Rotary compressor

A technology of rotary compressors and cylinders, applied in rotary piston machines, rotary piston pumps, rotary piston/oscillating piston pump components, etc., can solve problems such as increased sliding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

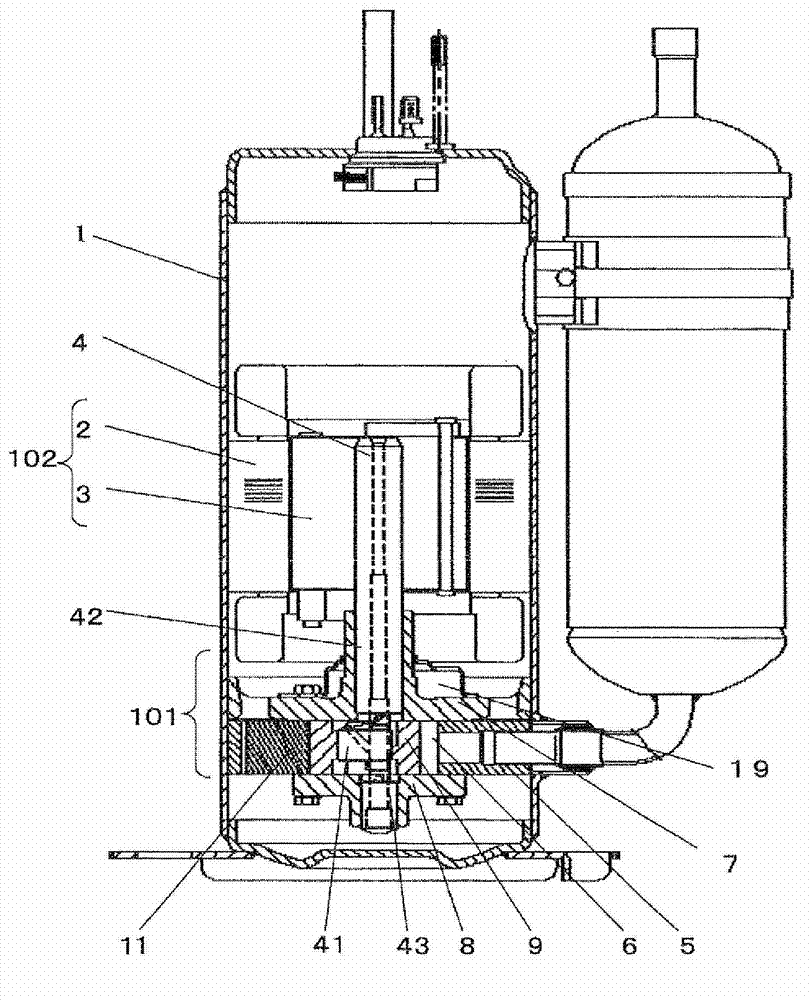

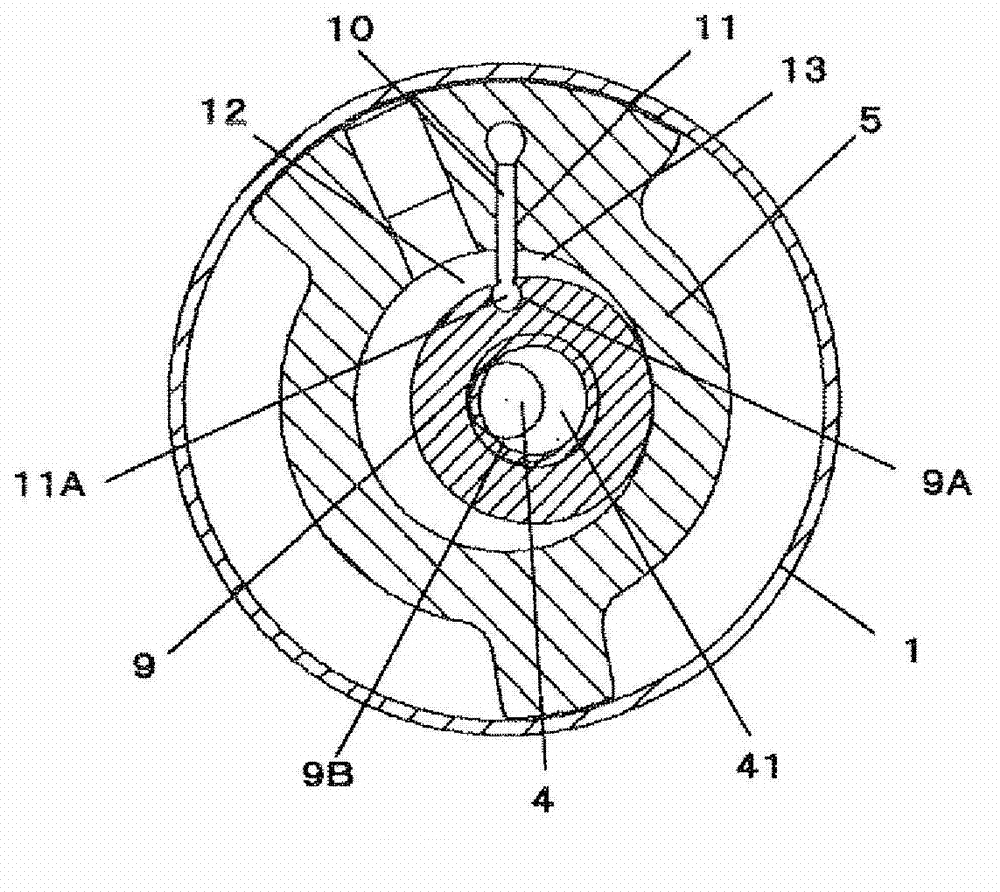

[0041] figure 1 It is a longitudinal sectional view of a rotary compressor provided with one compression mechanism unit 101 as an embodiment of the rotary compressor of the present invention, figure 2 is a cross-sectional view showing the compression mechanism.

[0042] Such as figure 1 The illustrated rotary compressor includes: a cylindrical airtight container 1; an electric motor unit 102 arranged on the upper side of the airtight container 1; Part 101 uses the bottom of the airtight container 1 as an oil tank.

[0043] The motor part 102 includes: the stator 2 installed annularly along the inner peripheral surface of the inner upper side of the airtight container 1; The direction is fixed to axis 4.

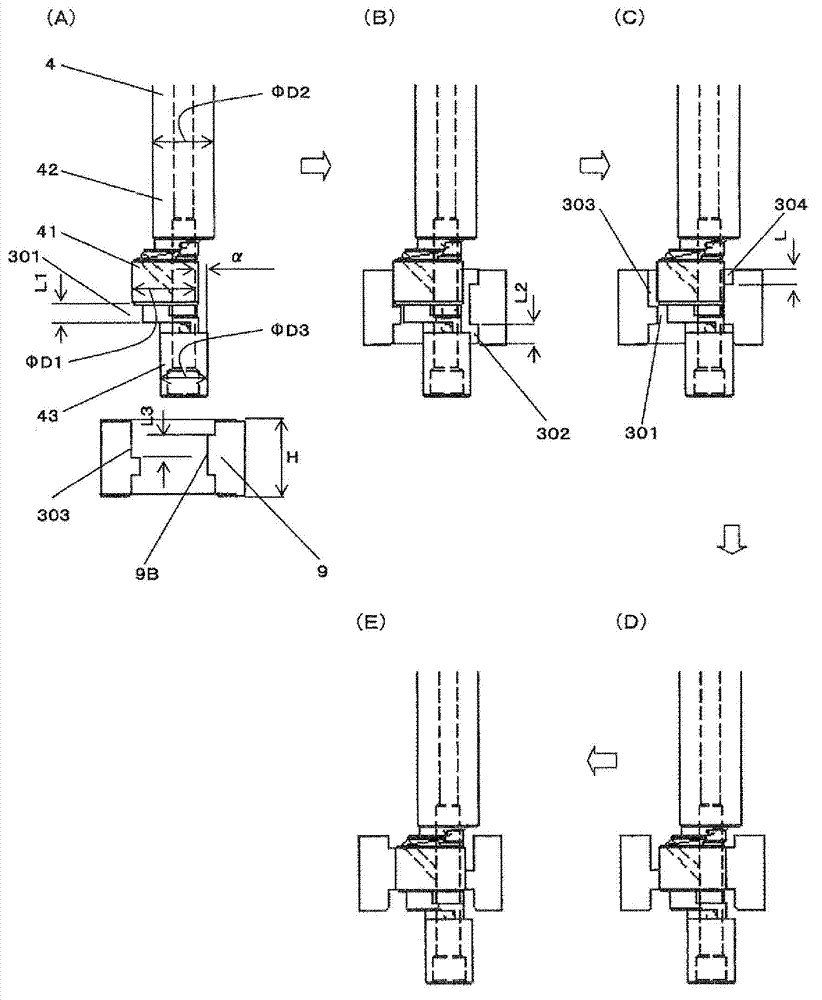

[0044] Such as figure 1 and figure 2 As shown, the compression mechanism part 101 has: a cylinder 5; a main bearing 7 and a sub-bearing 8 that connect the two end faces of the cylinder 5 to form a cylinder chamber 6; 4; the piston 9 fitted in the eccentric portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com