Water-lubricated sliding bearing

A technology of sliding bearings and water lubrication, which is applied in transmission devices, transmission device parts, gear transmission devices, etc., can solve the problems of boundary lubrication limiting the increase of journal speed, and achieve benefits for lubrication and cooling, performance improvement, and efficiency improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

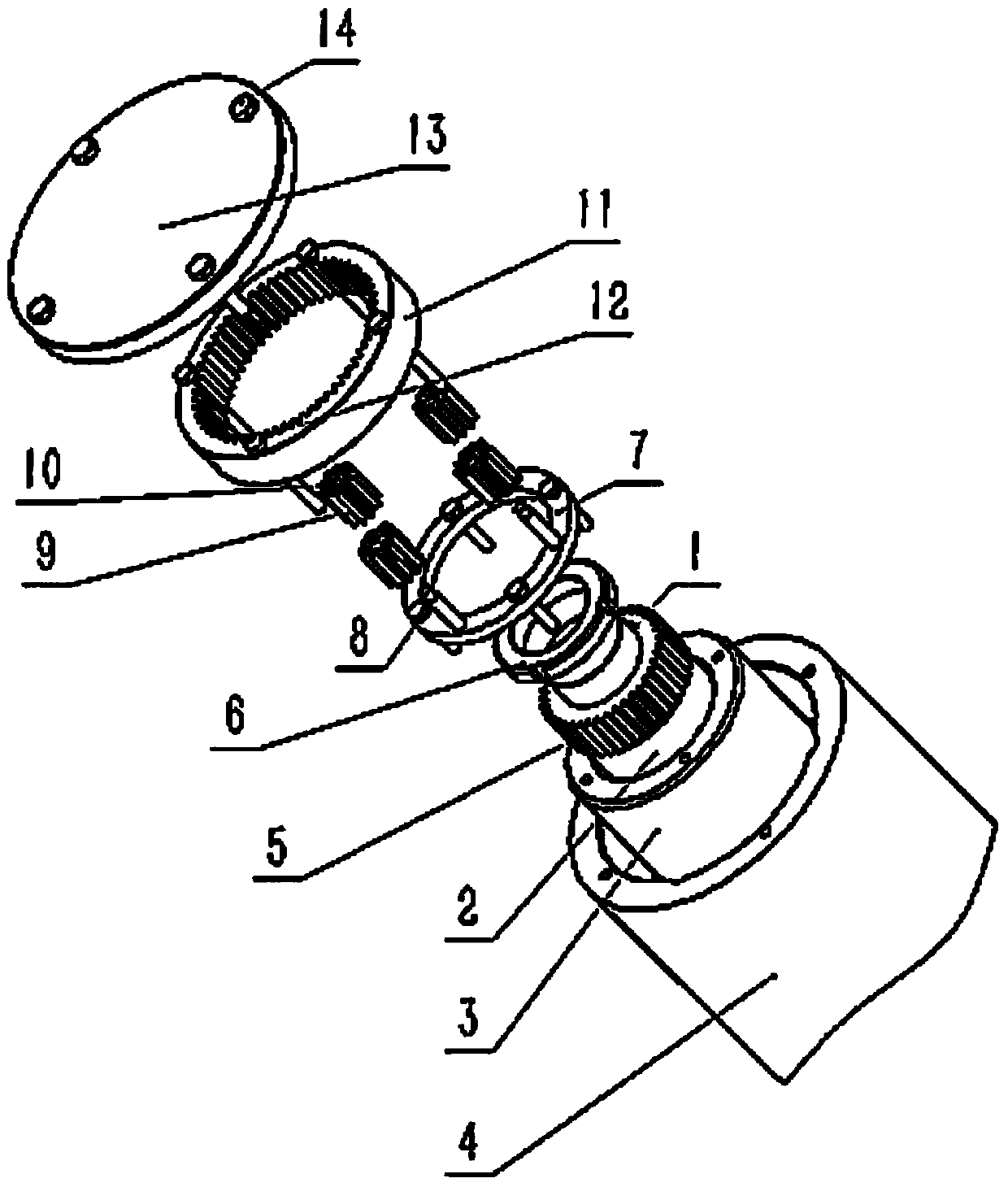

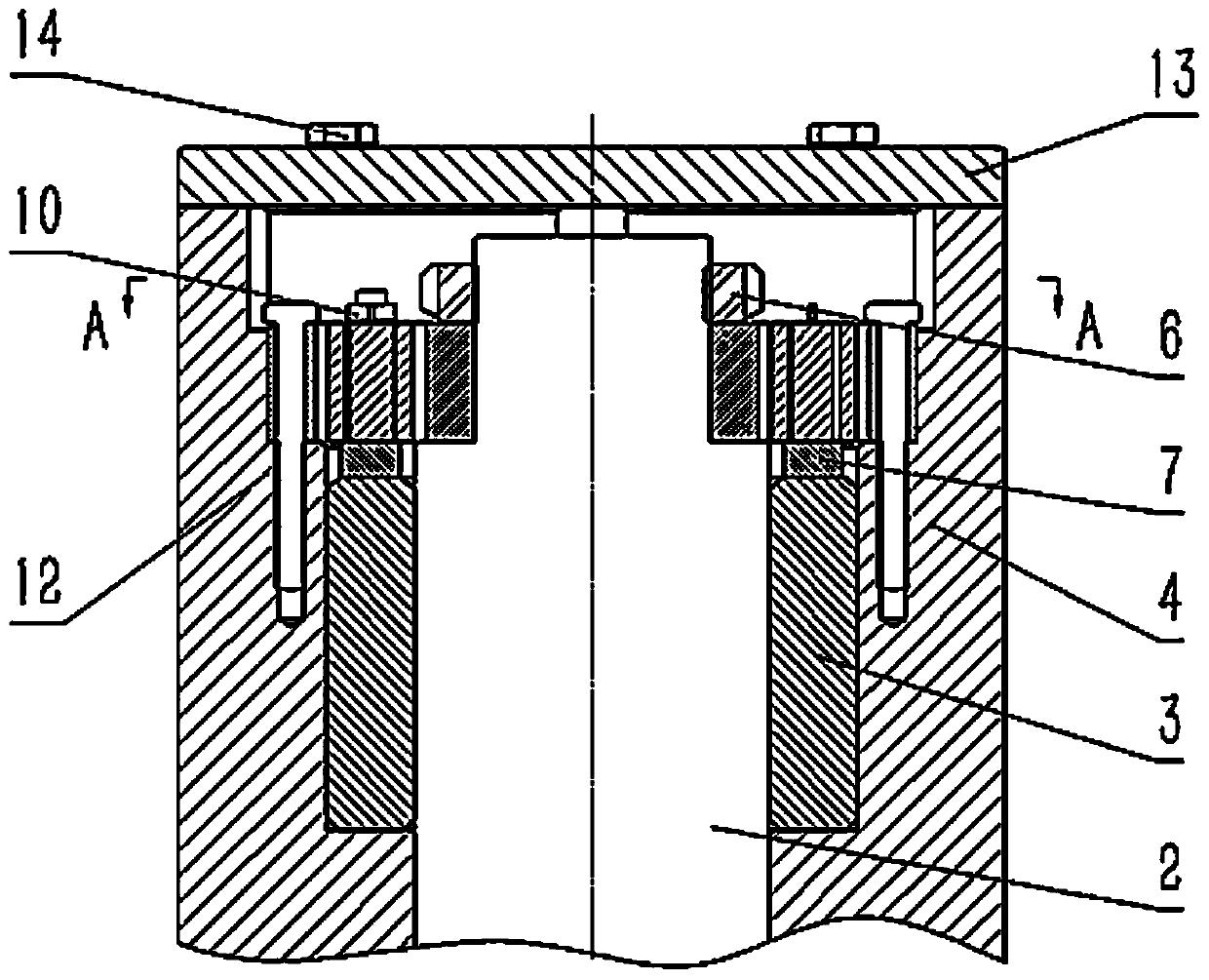

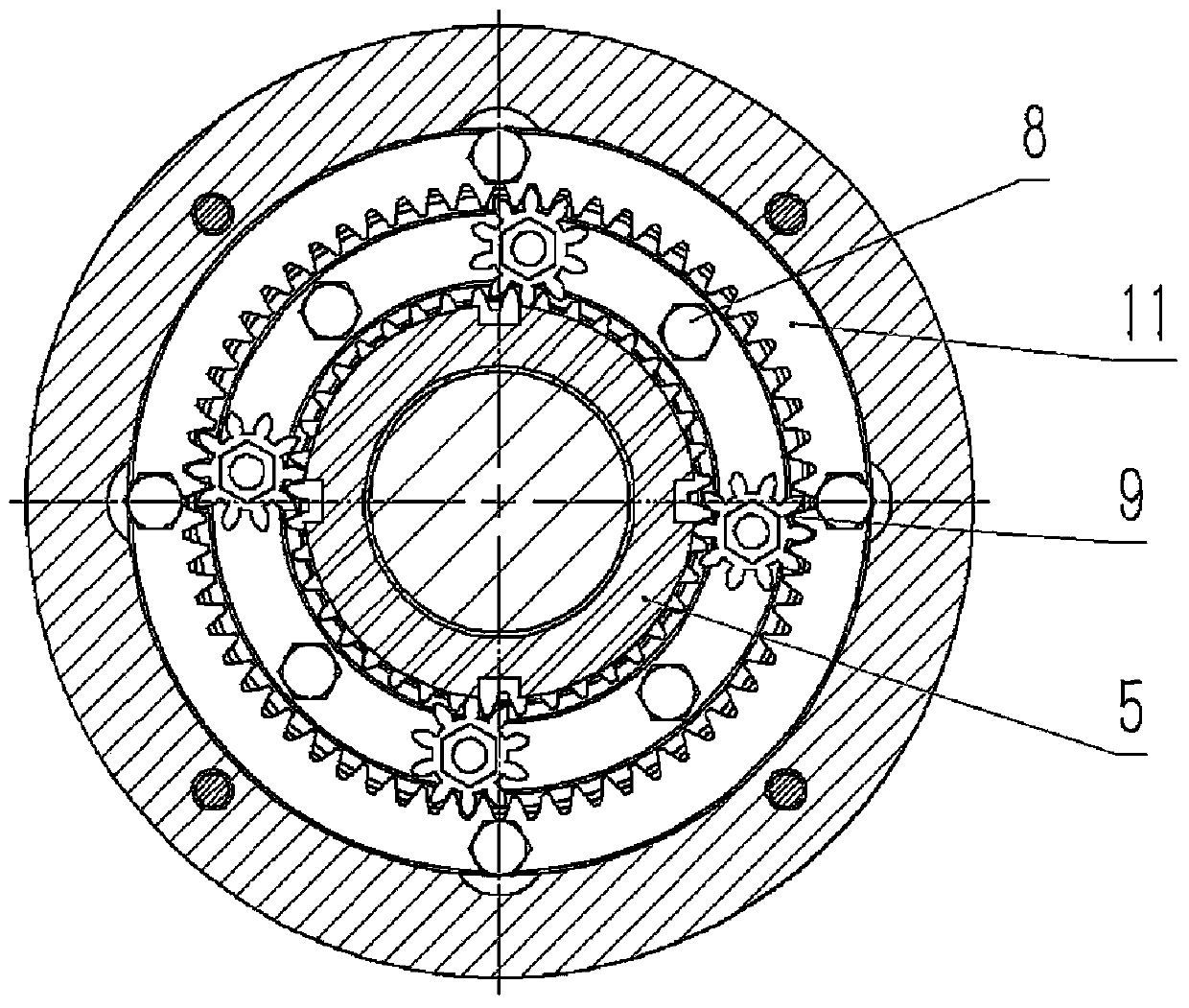

[0017] figure 1 The interrupted part on the lower right side of the center is the bearing housing 4 connected with the screw compressor and the screw expander, the main shaft 2 extends from the right end of the bearing housing 4, and the bearing housing 4 provides support for the main shaft 2 through the sliding bearing 3. The main shaft 2 rotates and drives the sliding bearing 3 to rotate through the planetary gear reduction mechanism. The planetary reduction mechanism includes a sun gear 5 , a planetary gear 9 , a planet carrier 7 and an inner ring gear 11 . The main shaft 2 is connected with the sun gear 5 through the key 1; the sliding bearing 3 is connected with the planet carrier 7 through the first screw 8; each planetary gear 9 is installed on the planetary gear shaft; the inner ring gear 11 is fixed on the bearing seat 4 through the screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com