Method for microbial vanadium leaching and selective vanadium enrichment

A microbial leaching and selective technology, applied in the direction of improving process efficiency, can solve the problems of low efficiency, many impurities, and high energy consumption of vanadium extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail through the drawings and examples below, but it is not intended to limit the protection scope of the present invention.

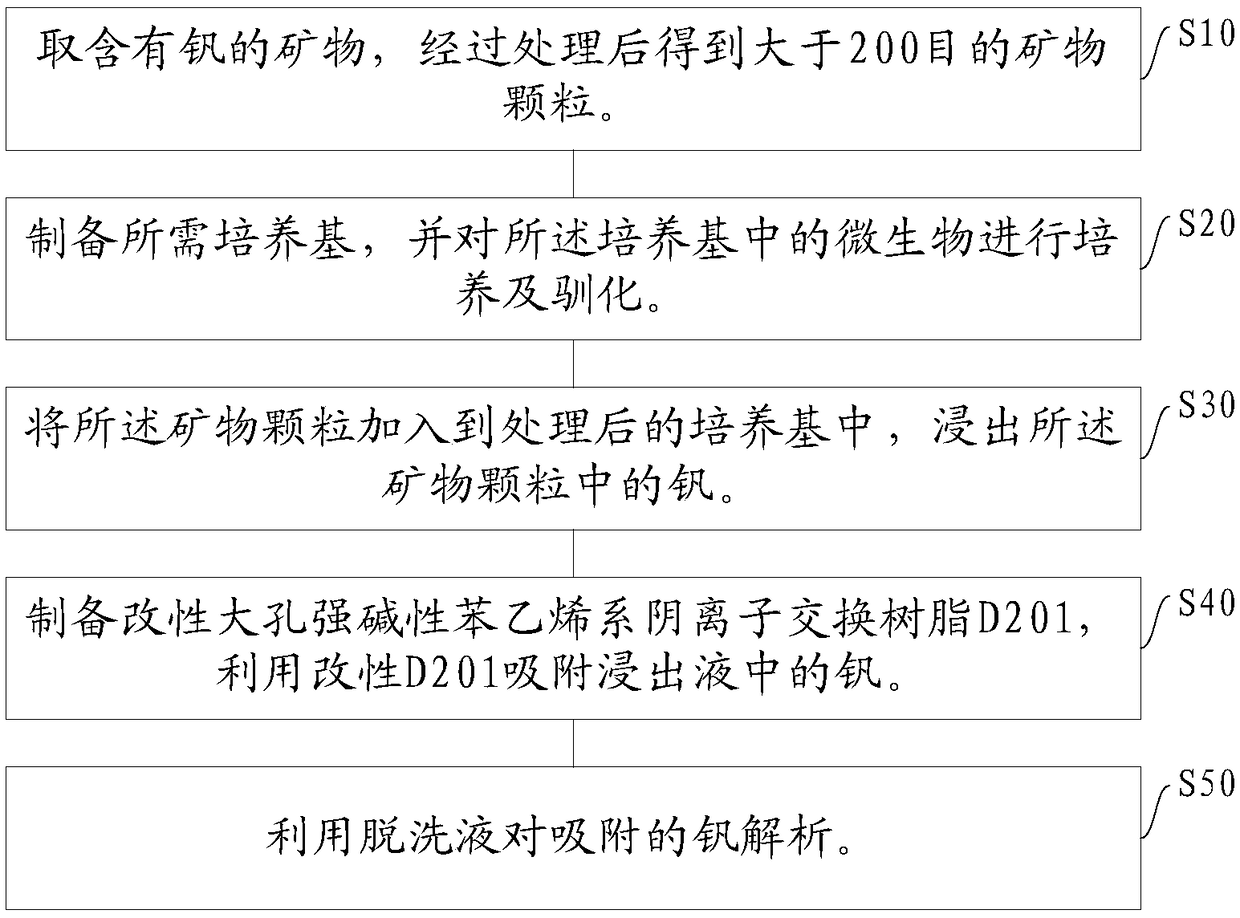

[0049] The embodiment of the present invention provides a method for leaching vanadium and selectively enriching vanadium, comprising the following steps:

[0050] In step S10, minerals containing vanadium are taken and processed to obtain mineral particles larger than 200 meshes.

[0051] Specifically, the minerals selected in the present invention mainly include stone coal, clinker, steel slag, and vanadium-titanium magnetite. Among them, clinker is the product of steel slag after roasting. The sources of minerals are as follows: stone coal is obtained from the Huitong mining area in Huaihua City, Hunan Province; clinker and steel slag are obtained from Xichang Steel and Vanadium Co., Ltd. of Xichang Pangang Group, Sichuan Province; vanadium-titanium magnetite is obtained from Panzhihua Cit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com