Gypsum preparation device for orthopedic treatment

A preparation device and gypsum technology, which is applied in the direction of clay preparation device, mixing operation control device, cement mixing device, etc., can solve the problem of low uniformity between gypsum powder and water, and achieve the goal of promoting mixing, reducing adhesion and improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

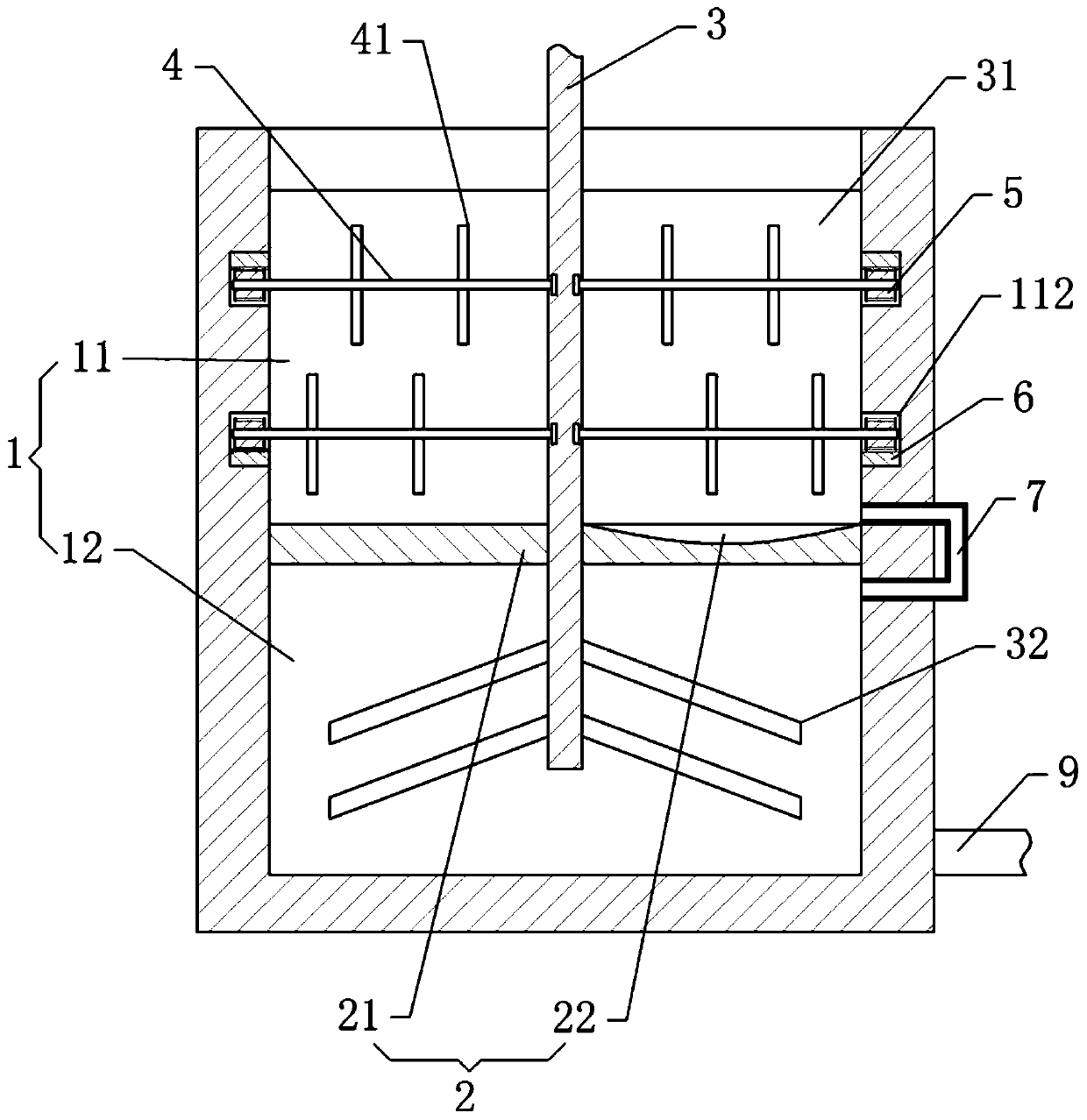

[0033] A gypsum preparation device for orthopedic treatment, basically as attached figure 1 As shown, it includes a mixing tank 1 and a mounting frame. A partition 2 is fixed inside the mixing tank 1. The partition 2 divides the mixing tank 1 into an upper primary mixing tank 11 and a lower final mixing tank 12. The motor is fixed on the mounting frame. , the output shaft of the motor is coaxially fixed with a rotating shaft 3, the rotating shaft 3 is located in the mixing tank 1, and the rotating shaft 3 extends through the partition 2 to the final mixing tank 12, and the rotating shaft 3 is connected to the partition 2 in rotation.

[0034] The part of the rotating shaft 3 located in the primary mixing tank 11 is fixed with a plurality of stirring blades 31 , and the part of the rotating shaft 3 located in the final mixing tank 12 is fixed with a mixing rod 32 . The number of stirring pieces 31 can be selected according to the actual situation. In this embodiment, there are ...

Embodiment 2

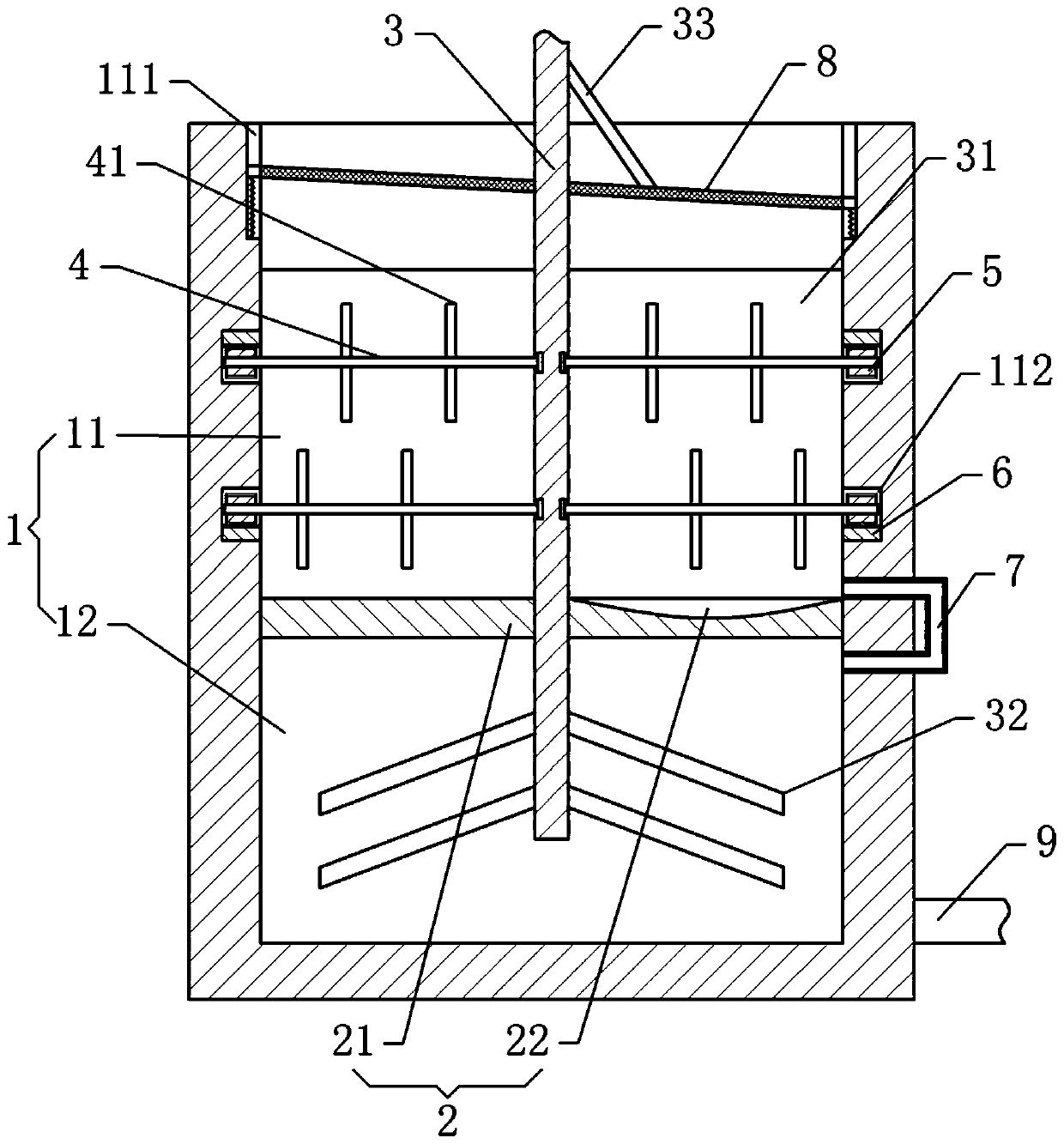

[0042] Embodiment 2 differs from Embodiment 1 only in that, as figure 2 As shown, two vertical chutes 111 are arranged on the upper part of the primary mixing tank 11, and a slider is vertically slidably connected in the chute 111, and a spring is welded on the bottom of the slider, and the bottom end of the spring is welded on the bottom of the chute 111 ;The right slider is lower than the left slider. A screen 8 is fixed on the two sliders, and the outer wall of the screen 8 is attached to the inner wall of the primary mixing tank 11, and the screen 8 is inclined downward from left to right, and the angle of inclination is 5-15°. In this embodiment, the inclination The angle is 10°. The rotating shaft 3 runs through the screen cloth 8, and the screen cloth 8 can slide vertically along the rotating shaft 3. The part of the rotating shaft 3 above the screen cloth 8 is provided with a breaking rod 33. The primary mixing tank 11 is located below the screen cloth 8 and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com