Preparation method of nanoimprint hard templates

A technology of nano-imprinting and hard template, applied in the direction of photo-engraving process of pattern surface, opto-mechanical equipment, originals for opto-mechanical processing, etc., can solve the problems of low efficiency, unrealistic, fragile and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

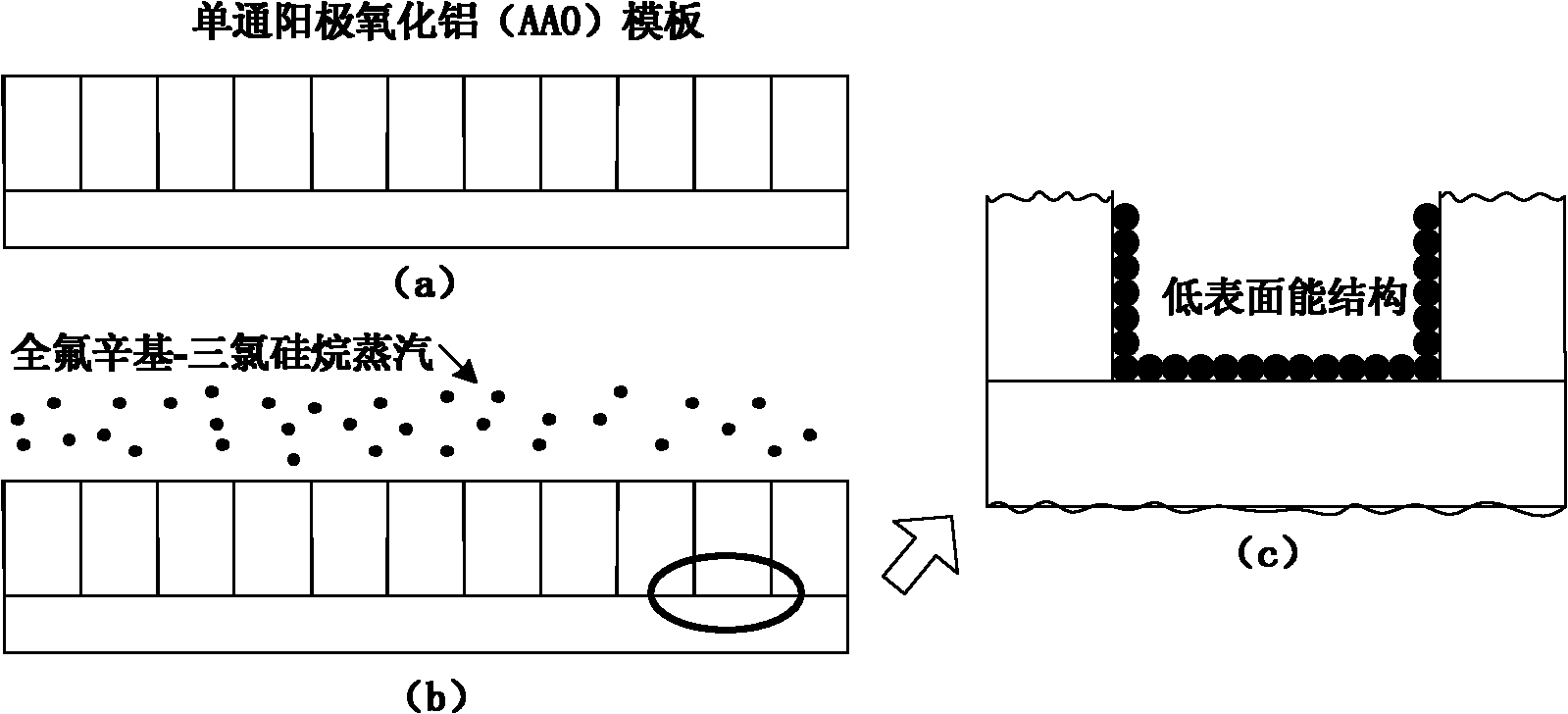

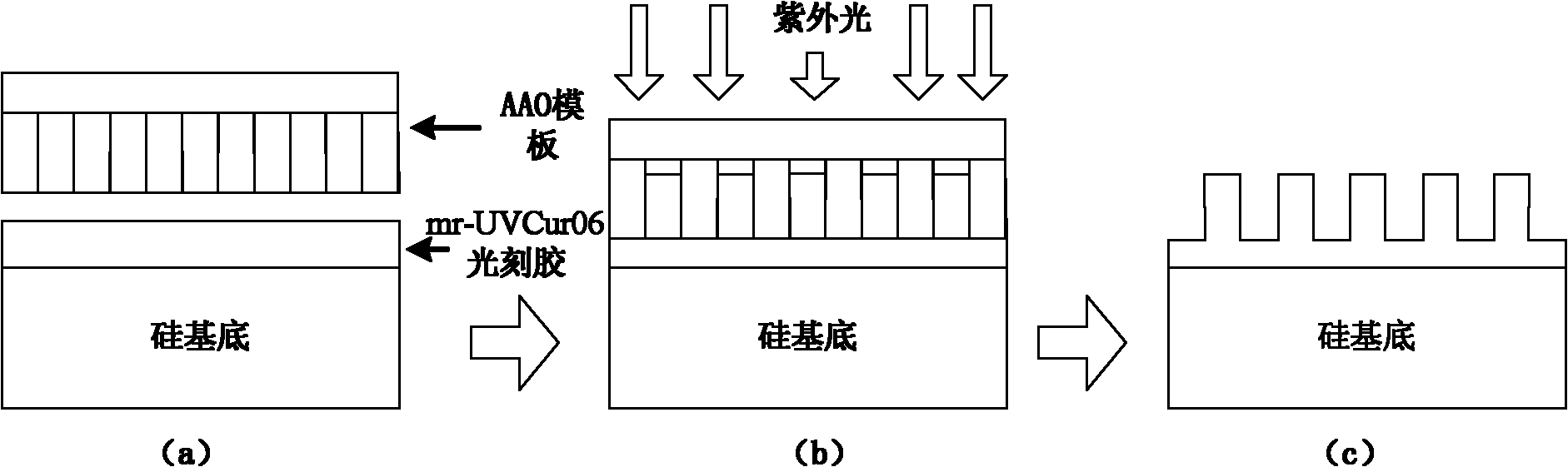

[0031] 1. First, a two-step electrochemical anodization method is used to prepare a regular anodized aluminum AAO template with adjustable size, ie, pore diameter, pore spacing, and pore depth, in a 0.1-0.5mol / L oxalic acid solution. The anode voltage is 40-50V. The temperature is 0-15°C, the first oxidation time is 2 hours, and the second oxidation time is 3-5 minutes. 3 PO 4 Reaming is carried out in the middle, and the AAO template of the required size is obtained as figure 1 as shown in (a);

[0032] 2. Next, under a standard atmospheric pressure and normal temperature, vapor-deposit the AAO template in the vapor atmosphere of perfluorooctyl-trichlorosilane for 80 to 100 minutes, and then bake it at 100°C for 13 to 15 minutes. A dense layer of organic molecules is formed, and this thin film makes the surface of the template have a very low surface energy, about 12 dynes / cm. figure 1 (b) is a schematic diagram of evaporation, figure 1 (c) is a schematic diagram of a low...

Embodiment 2

[0039] 1. First, a two-step electrochemical anodization method is used to prepare a regular anodized aluminum AAO template with adjustable size, ie, pore diameter, pore spacing, and pore depth, in a 0.1-0.5mol / L oxalic acid solution. The anode voltage is 40-50V. The temperature is 0-15°C, the first oxidation time is 2 hours, and the second oxidation time is 3-5 minutes. 3 PO 4 Reaming is carried out in the middle, and the AAO template of the required size is obtained as figure 1 as shown in (a);

[0040] 2. Next, under a standard atmospheric pressure and normal temperature, vapor-deposit the AAO template in the vapor atmosphere of perfluorooctyl-trichlorosilane for 80 to 100 minutes, and then bake it at 100°C for 13 to 15 minutes. A dense layer of organic molecules is formed, and this thin film makes the surface of the template have a very low surface energy, about 12 dynes / cm. figure 1 (b) is a schematic diagram of evaporation, figure 1 (c) is a schematic diagram of a low...

Embodiment 3

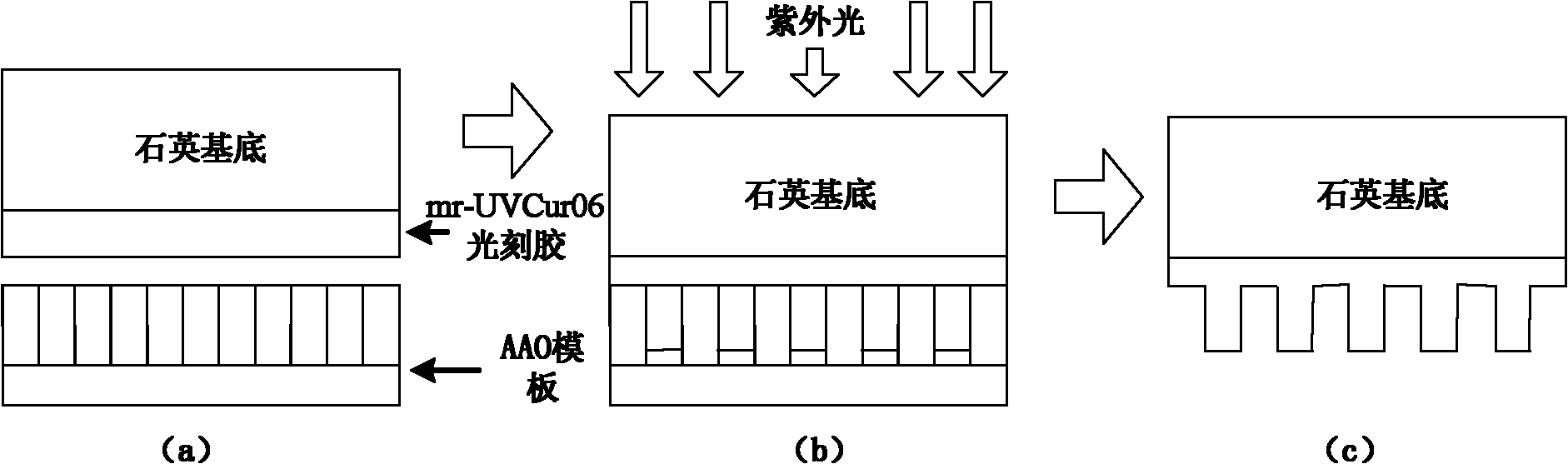

[0047] 1. First, a two-step electrochemical anodization method is used to prepare a regular anodized aluminum AAO template with adjustable size, ie, pore diameter, pore spacing, and pore depth, in a 0.1-0.5mol / L oxalic acid solution. The anode voltage is 40-50V. The temperature is 0-15°C, the first oxidation time is 2 hours, and the second oxidation time is 3-5 minutes. 3 PO 4 Reaming is carried out in the middle, and the AAO template of the required size is obtained as figure 1 as shown in (a);

[0048] 2. Next, under a standard atmospheric pressure and normal temperature, vapor-deposit the AAO template in the vapor atmosphere of perfluorooctyl-trichlorosilane for 80 to 100 minutes, and then bake it at 100°C for 13 to 15 minutes. A dense layer of organic molecules is formed, and this thin film makes the surface of the template have a very low surface energy, about 12 dynes / cm. figure 1 (b) is a schematic diagram of evaporation, figure 1 (c) is a schematic diagram of a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com