Road surface embedding device and method of piezoelectric substrate

A piezoelectric substrate, piezoelectric substrate technology, applied in the direction of road cleaning, roads, roads, etc., can solve the problems of unrealized mechanical automation, etc., and achieve the effect of improving the buried survival rate, good bonding, and good structural durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

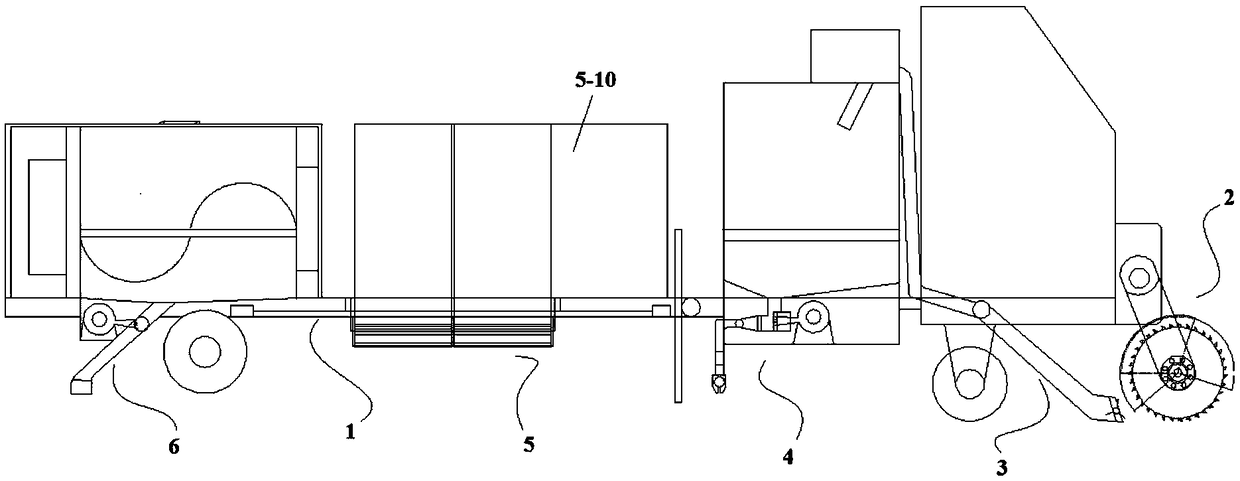

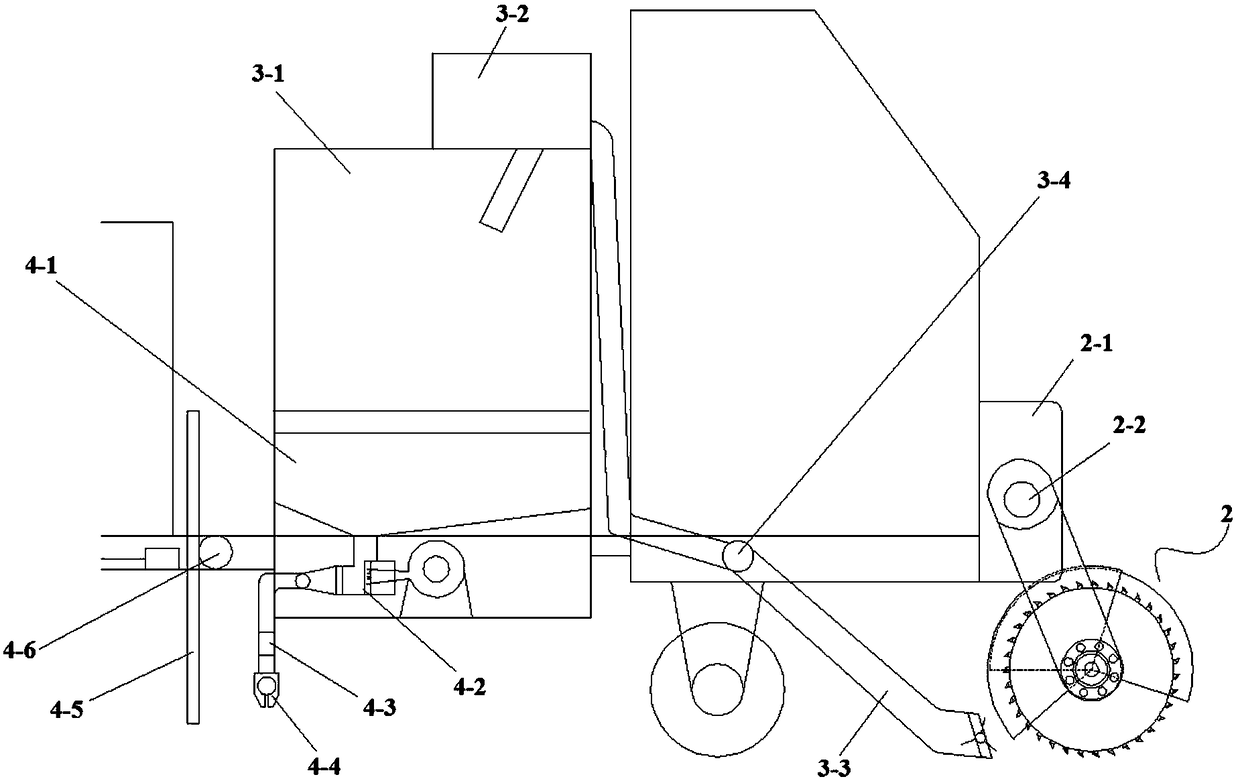

[0048] This embodiment provides a road surface embedding device of a piezoelectric substrate, such as Figure 1 to Figure 6 As shown, it includes a car body 1, on which a milling mechanism 2, a waste collection mechanism 3, an adhesive layer spraying mechanism 4, a piezoelectric substrate installation and embedding mechanism 5, and asphalt structure layer paving are sequentially installed on the car body 1. Agency 6;

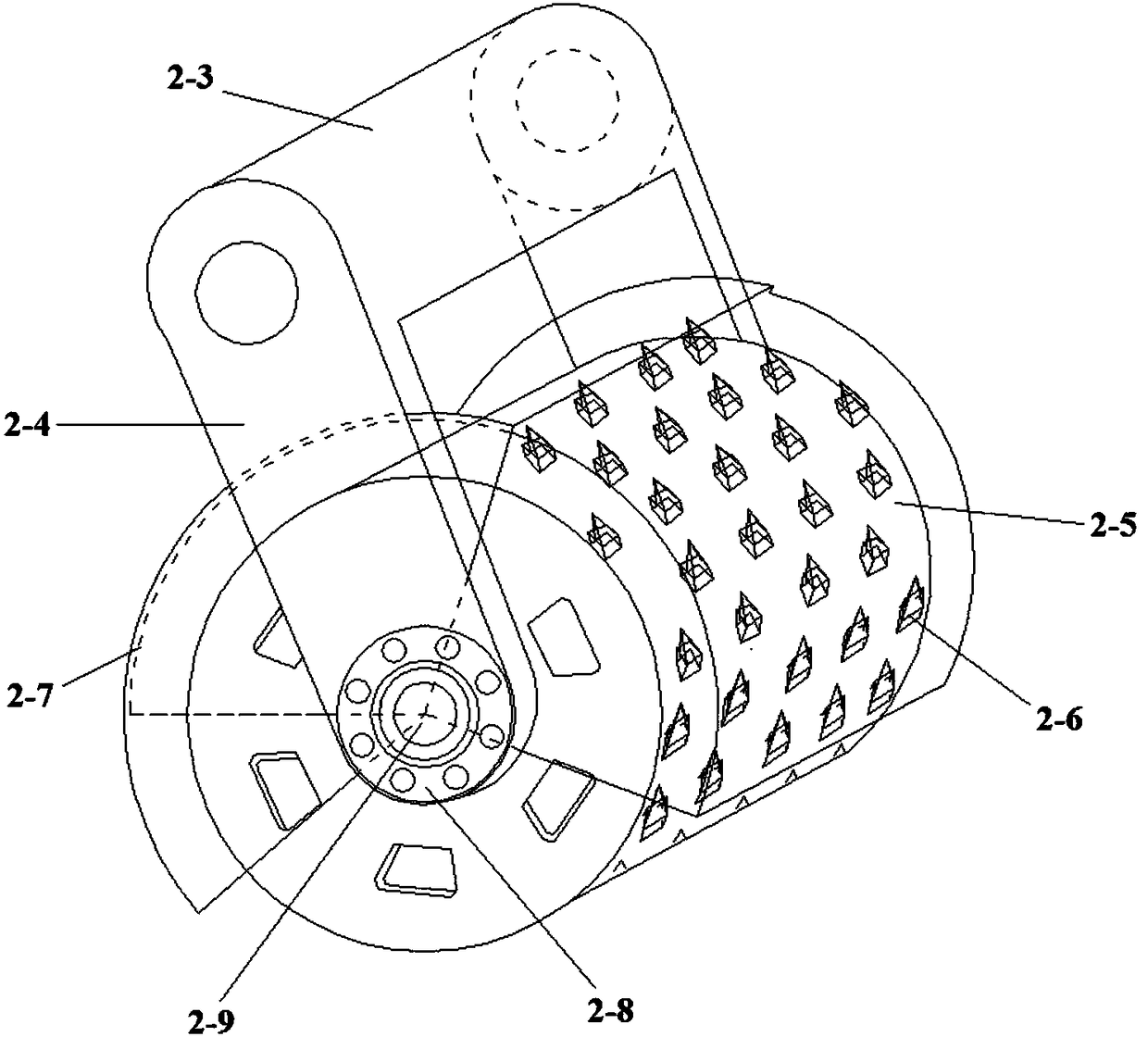

[0049] The milling mechanism 2 includes a fixed seat 2-1 fixedly mounted on the lower part of the car body 1, a fixed shaft 2-2 is installed on the fixed seat 2-1, and a rotating sleeve 2 is set on the fixed shaft 2-2. -3, a pair of side plates 2-4 are installed at the two ends of the rotating sleeve 2-3, a pair of side plates 2-4 are equipped with a rotatable milling drum 2-5, and the milling drum 2-5 is detachable A plurality of milling cutter heads 2-6 are installed, and when the car body 1 is moving, the milling drum 2-5 can mill the road surface to form an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com