Padding and drying and stock coiling all-in-one machine for piece goods

An all-in-one machine and padding machine technology, which is applied to the processing of textile material carriers, liquid/gas/vapor removal with squeeze rollers, and textile material processing, etc. It can solve the problems of long drying time, uneven heating of cloth, and excessive drying of cloth and other problems, to achieve the effect of high degree of automation, uniform and thorough drying, and uniform impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

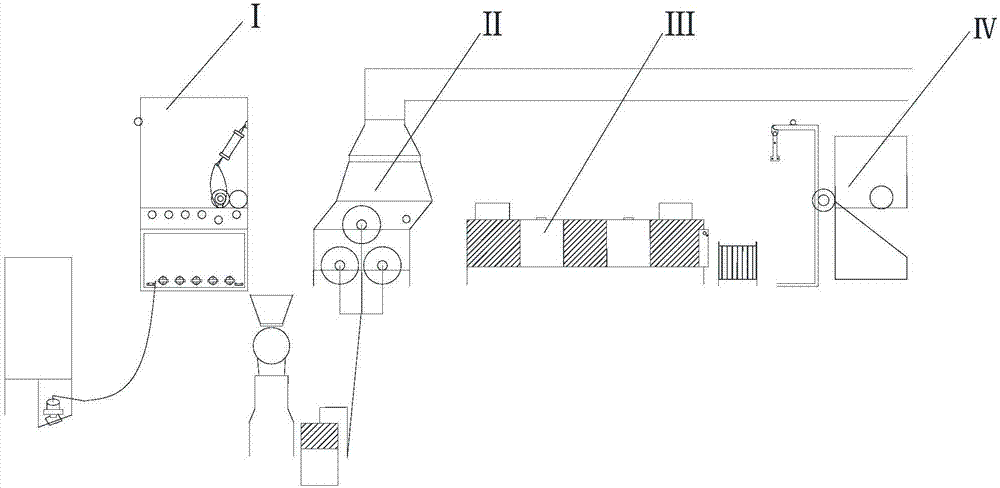

[0047] An all-in-one machine for padding, drying, and rolling materials for cloth, including a cloth padding device (I), a heat drying drum dryer (II), an oven (III), an automatic cloth rolling machine (IV), and a cloth padding device (I). The rear side of the device (I) is connected to the front side of the hot drying drum dryer (II), the rear side of the hot drying drum dryer (II) is connected to the left side of the oven (Ⅲ), and the right side of the oven (Ⅲ) is connected to the The rear side of the automatic cloth winder (Ⅳ).

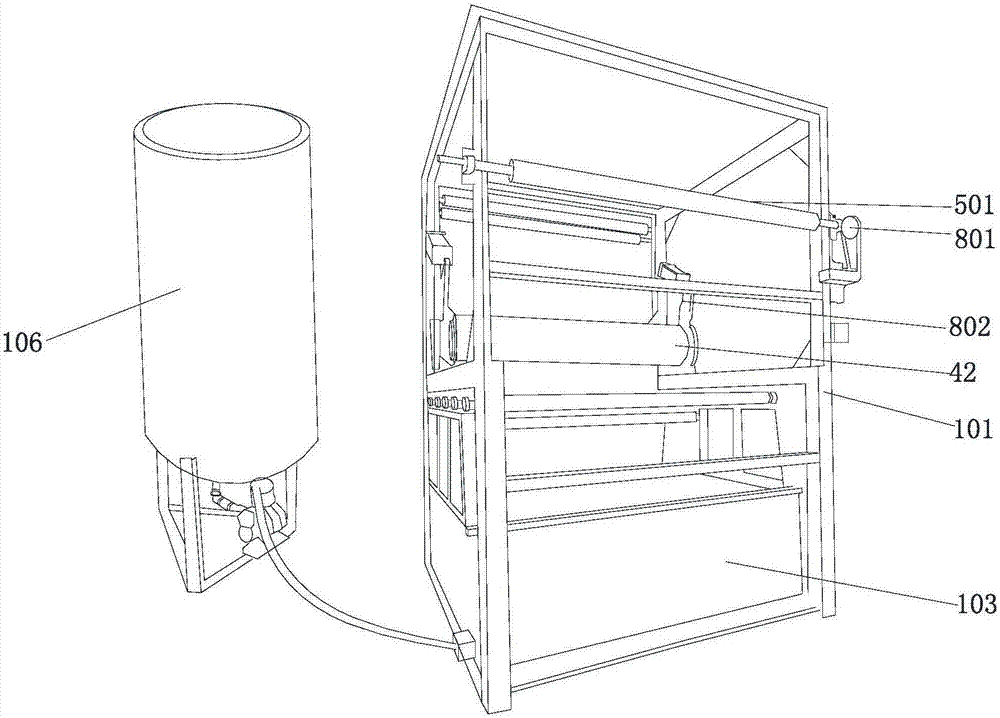

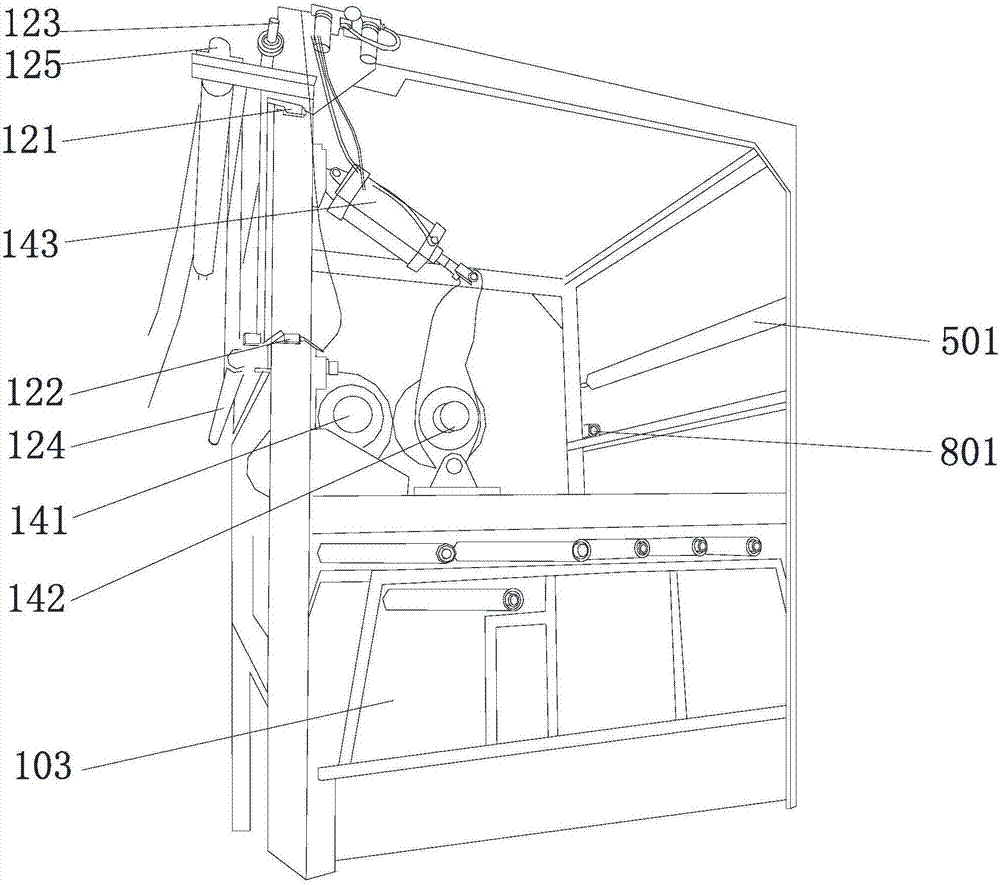

[0048] The cloth padding device (I) includes a padding frame (101), a cloth guiding mechanism (102), a liquid rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com