Stainless steel/aluminum alloy dissimilar metal pipeline welding method

A technology of dissimilar metals and welding methods, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems such as poor reliability, poor air tightness, and many joint defects, and achieve guaranteed strength and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

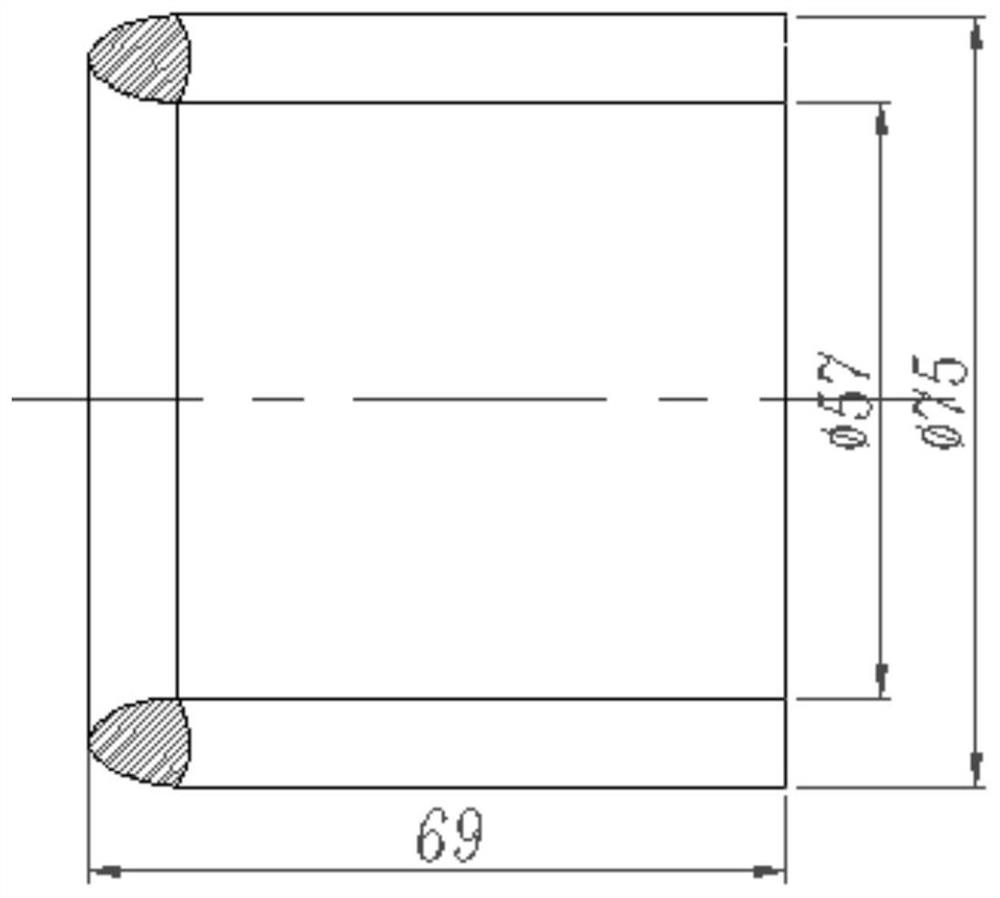

[0038] 1) At the end of the stainless steel (1Cr18Ni9Ti) tube blank, AgCu alloy (Cu mass percentage 28.1%) wire is selected, and the wire is melted and surfacing on one end of the stainless steel tube blank by argon arc wire filling welding, and the thickness of the surfacing layer is preset. 7-10mm, such as figure 1 ;

[0039] 2) X-ray inspection of stainless steel tube blank surfacing welds is required to meet the corresponding requirements of QJ2865A "Conduit Welding Technical Conditions";

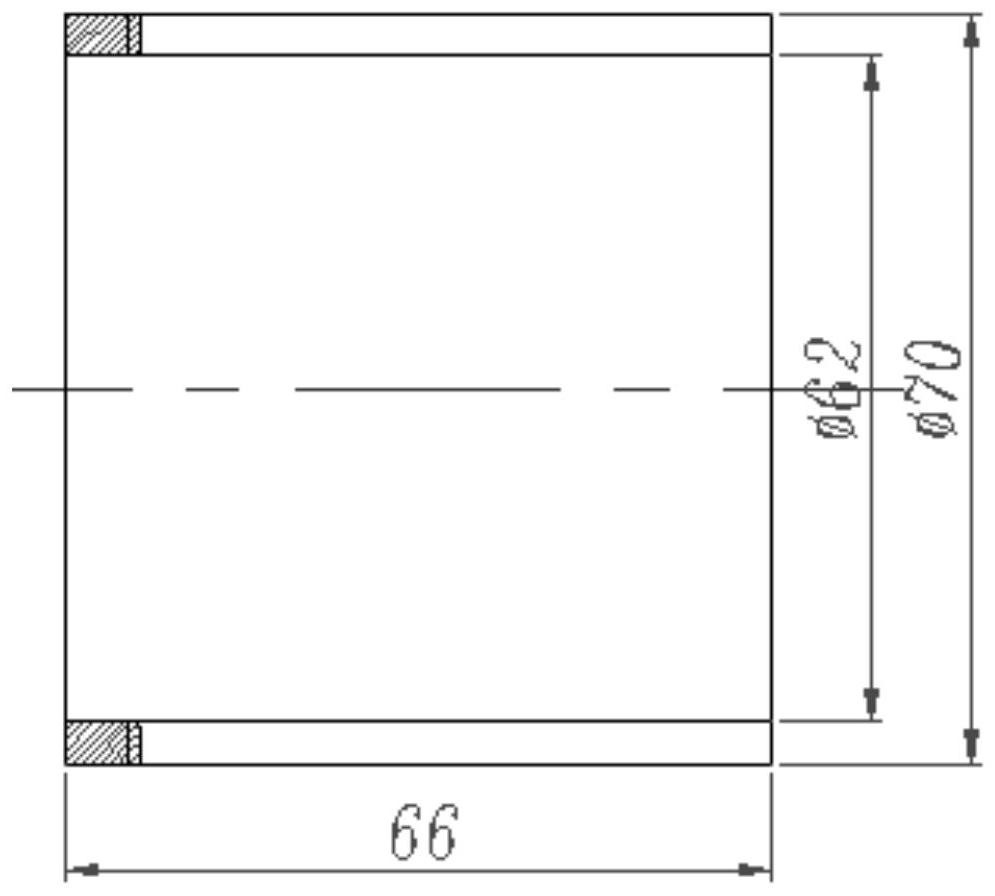

[0040] 3) Machining the stainless steel tube surfacing blank to obtain a finished tube with a slightly smaller diameter, wall thickness and length; such as figure 2 ;

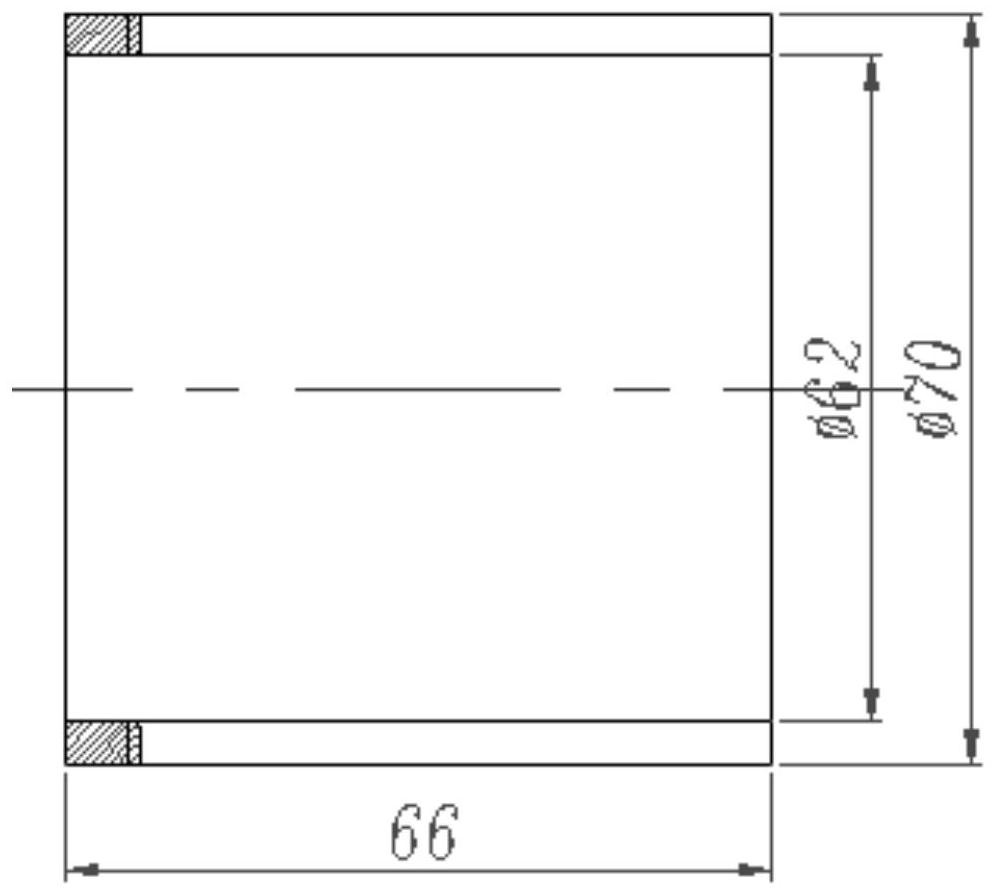

[0041] 4) According to the pipe diameter and wall thickness obtained in the previous step, process the 5A06 aluminum alloy pipe blank with the size as shown in the figure below; such as image 3 ;

[0042] 5) Use high-energy electron beams to weld the preset surfacing end of the finished stainless steel pipeline obt...

Embodiment 2

[0046] 1) At the end of the stainless steel (1Cr18Ni9Ti) tube blank, AgCu alloy (Cu mass percentage 28.1%) wire is selected, and the wire is melted and surfacing on one end of the stainless steel tube blank by argon arc wire filling welding, and the thickness of the surfacing layer is preset. 7-10mm, such as figure 1 ;

[0047] 2) X-ray inspection of stainless steel tube blank surfacing welds is required to meet the corresponding requirements of QJ2865A "Conduit Welding Technical Conditions";

[0048] 3) Machining the stainless steel tube surfacing blank to obtain a finished tube with a slightly smaller diameter, wall thickness and length, such as figure 2 ;

[0049] 4) According to the pipe diameter and wall thickness obtained in the previous step, process the 5A06 aluminum alloy pipe blank of the size shown in the figure below, such as image 3 ;

[0050] 5) Laser welding the prefabricated end of the finished stainless steel pipeline obtained in the third step and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com