Oil-resisting and cold-resisting nitrile butadiene rubber composition and preparation method thereof

A technology of nitrile rubber and composition, which is applied in the field of rubber, can solve the unsolved problems of nitrile rubber low temperature resistance, reduce nitrile rubber oil resistance, nitrile rubber material loss of elasticity, etc., achieve good compression set characteristics, Low processing cost and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: O-ring formulation for railway vehicle braking system

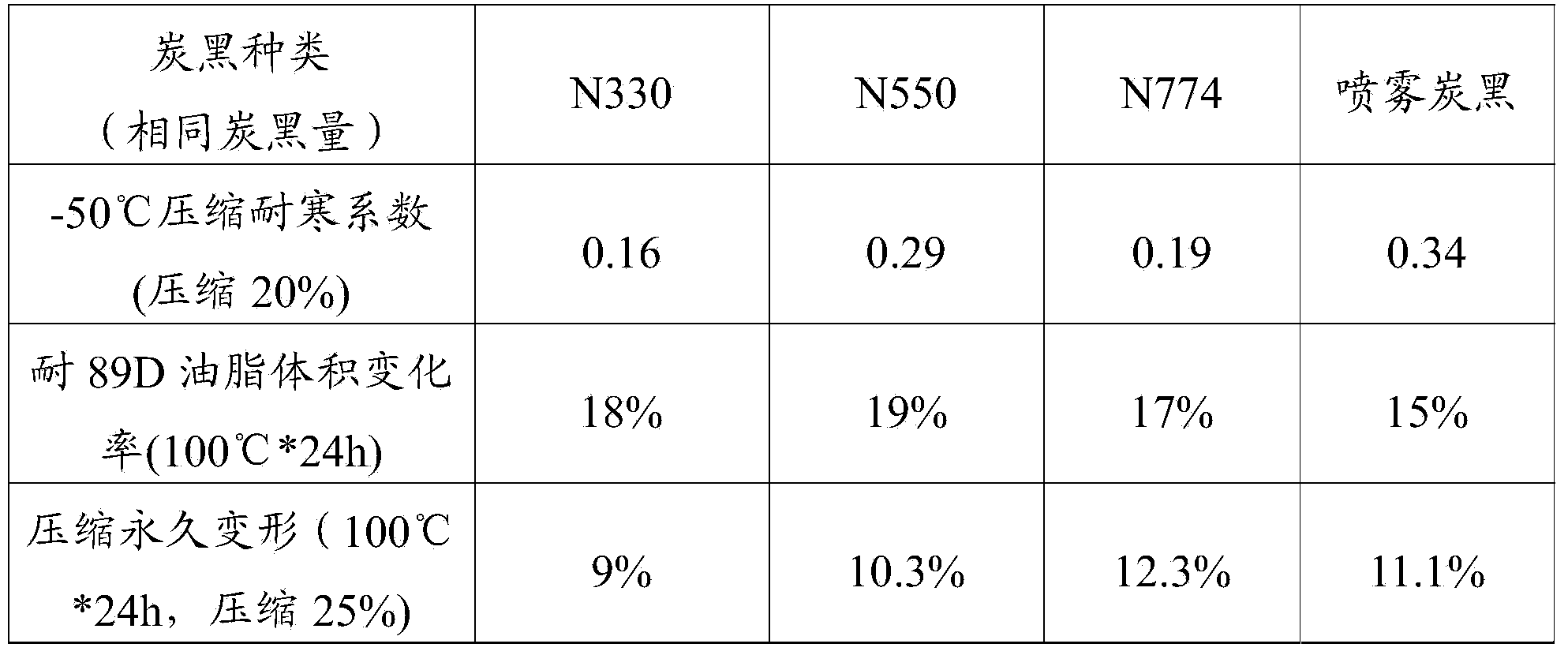

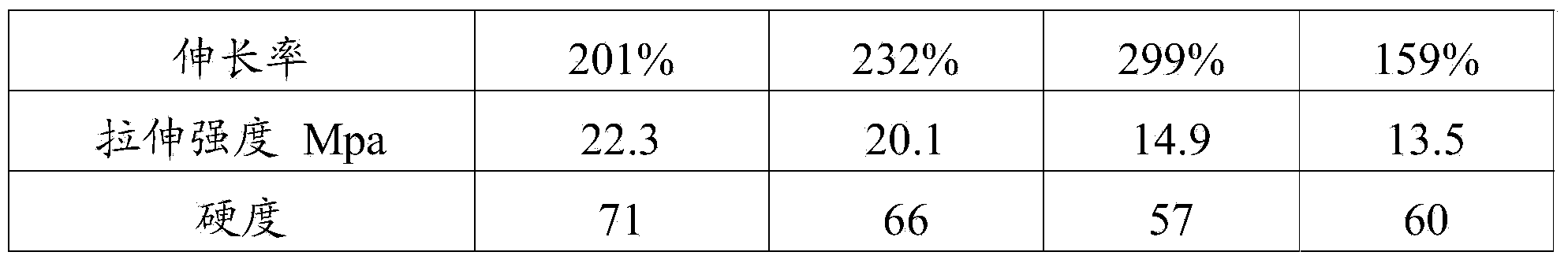

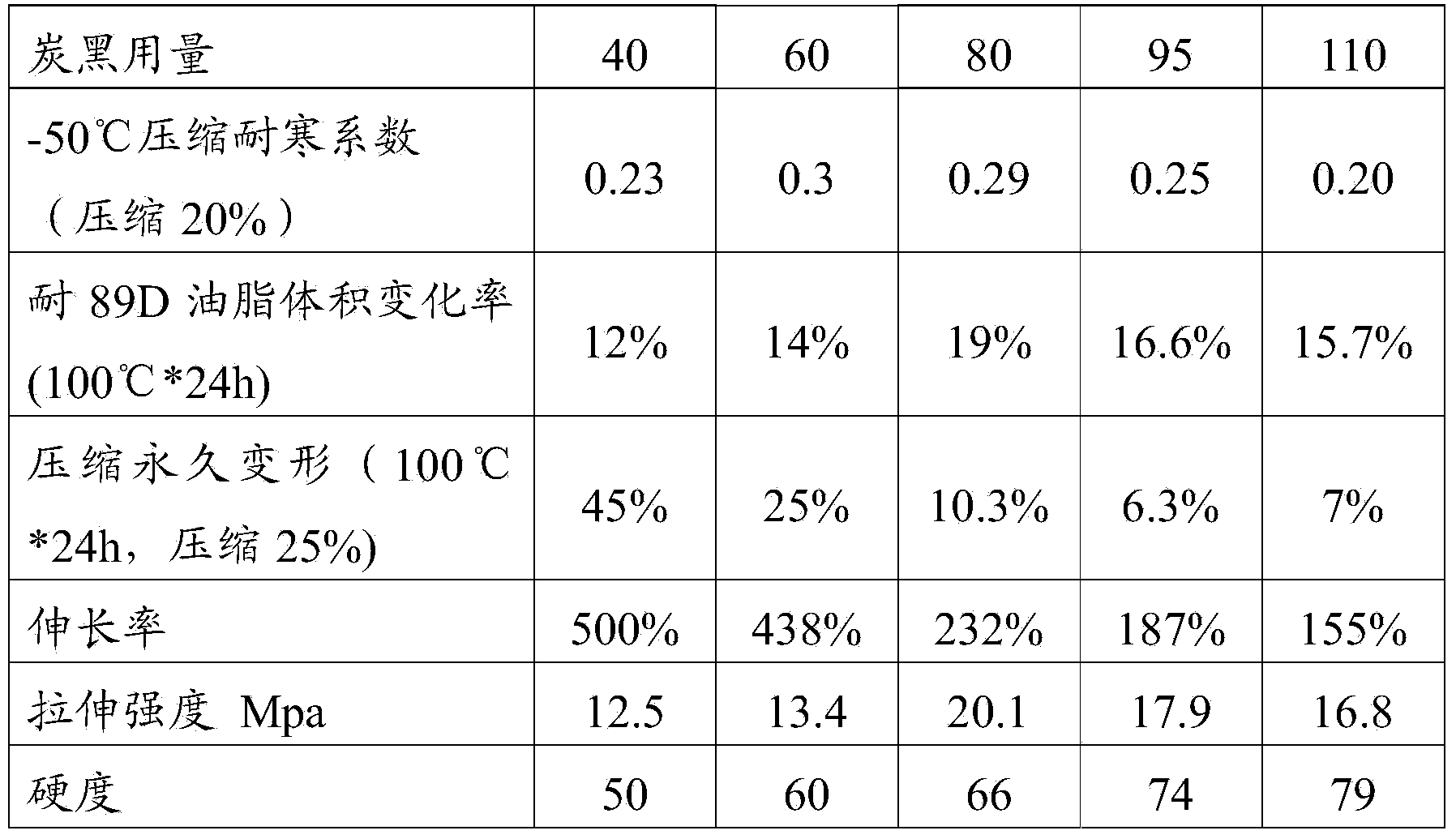

[0035] 100 parts of NBR (raw rubber) (Japan JSR company, brand N250S), after Botong plasticizing, add 1 part of anti-aging agent RD, 1 part of anti-aging agent MB, 80 parts of N550 carbon black (particle size 42nm), and mix evenly Then add 20 parts of RS107, and finally add 2 parts of DCP, 0.5 parts of S, and 1 part of accelerator TT, mix well and leave it for 1 day for vulcanization test. The vulcanization condition of the sample is: 170°C*10min.

[0036] Performance test results: hardness 66; tensile strength 20.1Mpa; elongation 232%; compression set 10.3% (100℃*24h, compression 25%); -50℃ compression cold resistance coefficient 0.29 (compression 20%); resistance 89D The oil volume change rate is 19% (100°C*24h).

Embodiment 2

[0037] Embodiment 2: leather cup formula for railway vehicle braking system

[0038]100 parts of NBR (raw rubber) (Japan JSR company, brand N250S), after Botong plasticizing, add 1 part of anti-aging agent RD, 1 part of anti-aging agent MB, 95 parts of N550 carbon black (particle size 42nm), and add after mixing evenly RS10725 parts, finally add 0.5 parts of S, 1 part of accelerator TT, 0.5 parts of accelerator DM, 1.5 parts of accelerator NOBS, mix well and park for 1 day, and test for vulcanization. The vulcanization condition of the sample is: 160°C*10min.

[0039] Performance test results: hardness 72; tensile strength 16.4Mpa; elongation 256%; compression set 18.2% (100℃*24h, compression 25%); -50℃ compression cold resistance coefficient 0.4 (compression 20%); resistance 89D The oil volume change rate is 16.3% (100°C*24h).

Embodiment 3

[0040] Embodiment 3: Diaphragm formula for railway vehicle braking system

[0041] 100 parts of NBR (raw rubber) (Japan JSR company, brand N250S), after Botong plasticizing, 2 parts of anti-aging agent 4010NA, 60 parts of N550 carbon black (particle size 42nm) were added in sequence, after mixing evenly, 20 parts of RS10720 were added, and finally Add 0.5 parts of S, 0.5 parts of accelerator TT, 1.4 parts of accelerator DTDM, and 1 part of accelerator CZ, mix well and park for 1 day for vulcanization test. The vulcanization condition of the sample is: 150℃*15min.

[0042] Performance test results: hardness 60; tensile strength 13.4Mpa; elongation 438%; compression set 25% (100℃*24h, compression 25%); -50℃ compression cold resistance coefficient 0.35 (compression 20%); resistance 89D The oil volume change rate is 14% (100°C*24h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com