Forming method of diffusion zone

A diffusion area and pre-doping technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven ion implantation, lattice damage, and increased production costs, and achieve uniform distribution of impurity ions, Improved crystal structure and improved production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

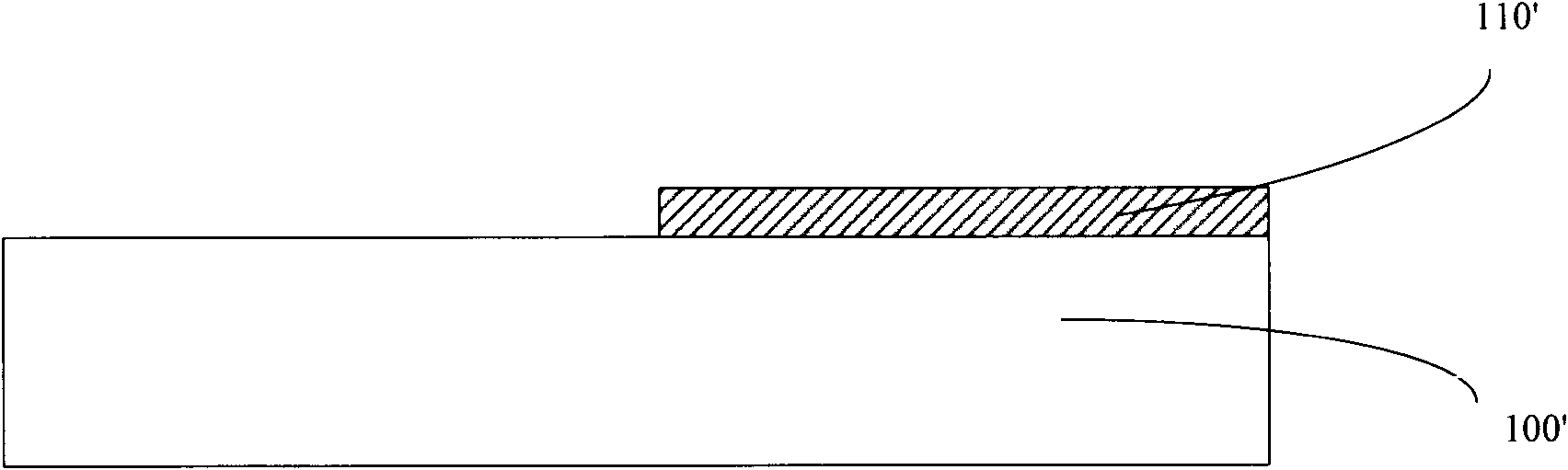

[0046] In order to characterize the doping of the buried layer region, the sheet resistance of the obtained N-type buried layer was measured by the four-probe method. In this embodiment, the measured Rs result was 140Ω / □, and the measured diffusion depth was 0.7 μm. The above is the content of the first embodiment of the present invention.

[0047] Due to the limitation of the saturated vapor pressure of TEASAT and the toxicity of the substance, for safety reasons, the As content in the pre-doped layer 310' is below a certain dose, and thus the content of As diffused into the semiconductor substrate 300 is also limited, resulting in The formed N-type buried layer has low doping rate and high resistivity. In this case, it is often necessary to achieve the corresponding resistivity requirements through multiple diffusions. The flow process of the second embodiment of the present invention is as follows Figure 8 As shown, a higher concentration of As doping in the N-type burie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com