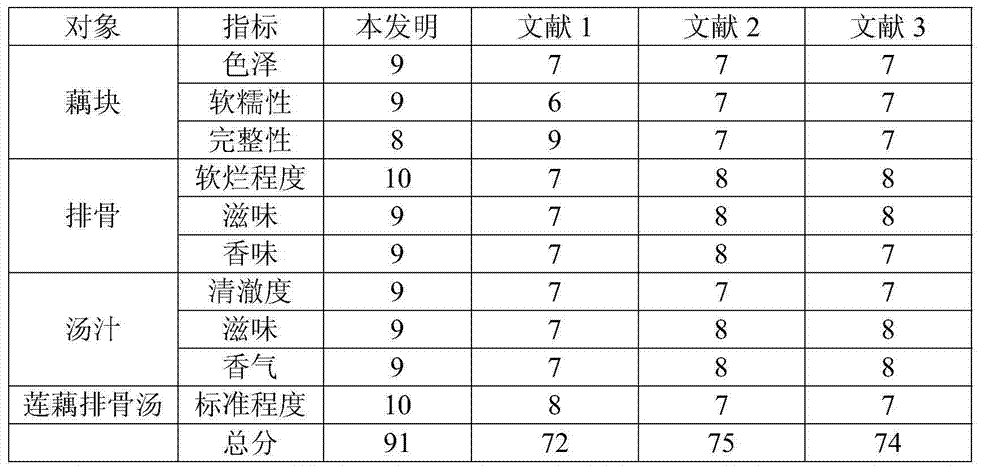

Automatic production method for lotus root and spare ribs soup cans

An automated production line and production method technology, which is applied to the functions of food ingredients, food ingredients containing alcohol, food ingredients containing natural extracts, etc., can solve problems such as short shelf life, difficulty in establishing one's own brand, and high labor intensity, and achieve stability Quality and taste, avoiding instability, maintaining product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

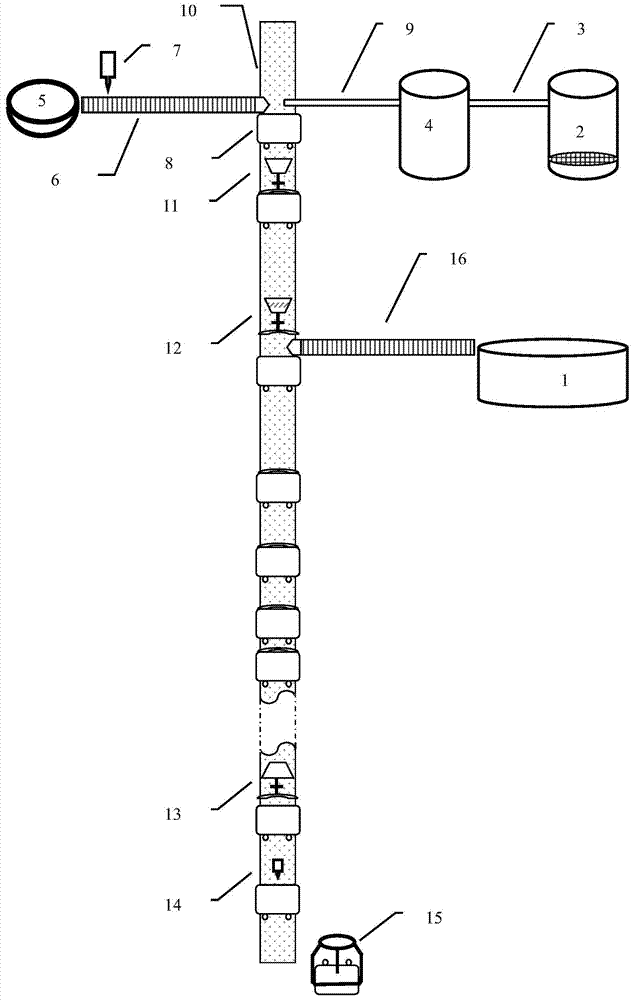

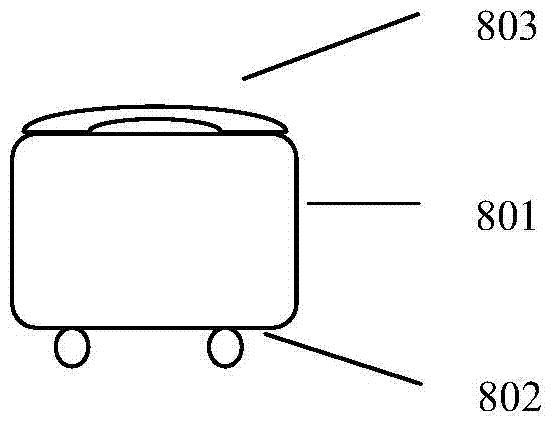

[0033] An automatic production method for canned lotus root and ribs soup is completed by using an automatic production line for canned lotus root and ribs soup. The described automatic production line for canned lotus root pork ribs soup comprises a immersion pool (1), a cooking pot (2) with a filter screen at the bottom, an insulated tank (4), an oil pan (5) and an automatic electric heating system; the automatic electric heating system includes A track (10) for the horizontal movement of the automatic electric heating pan (8) and several automatic electric heating pans (8) on it, and a capping machine (11), a capping and uncapping integrated machine (12), an openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com