Method for extracting magnolol from officinal magnolia barks

A magnolol and magnolol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of small extraction amount, large energy consumption, expensive equipment, etc., and achieve high magnolol content, Avoid damage, facilitate the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

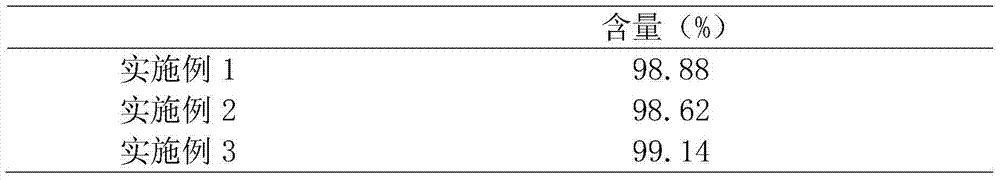

Examples

Embodiment 1

[0020] A method for extracting magnolol from magnolia bark, specifically comprising the steps of:

[0021] 1) Raw material processing: 100kg Magnolia officinalis is pulverized;

[0022] 2) High-pressure micro-jet superfine pulverization treatment: Add 800 kg of pure water to the pulverized magnolia bark, process it with a high-speed shear emulsifier for 20 minutes at a speed of 10,000 r / min, and then use high-pressure micro-jet superfine pulverization equipment at 25°C for processing , the treatment pressure is 120MPa, the number of treatments is 2 times, and a paste liquid is obtained;

[0023] 3) Ultrasonic extraction: Add 0.01mol / L KOH solution equivalent to 40% by weight of the paste liquid to the paste liquid obtained in step 1), ultrasonically treat for 40min, the action temperature is 50°C, the power is 350W, and then use pure water Wash until the pH is neutral, filter to obtain Magnolia officinalis extract;

[0024] 4) Collect the extract obtained after ultrasonic ex...

Embodiment 2

[0027] A method for extracting magnolol from magnolia bark, specifically comprising the steps of:

[0028] 1) Raw material processing: magnolia bark pulverized;

[0029] 2) High-pressure micro-jet micro-grinding treatment: Add 1,000 kg of pure water to the crushed magnolia bark, process it with a high-speed shear emulsifier for 15 minutes at a speed of 8,000 r / min, and then use high-pressure micro-jet ultra-fine pulverization equipment to process at 25°C , the treatment pressure is 80MPa, and the number of treatments is 3 times to obtain a paste liquid;

[0030] 3) Ultrasonic extraction: Add 0.25mol / L NaOH solution equivalent to 30% weight of the paste liquid to the paste liquid obtained in step 1), ultrasonically treat it for 20min, the action temperature is 55°C, and the power is 200W, then use pure water Wash until the pH is neutral, filter to obtain Magnolia officinalis extract;

[0031] 4) Collect the extract obtained after ultrasonic extraction, add petroleum ether acc...

Embodiment 3

[0034] 1) Raw material processing: magnolia bark pulverized;

[0035] 2) High-pressure micro-jet micro-grinding treatment: Add 900 kg of pure water to the crushed magnolia bark, process it with a high-speed shear emulsifier for 10 minutes at a speed of 12000 r / min, and then use high-pressure micro-jet ultra-fine pulverization equipment to process at 25 ° C , the treatment pressure is 100MPa, and the number of treatments is 4 times to obtain a paste liquid;

[0036] 3) Ultrasonic extraction: Add 0.50 mol / L NaOH solution equivalent to 20% by weight of the paste liquid to the paste liquid obtained in step 1), ultrasonically treat for 30 minutes, the action temperature is 60 ° C, the power is 250 W, and then use pure water Wash until the pH is neutral, filter to obtain Magnolia officinalis extract;

[0037] 4) Collect the extract obtained after ultrasonic extraction, add petroleum ether according to the weight ratio of 1:3, heat to a slight boil, keep warm for 10min, heat filter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com