Production system for steel wooden door metal raw material

A metal raw material and production system technology, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of low quality aluminum alloy castings, contact with air, and lack of refining effect, so as to improve quality, avoid damage, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

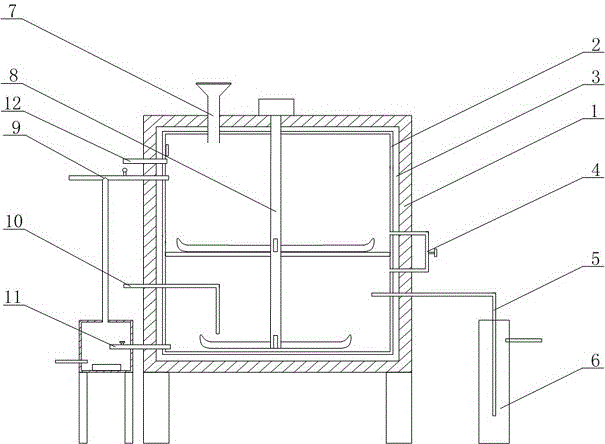

[0028] Such as figure 1As shown, the present invention is a production system for steel and wood door metal raw materials, including a furnace shell 1, a furnace inner shell 2 is arranged inside the furnace shell 1, and an electric heating layer 3 is arranged between the furnace shell 1 and the furnace inner shell 2 , the furnace inner shell 2 is provided with a baffle, and the baffle divides the inner space of the furnace inner shell 2 into two parts, wherein the upper part is a melting chamber, and the lower part is a refining chamber, and a feeding pipe 7 is arranged above the furnace shell 1 , the feeding pipe 7 runs through the furnace shell 1 and communicates with the melting chamber, and the outside of the furnace shell 1 is provided with a connecting pipe 4, a discharge pipe 11, a first air intake pipe 9, a second air intake pipe 10, and a second exhaust pipe 5 And the first exhaust pipe 12, wherein, the connecting pipe 4 communicates with the melting chamber and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com