Calibration system

A calibration system and calibration table technology, applied in the direction of hydraulic/pneumatic measurement, etc., can solve the problem that the construction accuracy cannot meet the requirements, and achieve the effect of ensuring strength, reliability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

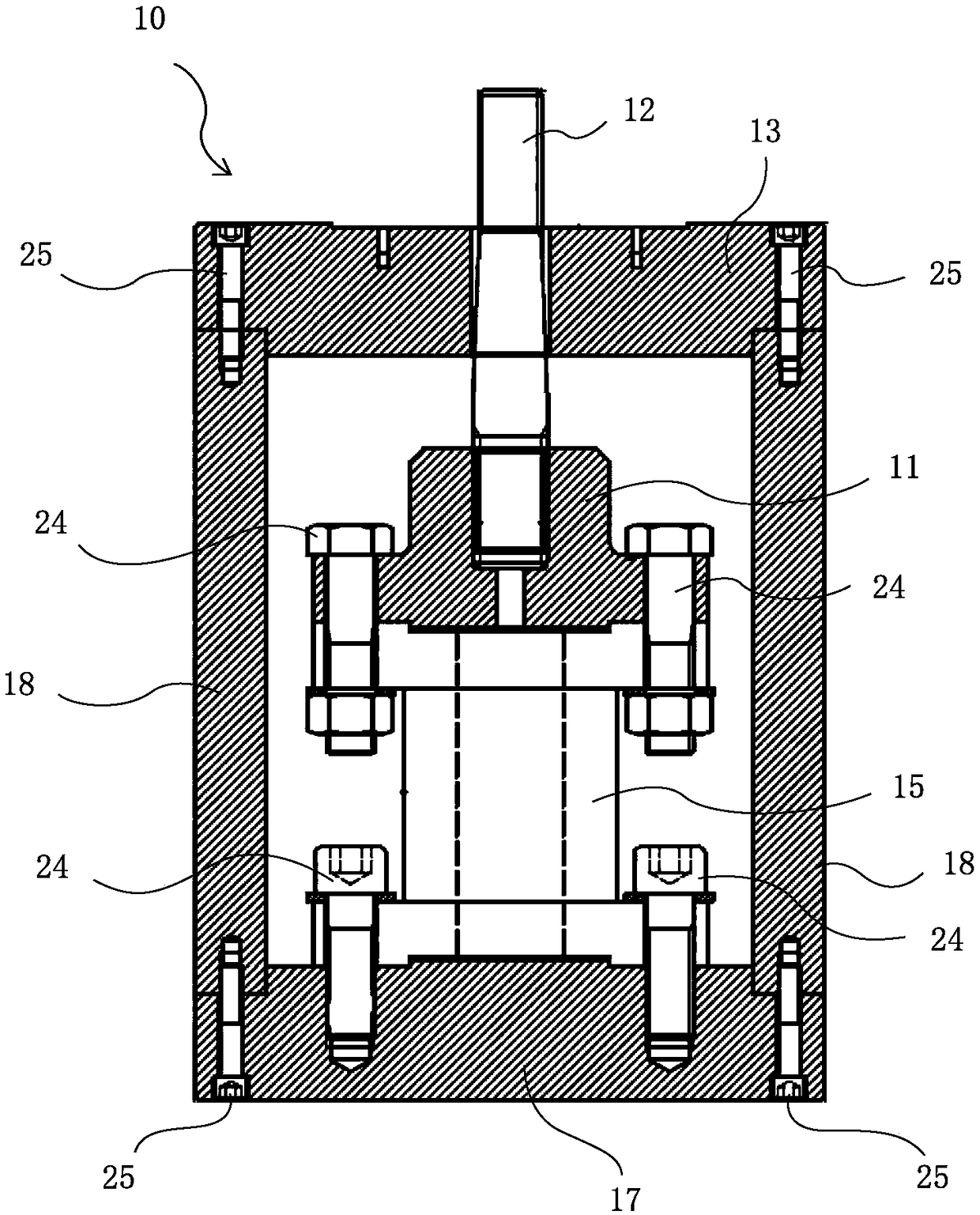

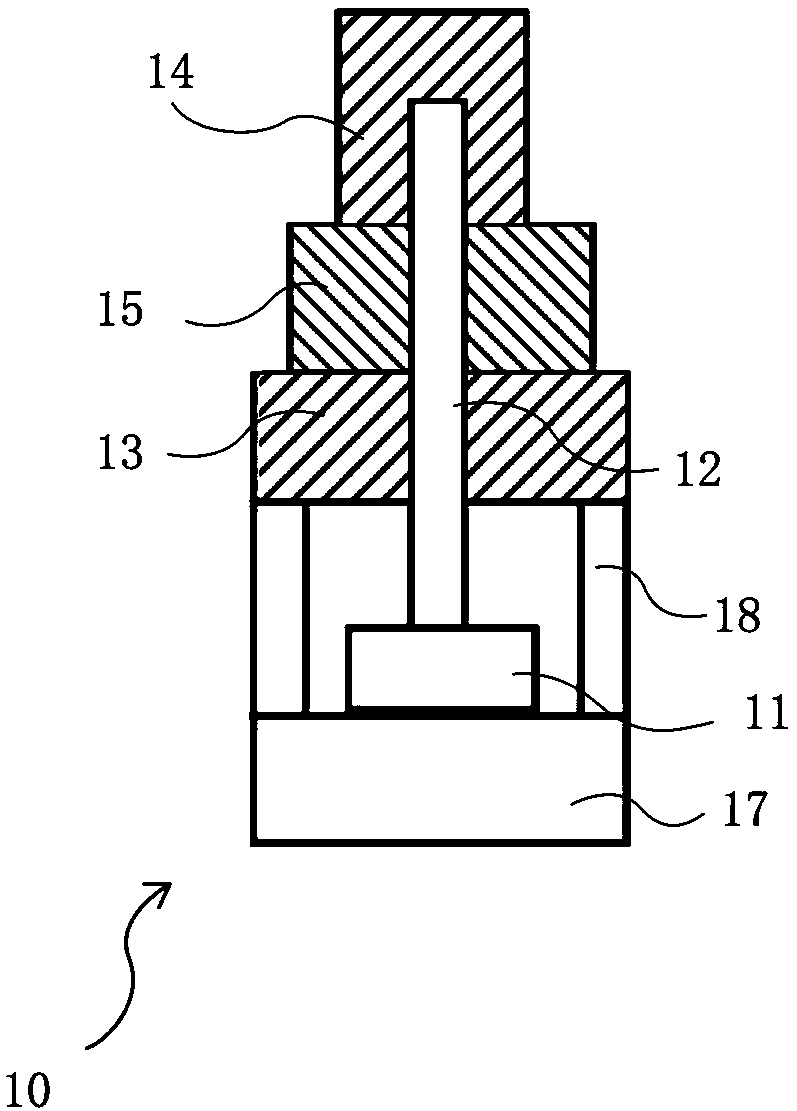

[0026] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings, examples of which are shown, in which like reference numerals refer to like components throughout.

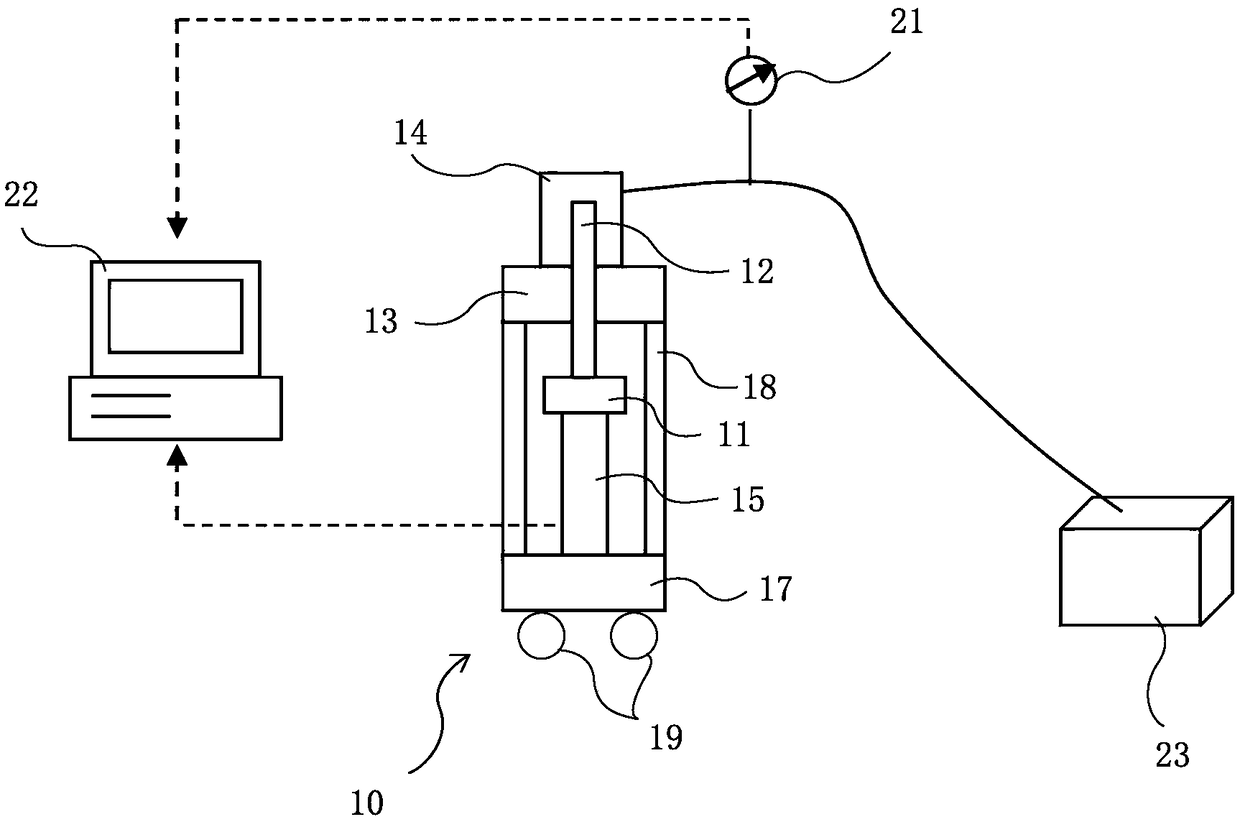

[0027] like figure 1 As shown, the calibration system according to the embodiment of the present invention includes: a force sensor 15, which is used to measure the force exerted by the tensioner 14 on the test bolt 12; The lower end of the test bolt 12), and when the stretcher 14 stretches the test bolt 12, the calibration table 10 can provide support for the stretcher 14; the pump station 23 is used to provide hydraulic pressure for the stretching action of the stretcher 14; The pressure sensor 21 is used to measure the hydraulic pressure provided by the pump station 23 for the stretcher 14; the controller 22 calculates the force applied to the stretcher 14 by the pump station 23 according to the hydraulic pressure measured by the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com