Nano-zirconium dioxide surface modified lubricating oil additive, lubricating oil and its preparation method

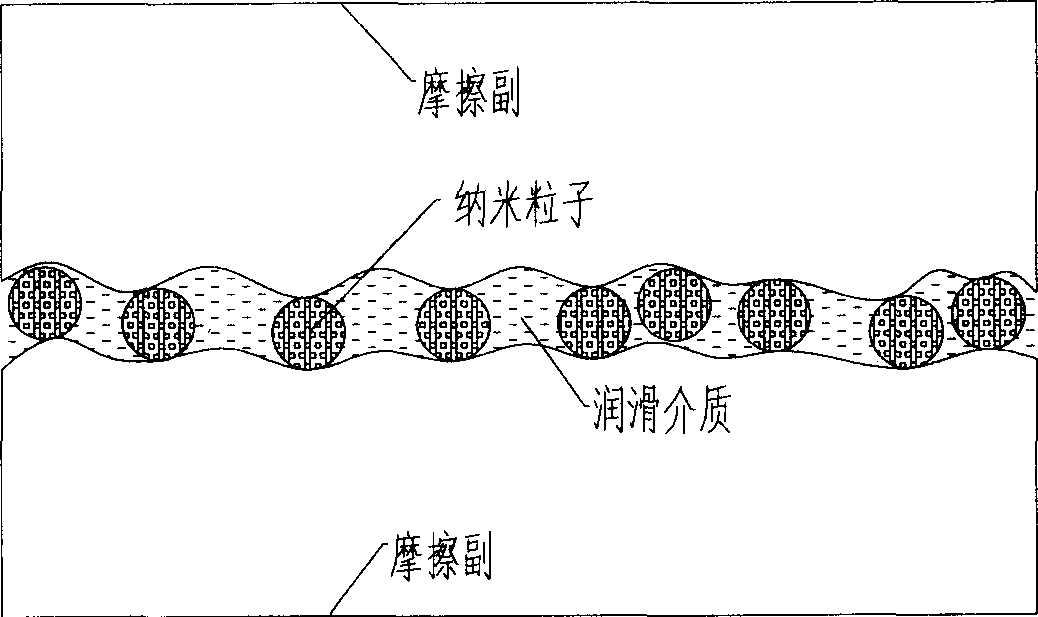

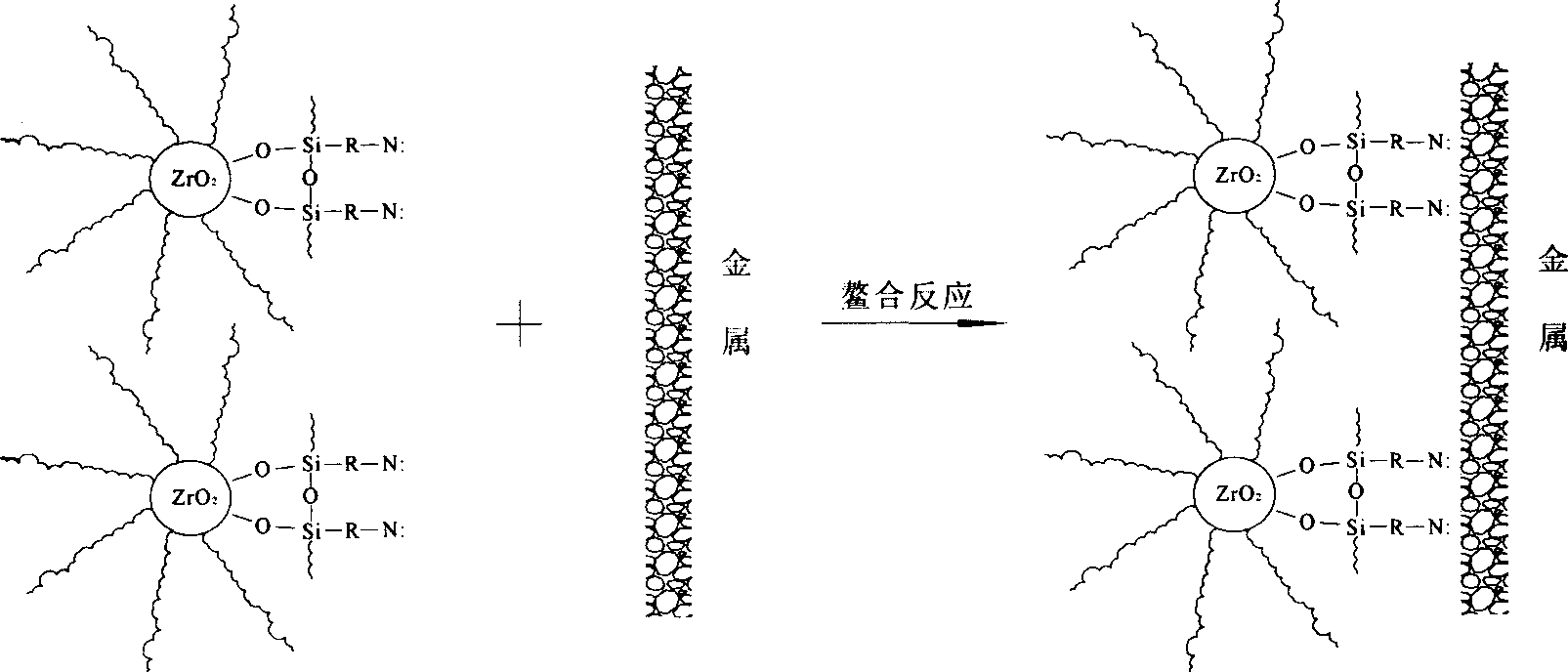

A lubricating oil additive and surface modification technology, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor compatibility between the surface and lubricating oil, stability, anti-friction performance, self-repairing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

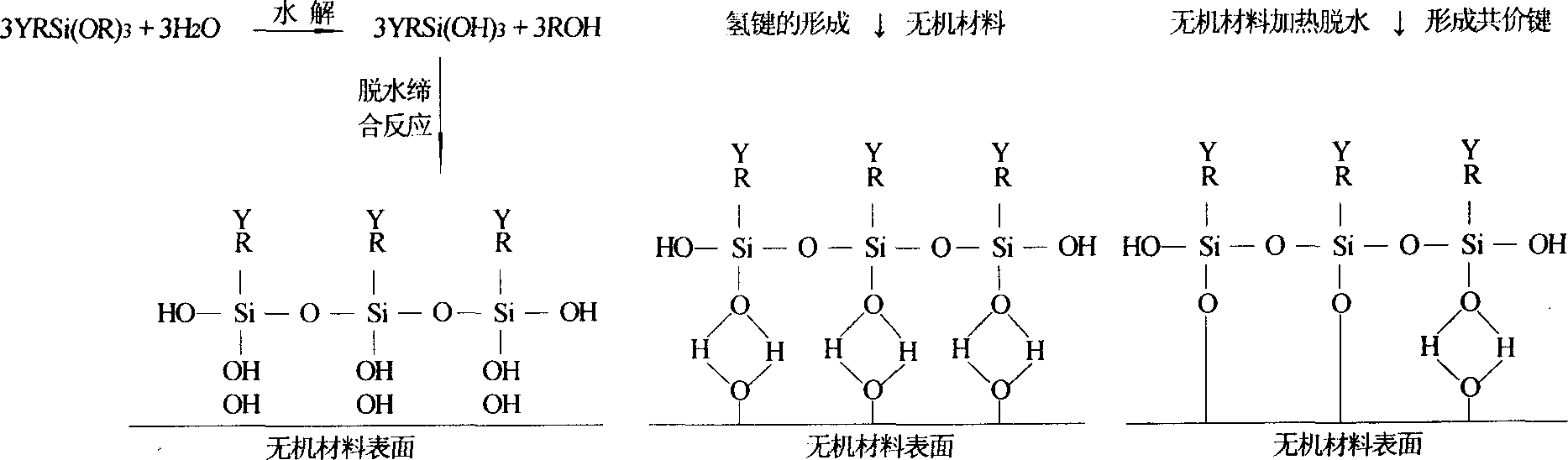

[0047] Amorphous Nano ZrO 2 preparation of

[0048] Preparation of Amorphous Nano-ZrO by Sol-Gel Method 2 . Preparation of Amorphous Nano-ZrO 2 The optimal preparation parameters for are as follows:

[0049] Prepare 0.5mol / L ZrOCl 2 The solution was heated in a water bath to keep the temperature at about 60°C; 0.5% dispersant polyethylene glycol was added, and after constant temperature for about 15 minutes, a certain amount of ammonia water was slowly added dropwise under rapid stirring to adjust the pH value of the system to 9 to obtain Hydrogel; after aging the hydrogel in the mother liquor for 3 hours, wash the precipitate with deionized water until the chloride ions are washed away, vacuum filter and dehydrate; then transfer the precipitate into a flask and add a certain amount of n-butyl Alcohol is subjected to azeotropic distillation to remove residual moisture in the precursor. When the temperature rises to 113°C, n-butanol starts to boil and is refluxed for one h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com