Equal-flow area conical screw-sleeve pair

A flow area, conical screw technology, applied in the direction of rotary piston machinery, machine/engine, rotary piston pump, etc., can solve the problem of no way to process, increase the instability of flow, large pressure pulsation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

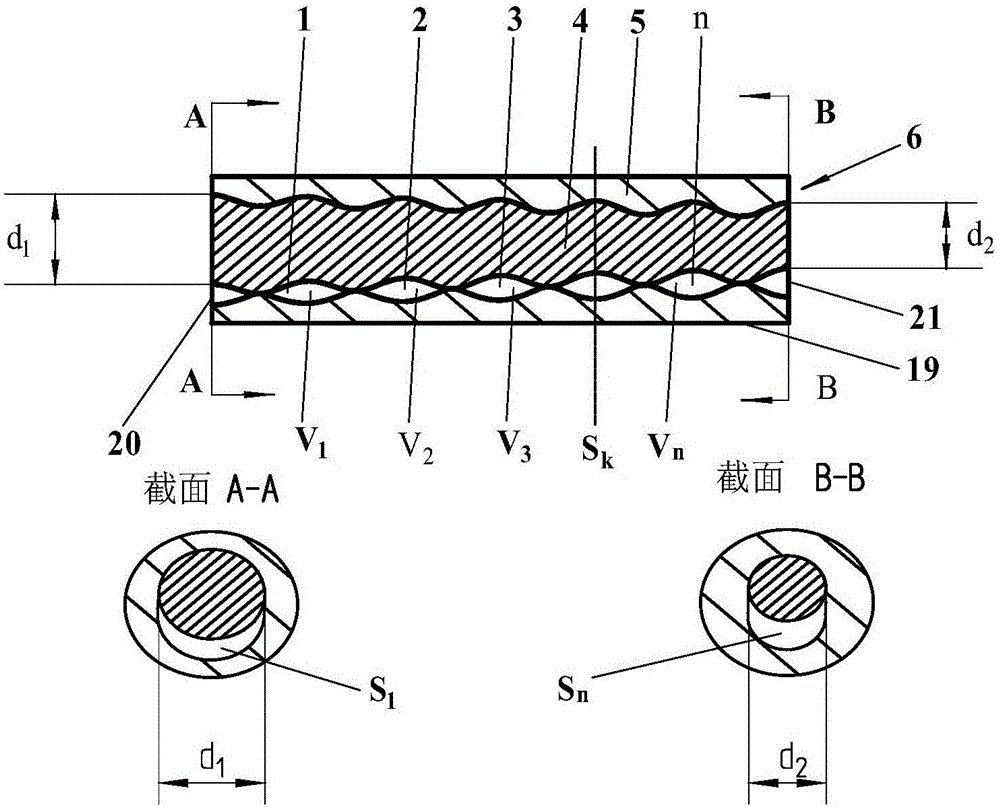

[0048] Such as Figure 1-6 Shown, a kind of conical screw-bush pair, it comprises conical screw rod 4, conical bushing 5; The tapered bushing 5 comprises a tapered bushing inner curved surface 16, a tapered bushing large end face 17, a tapered bushing small end face 18 and a tapered bushing outer cylindrical surface 19; the tapered screw large end face 10 and the cone The large end face 17 of the tapered bush forms the inlet end 20 of the tapered screw-bush pair; the small end face 11 of the tapered screw and the small end face 18 of the tapered bush form the outlet end 21 of the tapered screw-bush pair.

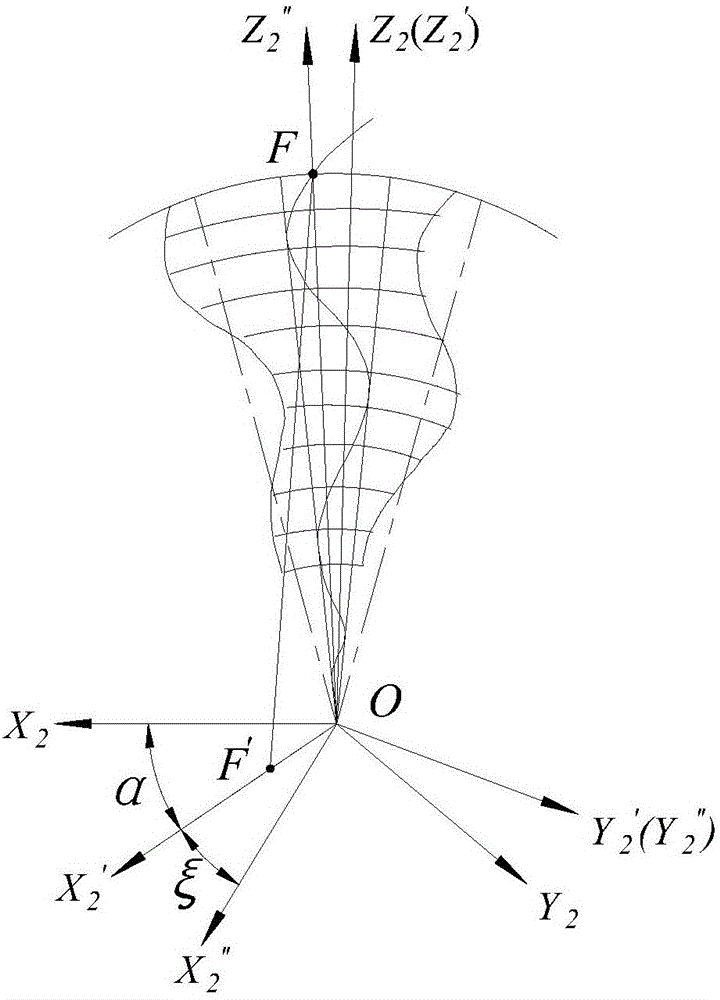

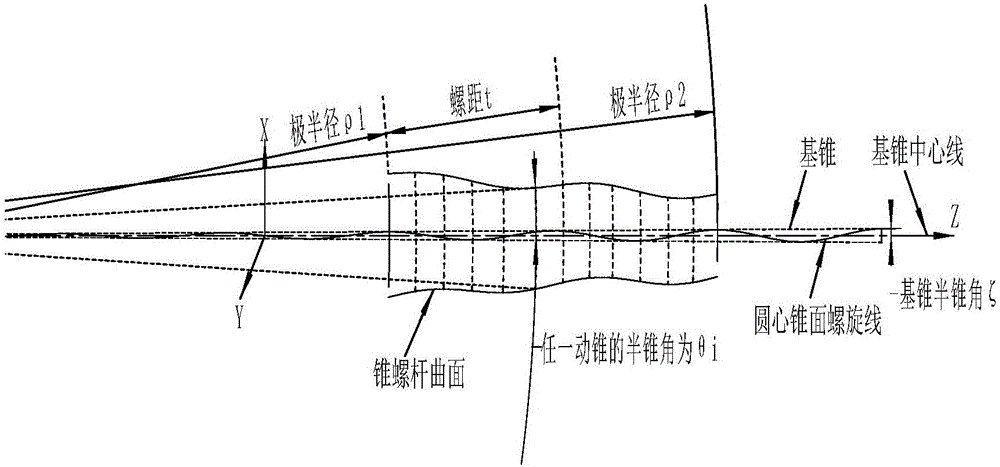

[0049] Based on the curved surface forming method of the traditional conical screw-bush pair, the proposed curved surface forming method of the new single-headed conical screw-bush pair (6) includes: the forming method of the S1 conical screw curved surface 9 and the S2 conical bush curved surface 16. Shaping method.

[0050] Curved Surface Forming Method of S1 Conical Scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com