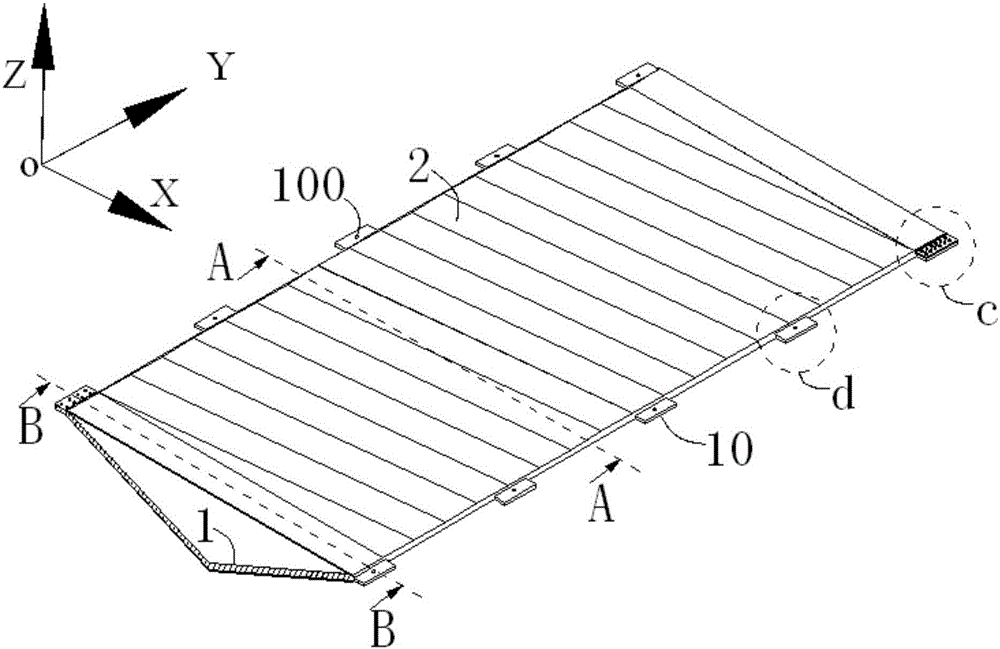

Vehicle bottom plate

A technology for base plates and vehicles, applied in the field of accessories for explosion-proof vehicles, can solve the problems of insufficient anti-explosion shock wave capability and insufficient safety protection performance of explosion-proof vehicles, and achieve the effect of reducing impact and casualty rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

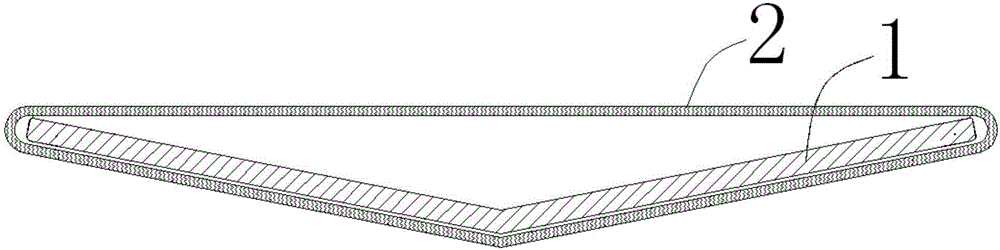

[0053] refer to figure 2 , in this embodiment, an accommodation space is formed between the side wall forming the groove 12 and the covering layer 2. In the process of forming the covering layer 2, in order to make each part of the vehicle floor plate have a relatively uniform impact resistance , the strip-shaped material wound on the substrate 1 to form the cladding layer 2 is evenly and tightly distributed.

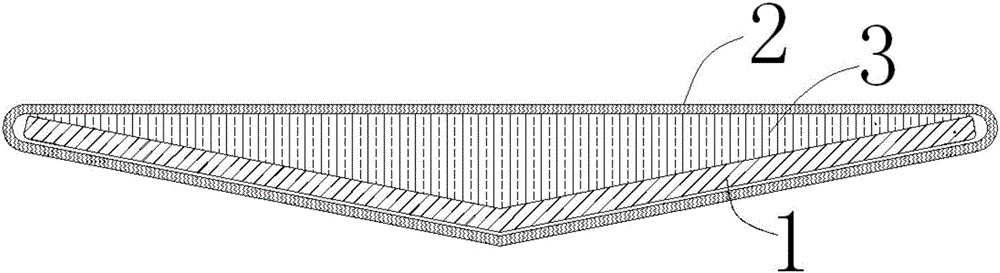

[0054] refer to image 3 ,and figure 2 The structures shown are different, image 3 The interior of the accommodation space is filled with honeycomb panels 3 or corrugated panels 3. The honeycomb panels 3 or corrugated panels 3 in the present invention are cut and formed according to the size of the groove 12 and then embedded in the groove 12. The honeycomb panels 3 or corrugated panels The board 3 has relatively excellent elastic cushioning, energy absorption, and impact resistance effects, and has a relatively large strength-to-weight ratio. The honeycomb board 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com