Method for preparing super high temperature complex phase ceramic ZrB2-ZrC-SiC near to zero ablation

A complex phase ceramic, zrb2-zrc-sic technology, applied in the field of special ceramics, can solve the problems of low sintering activity, low production efficiency, poor thermal shock resistance, etc., achieve lower sintering temperature, increase production efficiency, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

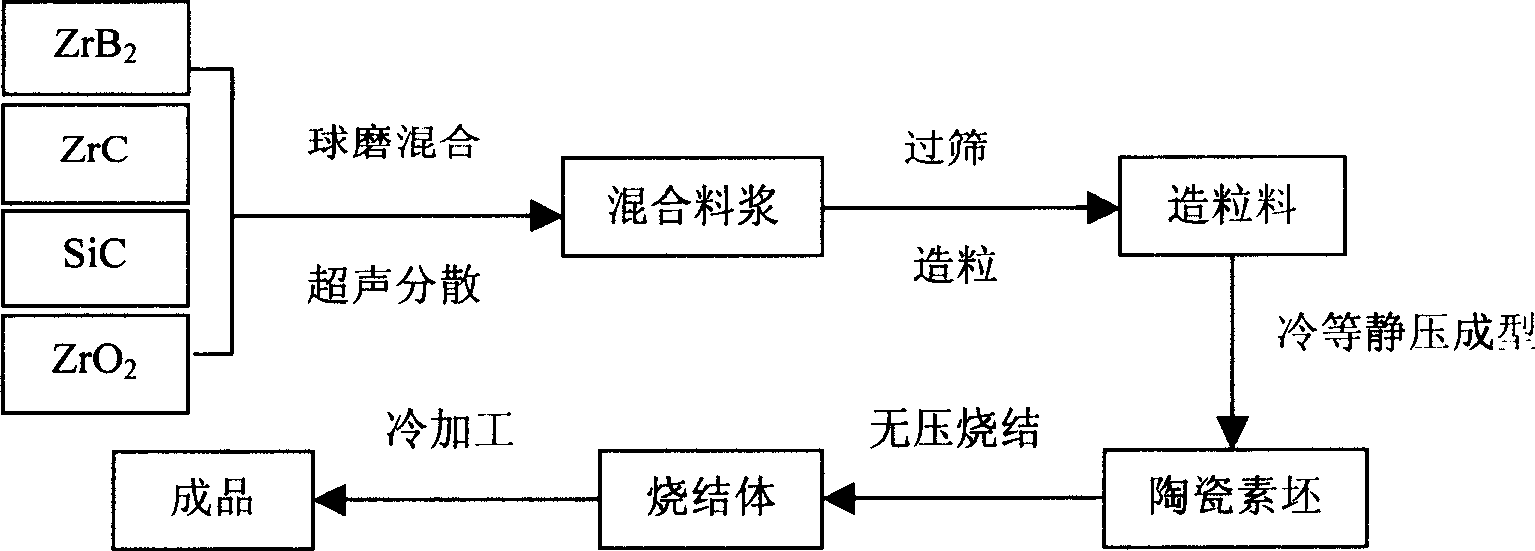

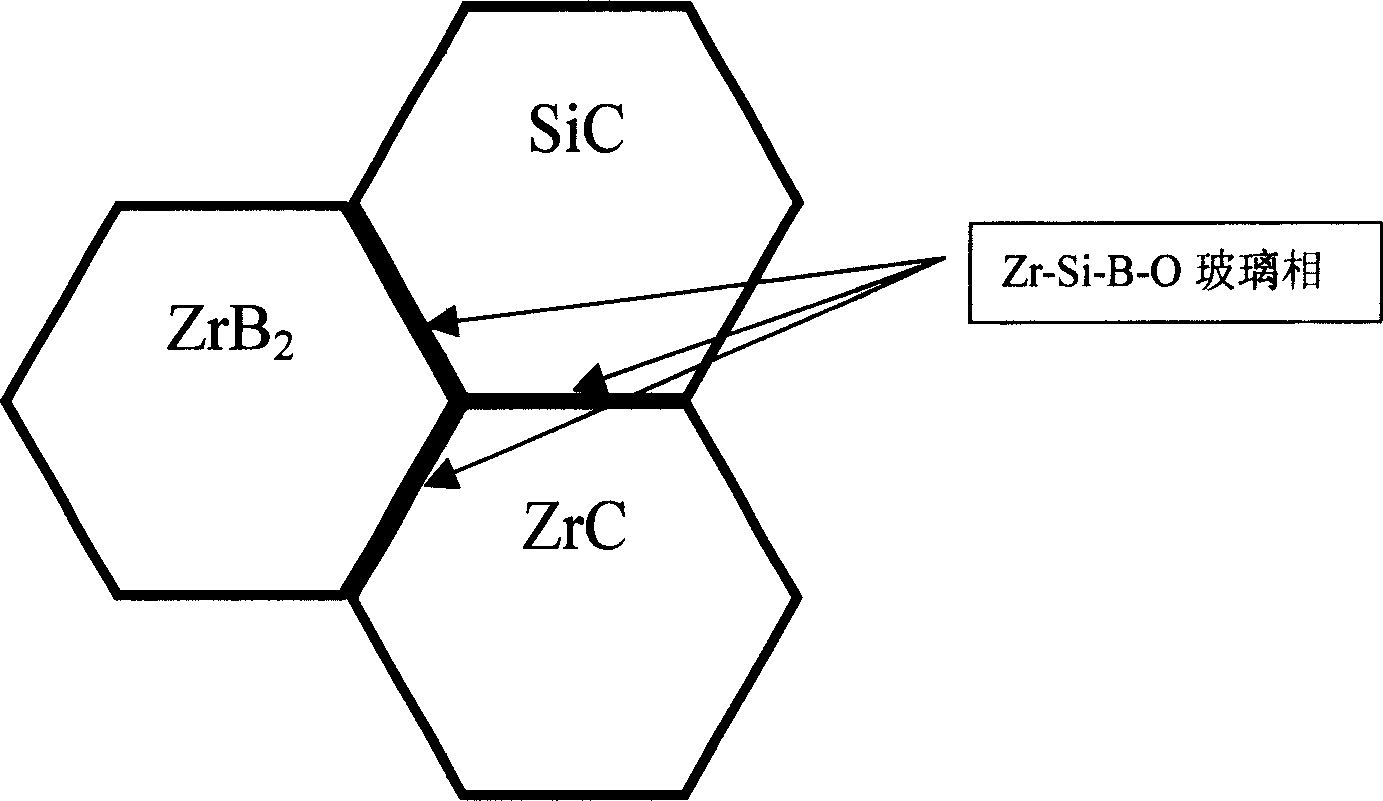

[0020] Ultra-high temperature near zero ablation ZrB of the present invention 2 -The preparation method of ZrC-SiC composite ceramics is carried out according to the following steps:

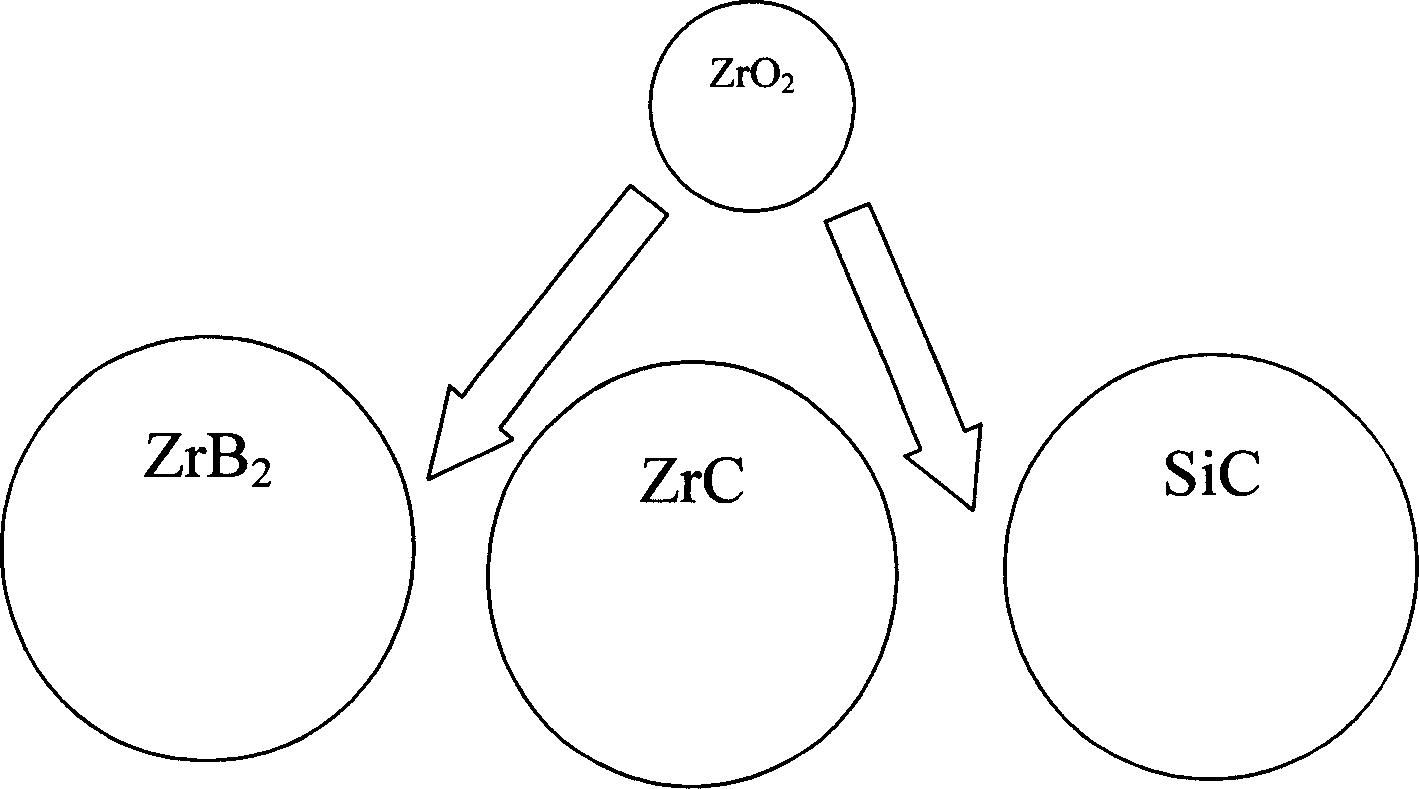

[0021] The proportion by weight is ZrB 2 , ZrC and SiC and additional ZrO 2 Respectively 60%, 25% and 15%, plus 12% to weigh the powder, the median particle size of the four powders are: 1.5μm, 1.3, 1.0μm and 0.5μm, using deionized water as a dispersant, Ball mill mixing, 25KHz ultrasonic dispersion uniformly, after passing through a 300-mesh sieve, granulate by centrifugal drying granulator, feeding speed is 8kg / h, drying temperature is 200℃, and granulated material particle size is 0.5-2mm. Then evenly put it into a special oil-resistant rubber abrasive tool, and shape it in a wet isostatic press with a maximum pressure of 180MPa. The formed sample is fired in a pressureless sintering furnace protected by argon gas, the highest firing temperature is 1800°C, and the temperature is kept for 2 hours....

Embodiment 2

[0023] The proportion by weight is ZrB 2 , ZrC and SiC and additional ZrO 2 Respectively 50%, 35% and 15%, plus 12% to weigh the powder, the others are the same as in Example 1. The performance is shown in Table 1.

Embodiment 3

[0025] The proportion by weight is ZrB 2 , ZrC and SiC and additional ZrO 2 Respectively 70%, 20% and 10%, plus 12% to weigh the powder, the others are the same as in Example 1. The performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com