Micro gas-turbine power station

A micro gas turbine and power station technology, applied in the field of power stations, can solve the problems that power stations cannot be applied in the field of distributed power supply, low maintenance cost, low noise, etc., and achieve low maintenance cost, prolong service life, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

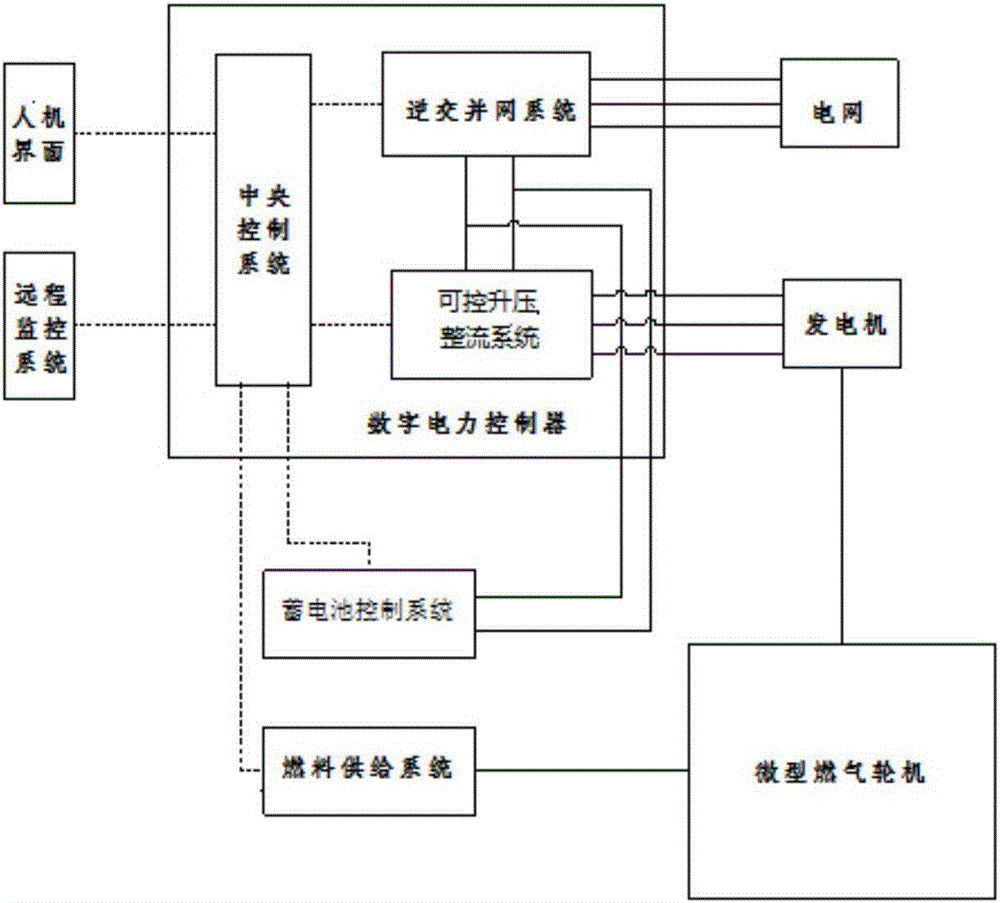

[0026] like figure 1 and 2 As shown, a micro gas turbine power station, the power station mainly includes a digital power controller, a generator and a micro gas turbine;

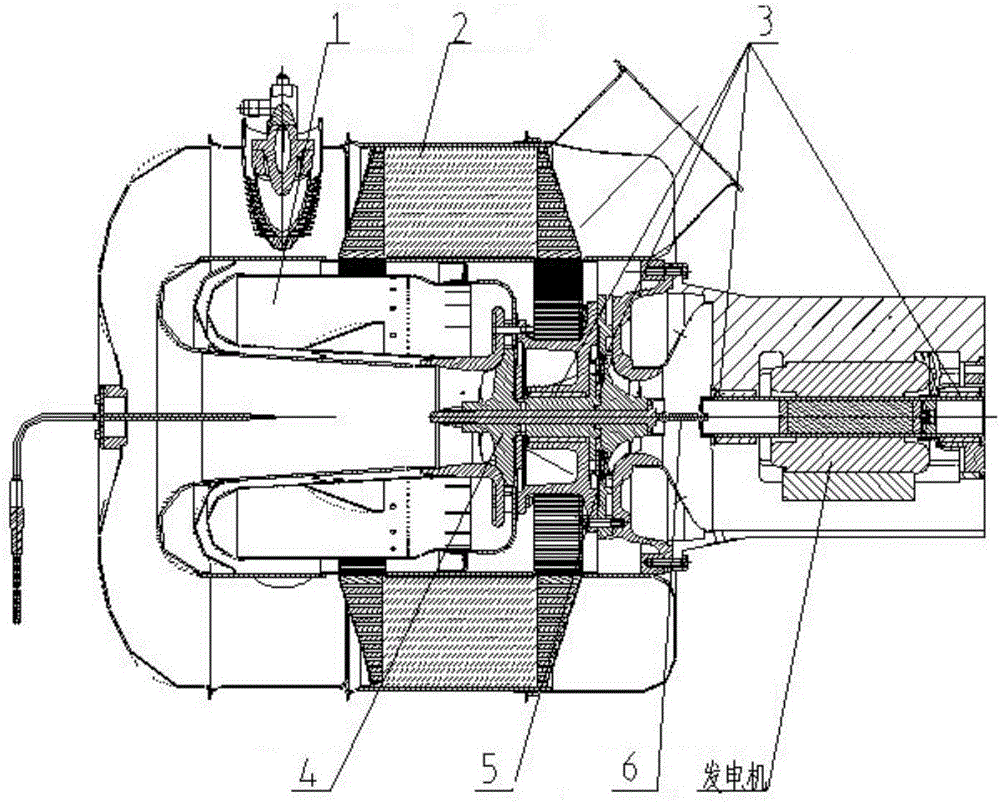

[0027] Wherein, the micro gas turbine is provided with a plate-fin regenerator 2, and the plate-fin regenerator 2 surrounds the outside of the micro gas turbine;

[0028] The digital power controller includes a controllable boost rectification system, an inverter grid-connected system and a central control system;

[0029] The micro gas turbine is coaxially and flexibly connected to the generator; the generator, the controllable boost rectification system and the inverter grid-connected system are sequentially connected by cables, and the controllable boost rectification system and the inverter The grid-connected systems are all connected to the central control system through cables.

[0030] Further, the micro gas turbine also includes a centrifugal compressor 5, an annular return combustion chamber 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com