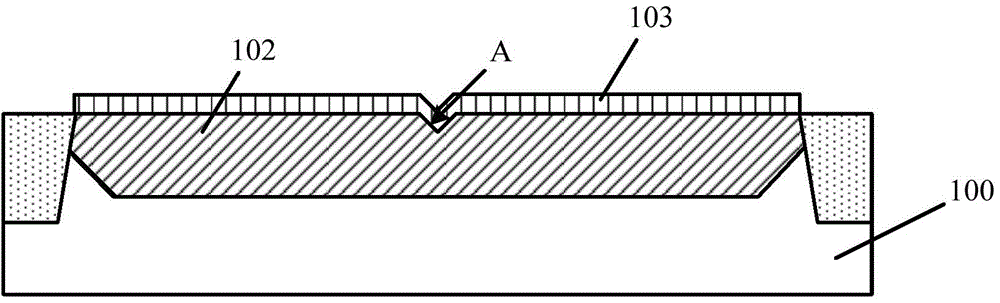

Semiconductor structure and formation method thereof

ActiveCN105826176AGood lookingImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

The invention relates to a semiconductor structure and a formation method thereof. The formation method comprises the steps of providing a substrate, wherein the surface of the substrate is provided with a pseudo gate dielectric film, and the surface of the pseudo gate dielectric film is provided with a pseudo gate film; forming a mask layer at part of the surface of the pseudo gate film, carrying out a first etching process on the pseudo gate film by taking the mask layer as a mask so as to form a first trench in the pseudo gate film, wherein the side wall of the first trench is vertical with the surface of the substrate, carrying out a second etching process on the pseudo gate film at the bottom of the first trench until the surface of the pseudo dielectric film is exposed, forming a second trench at the bottom of the first trench, forming a pseudo gate layer adjacent to the left pseudo gate film between the first trench and the second trench, wherein the top of the second trench is less than the bottom of the second trench in size, and the angle between the side wall of the second trench and the bottom surface of the second trench is an acute angle, and carrying out a third etching process on the exposed pseudo gate dielectric film until the surface of the substrate is exposed so as to form a pseudo gate dielectric layer. The formed semiconductor structure is good in appearance and improved in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

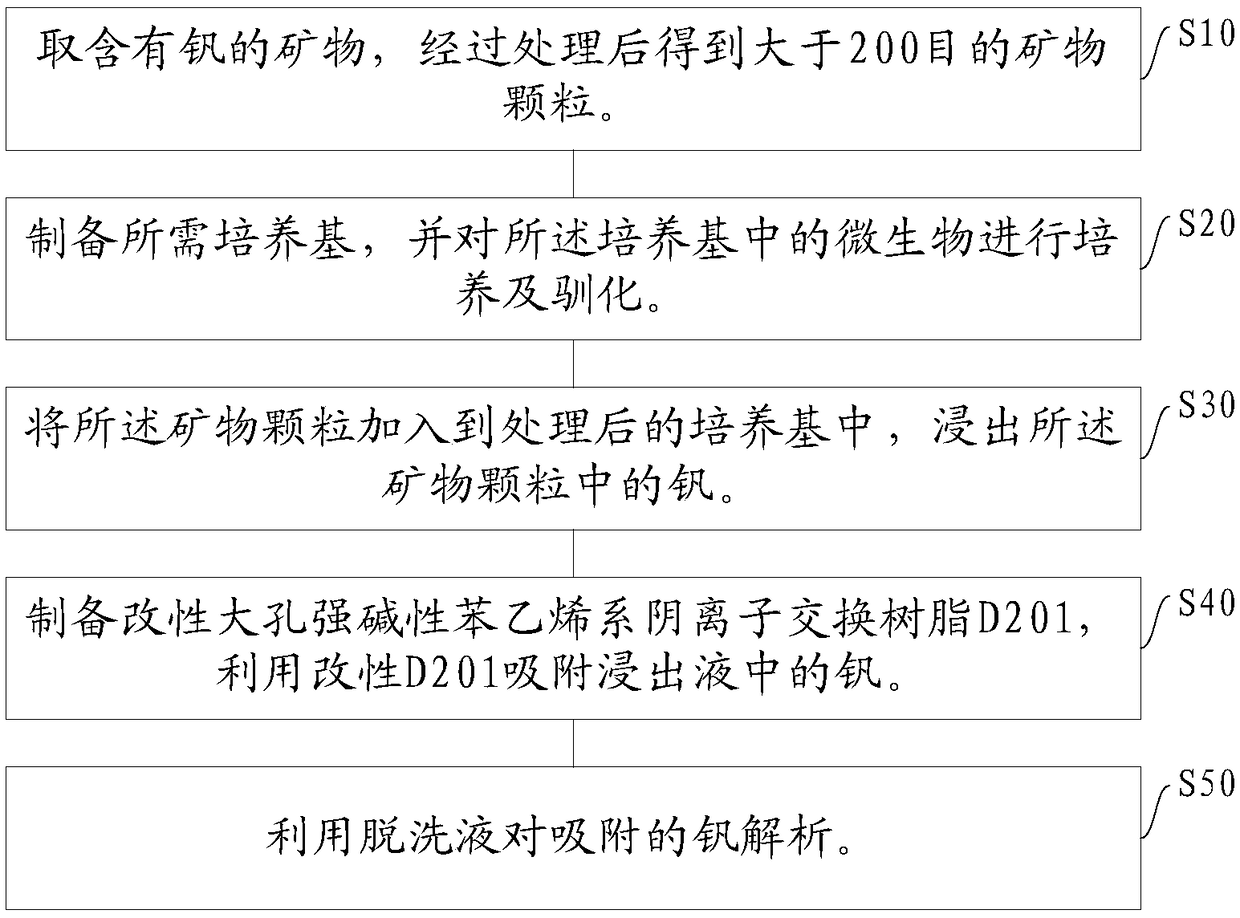

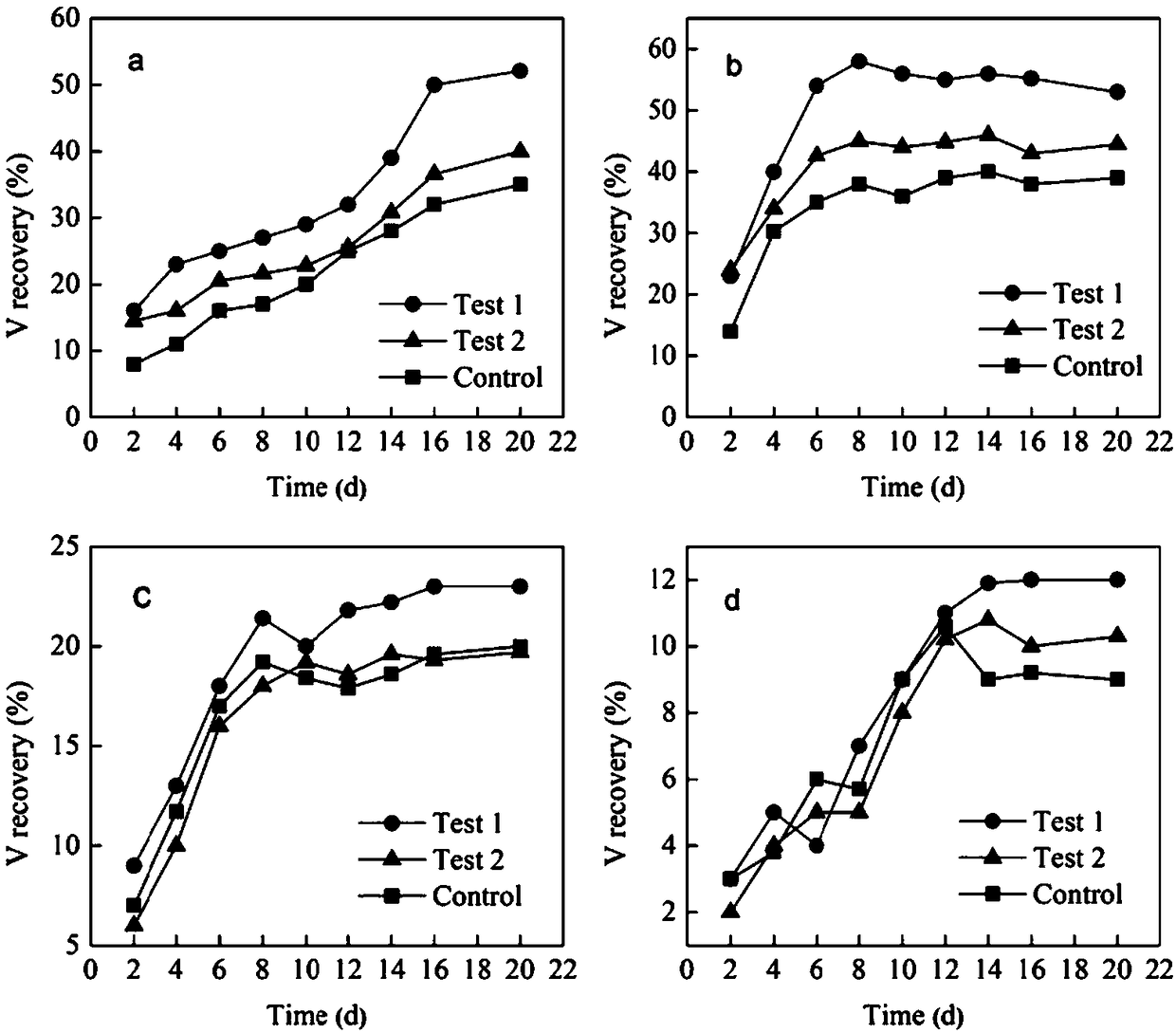

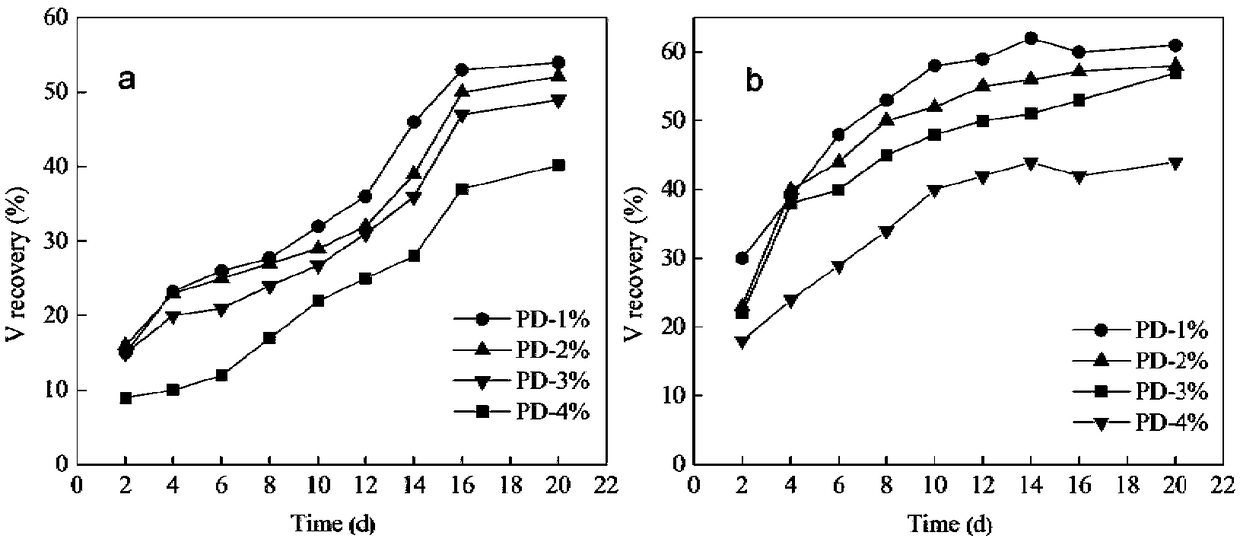

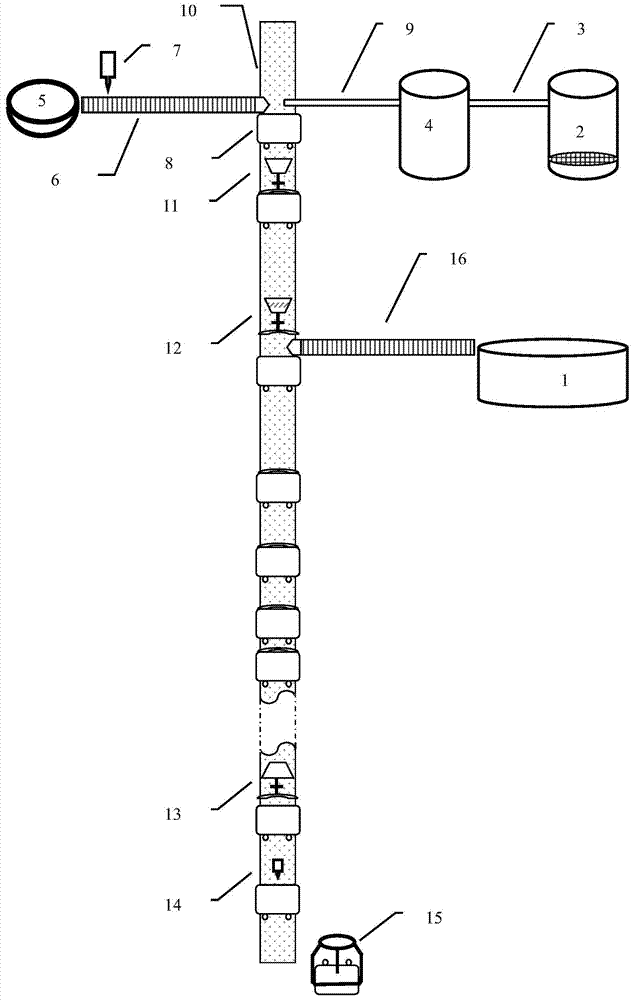

Method for microbial vanadium leaching and selective vanadium enrichment

InactiveCN108913889AHigh adsorption rateImprove leaching effectProcess efficiency improvementMicroorganismMineral particles

The invention discloses a method for microbial vanadium leaching and selective vanadium enrichment, which is summarized in an example, and the method comprises the following steps: taking and processing vanadium containing minerals to obtain mineral particles larger than 200-mesh; preparing a required culture medium, and cultivating and domesticating microorganisms in the culture medium; adding the mineral particles to the treated culture medium to leach vanadium from the mineral particles; preparing modified macroporous and strongly alkalic styrene anion exchange resin D201, and absorbing vanadium from a leachate by using the modified D201; and dissolving absorbed vanadium using an eluent. The invention adopts microbial leaching with a good leaching effect and little pollution, and adoptsmodified resin for selective adsorption with high adsorption rate and few impurities, which is beneficial to the subsequent process.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

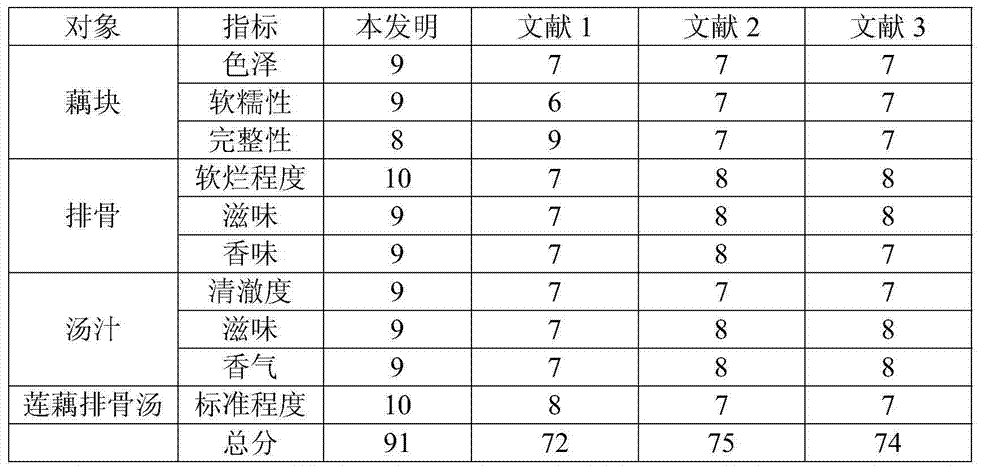

Automatic production method for lotus root and spare ribs soup cans

InactiveCN103932311AImprove qualityStable tasteAlcoholic food ingredientsNatural extract food ingredientsProduction lineEngineering

The invention discloses an automatic production method for preparing lotus root and spare ribs soup cans by adopting an automatic production line of the lotus root and spare ribs soup cans. The method comprises the following steps: adding acid into pig backbones and pig shank bones, soaking, cooking t obtain bone soup, and pressurizing and cooking with pretreated spare ribs for 30 minutes; cooking pretreated lotus roots at normal pressure for 180 minutes, naturally reducing the temperature to 60 DEG C, adding soup condiments for flavoring, reversing and pouring the soup, metering, filling, sealing and sterilizing to prepare the lotus root and spare ribs soup cans. According to the automatic production method, an initiated automatic production line of the lotus root and spare ribs soup cans is adopted, the method is safe, sanitary and high-efficiency, the instability of manual operation can be effectively avoided, the adding amount, heating pressure, temperature, time and the like of raw materials and auxiliary materials are accurately controlled, and the produced lotus root and spare ribs soup has the stable quality and mouthfeel.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI +1

Polyester polyamide and cotton bamboo blending process

InactiveCN107287729ANot easy to breakReduce the number of stoppersSucessive textile treatmentsLoomsPolyamidePolyester

The invention relates to a polyester polyamide and cotton bamboo blending process. The process includes following steps: (1), selecting polyester polyamide blended yarn; (2), selecting cotton bamboo blended yarn; (3), measuring maximum stretching limit of the cotton bamboo blended yarn, namely maximum pressure value that can be applied to the cotton bamboo blended yarn; (4), putting the polyester polyamide blended yarn into a water steamer; (5), presetting the polyester polyamide blended yarn after being treated in the step (4); (6), adopting a hydraulic loom to blend the polyester polyamide blended yarn and the cotton bamboo blended yarn at the maximum pressure value in the step (3), wherein a nozzle of 75-40 in specification is adopted for traction of the polyester polyamide blended yarn, and a nozzle of 45-20 in specification is adopted for traction of the cotton bamboo blended yarn. The polyester polyamide and cotton bamboo blending process has the advantage that the defect that finally woven products are unsatisfactory in quality due to the fact that characteristics of the polyester polyamide blended yarn and the cotton bamboo blended yarn are different when the polyester polyamide blended yarn and the cotton bamboo blended yarn are adopted for blending can be overcome.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

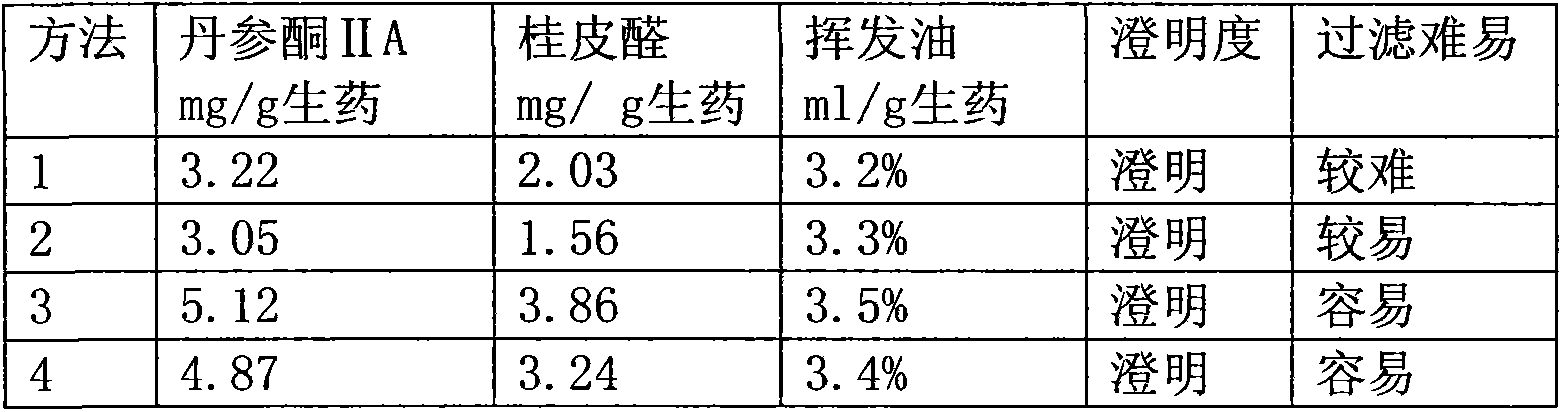

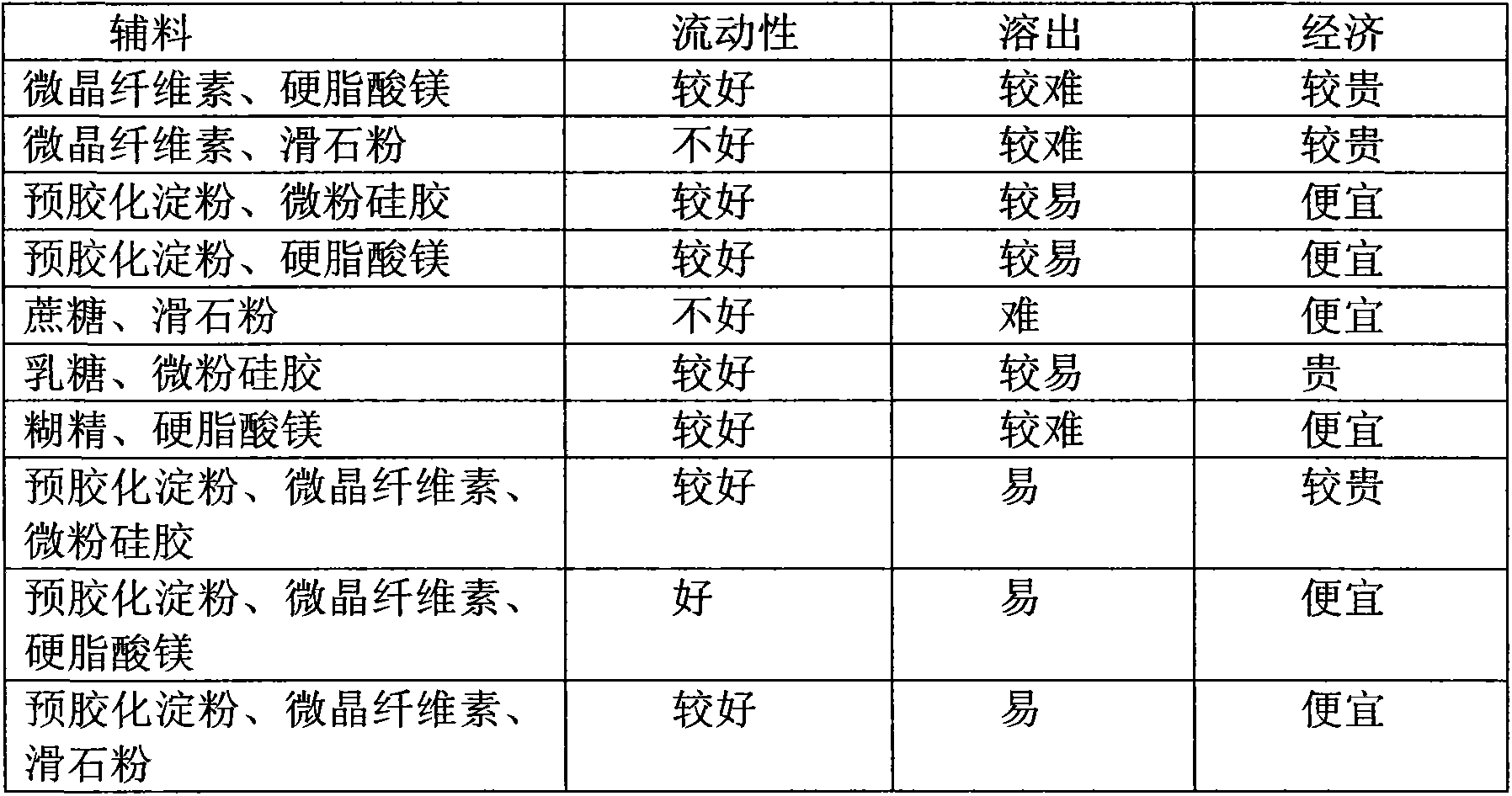

Traditional Chinese medicine composition for treating chest stuffiness and pains as well as preparation and preparation method thereof

InactiveCN103816466ATake advantage ofAvoid damageCardiovascular disorderPlant ingredientsSalvia miltiorrhizaDisease

The invention relates to a traditional Chinese medicine composition for treating chest stuffiness and pains as well as a preparation and a preparation method thereof. The composition is prepared from the following components in parts by weight: 4-20 parts of cassia twig, 2-10 parts of trichosanthes kirilowii maxim, 2-8 parts of allium macrostemon, 4-20 parts of radix salviae miltiorrhizae, 3-9 parts of sandalwood, 3-9 parts of fructus amomi, 2-10 parts of radix linderae, 4-10 parts of asarum and 4-18 parts of honey-fried licorice root. The composition is mainly used for treating a chest stuffiness and pain disease. Compared with the prior art, the traditional Chinese medicine composition and the preparation thereof disclosed by the invention are accurate in curative effect in treating a coronary disease and stenocardia caused by the chest stuffiness and pains, safe to use, reasonable in recipe, simple and convenient in preparation process and suitable for industrial large-scale production. The traditional Chinese medicine composition and the preparation thereof provide a new choice for preventing and treating the chest stuffiness and pains for a patient.

Owner:宋春兰

Method for forming semiconductor device

InactiveCN104733309AImprove electrical performanceQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricCondensed matter physics

A method for forming a semiconductor device comprises the following steps: providing a substrate, wherein the substrate is provided with a plurality of gate structures on the surface, each gate structure is composed of a gate dielectric layer disposed on the surface of the substrate, a gate electrode layer disposed on the surface of the gate dielectric layer, side walls disposed at the two sides of the gate dielectric layer and the gate electrode layer, and first spacers on the surface of the substrate, and each first spacer is provided with a second spacer on the surface; removing the second spacers to expose the first spacers; forming a third spacer on the surface of each first spacer after the second spacers are removed; forming conductive layers on the surface of the substrate at the two sides of the third spacers and the gate structures by taking the third spacers and the gate structures as masks; and removing the third spacers after the conductive layers are formed, wherein no by-product is attached to the surfaces of the substrate, the conductive layers and the gate structures in the process for forming the third spacers. The performance of a semiconductor device formed by the method is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Semiconductor structure forming method

ActiveCN106158654AInhibition of recrystallizationNot easy to cause deformationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

The invention provides a semiconductor structure forming method. The method comprises the steps of providing a substrate; forming an opening in the substrate; forming a stress layer in the opening; forming an initial covering layer on the surface of the substrate and the surface of the stress layer, wherein the material of the initial covering layer is composed of an amorphous semiconductor material; converting the part of the initial covering layer, that is positioned on the surface of the stress layer, into a covering layer through the crystallization process, wherein the material of the covering layer is composed of a crystalline semiconductor material; and removing the initial covering layer that is not converted into the covering layer after the crystallization process. The formed semiconductor structure is good in morphology and stable in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Blended spinning technology

InactiveCN107488930ANot easy to breakReduce the number of stoppersLoomsWoven fabricsPolyesterWater jet

The invention relates to a mixed textile process, which includes the following steps: (1) measuring the maximum stretchable limit of bamboo fiber silk, that is, the maximum pressure value that can be applied to it; (2) placing cotton fiber silk and polyester fiber silk in In a water steamer, steam at a water temperature of 75-85°C for 70-80 minutes; (3) place the cotton and polyester fibers treated in step (2) in a natural state for 12-16 hours; (4) Water-jet loom is used to weave cotton fiber, polyester fiber and bamboo fiber with the maximum pressure value in step (1); among them, the water-jet loom uses a nozzle with a specification of 75-40 to draw cotton fiber , use nozzles with a specification of 75-40 when drawing polyester fiber threads, and use nozzles with a specification of 45-20 when drawing bamboo fiber threads. The advantage of the present invention is that: the present invention can solve the shortcoming of unsatisfactory quality of the final weaving product caused by the different characteristics of cotton fiber and bamboo fiber when cotton fiber and bamboo fiber are used for mixed weaving.

Owner:NANTONG XIANGJIA TEXTILE SCI & TECH CO LTD

Healthcare sheep feed produced through corn straw-effective microorganisms (EM) fermentation

InactiveCN105831395AEliminate toxins from the bodyIncrease profitFood processingAnimal feeding stuffFruit juicePine pollen

Healthcare sheep feed produced through corn straw-effective microorganisms (EM) fermentation is disclosed. The feed is prepared from 450-480 parts by weight of corn straw, 4-6 parts by weight of oxalic acid, 9-12 parts by weight of sodium carbonate, 6-8 parts by weight of calcium chloride, 56-58 parts by weight of pine nut meal, 43-46 parts by weight of cassia bark broken bits, 4-6 parts by weight of Chinese date powder, 72-74 parts by weight of mung bean, 45-47 parts by weight of peach seeds, 13-15 parts by weight of pepper fruit juice, 23-26 parts by weight of fish scale powder, 15-18 parts by weight of field horsetail powder, 12-16 parts by weight of plantain herb, 14-18 parts by weight of camellia japonica, 0.4-0.6 part by weight of effective microorganisms, 1-2 parts by weight of broken pine pollen powder, 7-8 parts by weight of common yam rhizome powder, 10-12 parts by weight of seabuckthorn fruit seed powder, 3-5 parts by weight of fish meat, 2-3 parts by weight of Chinese cinquefoil powder and 5-7 parts by weight of chlorella powder. The feed is capable of improving digestion functions of sheep, regulating intestinal microecology of sheep, expelling toxins in sheep bodies and promoting body health of the sheep. The feed is rich in a plurality of vitamins and amino acids, and is capable of accelerating the sheep growth speed, increasing the weight gain rate and increasing the feed utilization rate.

Owner:SHOUXIAN LINHUAI ANIMAL HUSBANDRY BREEDING CO LTD

Preparation method of graphene thin film

The invention discloses a preparation method of a graphene thin film. The preparation method comprises the following steps: 1, adding graphene oxide into a mixed solvent and dissolving to obtain a precursor solution; 2, adding metal into the precursor solution and carrying out photocatalytic weak reduction reaction; after standing, layering to obtain weakly-reduced graphene colloid; 3, coating a substrate with the weakly-reduced graphene colloid to obtain a weakly-reduced graphene thin film attached on the surface of the substrate; 4, reducing the weakly-reduced graphene thin film attached onthe surface of the substrate and drying to obtain the graphene thin film. According to the preparation method disclosed by the invention, graphite oxide is weakly photocatalytically reduced into weakly-reduced graphene and then the weakly-reduced graphene is reduced into the graphene thin film; part of oxygen-containing groups are also remained on the weakly-reduced graphene, so that the graphenethin film has a self-assembling capability and the orderliness of the weakly-reduced graphene colloid is ensured; the quality of the graphene thin film is improved, the shrinkage and agglomeration ofthe graphene thin film in a drying process are reduced, damages to the graphene thin film are avoided and a size range of the graphene thin film is expanded.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Artificial hemp weaving process

InactiveCN102367628AFeatures matchConducive to follow-up processLiquid/gas/vapor textile treatmentEngineeringPre treatment

The invention discloses an artificial hemp weaving process. In the artificial hemp weaving process, when artificial silk and dacron filaments are blended and woven into fabrics, i.e. artificial hemp, firstly, the artificial silk is placed into a water steaming box to be steamed for 80 minutes at the water temperature being 75 to 80 DEG C, the pre-forming is carried out for 12 to 20 hours after the artificial silk is taken out, and then, the artificial silk and the dacron filaments are fed into a knitting machine to be blended and woven into fabrics, i.e. the artificial hemp. When the process is adopted, different characteristics of the artificial silk and the dacron filaments are considered, and the artificial silks are pretreated, so the characteristics of the artificial silk more conform to the characteristics of the dacron filaments, the proceeding of the subsequent process is more favorably realized, and the quality of the finally woven products is improved.

Owner:SUZHOU DONGMAO TEXTILE IND

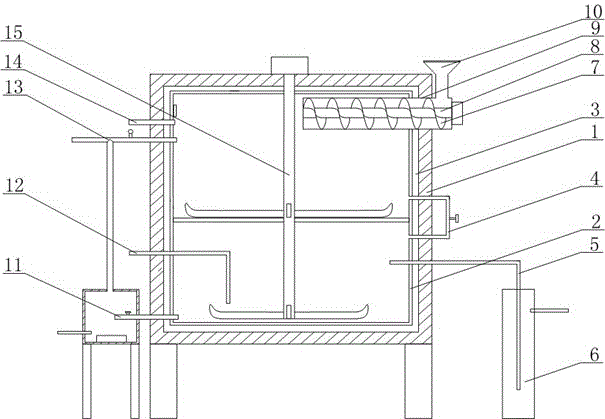

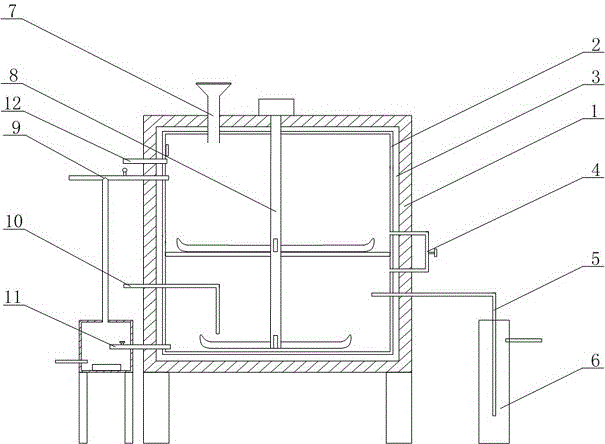

Oxygen separating system used for producing steel wooden door metal material

InactiveCN105861839AReduce workloadShorten melting timeCharge composition/stateCharge manipulationHydrogenSpiral blade

The invention discloses an oxygen separating system used for producing a steel wooden door metal material. The oxygen separating system comprises an outer furnace shell, an inner furnace shell and an electric heating layer, a baffle is arranged in the inner furnace shell and internally divides the inner furnace shell into a melting chamber and a refining chamber, a charging pipe is arranged on the outer furnace shell, a connecting pipe, a discharging pipe, a first air inlet pipe, a second air inlet pipe, a second exhausting pipe, a first exhausting pipe and a conveying pipe are arranged outside the outer furnace shell, and a conveying shaft is arranged in the conveying pipe, penetrates through the end face of the conveying pipe to the outer space and is connected with a driving device, and a spiral blade is arranged around the conveying shaft. The feeding mode is improved, a workpiece can be conveyed to the melting chamber while preheated, the refining chamber and a casting box are arranged, mixed gas is introduced into molten aluminum in the refining chamber to remove aluminum oxide and hydrogen in the molten aluminum, the quality of the molten aluminum is improved, and it is ensured that the molten aluminum does not make contact with air in the casting process; the working environment is improved as a tail gas purifying device is further arranged.

Owner:成都森邦世纪木业有限公司

Cotton cellosilk and bamboo cellosilk mixed spinning process

The invention relates to a cotton cellosilk and bamboo cellosilk mixed spinning process. The cotton cellosilk and bamboo cellosilk mixed spinning process comprises the following steps: (1) measuring a maximum extension extent of bamboo cellosilk, namely measuring the value of maximum pressure which can be applied to the bamboo cellosilk; (2) placing cotton cellosilk in a water steaming box, and steaming for 70-80 minutes at the water temperature of 75-85 DEG C; (3) pre-shaping the cotton cellosilk which is treated in the step (2) in a natural state for 12-16 hours; and (4) carrying out mixed spinning on the cotton cellosilk and the bamboo cellosilk through a hydraulic loom by the maximum pressure value obtained in the step (1). When the hydraulic loom pulls the cotton cellosilk, a nozzle with the specification of 75-40 is used; and when the hydraulic loom pulls the bamboo cellosilk, a nozzle with the specification of 45-20 is used. The cotton cellosilk and bamboo cellosilk mixed spinning process has the advantages that the shortcoming of poor quality of woven products due to different characteristics of the cotton cellosilk and the bamboo cellosilk during mixed spinning by the cotton cellosilk and the bamboo cellosilk can be overcome.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Blended spinning technology of woven fabric cellosilk

The invention discloses a blended spinning technology of woven fabric cellosilk. The blended spinning technology comprises the following steps that 1, the maximum stretchable limit of bamboo cellosilk, namely the maximum pressure value which can be applied to the bamboo cellosilk is measured; 2, cotton cellosilk is placed into a water steaming box, wherein the water temperature is 75-85 DEG C, andthe steaming time is 70-80 minutes; 3, the cotton cellosilk processed in the step 2 is placed under a natural state and preformed for 12-16 hours; 4, the cotton cellosilk and the bamboo cellosilk aresubjected to blended spinning by using a water jet loom with the maximum pressure value in the step 1, wherein a nozzle of the specification of 7540 is adopted by the water jet loom during traction of the cotton cellosilk, and a nozzle with the specification of 4520 is adopted during traction of the bamboo cellosilk. The blended spinning technology has the advantages that the technology can solvethe problems that when the cotton cellosilk and the bamboo cellosilk are used for blended spinning, the quality of finished woven products is not satisfactory due to different characteristics of thecotton cellosilk and the bamboo cellosilk.

Owner:江阴市博帆化纺有限公司

Production system for steel wooden door metal raw material

InactiveCN105890358AQuality improvementConducive to follow-up processCrucible furnacesExhaust gasAluminum can

The invention discloses a production system for a steel wooden door metal raw material. The production system comprises an outer furnace shell, an inner furnace shell and an electric heating layer; a baffle is arranged in the inner furnace shell and divides the internal part of the inner furnace shell into a melting chamber and a refining chamber, a feeding pipe is arranged on the upper portion of the outer furnace shell, the outer side of the outer furnace shell is provided with a connecting pipe, a discharging pipe, a first gas inlet pipe, a second gas inlet pipe, a second exhaust pipe and a first exhaust pipe, the connecting pipe is communicated with the melting chamber and the refining chamber, the discharging pipe is communicated with a casting box and the refining chamber, the first gas inlet pipe is communicated with an external space, the melting chamber and the refining chamber, the second gas inlet pipe is communicated with the external space and the refining chamber, and the first exhaust pipe is communicated with the external space and the melting chamber. According to the production system, the refining chamber and the casting box are arranged, the purpose of removing aluminum oxide and hydrogen in molten aluminum is achieved by introducing mixed gas into molten aluminum contained in the refining chamber, and the molten aluminum quality is improved; in addition, a tail gas purifying device is arranged, and therefore the working environment is improved; it is guaranteed that molten aluminum cannot make contact with air in the casting process through the casting box.

Owner:成都森邦世纪木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com