Environment-friendly, high-viscosity and weather-resistant modified starch adhesive and preparation method thereof

A starch adhesive, high viscosity technology, applied in the direction of starch derived adhesives, polymer adhesive additives, adhesive types, etc., can solve mildew adhesive ability, unsuitable for large-scale industrial application, weather resistance Poor problems, to achieve the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

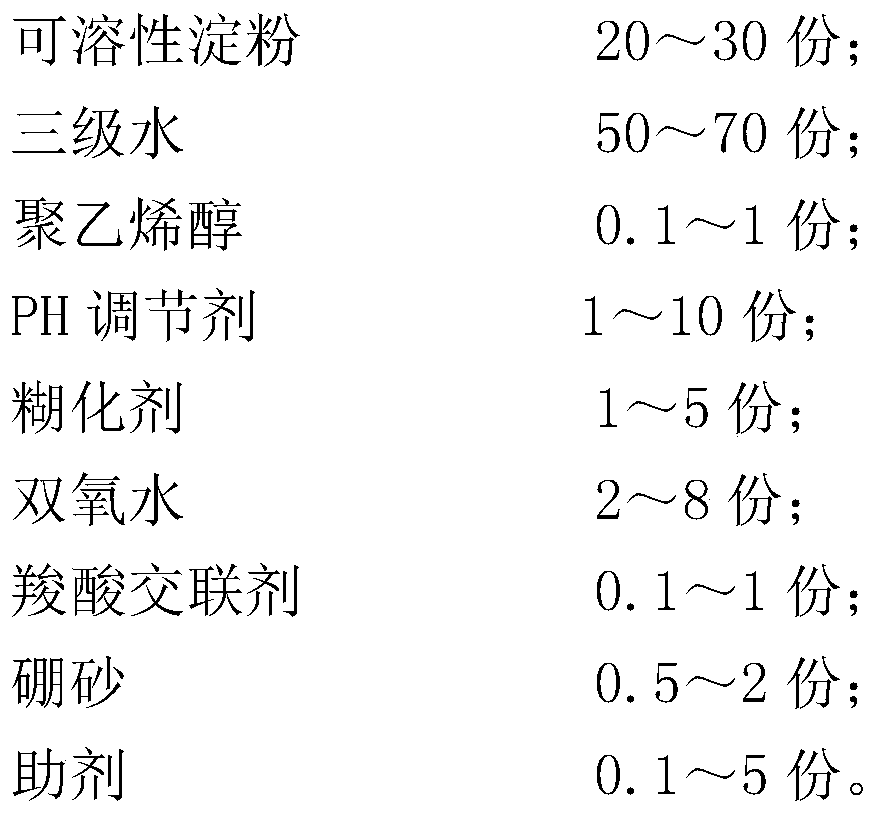

[0046] This embodiment provides an environmentally friendly high-viscosity weather-resistant modified starch adhesive, which includes the following components in parts by weight:

[0047]

[0048] Among them, the carboxylic acid crosslinking agent is a dibasic carboxylic acid, i.e. food-grade adipic acid, the mass fraction of hydrogen peroxide is 29%, the degree of polymerization of polyvinyl alcohol is 1700, and the auxiliary agents are potassium pyrophosphate, Dow Corning DC-67, butyl The mixture of alcohol and Dow Corning DC-65 silicone defoamer, the mass ratio of the four is 1:1:1:1, the pH regulator is 2% sodium hydroxide solution in mass fraction, and the pasting agent is The mass fraction is 30% sodium hydroxide solution, and the pH regulator and pasting agent are both prepared from analytically pure sodium hydroxide and third-grade water.

[0049] Its preparation method comprises the following steps:

[0050] S1. Mixing: Put the three-necked bottle in a constant temp...

Embodiment 2

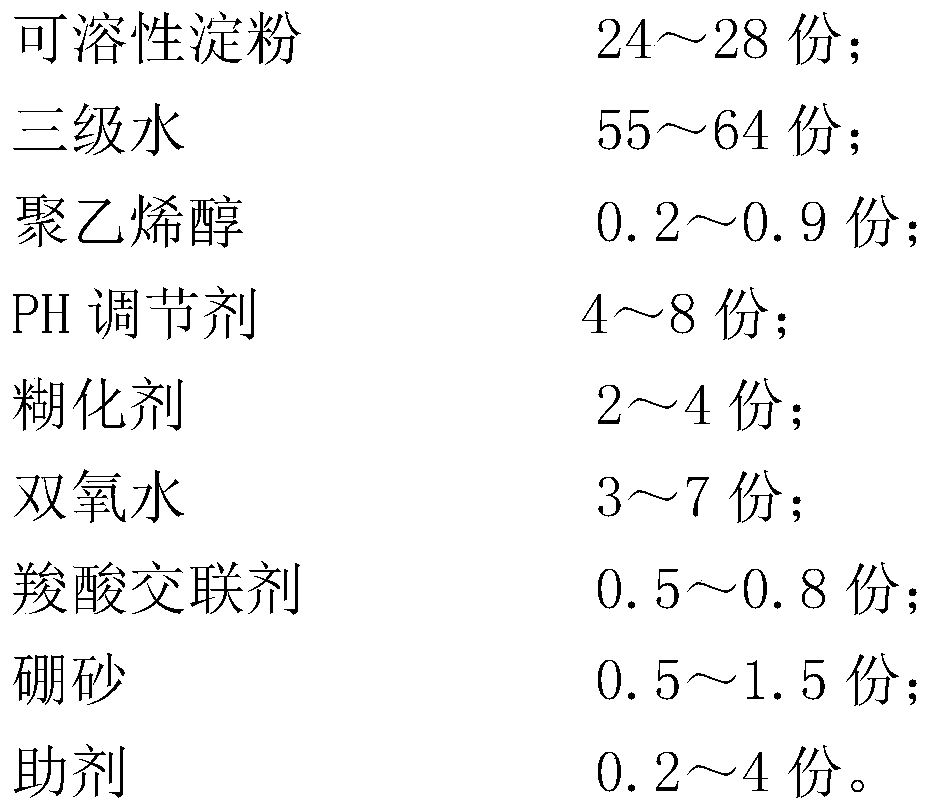

[0057] This embodiment provides an environmentally friendly high-viscosity weather-resistant modified starch adhesive, which includes the following components in parts by weight:

[0058]

[0059] Among them, the carboxylic acid crosslinking agent is polycarboxylic acid, the mass fraction of hydrogen peroxide is 30%, the degree of polymerization of polyvinyl alcohol is 1750, and the auxiliary agents are potassium pyrophosphate, Dow Corning DC-67, phenol and Dow Corning DC-65 silicone disinfectant. A mixture of foaming agents, the mass ratio of the four is 2:5:5:5, the pH regulator is 2% sodium hydroxide solution, and the pasting agent is 30% sodium hydroxide The solution, the pH regulator and the pasting agent are all prepared from analytically pure sodium hydroxide and tertiary water.

[0060] Its preparation method comprises the following steps:

[0061] S1. Mixing: Put the three-necked bottle in a constant temperature water bath at 60°C, add third-grade water into the t...

Embodiment 3

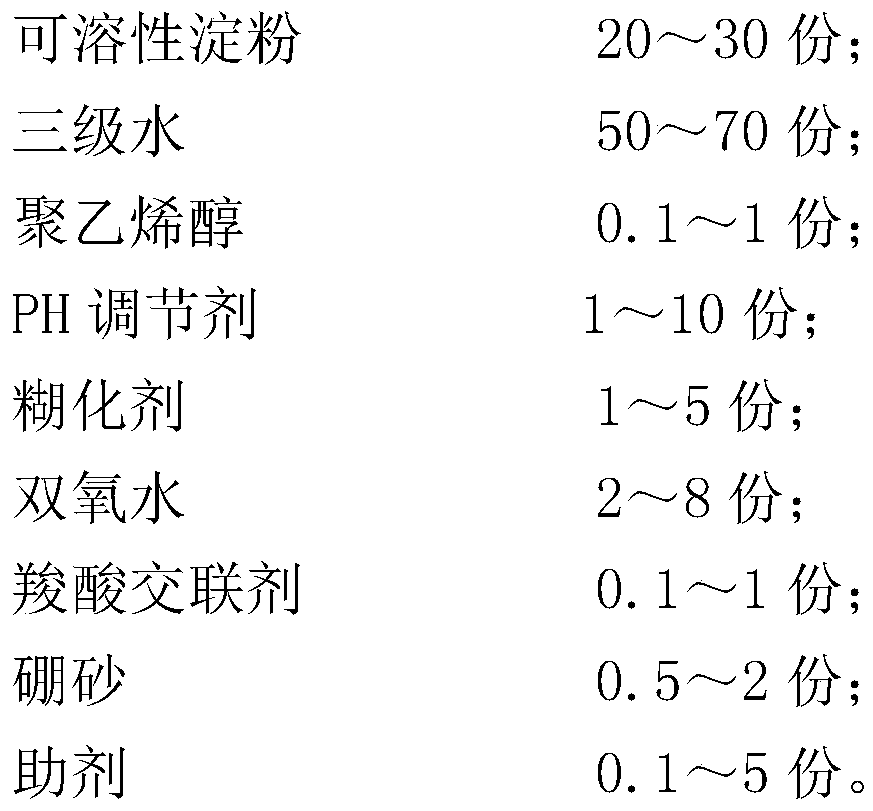

[0068] This embodiment provides an environmentally friendly high-viscosity weather-resistant modified starch adhesive, which includes the following components in parts by weight:

[0069]

[0070] Among them, the carboxylic acid crosslinking agent is food-grade adipic acid, the mass fraction of hydrogen peroxide is 30%, the degree of polymerization of polyvinyl alcohol is 1750, and the auxiliary agents are potassium pyrophosphate, Dow Corning DC-67, butanol and Dow Corning DC-65 silicon A mixture of ketone defoamers, the mass ratio of the four is 2:5:5:5, the pH regulator is 2% sodium hydroxide solution, and the pasting agent is 30% hydrogen The sodium oxide solution, the pH regulator and the pasting agent are all prepared from analytically pure sodium hydroxide and tertiary water.

[0071] Its preparation method comprises the following steps:

[0072] S1. Mixing: Put the three-necked bottle in a constant temperature water bath at 60°C, add third-grade water into the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com