Dynamic torque measurement sensor with speed measurement function

A technology for measuring sensors and rotational speed, applied in the directions of linear/angular velocity measurement, velocity/acceleration/impact measurement, measurement force, etc. Small size and other problems, to achieve the effect of broadening the working speed range, expanding the scope of use, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

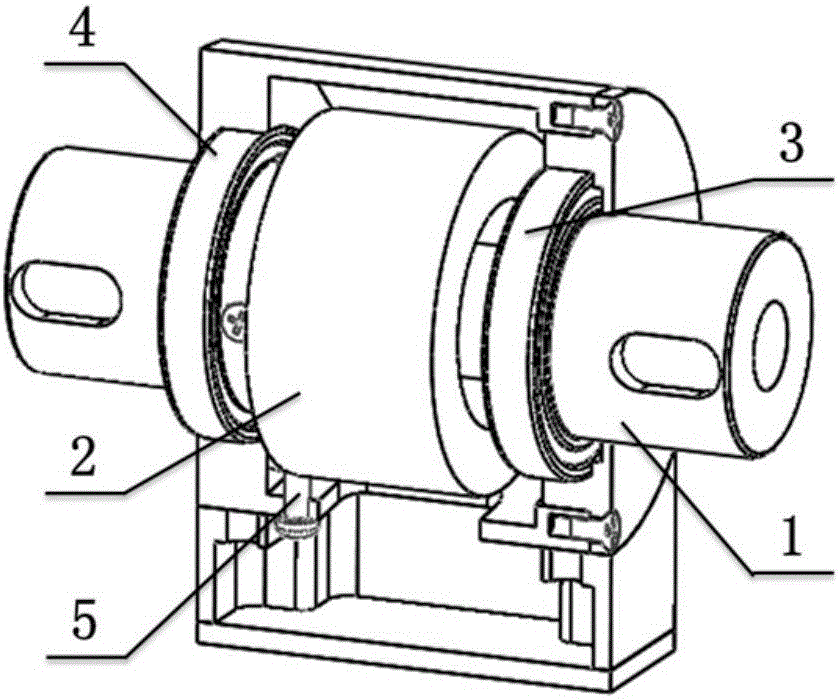

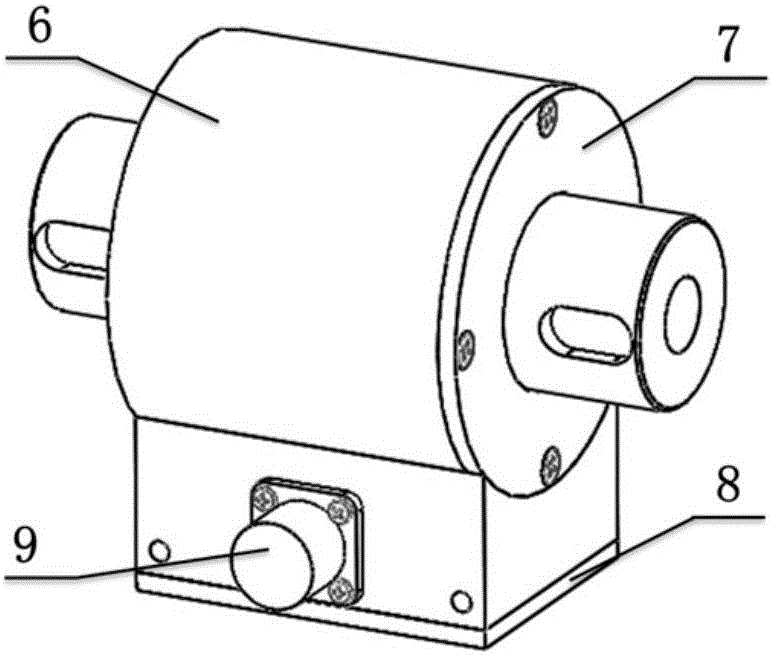

[0028] Such as figure 1 , figure 2 As shown, the structural composition of the dynamic torque sensor of the present invention mainly includes: an elastomeric main shaft 1, a conductive slip ring 2, a bearing 3, a bearing 4, a stop screw 5, a casing 6, a front cover 7, a bottom cover 8, an output socket 9.

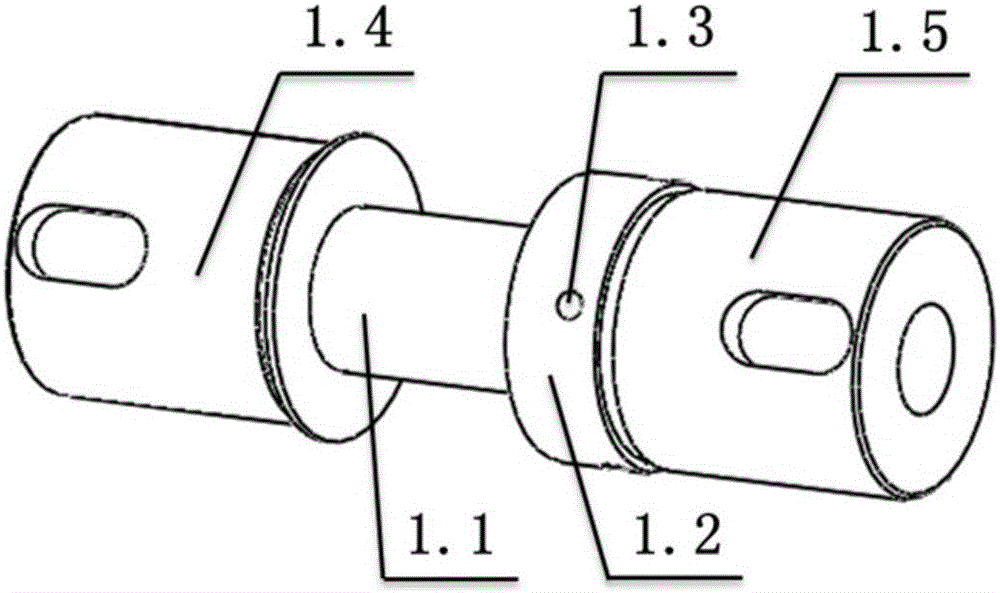

[0029] 1. Elastomer spindle 1

[0030] Such as image 3 As shown, the elastic body main shaft is the core component of the dynamic torque sensor. The strain gauge pasted on the surface of the 1.1 cylinder converts the deformation during the working process into an electrical signal. According to the measured target torque value, the elastic body main shaft can be selected from different The material, the structural dimensions of the elastomeric spindle 1 will also vary.

[0031] 2. Integral conductive slip ring 2

[0032] Such as Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com