High speed shaft system with torque measuring function

A high-speed shaft and functional technology, applied to components with teeth, belts/chains/gears, transmission parts, etc., can solve the problems of high cost, high speed of accessory pumps, easy damage, etc., to achieve high working speed, disassembly Quick and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

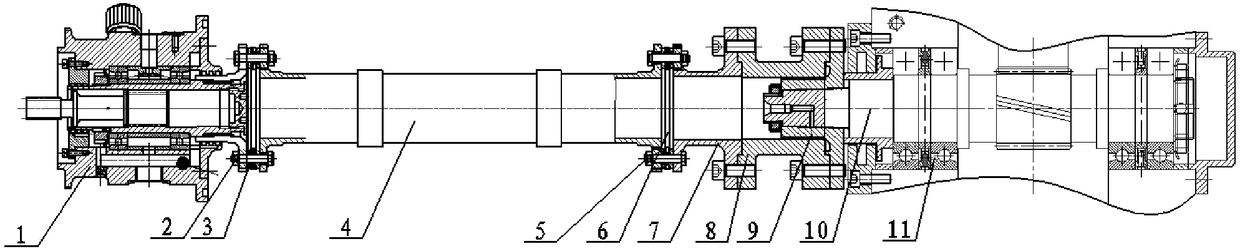

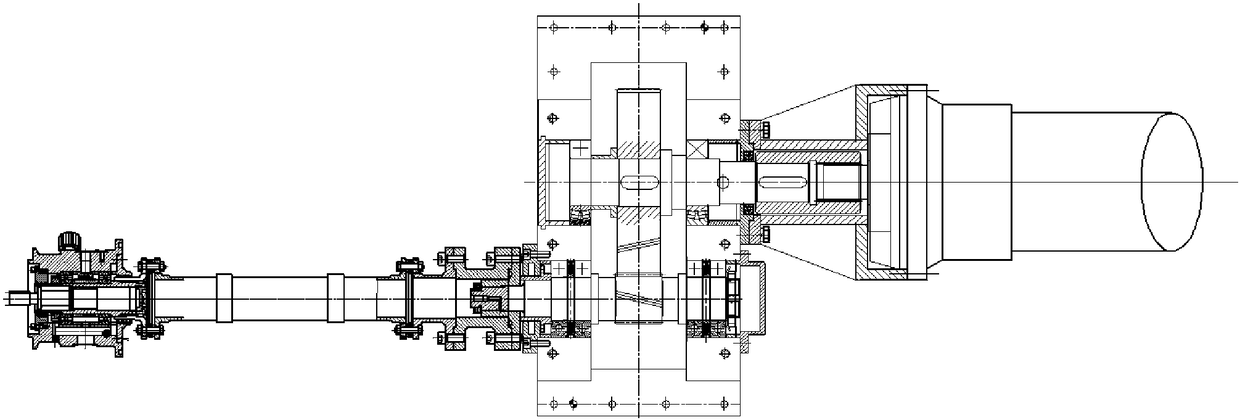

[0012] Such as figure 1 and figure 2 As shown, a high-speed shaft system with torque measuring function involved in this embodiment includes a transfer mechanism 1, a reaming hole bolt A2, a reaming hole screw B5, a diaphragm A3, a diaphragm B6, an intermediate shaft 4, Adapter flange 7, high-speed torque meter 8, conical flange 9, and high-speed shaft 10 of the gearbox, which are characterized in that the spline port of the connected device, that is, the spline port of the aero-engine accessory case, and the spline port with the external spline shaft Mechanism 1 is connected, and the transfer mechanism is fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com